Watts ORION RF-3000LE User manual

Installation Instructions

Rionfuse CF

Rionfuser™ 3000LE Bluetooth®

Rionfuser™ 3000LE LT

Rionfuser™ 3000LE USB

Polypropylene and PVDF Chemical Waste

Systems

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can result in death,

serious personal injury, property damage, or damage to the equipment.

Keep this Manual for future reference.

WARNING

!

Local building or plumbing codes

may require modifications to

the information provided. You

are required to consult the local

building and plumbing codes prior

to installation. If the information

provided here is not consistent

with local building or plumbing

codes, the local codes should be

followed. This product must be

installed by a licensed contractor

in accordance with local codes

and ordinances.

WARNING

!

NOTICE

Follow the guidelines listed here for

proper installation, operation, and

maintenance.

RF 3000LE

DANGER

!

Electricity, electrocution

and shock hazards.

2

Calibration Recommendations

It is strongly recommended that each processor be calibrated at least once every two (2) years. This

will help ensure that the Rionfuser™ Electrofusion Processor is in proper calibration and should

enable any potential problems to be identified early.

RF-3000LE

When the calibration period has expired the processor will display the message, "Error 113: Calibra-

tion Required," informing the operator that the calibration date has passed. When this occurs, the

processor will stop performing fusions until it has been recalibrated.

Rionfuser™ LT

When the calibration period has expired the processor will display the message "Error 113: Calibra-

tion Required," informing the operator that the calibration date has passed. This will not prevent the

processor from performing fusions; however, the processor should be calibrated as soon as possible.

Service Contact Information

Calibrating your Rionfuser™ Electrofusion Processor:

1. Send the processor to a WATTS service center and let our technicians do it.

Call (302) 451-1088 to make arrangements for service and to obtain an RMA number for the return.

Every effort will be made to return processors within 2 business days.

The correct output voltage cannot be assured

if the processor is not calibrated at least once

every two (2) years.

Consult your carrier for the proper method of

packaging the processor for return shipments.

Always insure the package for the full replace-

ment value. Keep in mind that most carriers will

not honor insurance claims if the product is not

shipped in accordance with their guidelines.

WATTS is not responsible for damage caused in

shipping.

NOTICE

NOTICE

3

RF-3000LE Product Overview

Rionfuser™ Electrofusion Processor

Connection Sizes: 1.5" – 12" (38mm to 305mm)

The Rionfuser™ RF-3000LE electrofusion processor is a reliable, easy-to-use, rugged tool designed to

withstand conditions found at typical construction sites. It comes with an integral splash-proof and shock

resistant outer suitcase-style enclosure. The Rionfuser™ RF-3000LE is used to thermally fuse Orion

Rionfuse RFCF couplings to Orion pipe and fittings, and can be used with Orion PP, FRPP or PVDF prod-

ucts. The RF-3000LE can be operated from any AC power source meeting the listed input power require-

ments, and comes with an intuitive user interface. The Rionfuser™ RF-3000LE cannot be used with other

manufacturers’ electrofusion couplings. The RF-3000LE supports Bluetooth®wireless technology that can

be viewed instantly via your mobile device using Apple®iOS and Android™ operating systems. A free app

can be downloaded from the App Store®online store or Google Play™ store.

Features

• Size-dependent multiple joint fusion capability

• Field calibration capability

• Downloadable internal memory for data storage

• Bluetooth wireless connection to mobile devices

• 4X20 LCD display with replaceable shield

• Compact and lightweight

• Field-replaceable output cable ends

• User-accessible fuse

• Emergency stop switch

• Can store fusion information for 1,000 fusions

Specification

Hermetically sealed joints conforming to ASTM F1290, Technique 1 are to be produced for the Orion chem-

ical piping system using the Orion Rionfuser™ machine model RF-3000LE, an electrofusion processor

designed to be used exclusively with Orion RFCF electrofusion couplings in either FRPP or PVDF material.

The RF-3000LE shall have an integral splash-proof and shock resistant outer suitcase-style enclosure,

intuitive LCD display user interface, size dependent multiple joint fusion capability, field calibration capabil-

ity, and downloadable internal memory. The fusion machine shall have user-accessible fuse, emergency

stop switch, Bluetooth® wireless communication, and will operate from any AC power source meeting

listed input power requirements.

