Watts TK-DL User manual

IS-TK-DL

Installation

The Watts TK-DL Computerized Backflow Tester is an advanced piece of test equipment designed to make pressure and differ-

ential gauges obsolete in the testing of backflow assemblies. Two solid-state, high-resolution pressure transducers provide the inter-

face to the computer. With 32K of memory, battery back up, 48 character super-twist display, 16 function keyboard and high-efficien-

cy thermal printer, the TK-DL is equipped to provide real time data handling and the outputs required to test, validate and certify every

backflow assembly. (See operating manual for details). The TK-DL allows you to download your test results into a personal computer

for permanent storage. In addition, the TK-DL menu driven software program allows for customizing of printed header and footer.

GENERAL INFORMATION

Before connecting hoses to tester, be sure to flush test cocks on backflow assembly.

CAUTION: To avoid freeze damage to the test kit, it should be stored in a dry warm area when not in use.

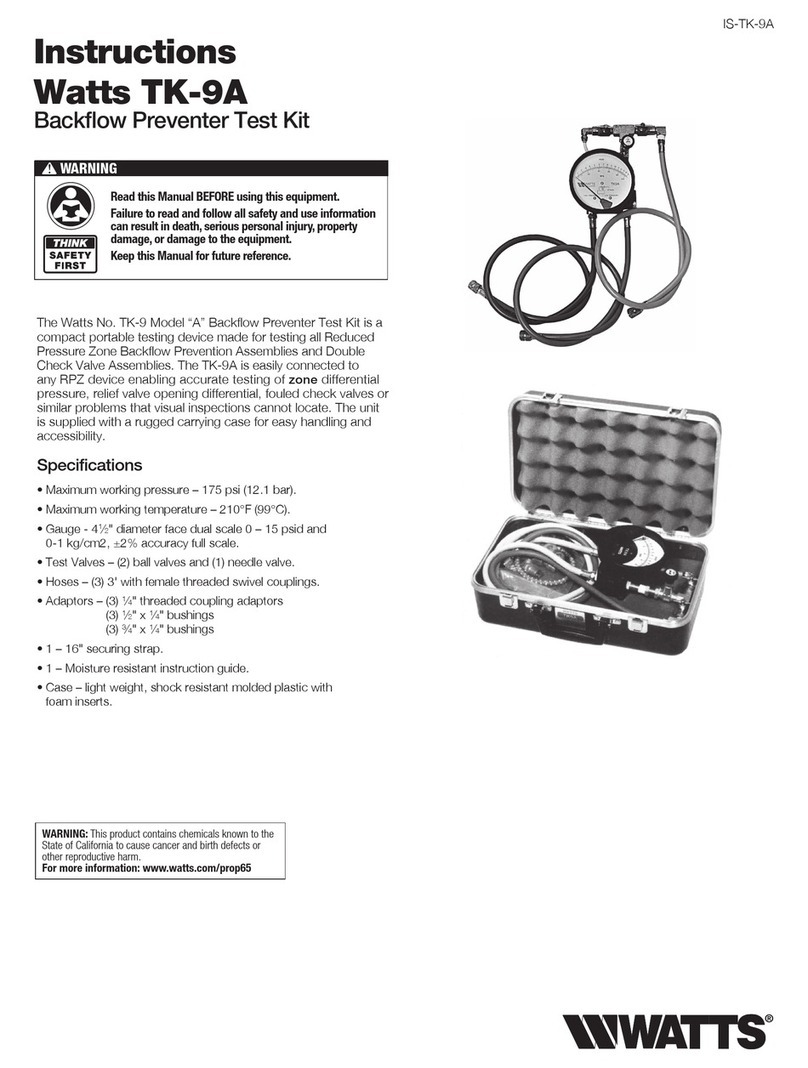

Watts TK-DL

(in carrying case - sold separately)

Watts TK-DL

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

Watts TK-DL

Digital Print-out Test Kit for Backflow Preventer Assemblies

IS-TK-DL.indd 1 9/5/08 2:18:57 PM

2

The following Test Procedure is one of several that is recognized

throughout the United States for verification of the functioning of

Backflow preventers.

The following procedure is not a specific recommendation. The

Watts series of test kits are capable of performing any of the

recognized Backflow test procedures.

Note: For both of the following test, the TK-DL must be held at

the same level as the assembly being tested.

A. Flush TC #1 and #2.

B. Turn tester on (before connecting hose). Tester

must read all zeros. Close VA and VB.

Test No. 1 - Air Inlet

1. Install high side hose between TC #2 and tester connection

A.

