8

WCM-TT-040-40BB User Manual Wavecom

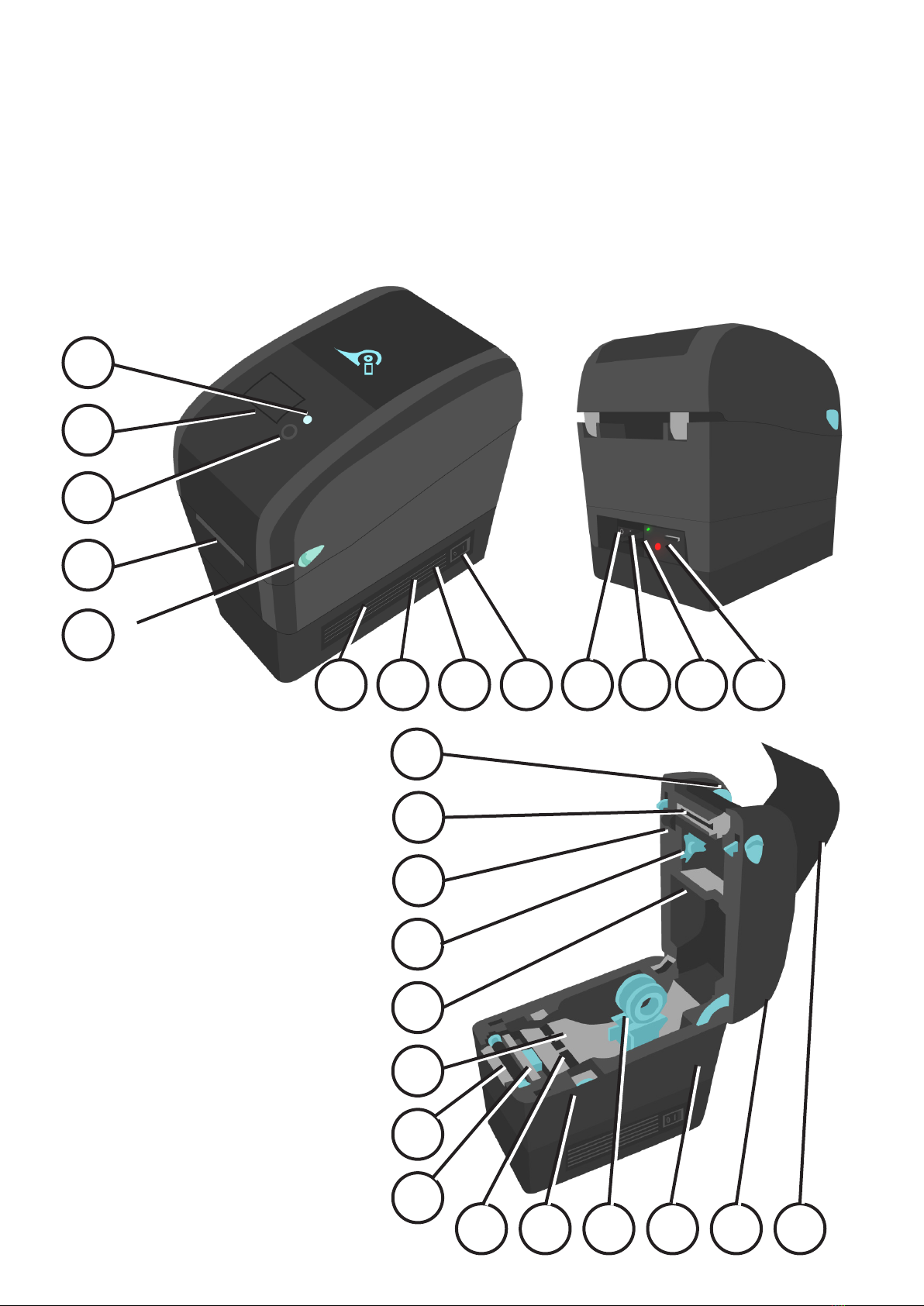

Printer Functions

LED and Button Functions

This printer has one button and one three-colour LED indicator. By indicating the LED with different colour and

pressing the button, printer can feed labels, pause the printing job, select and calibrate the media sensor, print

printer self-test report, reset printer to defaults (initialization). Please refer to the button operation below for

different functions.

LED Colour Description

Solid Green This indicates that the power is on and the device is ready to use.

Flashing Green This indicates that the system is downloading data from PC to memory or the printer is paused.

Amber This indicates that the system is clearing data from printer.

Solid Red This illuminates printer head open, cutter error.

Flashing Red This indicates a printing error, such as head open, paper empty, paper jam or memory error etc.

Regular Button Function

Feed labels

When the printer is ready, press the button to feed one label to the beginning of next label.

Pause the printing job

When the printer is printing, press the button to pause a printing job. When the printer is paused, the LED will

be green flashing. Press the button again to continue the printing job.

