Watts HIU 2 Series User manual

HIU 2 series

Heat Interface Unit for hygienic domestic hot water

generation and heat distribution

Installation and Operating Manual (translated

from the original operating manual)

Issued 08/2018 Revision 1

Watts Industries Deutschland GmbH

Godramsteiner Hauptstr. 167

76829 Landau

Tel.: +49 (0) 6341 96560

wide@wattswater.com

WattsWater.de

2HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS|Art.No.10078860

EN ENGLISH

Contents

1 General information ...................................... 2

1.1 Important information about this installation and operating

manual ...........................................................................2

1.2 Product conformity .........................................................2

1.3 Product features..............................................................2

1.4 Product label...................................................................3

2 Technical data ............................................... 4

3 Safety.............................................................. 5

3.1 Depiction of safety information........................................5

3.2 Important safety information ...........................................5

3.3 Intended use ...................................................................5

3.4 Foreseeable misuse ........................................................5

3.5 Responsibilities of the operator.......................................5

3.6 Personnel groups............................................................6

3.7 Information on the operating environment.......................6

4 Structure ........................................................ 7

4.1 Hydraulic diagram ...........................................................8

4.2 HIU 2 HK.........................................................................9

4.3 HIU 2 HKM.................................................................... 10

5 Installation and commissioning .................11

5.1 Installation ..................................................................... 11

6 Power curves and diagrams ...................... 13

6.1 Power curves ................................................................ 13

6.2 Pressure loss diagrams................................................. 14

7 Maintenance ................................................ 16

7.1 Annual maintenance intervals ........................................ 16

7.2 Replacement of wear parts ........................................... 16

7.3 Cleaning the dirt trap..................................................... 17

7.4 Replacing the plate heat exchanger .............................. 17

8 Spare parts list ............................................ 18

9 Disposal........................................................ 19

9.1 Return shipment to the manufacturer............................ 19

9.2 Reporting to administrative bodies and the

manufacturer................................................................. 19

1 General information

1.1 Important information about the installa-

tion and operating manual

The operator is responsible for ensuring

adherence tothelocal lawsandregulations

(e.g. accident prevention regulations,

etc.).

Incorrect operation or operating the HIU 2

contrary to the specifications shall void all

rights to any warranty claim.

This installation and operating manual

• is a component of the HIU 2

• contains instructions and information on safe and correct

installation and commissioning of the HIU 2

• must be available to all users throughout the entire service

life of the HIU 2

• is intended for trained personnel who are familiar with the

applicable standards and provisions and, in particular, with

the relevant safety concepts and the operation and mainte-

nance of the HIU 2

• is protected by copyright and may not be altered without

the manufacturer’s permission

• may not be made accessible to unauthorized personnel,

either in original form or as a copy.

1.2 Product conformity

A Declaration of Conformity according to the Machinery

Directive 2006/42/EC has been issued for this HIU 2 product.

1.3 Product features

• Stable bracket

• Intended for installation in a surface-mounted cabinet,

flush-mounted cabinet or EPP insulation.

• All connections to the system with 1” male thread and 3/4”

male thread, and flat sealing

• Tapping temperature adjustable

• Max. draw-off capacity of DHW 12 l/min and 17 l/min

at DHW heated from 10 to 45 °C, at a primary supply

temperature of 65 °C and 200 mbar delta p.

• Very convenient controls, compact, space-saving design.

• Modular structure and suitable for connection to manifolds.

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 3

EN

ENGLISH

1.4 Product marking

4HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

2 Technical data

Hydraulic performance data

HIU 2 HK / HIU 2 HKM

Max. operating pressure

10 bar (PN 10)

Max. ambient temperature

60 °C

Max. operating temperature

90 °C

Differential pressure

200 mbar preset. Adjustable: 100 to 300 mbar

Media

Water/water-glycol mixture as per VDI 2035/ÖNORM (Austrian standard) 5195

Actuating drive

Voltage

230 V; +10…-20 %; 50/60 Hz

Power consumption, operating

2.5 W

Power consumption, end position

<1 W

Actuating power

100 N

Protection class

IP 54

Ambient temperature

0 to 60°C

Dimensions

Width x height x depth

HK

HKM

490 X 705 X 130 mm

500 x 705 x 140 mm

Weight

Total weight excluding packaging

HK12 / HK17 / HKM12 / HKM17

approx. 13 kg / 14 kg / 16 kg / 17 kg

Total weight including packaging

HK12 / HK17 / HKM12 / HKM17

approx. 15 kg / 16 Kg / 18 Kg / 19 kg

Connections to pipe network

Heat interface unit

1” male thread and ¾” male thread, flat sealing

Meter connections

Adapter for heat meter

110 mm G ¾

Adapter for cold water meter

110 mm G ¾

Materials

Pipes

Stainless steel Ø22 & Ø27 mm

Fittings

Brass

Seals

AFM34/2 and EPDM

Plate heat exchanger

stainless steel EN 1.4404/copper (solder) | optional stainless steel/stainless steel (solder)

