X100L Load Bank

2

Read all instructions before using the load bank

Contents

1.

Components .............................................................................................................................. 3

Total Assembl ................................................................................................................................. 3

2) Specifications ............................................................................................................................... 4

a)

X100L Load Bank ............................................................................................................ 4

3) Receiving ...................................................................................................................................... 5

4) Safet ........................................................................................................................................... 5

a)

Grounding ............................................................................................................................. 6

b)

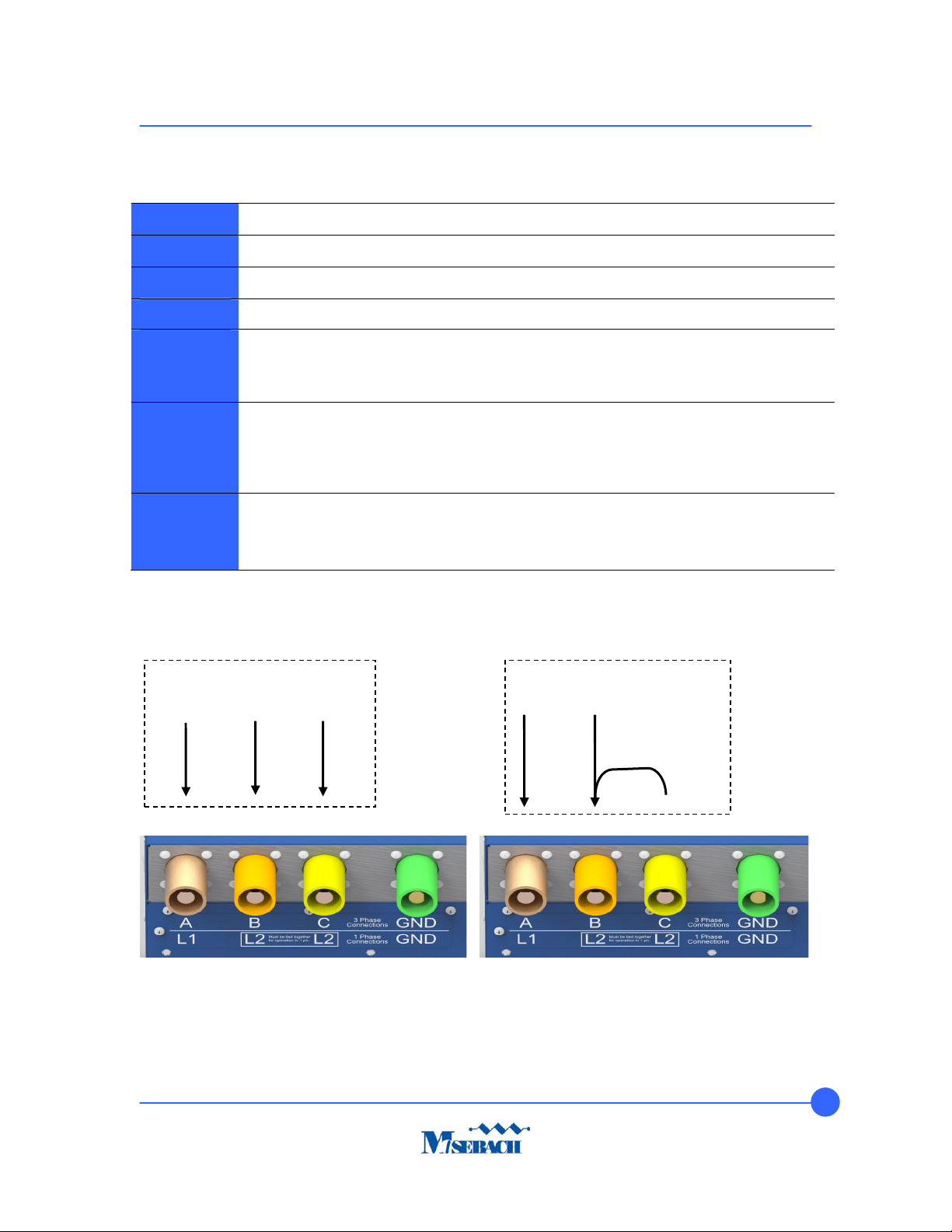

Power connections ............................................................................................................... 7

d)

Air intakes and exhaust ports ............................................................................................... 7

e)

Exhaust temperature ............................................................................................................ 7

f)

Connecting and disconnecting ............................................................................................. 8

5)

Operation ................................................................................................................................... 8

a)

Pre-startup ............................................................................................................................ 8

b)

Startup .................................................................................................................................. 9

c)

Testing .................................................................................................................................. 9

d)