Model RF-3000LE

Operating Parameters

Supply Voltage – 97 VAC to 150 VAC

Supply Frequency – 47 Hz to 70 Hz

Supply Waveform – Sine Wave or Square Wave

Output Current – 20 Amps AC

Output Voltage – 95 VAC at 120 Volts Input

Operating Temp. Range – 0°F to 120°F (-18°C to 49°C)

Operating Modes – CF FRPP, PVDF, Manual

Input Cable Length – 12ft (3.66m)

Output Cable Length – 24ft (7.315m)

Fusion Information Storage – 1,000 Fusions

Languages – English

Environmental Protection – IP54 Splash-Proof

Calibration Interval – 2 Years

Dimensions – 19in x 14in x 7in (47mm x 36mm x 18mm)

Weight – 17lbs (7.7kg)

Installation Instructions

Step 1

Confirming RF-3000LE is Calibrated

Start up your Rionfuser™ RF-3000LE and it will perform a Self Test. If the Cal

Due date has passed or is within the life of your project, then STOP, and con-

tact your Orion Representative for instructions on how to get your machine

recalibrated. Watts disclaims all liability for installations performed with a

Rionfuser past its calibration date.

For additional information reference the RF-3000LE Instruction Manual

included in the carrying case.

Step 2

Preparing the Pipe

Material preparation is essential to achieving satisfactory fusion results. Deburr all

field-cut pipe ends. Following the coupling insertion depth chart, mark the coupling

insertion depth from the end of the pipe/fitting to insure that the coupling is properly

positioned during the fusion cycle. Then, using 60 grit emery cloth, abrade the

marked ends of the pipe and fitting to remove the natural “sheen” of the plastic. After

abrading, clean all joint surfaces thoroughly with isopropyl alcohol to remove any dirt,

grease and the contaminants left from the sandpaper and any other foreign matter

from the surface. We suggest using a spray bottle with 90% or higher isopropyl

alcohol to soak a lint resistant cloth to thoroughly wipe the joint surface clean.

COUPLING INSERTION DEPTH MARKING

Pipe Diameter Mark Distance from Pipe End

in. in.

1

1⁄2

1

2 1

31

3⁄8

41

3⁄8

6 2

82

5⁄8

10 2

5⁄8

12 2

5⁄8

Abrade surfaceMark coupling depth

From table

5

Step 3

Joint Assembly

Insert the prepared ends of the pipe/fitting into both hubs of the Rionfuse CF

coupling. Double check the markings to verify proper seating of the pipe.

Step 4

Connecting Lead Cables

The installer must make sure the joint is properly supported during the fusion cycle

and afterwards as the joint cools to ambient. For underground installation the

joint must be protected from soil falling into the fusion assembly area. If ambient

temperature has dropped below 60F in the last 24 hrs, we recommend the use of

warming blankets to support, wrap, and protect the pipe during the fusion process.

With the Rionfuser unit connected to a dedicated power source and powered ON,

connect the lead cables to the coupling.

Step 5

Selecting Fitting Style

The unit will now prompt the installer to “SELECT FITTING STYLE”. Scroll UP or

DOWN to highlight the proper fitting style being fused, then press START to select

the fitting style.

Insert into coupling and

verify proper seating

Connect lead cables

Fitting style selection screen

6

Step 6

Selecting Pipe Size

Next the unit will prompt the installer to select the size of the joint being fused.

Scroll UP or DOWN to highlight the correct size, then press START to select size.

Step 7

Selecting Heat Cycle

The unit will ask if a pre-heat cycle is needed for the joint. If fusion will be performed

where pipe temperatures are outside the range of 60 - 90 degrees F, please consult

Orion Fittings Technical department at (910) 865-7530 before proceeding. All other

fusions should be performed using the STANDARD cycle, which is selected by

pressing the START button.

Step 8

Verifying Welding Parameters

The screen will display “VERIFY WELDING PARAMETERS” and an audible beep

will sound to indicate the fusion unit is ready to begin welding. Verify the welding

data displayed on the screen matches the joint being fused. If the information is

incorrect, press the STOP/BACK button to return to any of the menu options to

correct the fusion parameters. Once the parameters have been verified, press

START to begin the fusion weld.

