2

Basic Installation Instructions

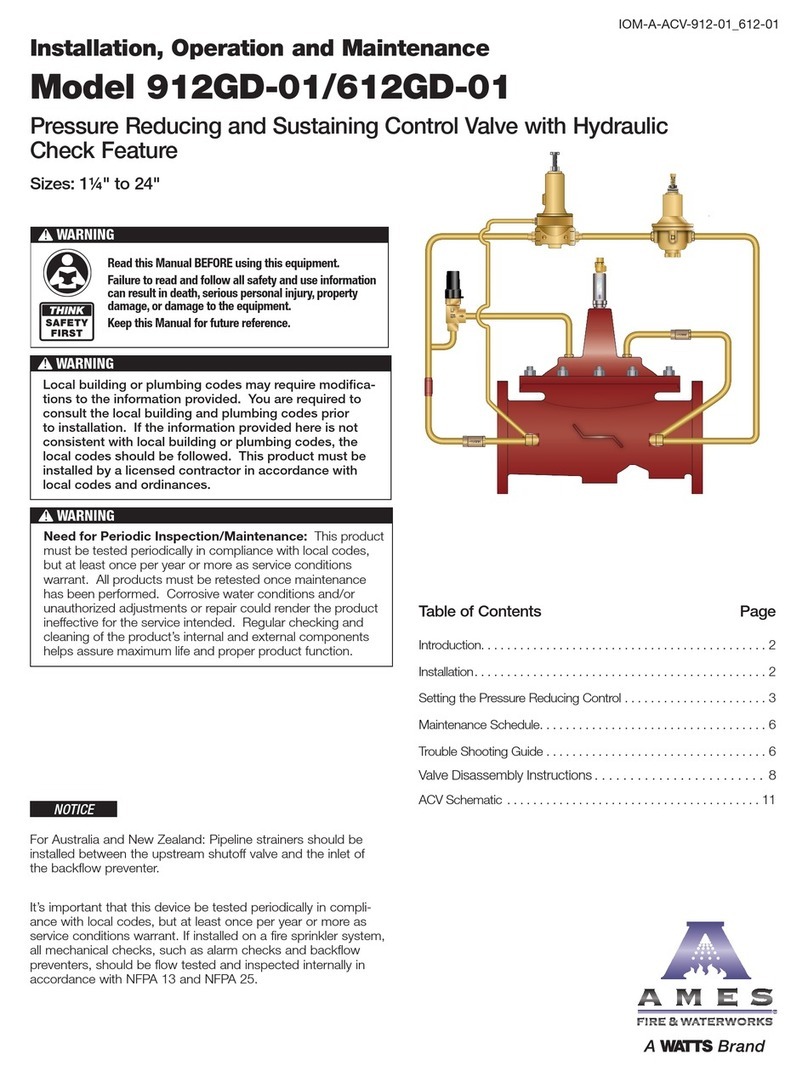

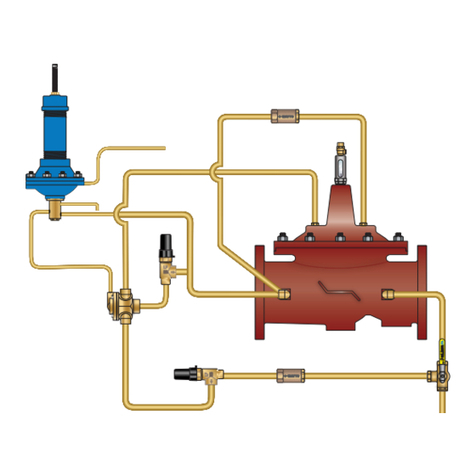

Most field problems occur because dirt and debris present in

the system at the time of installation becomes trapped in the

check valves. The system should be flushed before the valve

is installed. If the system is not flushed until after the valve is

installed, remove both check modules from the valve and open

the inlet shutoff to allow water to flow for a sufficient time to flush

debris from the water line. If debris in the water system contin-

ues to cause fouling, a strainer can be installed upstream of the

backflow assembly.