Refer to the corresponding data sheets for more detailed information on the media used

Circulation pump, actuator and other

components

Technical data can be found in the enclosed technical documentation.

DHW per-

formance

Primary

temperature

Secondary

temperature

Pressure loss Flow rate Flow rate

Supply Return DCW DHW Primary Primary Secondary

26 plates 33 kW 65 °C 19 °C 9 °C 48 °C 19 kPa 11.2 l/min 12.0 l/min

36 plates 40 kW 65 °C 18 °C 11 °C 45 °C 19 kPa 13.4 l/min 17.1 l / m i n

HIU 2 performance

Heat output (10K) Q= 13 kW

Heat output (20K) Q= 26 kW

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 5

EN

ENGLISH

3 Safety

3.1 Depiction of safety information

DANGER indicates an imminent danger

that may cause serious physical injury or

death if the appropriate safety precau-

tions are not in place.

WARNING indicates a danger arising

through incorrect behavior (e.g. misuse,

disregarding notices, etc.) that may cause

serious physical injury or death.

CAUTION indicates a potentially danger-

ous situation that may cause minor or

slight injuries if the appropriate safety

precautions are not in place.

NOTICE indicates a situation that may

cause material damage if the correspond-

ing precautions are not taken.

3.2 Important safety information

• Before using the device, read this operating manual

through carefully.

• Only connect the HIU 2 to a power source that corre-

sponds to the mains voltage specified on the rating plate of

the HIU2.

• The power supply to the HIU2 must be disconnected prior

to maintenance, cleaning and repair work.

• Maintenance, cleaning and repair work may be carried out

by trained specialist personnel only.

• The HIU2 must not be used if it is damaged or if the HIU2

is no longer operating correctly. In this case, contact your

specialist dealer immediately.

• Observe the maintenance instructions and intervals.

• Protect the HIU2 from the influences of weather.

• Never use the HIU2 outdoors.

• The unit may be used only in accordance with its intend-

ed use.

3.3 Intended use

Ready-to-install compact, decentralized heat interface unit for

hygienic domestic hot water generation and heat distribution

in single-family houses and townhouse systems as well as for

use in multi-story apartment blocks.

The HIU2 is not intended to be operated by people (includ-

ing children) with physical, sensory or mental disabilities, nor

by people with insufficient experience or previous knowledge.

3.4 Foreseeable misuse

The following is considered to be foreseeable misuse:

• Operating the HIU 2 contrary to the specifications

• Improper use of the HIU2

• Modifications to the HIU2 that were not agreed with the

manufacturer

• Use of replacement or wear parts that were not approved

by the manufacturer

• Operating the HIU2 outdoors (parts and components are

not UV resistant)

• Use of prohibited media

3.5 Responsibilities of the operator

The operator must ensure that:

• the HIU2 is only used for its intended purpose

• the HIU2 is installed, operated and maintained accord-

ing to the specifications in the Installation and Operating

Manual

• the HIU2 is only operated according to local regulations

and occupational health and safety regulations

• all precautionary measures have been carried out to avoid

dangers originating from the HIU2

• all precautions for first aid and fire suppression are carried

out

• only authorized and trained users have access to the HIU2

and operate it

• users have access to this installation and operating manual

at all times

6HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

3.6 Personnel groups

Only qualified persons may install and operate the HIU 2 or

perform maintenance work.

Operator

An operator is deemed to be qualified if they have read these

operating instructions and understood the potential hazards

associated with improper behavior.

Fitter/commissioning engineer

A plumber or commissioning engineer is in a position, taking

into consideration the applicable standards, provisions, regu-

lations and laws and his/her technical training and technical

knowledge, to carry out work on the HIU 2 and to detect and

prevent potential hazards.

3.7 Information on the operating environment

Limescale deposits (from hard water) and corrosion, as well

as chemical and physical reactions, can cause damage to the

home station.

The selection of material for the plate heat exchanger (copper

or stainless steel) must be checked with reference to the water

quality (corrosion resistance).