Fitting size selection screen

Fusion cycle type selection screen

Fusion cycle type selection screen

7

Step 9

Successful Weld Completion

After pressing START, the Rionfuser™ will begin the weld. After the welding cycle

has completed, another audible beep will sound to indicate that the fusion weld

is complete. If the beeping pattern is an equal, consistent beeping, the joint was

successful. If the beeping pattern is irregular, it indicates that an error has occurred

during the fusion cycle (if an error code is received during fusion, please contact

your local Orion rep for troubleshooting information). Once the joint is completed,

the lead cables can be removed and the process repeated for the next joint.

To download completed fusion data, please see our IOM-OR-RIONFUSE 2128 for

instructions.

Successful weld

completion screen

NOTICE

Do not stress newly-fused joints until fully cooled to ambient, typ-

ically 10-20 minutes depending on size. Successful weld comple-

tion screen does not eliminate need for system leak testing.

POLYPROPYLENE RIONFUSE CF COUPLING

Pipe Size Fusion Time Fusion Current

in. min. amps

1 -

1⁄2

2:00 8.25

22:00 8.25

33:00 14.25

43:00 14.25

64:30 19.00

84:45 19.00

10 7:20 17.00

12 8:00 16:50

MULTIPLE JOINTING RIONFUSE CF

Pipe Size Maximum number of couplings

in. num.

1 -

1⁄2

4

2 3

3 3

4 2

6 1

8 1

10 1

12 1

PVDF RIONFUSE CF COUPLING

Pipe Size Fusion Time Fusion Current

in. min. amps

1 -

1⁄2

2:00 8.25

22:00 8.25

33:00 14.25

43:00 14.25

64:45 18.00

8

Downloading to a USB Flash Drive

Fusion data from an RF-3000LE USB or Rionfuser™ LT Electrofusion Processor is downloaded onto an

external USB flash drive. The data is output in a binary format that is compatible with a free macro-en-

abled Excel Spreadsheet available from Orion Engineering Department.

To download fusion data from the processor to a USB flash drive, perform the following steps:

1. Turn On the processor and allow it to proceed through the INTERNAL SELF TEST until it reaches

the CONNECT LEADS screen.

2. Plug a formatted USB flash drive into the USB host connector on the face of the processor.

3. The USB flash drive will be detected automatically, and the fusion data will be written to the

drive.

4. A progress screen similar to the following will be displayed as the download proceeds:

5. After the download is complete, the processor will return to the CONNECT FITTING screen. You

may now disconnect the USB flash drive from the USB Host Port to resume normal operation.

NOTE:

Only new fusions performed since the last download will be written to the drive.

The USB flash drive must be formatted using FAT or FAT32 with a sector size of 512 bytes.

Rionfuser™ LT

The Rionfuser™ LT Electrofusion Processor has a 9 pin D-sub connector instead of a USB host

connector. To download fusion data from a Rionfuser™ LT Electrofusion Processor onto a USB

flash drive, you will need a USB to Serial Port adapter. This adapter is available for purchase from

WATTS. One adapter may be used with multiple processors.

The pictures below show a 9 pin D-sub connector and the installed adapter for your reference.

DOWNLOADING DATA

48%

9 Pin D-Sub

Connector

USB Host

Adapter

Installed

9

Downloading Wirelessly

Fusion data from an RF-3000LE Bluetooth®Electrofusion Processor is downloaded wirelessly

through the EF Utilities app. Once data has been downloaded, it can be viewed at any time with a

smart phone, tablet, or computer.

To download fusion data from the processor to the EF Utilities app, perform the following steps:

1. Turn ON the processor and allow it to proceed through the INTERNAL SELF TEST until it

reaches the CONNECT LEADS screen.

2. Open the EF Utilities app on your smart phone or tablet and select, "Connect to EF Machine."

3. Follow the download instructions in the app.

All progress indications and user feedback are communicated through the EF Utilities app which is

available on iOS and Android app stores. To set up an account and register your EF processor(s),

contact EF Technologies.

