POSITIVE TEMPERATURE COEFFICIENT (PTC2) HEATER MANUAL

PTC2 Heater Systems are manufactured and distributed by Waukesha®Service & Components, a division of SPX Transformer Solutions, Inc.

PTC2-Manual Rev. 1.3, 04/2013

2

GENERAL DESCRIPTION

The Waukesha®Positive Temperature Coefficient (PTC2) Heater improves the reliability of your electrical

equipment by maintaining an enclosure temperature slightly higher than the outside ambient temperature.

The system offers unparalleled reliability due to the elimination of a thermostat or other controls. In addition,

standard PTC2 convection heaters utilize an integrated fan assembly that ensures even heat distribution

throughout the enclosure.

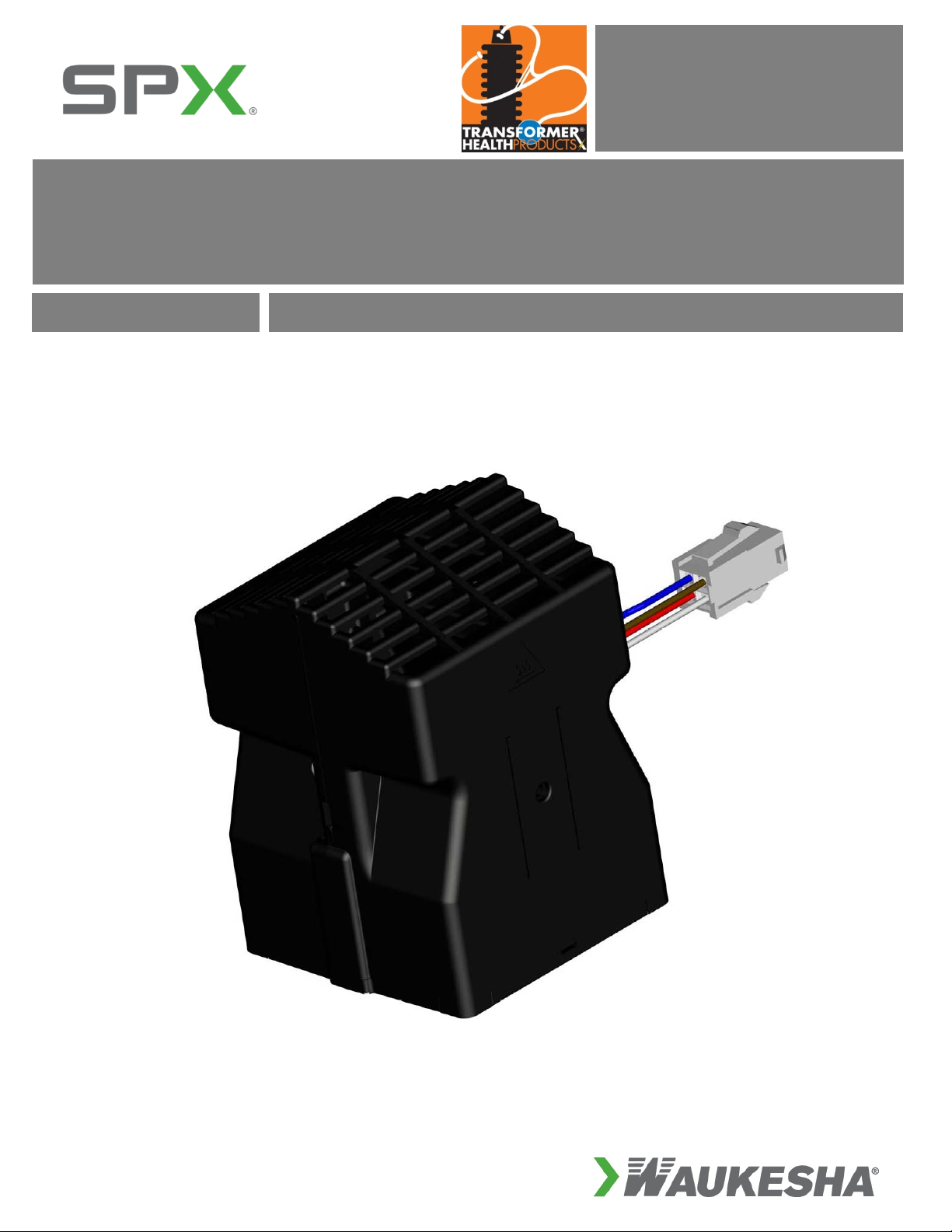

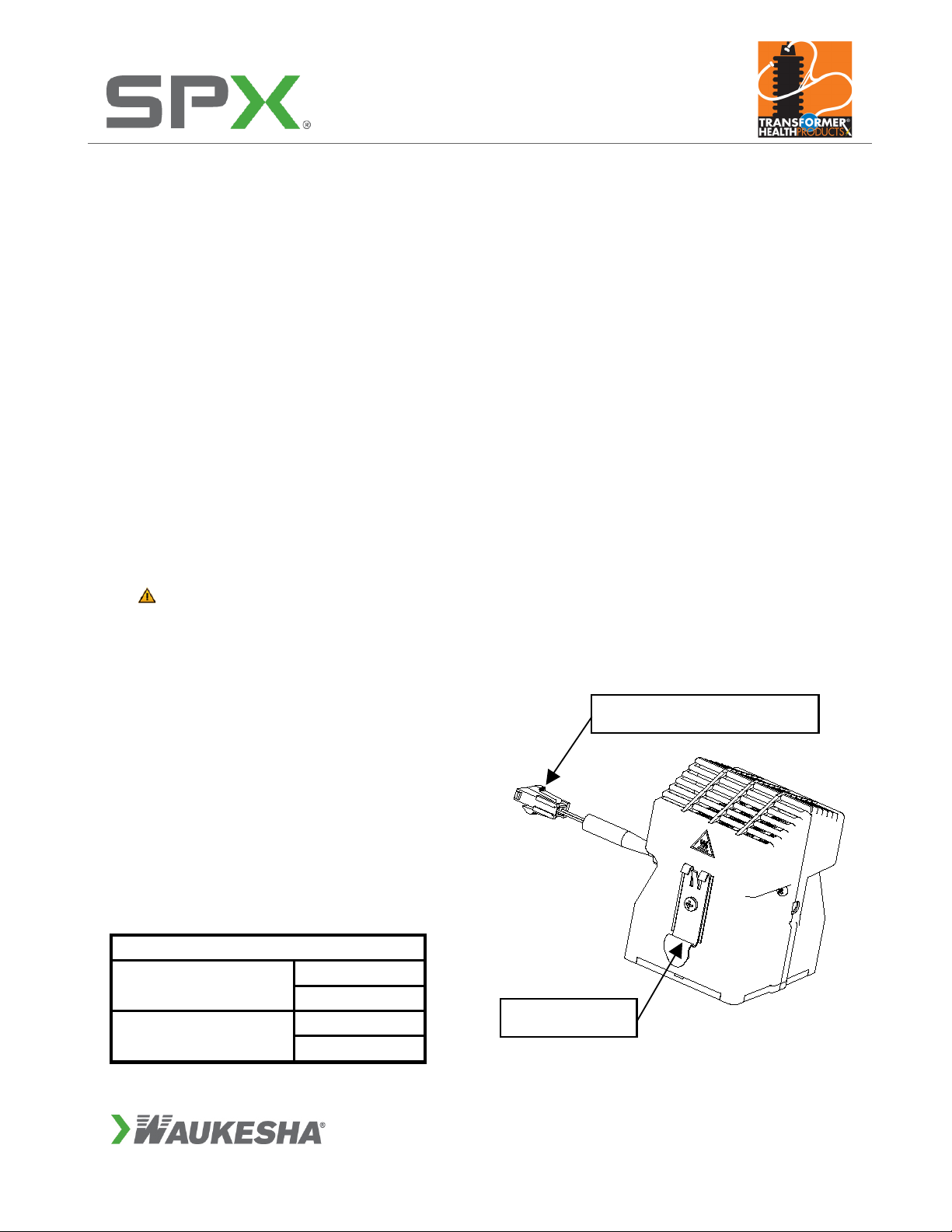

CONSTRUCTION

PTC2 heaters feature a heating element constructed with a variable resistance material that automatically