The system planner is responsible for evaluating these

parameters and taking appropriate precautions.

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 7

EN

ENGLISH

4 Structure

HIU 2 HK

10079852 HIU 2 HK 12 CU

10079891 HIU 2 HK 12 STS

10078464 HIU 2 HK 17 CU

10079893 HIU 2 HK 17 STS

• For heating and drinking water heating

• Hot water priority circuit

• Differential pressure control

• Pre-installed adapters for heat meters and cold water

meters

• Optional:

- Water hammer arrestor (Art. No. 10079166)

- Circulation set (Art. No. 10080335)

- Thermostatic circulation bridge (Art. No. 10079903)

HIU 2 HKM

10079851 HIU 2 HKM 12 CU

10079892 HIU 2 HKM 12 STS

10078463 HIU 2 HKM 17 CU

10079894 HIU 2 HKM 17 STS

• For heating and drinking water heating

• Hot water priority circuit

• Differential pressure control

• Pre-installed adapters for heat meters and cold water

meters

• Mixer module

• Optional:

- Water hammer arrestor (Art. No. 10079166)

- Circulation set (Art. No. 10080335)

- Thermostatic circulation bridge (Art. No. 10079903)

8HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

4.1 Hydraulic diagram

HIU 2 HK

Optional

:

Optional

:490mm 130mm

705mm

Optional:500mm 140mm

705mm

HIU 2 HKM

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 9

EN

ENGLISH

4.2 HIU 2 HK

1

2

5 6

15

4

11

18

16

14

17

10

3

19

20

7

12

21

13

22 23 24

8

9

1Vent

2Temperature sensor

3Water hammer arrestor (optional)

4Junction box

5Thermal valve

6Plate heat exchanger

7Switch valve, heating circuit/hot water

8Actuating drive

9Flow switch

10 Connection for supply temperature sensor of the

heat meter

11 Dirt trap

12 Membrane regulator/differential pressure regulator

13 Circulation set (optional)

14 Zone valve (heating circuit)

15 Adapter for cold water meter

16 Adapter for heat meter connector

17 Supply heating circuit

18 Return heating circuit

19 Domestic hot water outlet

20 Domestic water circulation inlet

21 Domestic cold water outlet

22 Domestic cold water inlet

23 Primary supply

24 Primary return

10 HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

4.3 HIU 2 HKM

1

2

5 6

15

4

11

18

16

26

17

10

3

19

20

7

12

21

13

22 23 24

25

8

9

1Vent

2Temperature sensor

3Water hammer arrestor (optional)