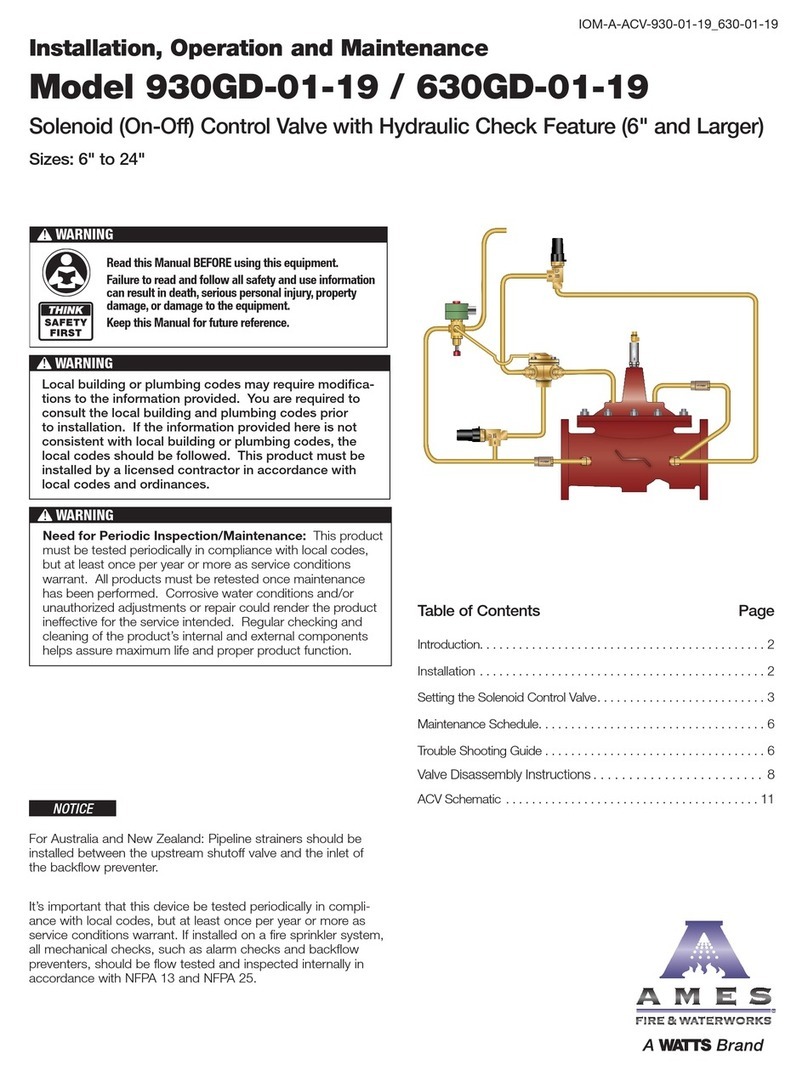

Series C200 and C300 may be installed in either horizontal or

vertical position as long as the backflow assembly is installed in

accordance with the direction of the flow arrow on the assem-

bly and the local water authority approves the installation. The

assembly should be installed with adequate clearance around the

valve to allow for inspection, testing, and servicing. A minimum

clearance of 12" is needed between the lower portion of the

assembly and the floor or grade.

The control valves on the OSY-TS model have integrated super-

visory tamper switches that require connection to a fire alarm

control panel.

NOTICE

Assembly body should not be painted.