2. Open VA then TC #2. Bleed hose, then close VA.

3. Close shutoff valve #2 then #1.

Push - Print Head (wait) then Push -

Start Test

4. Slowly open VA when air inlet float opens, push “hold” but-

ton for at least 2 seconds.

Record differential reading (must be 1 PSID or more). Close

VA.

Push - Stop Test

5. Close TC #2 and remove hose.

6. Open shutoff valve #1.

Test No. 2 - Test Check Valve

7. Install highside hose between TC #1 and tester connection

A.

8. Open VA then TC #1. Bleed hose, then close VA.

9. Close shutoff valve #1.

Push - Start Test

10. Open TC #2. When flow of water out of TC #2 stops, the

differential reading is the pressure drop. Record (must be 1

PSID or more).

Stop Test (Push Stop Test twice)

11. Close test cocks and remove tester. Return assembly to

normal operating condition.

Test Cock No. 1

Test Cock No. 2

800M4-QT

Test Procedure for Pressure Vacuum Breakers

IS-TK-DL.indd 2 9/5/08 2:18:58 PM

3

Test No. 1 - Differential Test

Make sure that the test kit is at the same elevation as the device

being tested.

1. Remove the two screws from hood and remove hood so that

vent is visible.

2. Turn test kit on, wait until self check is complete.

3. Connect hose from test cock to VA HIGH.

4. Open test cock, then VA, (VB LOW should be opened and

remain open through the test). Bleed hose and test kit of air,

when bleeding hose fill vent with water, shut off VA.

5. Close #2 shutoff, then close #1 shutoff.

6. Press PRINT HEADER button. Wait until header stops print-

ing. Press START TEST RESUME button.

7. Slowly unscrew bleed screw on SVB (about three turns).

8. When dripping from bleed screw stops, and gauge reading

settles, this is the check differential. This must be 1 PSI or

greater.

9. Press PAUSE STOP button.

Test No. 2 - Air Inlet (Vent Opening)

10. Press START TEST RESUME.

11. Slowly open VA and watch vent, with finger over DISPLAY

HOLD button. When the water level above the vent starts to

drop this is the vent opening press DISPLAY HOLD button.

This will record the vent opening point. This value must be 1

PSI or greater.

12. Visually inspect vent to ensure that vent goes to full open

position when the pressure is at zero.

13. Press PAUSE STOP TEST button twice.

14. Tighten bleed screw, close test cock and reinstall hood, open

shutoff #1, open shutoff #2, remove hose. Testing is com-

plete.

008QT

Bleed Screw

Test Cock

Test Procedure for Anti-spill, Anti-siphon Vacuum Breaker (SVB)

IS-TK-DL.indd 3 9/5/08 2:18:58 PM

4

The following Test Procedure is one of several that is recognized throughout the United States for verification of the functioning of

Backflow preventers.

The following procedure is not a specific recommendation. The Watts series of test kits are capable of performing any of the recog-

nized Backflow test procedures.

A. Flush all test cocks.

B. Turn tester on (before connecting hoses).

Tester must read all zeroes. Close VA and VB.

Test No. 1 - Test No. 1 Check Valve

1. Install high side hose between TC #2 and tester connection

A.

2. Install low side hose between TC #3 and tester connection B.

3. Open VA then TC #2, bleed hose, then close VA.

4. Open VB then TC #3, bleed hose, then close VB.

5. Install a bypass hose between VB and TC #1. Open TC #1

and bleed by loosening hose connection at VB. Tighten

hose connection, fully open VB.

Push - Print Head (wait) then Push - Start Test.

6. Close shutoff valve #2 then #1.

7. Slowly open VA and lower high side pressure about -2 PSID

below the low side pressure (differential reading about -2.0

PSID). Close VA. If reading is maintained, record as “tight”. If

reading returns to 0 and the pressure A increases to pressure

B, the check is recorded as leaking. If the reading returns to

+PSID, No. 2 shutoff valve is leaking excessively and must be

replaced to test the valve.

8. Close all test cocks, remove hoses from TC #2 and TC #3

and TC #1. reopen shutoff valve #1. Proceed to Test No. 2.

Push - Stop Test.

Test No. 2 - Test No. 2 Check Valve

1. Install high side hose between TC #3 and tester connection A.

2. Install low side hose between TC #4 and tester connection B.

3. Open VA then TC #3, bleed hose, then close VA.

4. Open VB then TC #4, bleed hose, then close VB.

5. Install a bypass hose between VB and TC #1.

Loosen hose at VB, open TC #1 and bleed, retighten hose

connection.

Push - Start Test.