4Junction box

5Thermal valve

6Plate heat exchanger

7Switch valve, heating circuit/hot water

8Actuating drive

9Flow switch

10 Connection for supply temperature sensor of the

heat meter

11 Dirt trap

12 Membrane regulator/differential pressure regulator

13 Circulation set (optional)

14 -

15 Adapter for cold water meter

16 Adapter for heat meter connector

17 Supply heating circuit

18 Return heating circuit

19 Domestic hot water outlet

20 Domestic water circulation inlet

21 Domestic cold water outlet

22 Domestic cold water inlet

23 Primary supply

24 Primary return

25 Actuator including regulator

26 Heating circuit pump

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 11

EN

ENGLISH

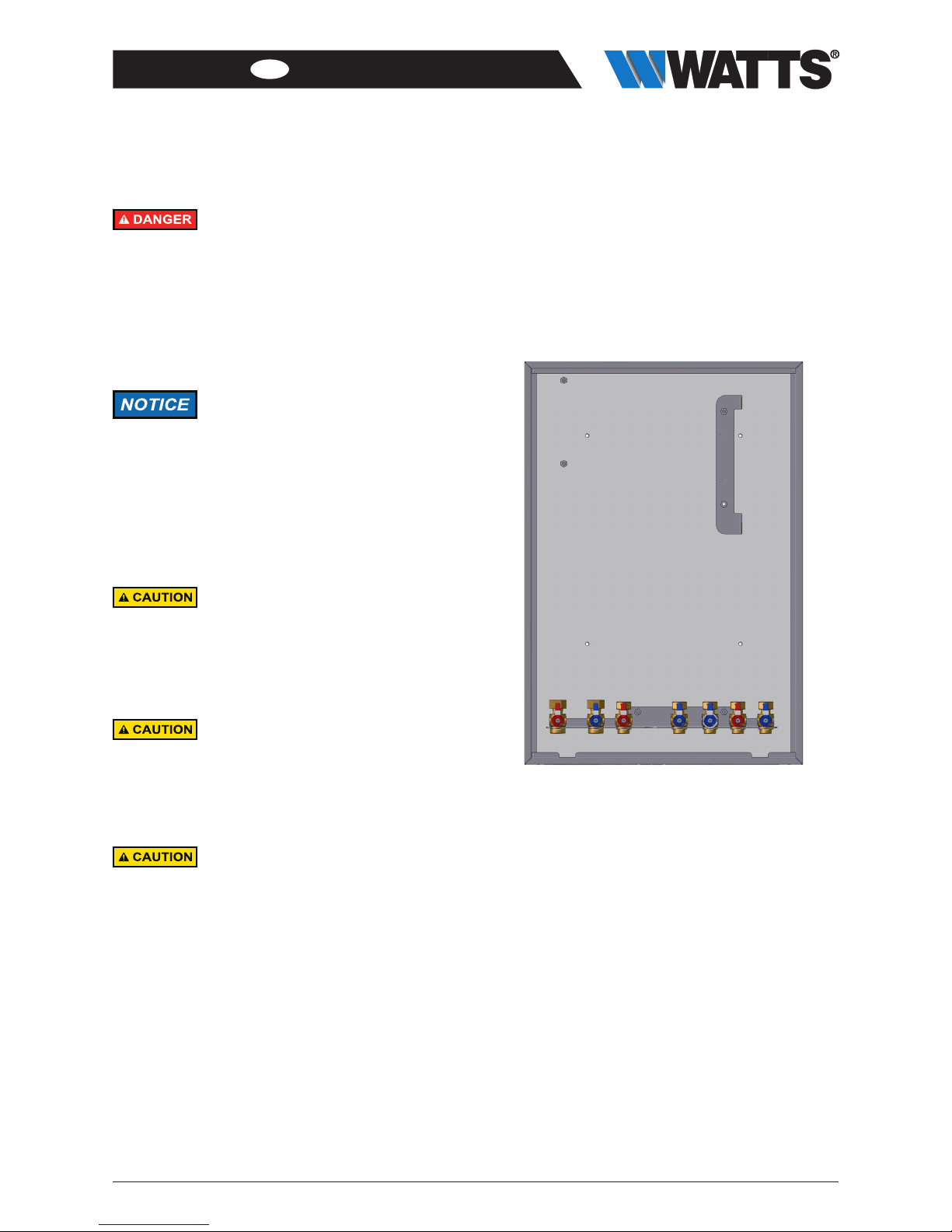

5 Installation and commissioning

Electricity!

Risk of death from electric shock.

• Work on parts carrying live voltage must

only be carried out by trained electricians.

• Disconnect the power supply of the sys-

tem and secure it against being switched

back on before carrying out any installa-

tion, maintenance, cleaning or repair work.

The installation and commissioning of the

HIU 2 must only be carried out by trained

personnel who have been authorized by

the manufacturer.

When installing and operating a circula-

tion system, the recognized rules of engi-

neering as well as the hygiene regulations

according to “DVGW Arbeitsblatt W551”

(German association for gas and water,

worksheet W551) must be observed.

The HIU 2 may only be installed in an

upright position.

When repairing the unit or replacing parts,

be sure to observe the specified installa-

tion positions and flow directions of the

parts being replaced.

Material damage!

Pressure shocks may occur if the stop

valve is opened quickly.

• Always open the stop valve slowly and in

a controlled way.

Bad water quality!

Hard water causes limescale deposits in

the HIU 2 and diminishes the quality of

the water.

• Measure the water hardness in the supply

system.

• Install a water softening unit from a degree

of hardness of 17° dH.

5.1 Installation

All screw fittings must be checked and tightened if nec-

essary prior to installation and commissioning.

Torque:

• ¾” screw fittings 35 Nm

• 1” screw fittings 55 Nm

Requirements

• The HIU 2 cabinet (surface-mounted or flush mounted) is

installed.

• A safety valve that cannot be shut off must be installed in

the cold water inlet to the HIU 2. In so doing, the acknowl-

edged rules of technology must be taken into account.

• The installation sequence must be observed to prevent

electrochemical corrosion of galvanized lines and fittings.

• The valves are pre-installed at the factory but must be

checked for leaks during commissioning (hydraulic pressure

test).

Recommendation: Install water filter into the cold

water inlet.

