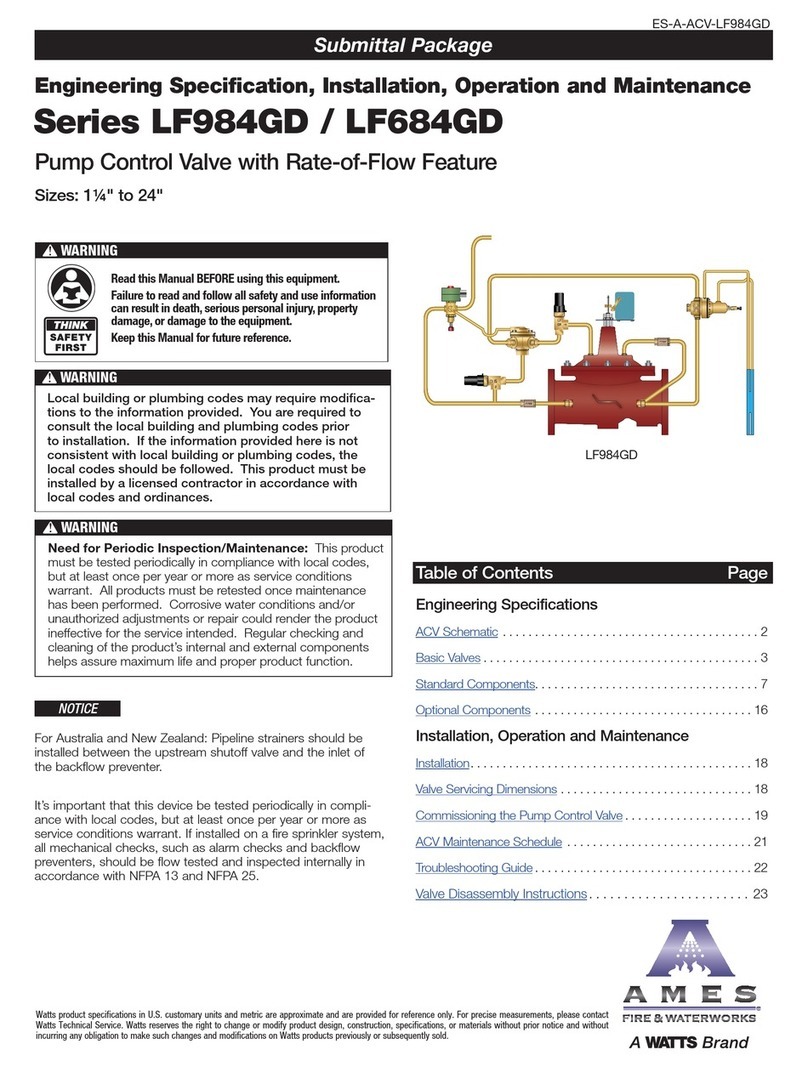

Watts AMES Deringer 40 User manual

Other Watts Control Unit manuals

Watts

Watts LF25AUB-Z3 Series Setup guide

Watts

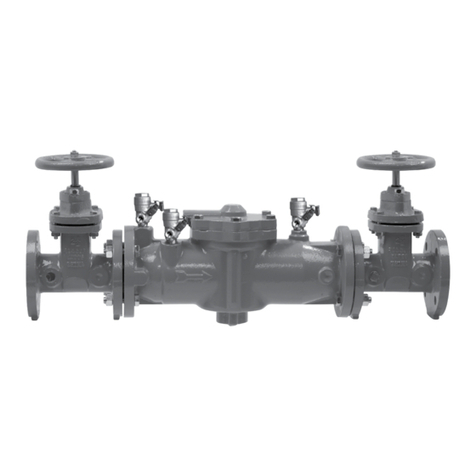

Watts 909 Series Instruction Manual

Watts

Watts AMES 933GD User manual

Watts

Watts LF007 IOT Series Operating instructions

Watts

Watts LFM115-7 Owner's manual

Watts

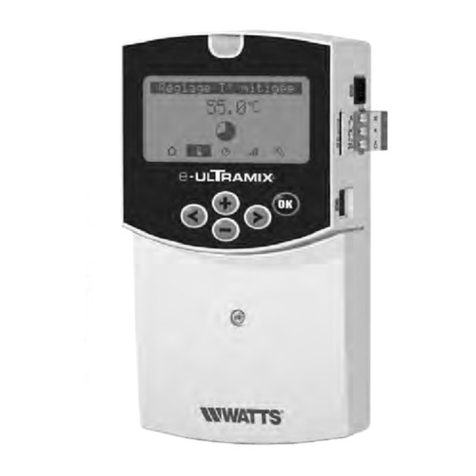

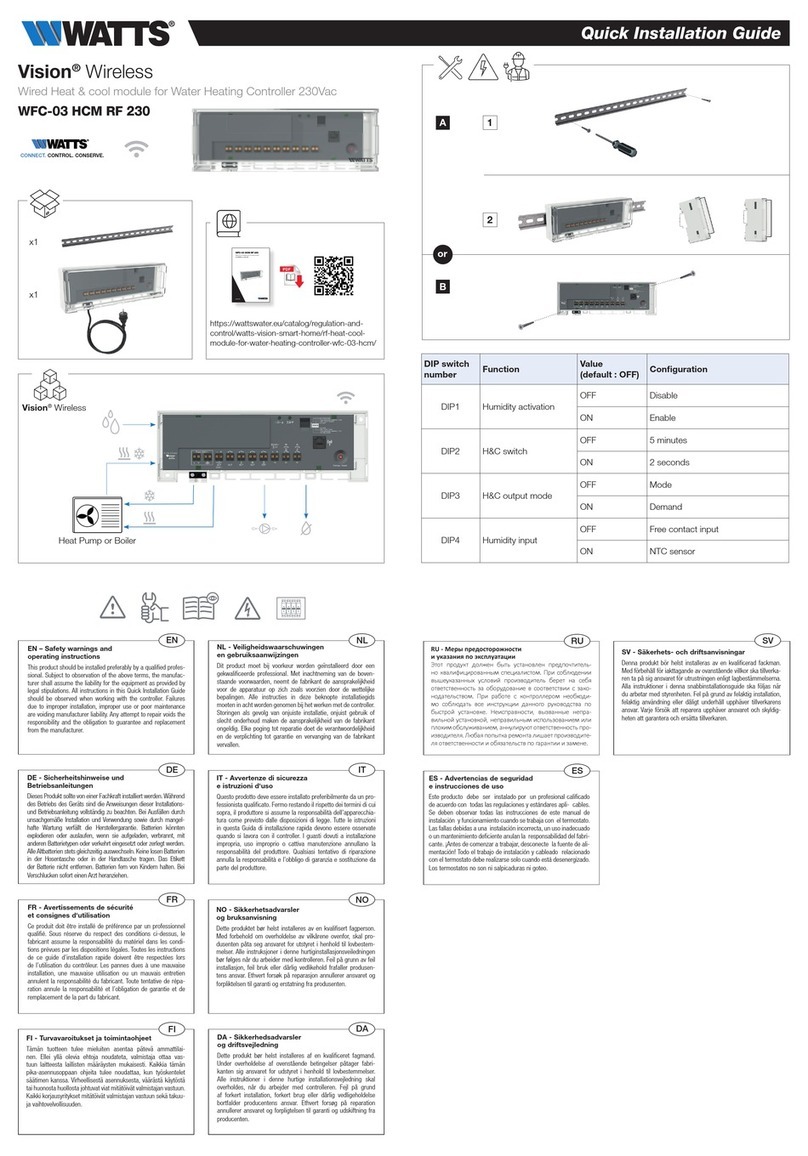

Watts WFC-03 HCM RF 230 User manual

Watts

Watts 709 Series Operating instructions

Watts

Watts Ames 986GD User manual

Watts