POWER SOURCES

When installing electrofusion fittings in field applications, it is necessary to have a reliable source of

AC power for the processor. This AC power source should:

• be well maintained and subjected to a periodic maintenance schedule.

• provide output voltage within the specified operating range.

• contain a matching outlet, which is required to connect with the plug equipped on the

processor.

Utility Power

Utility power is a reliable and ideal power source for the Rionfuser™ Electrofusion Processor.

However, it is not practical to gain access to this kind of power source in field applications. When

fusing with utility power, a dedicated connection to the service panel is recommended because the

potential amperage draw is very high.

Generators

Fuel powered generators are also a good source of electrical power for the Rionfuser™ Electrofu-

sion Processor. Always make a note of the minimum fitting power requirements. Additional power

capacity is recommended for intangibles (i.e. powering other accessories, wear & tear, etc.). Before

starting a fusion, it is important to make sure:

• the generator has enough fuel to complete the electrofusion cycle.

• the auto-throttle is disengaged (in anticipation of immediate power draw).

Inverters

Inverters are an acceptable AC power source for the Riofuser™ Electrofusion Processor, though

some produce output waveforms that are troublesome with specific fittings. We recommend perform-

ing compatibility tests using the lightest and heaviest anticipated loads before approving an inverter

system. Feel free to contact us to discuss issues regarding the use of inverters.

Power Specifications

Extension Cords

Because electrofusion fittings produce a high amperage draw, the use of an extension cord is not

encouraged. In the event such usage is necessary, the following lengths and wire gauges are recom-

mended:

Extension cords should not be used when fusing multiple fittings at the same time.

Cord Length Wire Gauge

Less than 25 feet 12/3

Less than 50 feet 10/3

Less than 100 feet 8.3

Supply Voltage 97 VAC to 150 VAC

Supply Frequency 47 Hz to 70 Hz

Supply Waveform Sine Wave or Square Wave

Output Current 20 Amps AC

Output Voltage 95 volts AC at 120 Volts Input

10

Calibration Warnings

**This section applies to the RF-3000LE Electrofusion Processor only.

Rionfuser™ Electrofusion Processors are programmed to provide operators with plenty of time to

schedule a calibration. However, if the RF-3000LE Electrofusion Processor reaches its calibration

due date, it will stop fusing until it has been calibrated.

When the calibration due date is within 90 days or less, the processor will display reminders whenev-

er the machine is powered on. The calibration reminder will look similar to this:

The processor will countdown the number of days until calibration is due. The text mm/dd/yyyy

shows the month, day, and year that the calibration is due.

To avoid being locked out of the processor, WATTS recommends scheduling a calibration

as soon as it starts to display this reminder message.

On the date that calibration is due, the processor will display, "Error 113: Calibration Required," and

stop fusing until it is calibrated.

When the RF-3000LE Electrofusion Processor displays Error 113, it will not fuse until it has

been calibrated.

To schedule a calibration, please see page 2 for instructions and contact information.

90 DAY REMINDER

Calibration Due On

mm/dd/yyy

PRESS START

General Maintenance

Changing the Fuse

** This section applies to the RF-3000LE Electrofusion Processor only. The Rionfuser™ LT Elec-

trofusion Processor has no external fuse that can be changed.

Important Notes

• The fuse protects the internal electronic circuitry. If the display lights up when power is

turned on, you DO NOT need to replace the fuse.

• This procedure should be performed in a "shop" environment, never a "field" environment.

• The most probable cause of fuse failure is a defective or inappropriately sized generator. If

you have a fuse problem, check your generator first.

Tools Required

• 1/8" Flat Blade Screwdriver

• 5 x 20mm, 250V, 2 Amp Slow Blow Fuse.

Use a Cooper Bussman Fuse Part Number BK1/S506-2-R or equivalent.

Procedure

1. Insert a screwdriver into the slot in the fuse holder cap. Press in slightly while turning count

er-clockwise, then remove the cap. The fuse should come out when the cap is removed.