12 HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

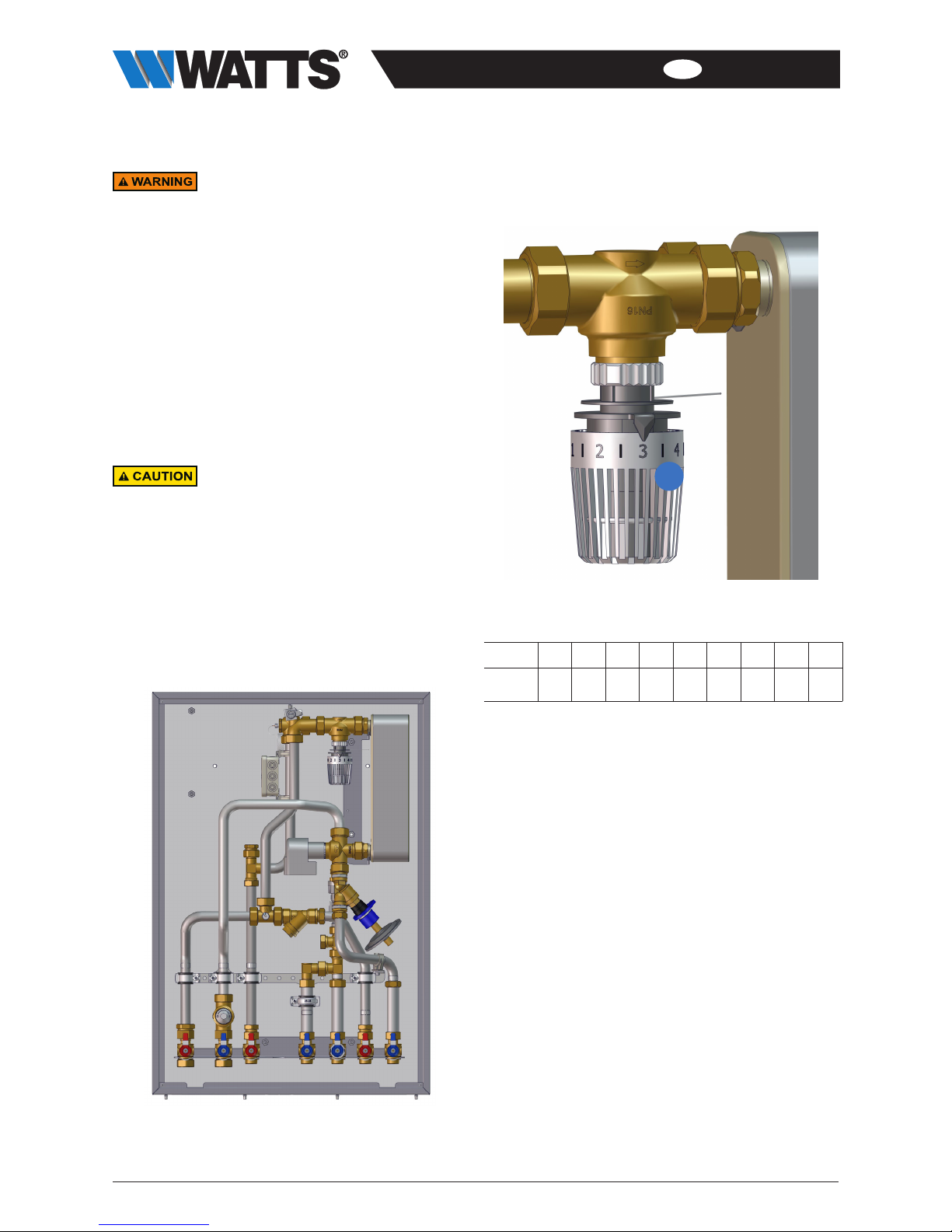

Hot water!

Severe scalding possible.

Do not reach into the hot water when

emptying the HIU2.

Ensure that the HIU 2 has cooled down

before carrying out maintenance, clean-

ing and repair work.

Install a suitable scalding protection

device at every tapping point (for exam-

ple, safety shut-off valve or thermostat

mixer tap).

More detailed information on scalding

protection can be found in DIN 1988,

sheet 2, clause 4.2.

Danger of scalding!

To avoid scalding when tapping hot water,

appropriate scalding protection must be

provided.

Observe the recognized rules of technology

when doing so.

1. Insert the HIU 2 and connect to the connection rail.

Optional:

2. Install the water hammer arrestor, circulation set and

circulation manifold.