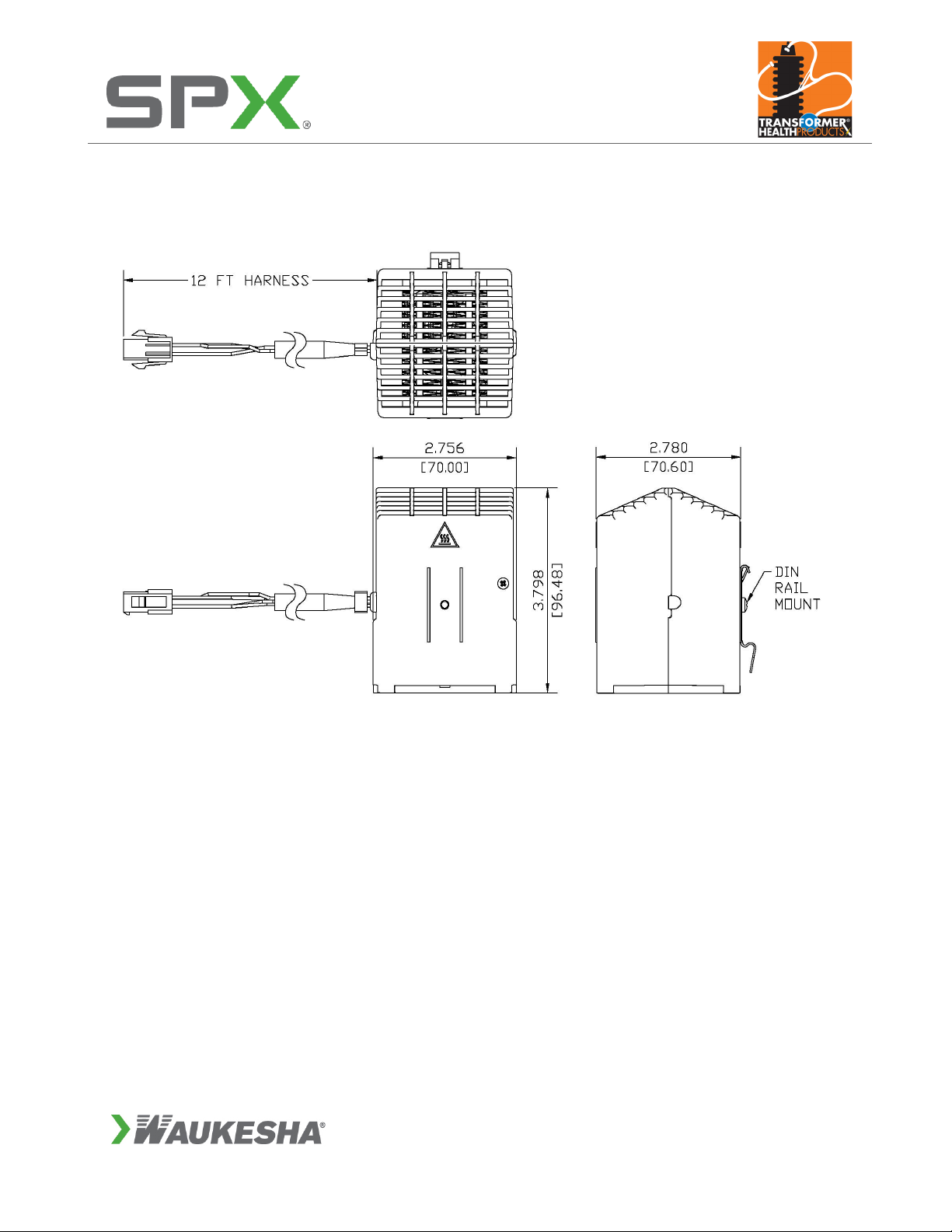

reacts to the cabinet (inlet air) temperature. A fan (if equipped) is attached to the heat guard and provides

forced conduction of the heat as well as uniform enclosure distribution. Mounting brackets allow easy

cabinet or panel installation. A twelve-foot wiring harness (on forced air units) is also included to make

installation as easy and flexible as possible.