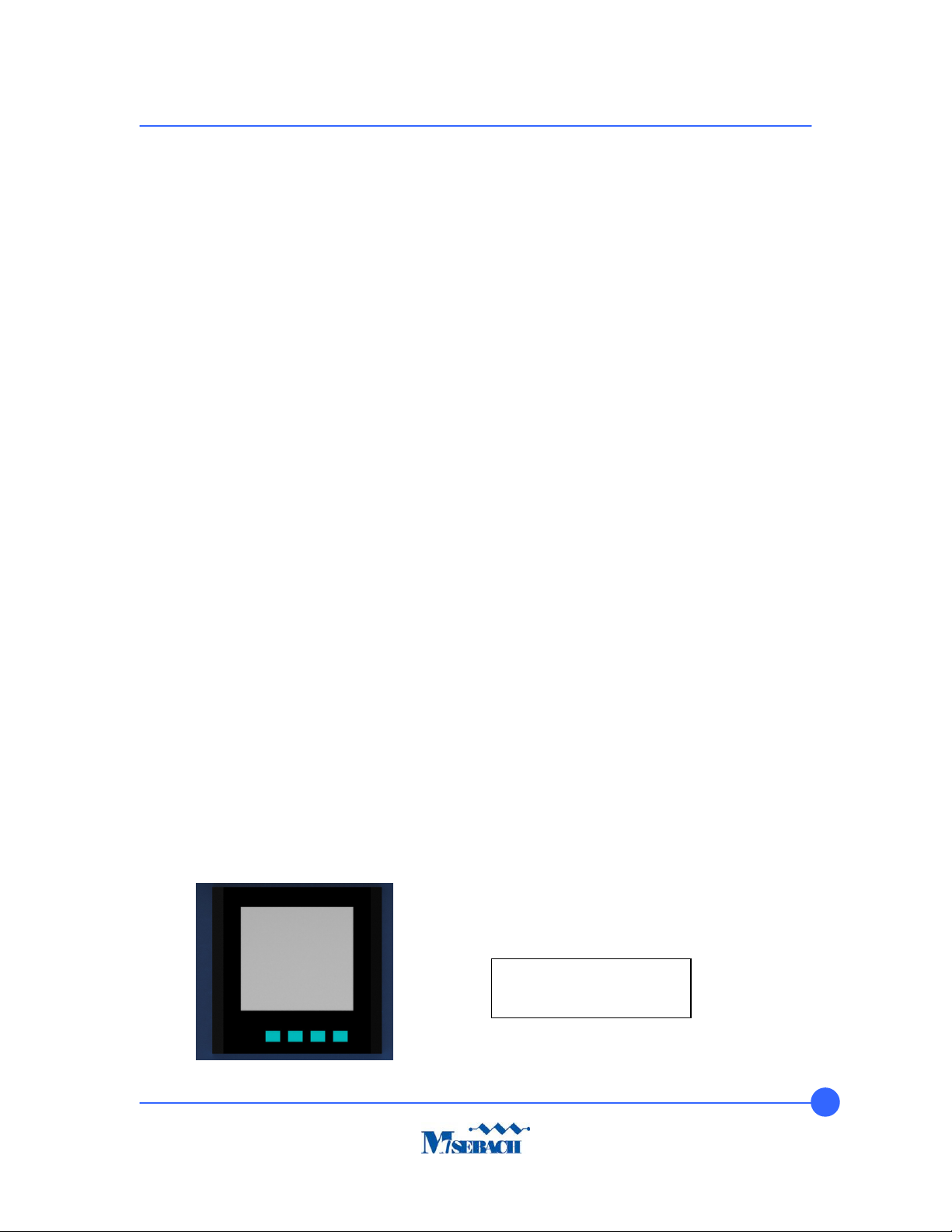

Acuvim II Power Meter.......................................................................................................... 9

e)

Shutdown ............................................................................................................................ 10

6)

USB Communication Port ....................................................................................................... 10

7)

Troubleshooting ....................................................................................................................... 11

8)

Replacing Fuses ...................................................................................................................... 12

9)

Replacing Resistors ................................................................................................................ 13

10)

Preventative Maintenance of the Load Bank ...................................................................... 15

11)

Service Parts ...................................................................................................................... 16

Figure list:

1) Total Assembl of X100L Load Bank

2) Grounding Cam

3) Switch Panel

4) Acuvim II Power Meter

5) T pical USB A to USB B male

6) Blower/Control/Main Fuses

7) Thermal Switch

8) Replacing Fuses

9) Switch Panel Support Bolts

10) Replacing Resistors

11) Resistor/Contactor Connections