Watts LFM116-32 Installation and operating instructions

Watts

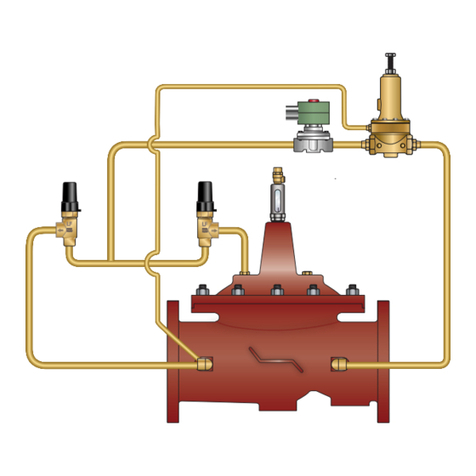

Watts AMES 930GD-01-19 Manual

Watts

Watts AMES 910GD Installation and operating instructions

Watts

Watts LFM114 Installation and operating instructions

Watts

Watts LFM118-4 Owner's manual

Watts

Watts POWERS HydroGuard LFG480 Series User manual

Watts

Watts 007 Series Operating instructions

Watts

Watts Ames 920GD-15 Owner's manual

Watts

Watts 972GD-20 User manual

Watts

Watts 007 Series Instruction Manual

Watts

Watts 779655030518 User manual

Watts

Watts 994 Series Instruction Manual