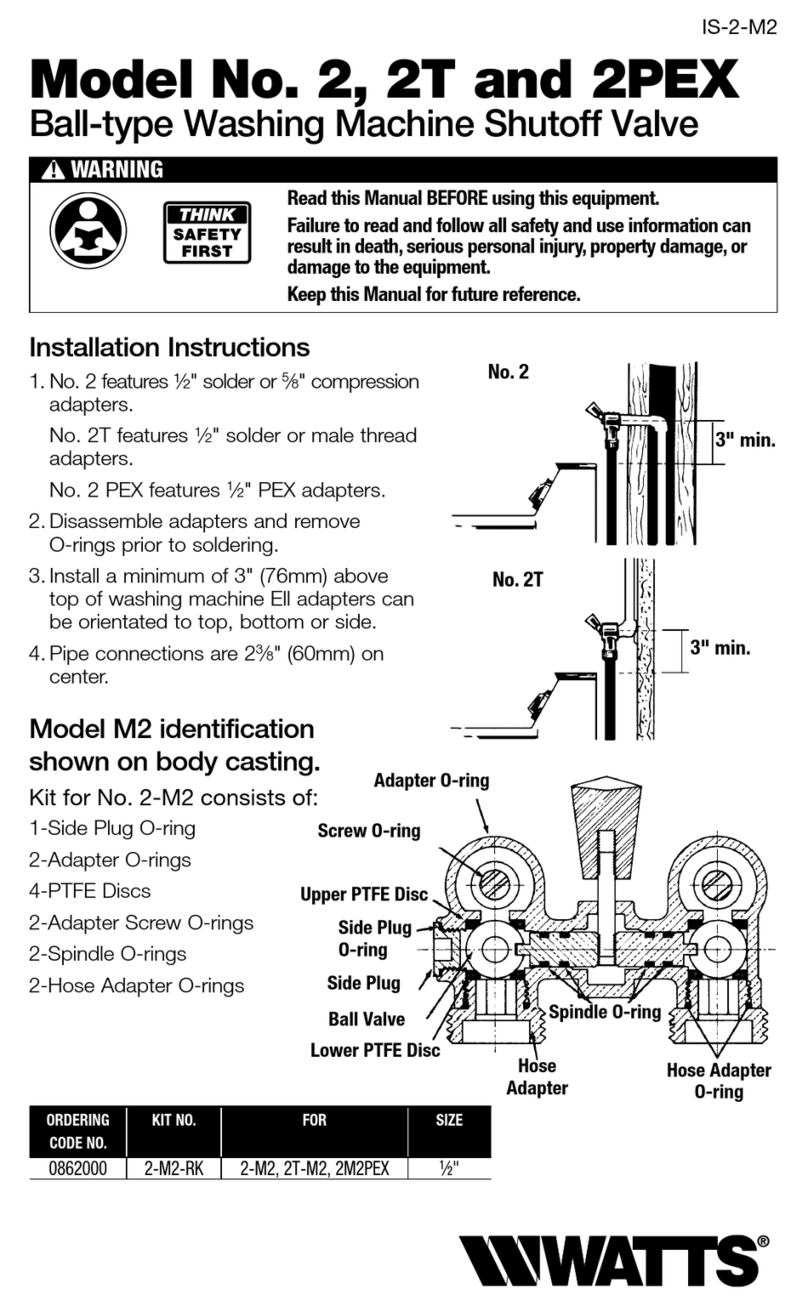

Horizontal Installation

Vertical Installation

Wiring the Tamper Switch

The supervisory tamper switch consists of two SPDT switches.

The device is designed to send a signal when the valve is closed

and when the switch is removed from the valve. In the neutral

position, the switch indicates the valve is fully open. Closing

the valve causes the switch rod to come out of the valve stem

groove, activating the switch. Removing the device also activates

the switch.

Use the schematic diagram and the wiring notes for proper

wiring of the tamper switch to a fire alarm control panel. (For

more information refer to Tamper Switch Wiring Instructions at

watts.com.)

CAUTION

!

Before wiring supervisory switches in fire protection sys-

tems, refer to the following standards:

NFPA 13: Standard for the Installation of Sprinkler Systems

NFPA 25: Inspection, Testing, Maintenance of Water-based Fire

Protection Systems

NFPA 70: National Electrical Code

NFPA 72: National Fire Alarm Code

CSA C22.1 NO.1 Canadian Electrical Code, Part 1, Safety

Standard for Electrical Installations Section 32

CAN/ULC-S524, Standard for Installation of Fire Alarm Systems

Wiring Notes

• Connection to power limited circuitry is required.

• The auxiliary switch is for supplemental use only and shall not

be used for fire alarm signaling applications.

• Switch functions are checked at the factory. Checking the

switch after field installation is strongly advised. Check conti-

nuity with the valve fully open. Switch functions activate within

two (2) turns from open.

WARNING

!

Metallic conduit required by NEC for proper grounding conduit

joint must be sealed with a conductive sealant.

Install switch in accordance with National Electrical Code and/or

local ordinances.

Wiring methods shall be in accordance with CSA C22.1,

Canadian Electrical Code, Part 1, Safety Standard for Electrical

Installations, Section 32 and CAN/ULC-S524, Standard for

Installation of Fire Alarm Systems Assure All Devices Are Properly

Grounded.