© 2017 www.teamWavelength.com 9

FL591FL LASER DIODE DRIVER

SET THE OUTPUT CONFIGURATION JUMPER

The Output Conguration Jumper (JP2), located between

the output connectors, determines whether the outputs are

paralleled to drive up to 500 mA output on a single channel,

or separate to drive up to 250 mA on two channels.

When the driver outputs are separate, connect each laser

diode to the respective output connector, LD1 and LD2.

When the driver outputs are paralleled, each channel

drives one-half of the total output current. When operating

in parallel driver mode, use output connector LD1 to drive

current to the load.

When the FL591FL is delivered, the default conguration

is with two separate 250 mA output channels (jumper set

to “S”).

WIRE THE POWER SUPPLY AND TEST LOAD

Wire the FL591FL power supply according to Figure 2, use

the test load shown in Figure 4.

When the power supply is switched on, power is applied

to the FL500 and the POWER LED will illuminate, but the

output current is not enabled.

SET THE DRIVE CURRENT LIMITS;

SEPARATE OUTPUT CONFIGURATION

First calculate the VLIM voltage; use the transfer function on

page 5 according to your input/output conguration:

VLIM = ILIMx / Transfer Function (Separate) (V)

Connect the DMM to the LIM1 testpoint and the GND

testpoint, and apply power to the FL591FL. Adjust the LIM1

trimpot until the voltage displayed on the DMM matches the

VLIM value calculated above. Turn the trimpot clockwise to

increase the current limit.

Connect the DMM to the LIM2 testpoint, and set the current

limit on channel two using the same procedure.

SET THE DRIVE CURRENT LIMITS;

PARALLEL OUTPUT CONFIGURATION

If the FL591FL is congured to drive paralleled outputs, the

current limit is set using the LIM1 trimpot only.

First calculate the VLIM voltage; use the transfer function on

page 5 based on your input/output conguration:

VLIM = ILIM1 / Transfer Function (Parallel) (V)

Connect the DMM to the LIM1 testpoint and the GND

testpoint, and apply power to the FL591FL. Adjust the LIM1

trimpot until the voltage displayed on the DMM matches the

VLIM value calculated above.

CONFIGURE FOR CONSTANT CURRENT OR

CONSTANT POWER MODE

The FL591FL will drive lasers in Constant Current mode or

Constant Power mode. Constant Power mode operation

requires photodiode feedback from the laser.

To congure channel one for Constant Current mode

operation, set the LD1 MODE switch to CC (left); for

Constant Power mode set the switch to CP (right). Set

channel two in the same manner.

!

donot change swItch posItIons whIle power Is

applIed to the fl591fl. doIng so may damage the

laser. remove power from the fl591fl board

before changIng mode swItch posItIons.

If the FL591FL outputs are paralleled and operated in

CP-mode, the signal on the channel one photodiode is used

in the control feedback loop.

When the FL591FL is delivered, the default conguration is

Constant Current mode on both channels.

SET THE INPUT SIGNAL CONFIGURATION

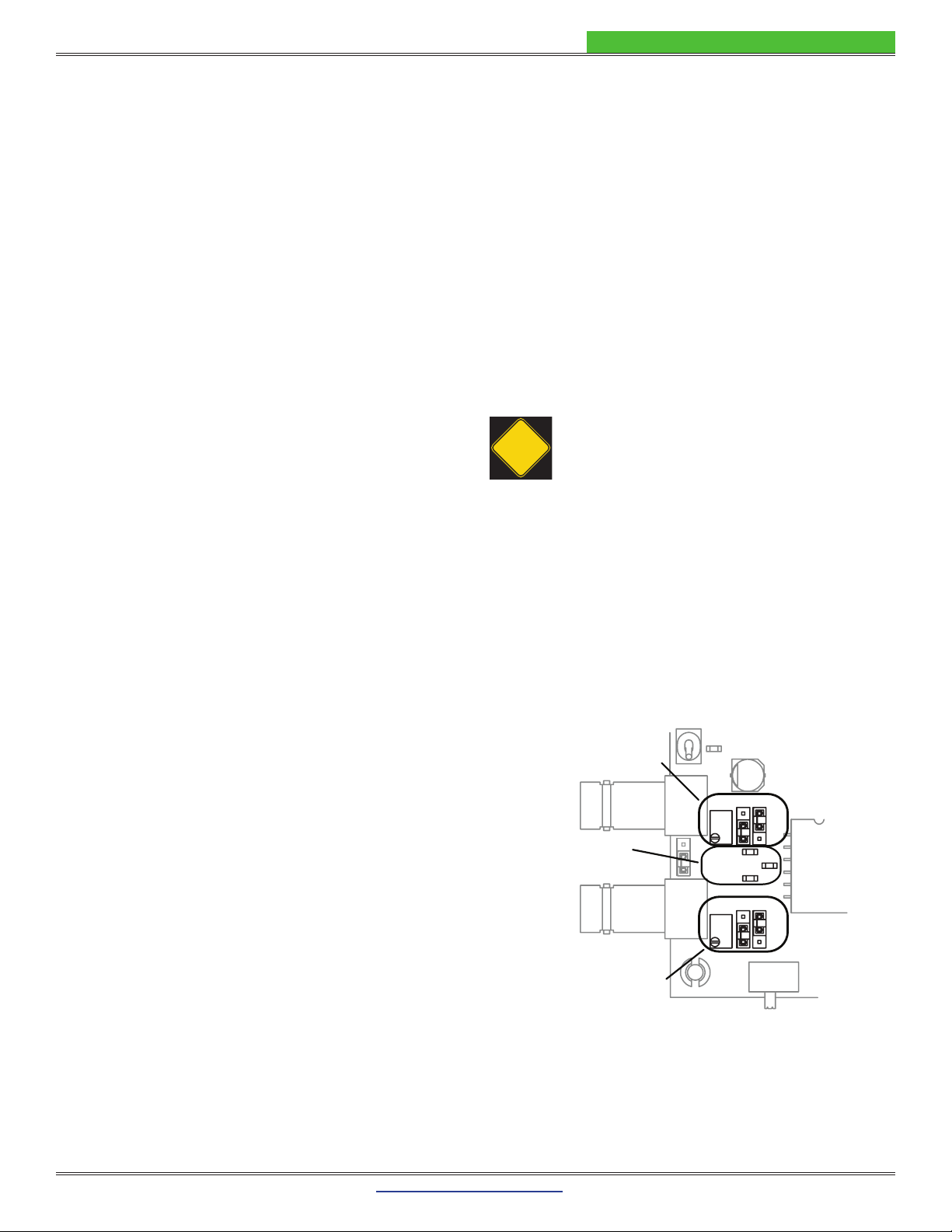

Figure 6 shows the setpoint adjust section of the FL591FL.

ENABLE

DIS

INPUT 1

INPUT 2

TRIMPOT

TRIMPOT

BNC

BNC

VSET 1

VSET 2

GND

LD1 MODE

CC

CP

]ON

]OFF

]ONE

]TWO

]OFF

]ON

Channel 2 Controls

SET Testpoints

Channel 1 Controls

LD1 MODE

CC

CP

FL500

Figure 6. Current Setpoint Section

The drivers can be congured to reference only the signal

input on the BNC connector, only the onboard trimpot, or

the sum of the two signals. This versatility allows the driver

to be congured with a bias current set by the trimpot, and

an external modulation signal input on the BNC.