6. Close shutoff valve #1.

7. Slowly open VA and lower high side pressure about -2 PSID

below the low side pressure (differential reading about -2.0

PSID). Close VA. If reading is maintained, record as “tight”. If

reading returns to 0 and the pressure A increases to

pressure B, the check is recorded as leaking. If the reading

returns to + PSID, No. 2 shutoff valve is leaking excessively

and must be replaced to test the valve.

Push - Stop Test.

VHL V

1234

1234

VHL V

Test Procedure for Anti-spill, Anti-siphon Vacuum Breaker (SVB)

IS-TK-DL.indd 4 9/5/08 2:18:58 PM

5

The following Test Procedure is one of several that is recognized throughout the United

States for verification of the functioning of Backflow preventers.

The following procedure is not a specific recommendation. The Watts series of test kits are

capable of performing any of the recognized Backflow test procedures.

A. Open TC #4 and flush test cocks Nos. 1, 2 and 3 on BF as-

sembly, then close TC #4.

B. Turn tester on (before connecting hoses). Tester must read all

zeros. Close VA and VB.

Test No. 1 - Relief Valve

1. Install high side hose between TC #2 and tester connection A.

2. Install low side hose between TC #3 and tester connection B.

3. Open VB then TC #3. Now open VA then TC #2 slowly.

Close VA then VB.

4. Close #2 shutoff valve.

5. Observe the apparent first check valve differential pressure

(A - B).

6. Install bypass hose between VA and VB.

Open VB and bleed air by loosening hose connection at VA.

Tighten hose connection and close VB.

Push - Print Head (wait) then Push - Start Test

7. Open VA, then slowly open VB (no more than 1⁄4 turn). When

relief valve drips, push the “hold button for 2 seconds. Record

reading (must be 2 PSID or more).

Push - Stop Test

8. Close VA and VB.

Test No. 2 - Test No. 2 Check Valve

9. Install bypass hose between VA and TC #4.

Open VA, then bleed air by loosening hose connection at TC

#4. Tighten hose connection. Close VA.

Push - Start Test

10. Open VB to reestablish pressure within the “zone”. Close VB.

11. Open VA the TC #4. If relief valve does not drip,

record second check valve as “closed tight”.

12. Close VA and TC #4 and remove bypass hose.

Test No. 3 - Test No. 1 Check Valve

13. Open VB to reestablish first check valve differential pressure.

Close VB. Record pressure differential.

Stop Test (Push Stop Test twice)

14. Close test cocks and remove tester, return assembly to nor-

mal operating condition.

VHLV

1

2

34

VHLV

1

23

4

1234

VHL V

Test Procedure for Reduced Pressure Zone Assemblies

IS-TK-DL.indd 5 9/5/08 2:18:58 PM

6

Nicholson Labs

1423 Queen City Ave.

Cincinnati, OH 45214

Tel: (513) 251-8378

Fax: (513) 251-4388

BAVCO

20435 S. Susana Road

Long Beach, CA 90810-1136

Tel: (310) 639-5231

Fax: (310) 639-0721

SYMPTOM CAUSE SOLUTION

1. Check valve fails to hold a. Debris on check disc Disassemble and clean

1.0 PSID minimum sealing surface

b. Leaking gate valve Disassemble and clean or repair

c. Damaged seat disc or Disassemble and replace

seat o-ring

d. Damaged guide holding Disassemble clean or replace

check open

e. Weak or broken spring Disassemble and replace spring

2. Chatter during flow a. Worn, damaged or Disassemble and repair or

conditions defective guide replace guide

3. Low flows passing a. Mainline check fouled Disassemble and clean

through mainline

valve (709DCDA only)

b. Meter strainer plugged Disassemble and clean

c. Damaged mainline seat Disassemble and replace

disc or seat

d. Broken mainline spring Disassemble and replace

Calibration Centers

Troubleshooting Guide

Double Check Valve Assemblies

IS-TK-DL.indd 6 9/5/08 2:18:58 PM

7

Should valve

PROBLEM CAUSE be replaced? SOLUTION

A. Valve spits periodically from the vent.

A.1 Fluctuating supply pressure. No A.1 Install a soft seated check valve immediately upstream

of the device. (Watts 3/4”- 2” No. 601 bronze valve.)

A.2 Fluctuating downstream pressure. No A.2 Install a soft seated check valve downstream of the

device close as possible to the shutoff valve.

(Watts 3/4”- 2” No. 601 bronze valve.)

B. Valve drips continually from the vent.

B.1 Fouled first check. No B.1 Flush valve. If flushing does not resolve problem,

disassemble valve and clean or replace the first check.

B.2 Damaged or fouled relief valve seat. No B.2 Clean or replace the relief valve seat.