3. Connection to power mains (230V).

4. Set the desired tapping temperature on the thermostatic

head (X).

X

Setting, at max. flow rate with a supply temperature of

65 °C:

Scale 1I2I3I4I5

approx.

°C 34 37 41 44 48 51 55 58 63

5. Vent the primary (heating) circuit.

• Slowly open the stop valves on the heat network connec-

tors (see Chapter 4).

• Open and hold open the vent valve (see Chapter 4) until air

no longer escapes.

6. Vent the secondary circuit (domestic water).

• Slowly open all of the tapping points, one after the other,

and draw water until all lines fill up and all air has been

vented from the system.

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 13

EN

ENGLISH

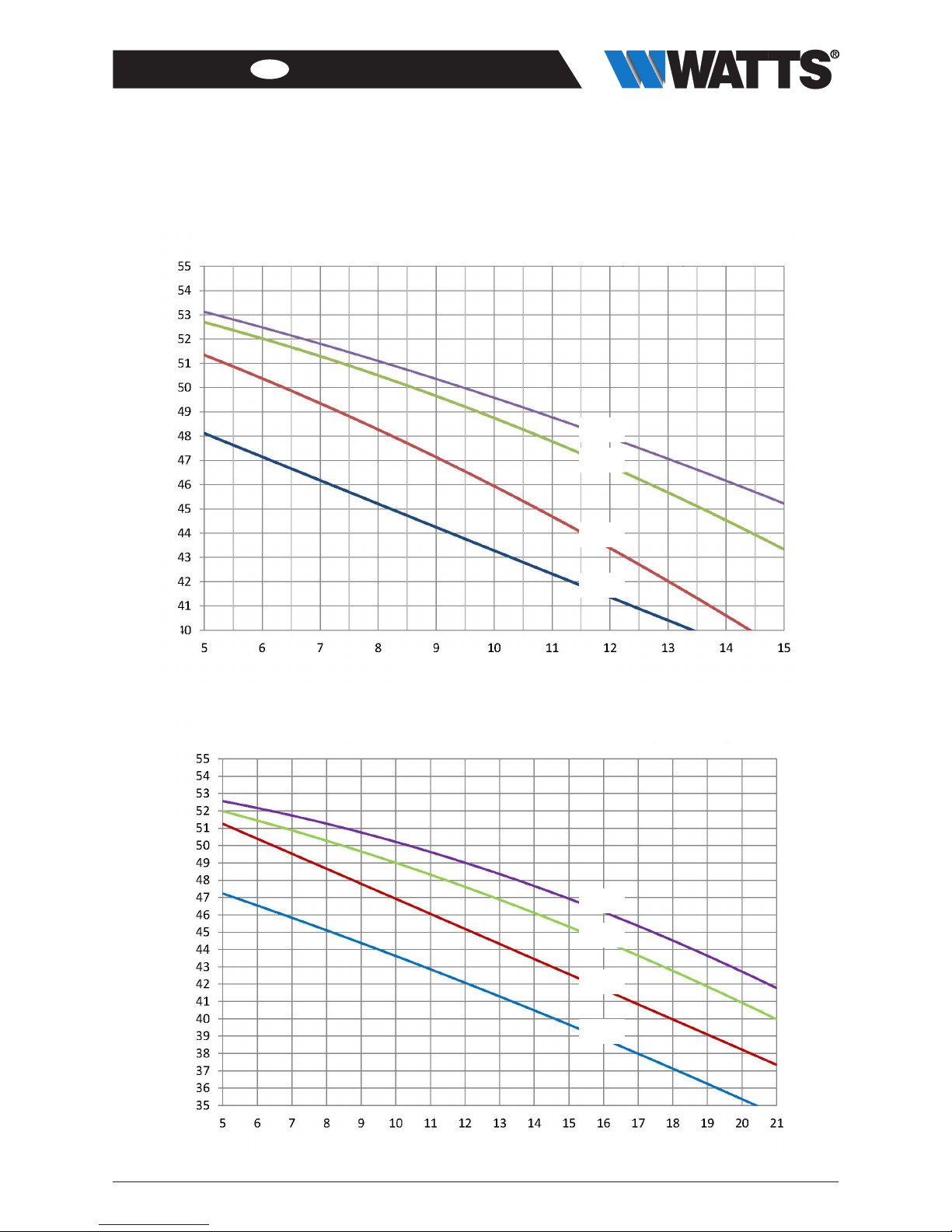

6 Power curves and diagrams

6.1 Power curves

65 °C

55 °C

60 °C

50 °C

65 °C

55 °C

60 °C

50 °C

Heat interface unit HIU 2, 26 plates, 12 l/min., 200 mbar

DHW temperature, secondary circuit, with various primary supply temperatures

Heat interface unit HIU 2, 36 plates, 17 l/min., 200 mbar

DHW temperature, secondary circuit, with various primary supply temperatures

DHW temp. [°C]