2. Remove the old fuse and replace it with the new one.

3. Replace the fuse cap by pushing down and turning it clockwise.

IS-OR-Rionfuse CF 2141 EDP# 1915462 © 2021 Watts

Warranty: Our products are carefully inspected for manufacturing defects. However, it is not always possible to detect

hidden defects. Our products are warranted only to the extent that we will replace them without charge if they are proved

to have manufacturing defects within one year of the date of delivery to the site where they are to be used, or installed,

and provided we have been given an opportunity to inspect any product alleged to be defective and the installation or

use thereof.

NO WARRANTY IS INCLUDED AGAINST ANY EXPENSE FOR REMOVAL, REINSTALLATION OR OTHER CONSEQUENTIAL

DAMAGES ARISING FROM ANY DEFECT. THE WARRANTIES SET OUT ABOVE ARE THE ONLY WARRANTIES MADE AND

ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

USA: T: (800) 334-6259 • OrionFittings.com

Canada: T: (888) 208-8927 • F: (905) 481-2316 • OrionFitting.ca

Latin America: Tel: (52) 55-4122-0138 • OrionFittings.com

NOTICE

Inquire with governing authorities for local installation

requirements.

Table of contents

Other Watts Computer Hardware manuals

Popular Computer Hardware manuals by other brands

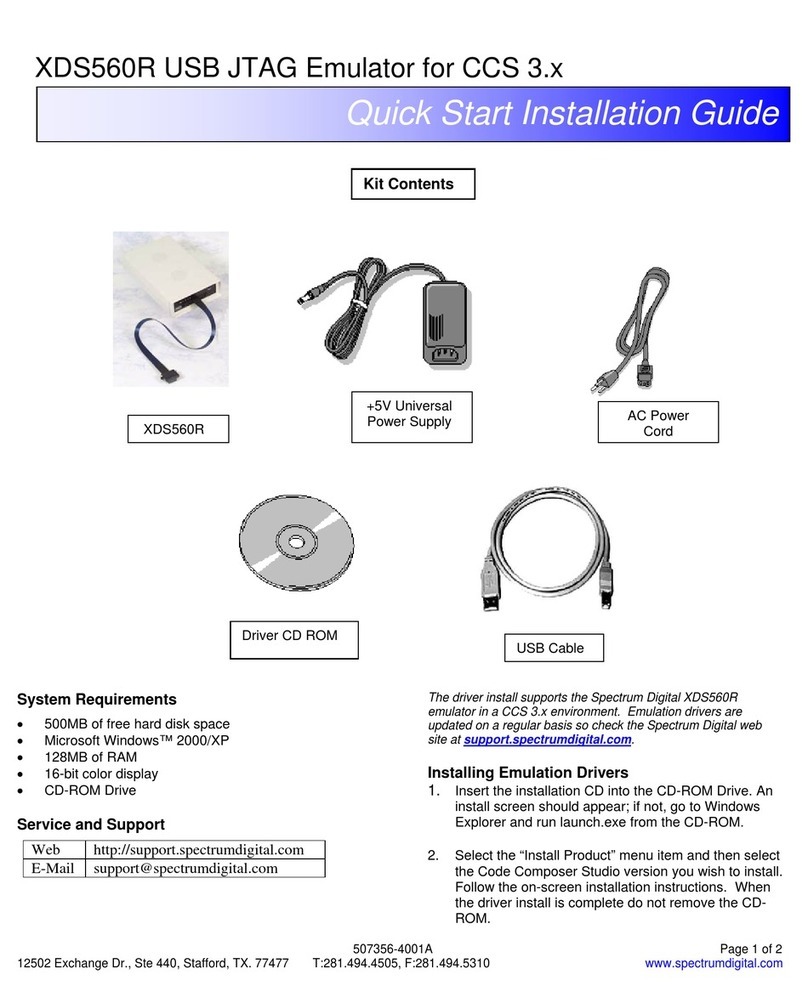

Spectrum Digital

Spectrum Digital XDS560R Quick start installation guide

Velleman

Velleman VM205 manual

EK-Quantum

EK-Quantum Vector RX 6700XT Backplate user guide

Peco

Peco CLIPPER 49651202 Operator's manual

Texas Instruments

Texas Instruments TPS25762Q1EVM-146 user guide

Compaq

Compaq EV68A Hardware reference manual