B.3 Relief valve piston “O” ring not free to move due to No B.3 Clean, grease or replace the piston “O” ring.

pipe scale, dirt or build-up of mineral deposits.

B.4 Excessive backpressure, freezing, or water hammer No B.4 Eliminate source of excessive backpressure or water

has distorted the second check. hammer in the system downstream of the device. Use

Watts No. 601 to dampen out backpressure and No. 15

to eliminate water hammer. Replace defective second

check assembly. In case of freezing; thaw,

disassemble, and inspect internal components.

Replace as necessary.

B.5 Electrolysis of relief valve seat or first check seats. No B.5 Replace relief valve seat or inlet cover. Install dielectric

unions (Watts Series 3001 through 3006). Electrically

ground the piping system and/or electrically isolate the

device with plastic pipe immediately upstream and

downstream of the device.

B.6 Valve improperly reassembled. No B.6 If valve is diassembled during installation, caution must

be exercised to install check springs in

their proper location.

C. Valve exhibits high pressure drop.

C.1 Fouled strainer. No C.1 Clean strainer element or replace.

C.2 Valve too small for flows encountered. Yes C.2 Install proper size device based upon flow

requirements.

D. No water flows downstream of valve.

D. Valve installed backwards. No D. Install valve in accordance with flow direction arrow.

E. Valve does not test properly.

E.1 Follow manufacturer’s test procedure. No E.1, E.2 Clean or replace gate valve with full port ball

E.2 Leaky downstream gate valve. No valves or resilient wedge shutoff valves.

F. Valve quickly and repeatedly fouls following servicing.

F. Debris in pipe line is too fine to be trapped by strainer. No F. Install finer mesh strainer element in the strainer.

G. Winterization of backflow preventers. G. Electric heat-tape wrap closely together around valve

body. Build a small shelter around the valve with a

large light bulb installed and left on at all times.

If supply line is not used during the winter, removal

of the complete body is the best. This would create

an air gap to eliminate any possible backflow.

Troubleshooting Guide

Reduced Pressure Zone Assemblies

IS-TK-DL.indd 7 9/5/08 2:18:59 PM

Watts TK-DL Software Instructions

The Watts TKDLC102 Software Disc is menu driven and will prompt you throughout the process of down loading your Watts

TK-DL test results to a personal computer. The following information has been provided to assist you in utilizing your Watts

TK-DL test kit.

TK DLC 102: Enter

READ WRITE TO TESTER: Enter

Connect TK-DL to computer and turn on

(on screen instructions)

A. Load Data from Tester

Reads Tester information in memory.

B. Display settings

Model = Watts TK-DL

Eprom Version

Serial #

Time/Date

Last Calibrated

Next Cal Due

Next Test #

C. Change Settings

Time/Date - day only

D. Display Heading and Footer

Displays heading and footer in TK-DL

memory printed on tape.

E. Change Heading and Footer

Allows heading and footer to be changed

by using computer keyboard.

F. Write Data to Tester (Saves information to the

Test Kit once you have changed the header or

the footer or anything in the “Change Settings”

option).

G. Load Heading File

It recalls a heading that was previously

saved. You can then load into the TK-DL

when you are connected to the computer.

After loading you must write data to tester

(Step F).

➝

➝

H. Load Footing File

Same as load heading, except for footer.

G., H. Brings up headers and footers that were pro-

grammed and saved at an earlier time. You may

recall the footer or header to program into you test

kit. The recalled or “Loaded” information will

overwrite current information.

I. Save Heading

J. Save Footing

I, J, Use this option when you have changed the header

or the footer and want to save the changes. You

can save each header and footer in a separate le.

You can then recall or “Load” the header or footer to

be programmed into your test kit.

K. Down Load Tests

Down loads from TK-DL to disc.

L. Print Tests

On screen prompts:

F2 OK, F4 scroll up, F6 scroll on,

Esc to cancel.

Lists date and Time tests

were recorded.

to select test to print

Note: The disc included with your test kit allows you

to change your header or footer. Therefore, the disc

should not be carried in the test kit case.

IS-TK-DL 0829 EDP# 1910763 © Watts, 2008

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

Backflow Prevention Products

IS-TK-DL.indd 8 9/5/08 2:18:59 PM

Table of contents

Other Watts Test Equipment manuals

Popular Test Equipment manuals by other brands

Keysight Technologies

Keysight Technologies X Series Getting started guide

Pilot Communications

Pilot Communications 70268 user manual

Atlona

Atlona AT-DIS7-PROHD Q&A

WIKA

WIKA Wally Box III CPH7600 operating instructions

Tektronix

Tektronix 2430A user manual

Quantifi Photonics

Quantifi Photonics SLED 1000 Series user manual