DHW temp. [°C]

tapping rate [l/min]

tapping rate [l/min]

14 HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

6.2 Pressure loss diagrams

1

10

100

1.000

10 100 1.000 10.000

Druckabfall (mbar)

Durchfluss (L/h)

Primäre Seite, Trinkwassererwärmung über Wärmetauscher

26 Platten, 12 l/min., Kvs-Wert: 1,35 m³/h (gestrichelte Linie)

36 Platten, 17 l/min., Kvs-Wert: 1,42 m³/h (durchgehende Linie)

1

10

100

1.000

10 100 1.000 10.000

Druckabfall (mbar)

Durchfluss (L/h)

Sekundäre Seite, Trinkwasser warm

26 Platten, 12 l/min. Kvs-Wert: 2,2 m³/h (gestrichelte Linie)

36 Platten, 17 l/min. Kvs-Wert: 2,5 m³/h (durchgehende Linie)

Pressure drop (mbar)

Pressure drop (mbar)

26 plates, 12 l/min., Kvs value: 1.35 m³/h (dotted line)

36 plates, 17 l/min., Kvs value: 1.42 m³/h (solid line)

Secondary circuit, domestic hot water

26 plates, 12 l/min. Kvs value: 2.2 m³/h (dotted line)

36 plates, 17 l/min. Kvs value: 2.5 m³/h (solid line)

Primary circuit, domestic hot water generated by the heat exchanger

Flow rate (l/h)

Flow rate (l/h)

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 15

EN

ENGLISH

1

10

100

1.000

10 100 1.000 10.000

Druckabfall (mbar)

Durchfluss (L/h)

Primäre Seite, Heizungsbedarf, Wohnungsstation

HIU 2 HKM, Kvs-Wert: 1,6 m³/h (gestrichelte Linie)

HIU 2 HK, Kvs-Wert: 1,7 m³/h (durchgehende Linie)

1

10

100

1.000

10 100 1.000 10.000

Druckabfall (mbar)

Durchfluss (L/h)

Sekundäre Seite, Trinkwasser kalt

Kvs-Wert: 6,5 m³/h

Pressure drop (mbar) Pressure drop (mbar)

Primary circuit, demand heating, heat interface unit

HIU 2 HKM, Kvs value: 1.6 m³/h (dotted line)

HIU 2 HK, Kvs value: 1.7 m³/h (solid line)

Secondary circuit, domestic cold water

Kvs value: 6.5 m³/h

Flow rate (l/h)

Flow rate (l/h)

16 HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

7 Maintenance

Electricity!

Only perform maintenance work on the

HIU 2 if the voltage supply has been

disconnected.

Hot water!

Severe scalding possible.

Do not reach into the hot water when

emptying the HIU2.

Ensure that the HIU 2 has cooled down

before carrying out maintenance, clean-

ing and repair work.

Hot surfaces!

Serious burns possible.

Do not touch the tubings/pipings or com-

ponents during operation.

Ensure that the HIU 2 has cooled down

before carrying out maintenance, clean-

ing and repair work.

Wear heat-resistant safety gloves if it

is necessary to carry out work on hot

components.

The maintenance of the HIU 2 must only be

carried out by trained personnel who have

been authorized by the manufacturer.

7.1 Annual maintenance intervals

1. General visual inspection

• Check the station for leaks, annual maintenance intervals,

if necessary

1. General visual inspections

• Check the station for leaks and retighten sealing connec-

tions or replace seals, as required.

2. Functional checks

• Check that settings and operating and performance

parameters are set correctly.

• Check flow noise during operation.

• Ask users if there are any noticeable problems.

3. Ball valves

• Check that stop valves and ball valves can move freely.

4. Dirt trap

• Check and clean the dirt trap.

5. Plate heat exchanger

• Check the plate heat exchanger for limescale deposits and

clean if necessary.

6. Actions following maintenance work

• Check that all screw fittings that were unscrewed have

been retightened and retighten if necessary.

• Remove all tools, materials and other equipment used from

the working area.

• Restore the power supply.

• Slowly pressurize the HIU2 and vent it.