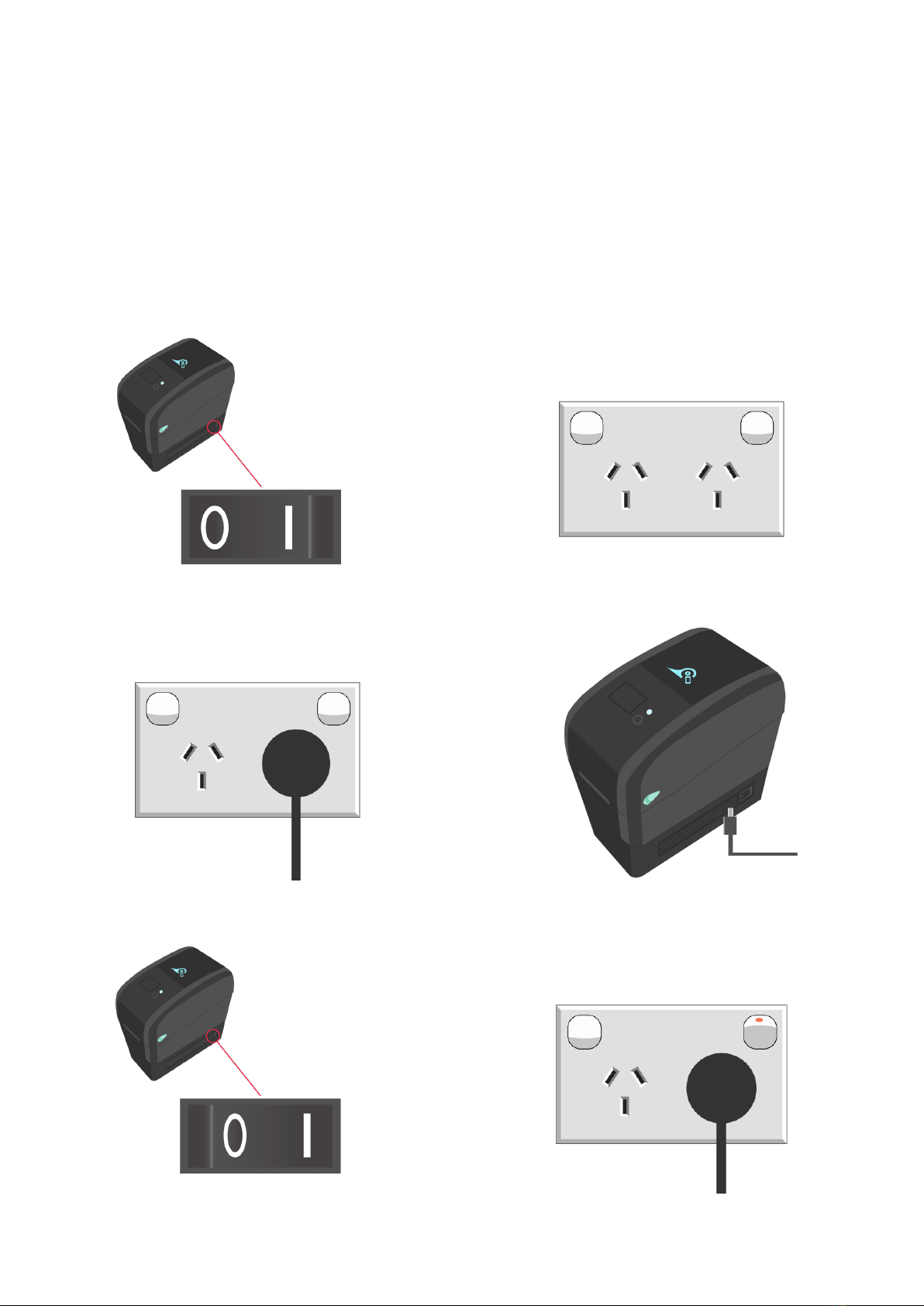

Power on Utilities

There are six power-on utilities to set up and test printer hardware. To use these utilies follow this procedure:

1. Turn off the power switch.

2. Hold the Feed button then turn on the power switch.

3. The printer LED will cycle through the following options. Release the button when the LED reaches the

relevant utility.

LED Colour & Action

Functions Amber Red

(5 Flashes) Amber

(5 Flashes) Green

(5 Flashes)

Green/

Amber

(5 Flashes)

Red/

Amber

(5 Flashes)

Solid

Green

Gap/Black Mark Sensor

Calibration Release

Gap/Black Mark Sensor

Calibration, Self Test and Enter

Dump Mode Release

Printer Initialisation Release

SetBlackMarkSensorasMedia

Sensor and Calibrate the Black

Mark Sensor Release

SetGapSensorasMediaSensor

and Calibrate the Gap Sensor Release

Skip AUTO.BAS Release