OPTIONS

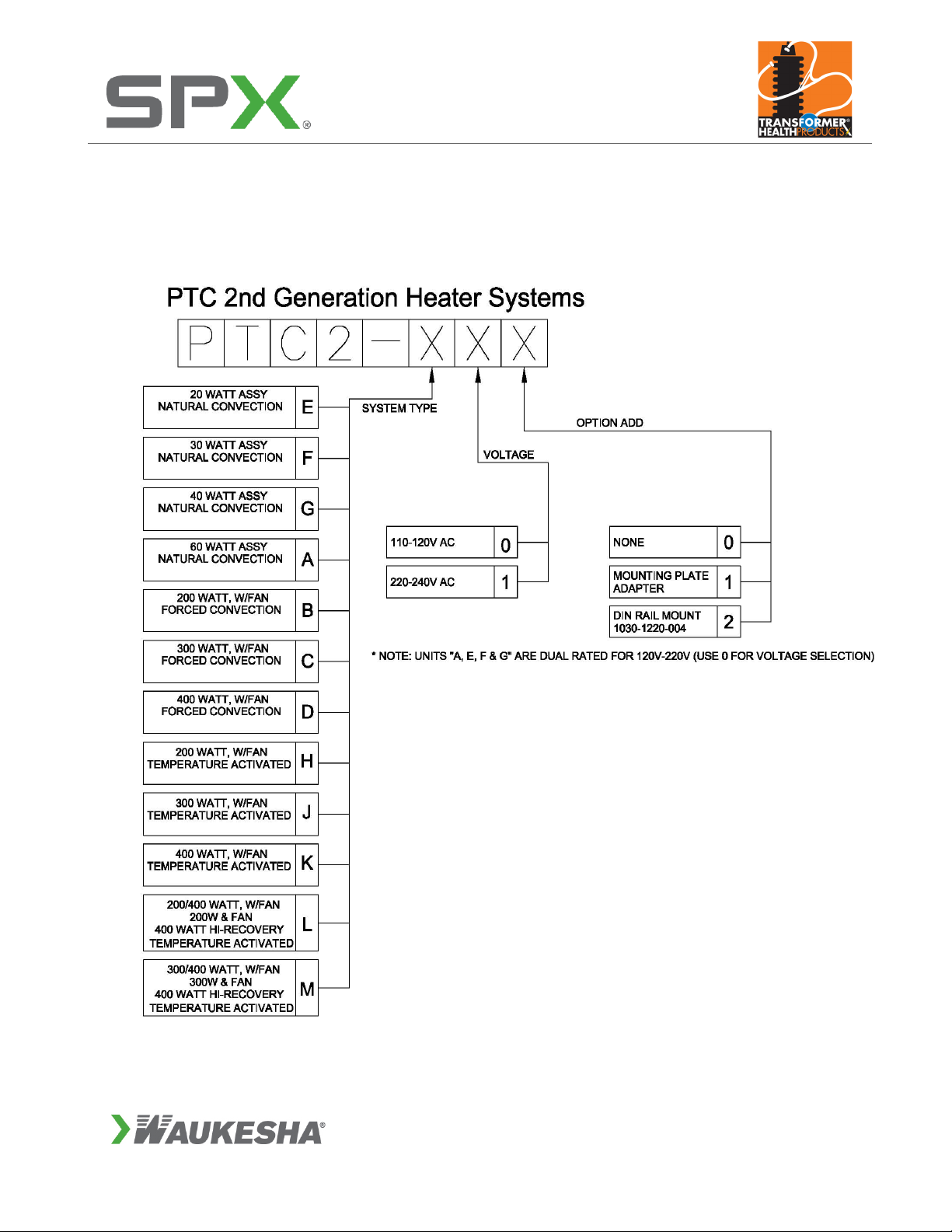

PTC2 heaters are available in the following configurations:

20 Watt: 120V or 240V (dual voltage) panel mount convection

30 Watt: 120V or 240V (dual voltage) panel mount convection

40 Watt: 120V or 240V (dual voltage) panel mount convection

60 Watt: 120V or 240V (dual voltage) panel mount convection

200 Watt: 120V or 240V fan forced with or without activating thermostat

300 Watt: 120V or 240V fan forced with or without activating thermostat

400 Watt: 120V or 240V fan forced with or without activating thermostat

200 Watt: 120V or 240V fan forced, Thermostat activated

300 Watt: 120V or 240V fan forced, Thermostat activated

400 Watt: 120V or 240V fan forced, Thermostat activated

200 Watt Constant/400 Watt High Recovery: Thermostat actuated, 120V or 240V fan forced

300 Watt Constant/400 Watt High Recovery: Thermostat actuated, 120V or 240V fan forced

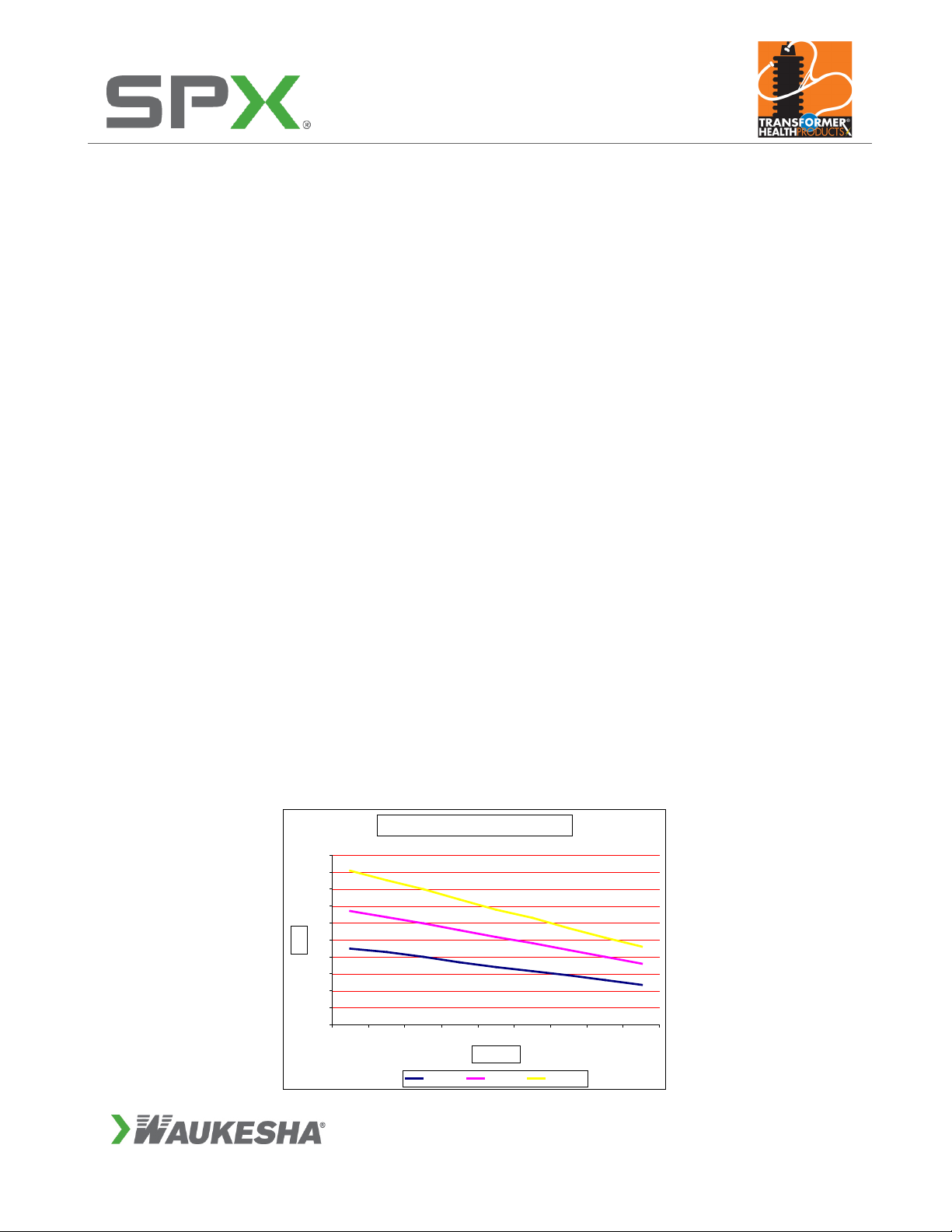

SELECTION

Several factors should be considered when selecting the appropriate heater. Primary concerns should

include the following:

Ambient temperature extremes—affects which part of the wattage curve is used to select the heater.

Rate of ambient temperature change—affects how much time a given wattage requires to return to

steady state.

Enclosure size, insulation rating and exposure to ambient conditions.

For anti-condensation purposes, heaters should be selected according to the calculated power required

(watts) to warm the enclosure to a minimum temperature difference of 5 degrees Celsius above ambient.