• Readjust the system settings if required.

7.2 Replacement of wear parts

Please note that the HIU 2 contains parts that, for technical

reasons, are subject to wear depending on the intensity of

use, even if the specified care and maintenance have been

observed.

This especially applies to mechanical parts and parts that

come into contact with water and steam, such as hoses,

seals, valves, etc.

By their nature, defects caused by wear do not constitute a

fault and are therefore not covered by the warranty or any

guarantee. Nevertheless, these defects and malfunctions

must be remedied only by trained specialist personnel.

Contact your specialist dealer for this.

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 17

EN

ENGLISH

7.3 Cleaning the dirt trap

1. Depressurize the HIU2 (e.g. by opening the vent valve).

2. Unscrew and remove the dirt trap and clean it.

3. Replace the filter into the dirt trap after cleaning.

4. Slowly open the stop valves and vent the system.

7.4 Replacing the plate heat exchanger

1. Close all stop valves.

2. Depressurize the HIU2 (e.g. by opening the vent valve).

3. Loosen the nuts (pos. A) and remove the plate heat

exchanger.

A

A

4. Replace all seals.

5. Insert the new plate heat exchanger and tighten the nuts

(pos. A). (Refer to the “Technical data” chapter for the

torque).

6. Slowly open the stop valves.

7. Slowly pressurize the HIU2, fill and vent it.

18 HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS| Art.No.10078860

EN ENGLISH

8 Spare parts list

Spare part Art. No:

Vent valve

1/2”

10001506

3-way valve

DN25

10001552

Dirt trap 3/4” 10017599

Balancing valve

for membrane regulator

10080350

Combination membrane

regulator

0.1-0.3 bar

10080351

2-way zone valves DN25 10046053

Actuating drive

230V 50Hz

10080349

Flow switch FS-01

3/4” female thread x 3/4”

male thread

10080352

Plate heat exchanger

XB06H-1-26, 4x3/4“, copper

brazed

10080356

Plate heat exchanger

XB06H-1-26, 4x3/4“, stain-

less-steel brazed

10080358

Plate heat exchanger

XB06H-1-36, 4x3/4“, copper

brazed

10080355

Plate heat exchanger

XB06H-1-36, 4x3/4“, stain-

less-steel brazed

10080357

Ball valve 1” red 10080359

Ball valve 1” blue 10080360

Ball valve 3/4” red 10080361

Ball valve 3/4” blue 10080362

Adapter

3/4”; 110 mm

10080363

Thermostatic head K [1-5]

incl. spiral immersion sensor

10080354

Actuator

230 V

10080348

3-way mixer

Kvs 4.0

10080053

Pump, UPM3 Auto L15-70

1”; 130 mm

10080353

HIU2-IM-DE-W-DE-08-2018-Rev1_DE-enUS | Art. No. 10078860 19

EN

ENGLISH

9 Disposal

Potential for contamination of the envi-

ronment and groundwater from improp-

er disposal!

The regulations and guidelines of the leg-

islature in the country of operation must

be complied with when disposing of com-

ponents and operating materials.

1. Ensure that all subassemblies and components are

de-energized.

2. Professionally disassemble the HIU 2 or commission a

specialist company with this task.

3. Sort the sub-assemblies and component parts into recy-

clable materials, hazardous substances and operating

materials.

4. Dispose of the sub-assemblies and components in accor-

dance with local laws and regulations or take them to be

recycled.

9.1 Return shipment to the manufacturer

Get in contact with the manufacturer if you would like to return

the HIU2 or parts of it.

9.2 Reporting to administrative bodies and

the manufacturer

Inform the manufacturer about decommissioning and disposal

of the HIU2 for statistical purposes.

10 Warranty

WATTS products are tested extensively. WATTS therefore

guarantees only the replacement or, at the sole discretion

of WATTS, the free-of-charge repair of components of the

supplied products where these, in the opinion of WATTS,

exhibit verifiable manufacturing faults. Warranty claims due

to defects or defects of title may be asserted within one (1)

year of delivery/transfer of risk. Excluded from the warran-

ty are damages attributable to normal product wear or fric-

tion and damages resulting from modifications or non-au-

thorized repairs on the products, for which WATTS rejects

all claims for compensation (direct or indirect). (For more

detailed information, please refer to our website.) In all cases,

supply is subject to the General Terms and Conditions,

which can be found at www.wattswater.de.

This manual suits for next models

2

Table of contents

Other Watts Recording Equipment manuals