© 2022 www.teamWavelength.com 11

WTC3243 TEMPERATURE CONTROLLER

SAFETY INFORMATION

& THERMAL DESIGN

CONSIDERATIONS

SAFE OPERATING AREA — DO NOT EXCEED

INTERNAL POWER DISSIPATION LIMITS

!

(SOA).

Visit the Wavelength Electronics website for the most

accurate, up-to-date, and easy to use SOA calculator:

www.teamwavelength.com/support/design-tools/soa-tc-calculator/

For more information on Safe Operating Area, see our

Application Note AN-LDTC01: The Principle of the Safe

Operating Area.

PREVENT DAMAGE FROM ELECTROSTATIC

DISCHARGE

Before proceeding, it is critical that you take precautions to

prevent electrostatic discharge (ESD) damage to the driver

and your laser. ESD damage can result from improper

handling of sensitive electronics, and is easily preventable

with simple precautions.

Enter the search phrase “ESD Precautions for Handling

on ESD-safe handling practices.

We recommend that you always observe ESD precautions

when handing the WTC controller.

THEORY OF OPERATION

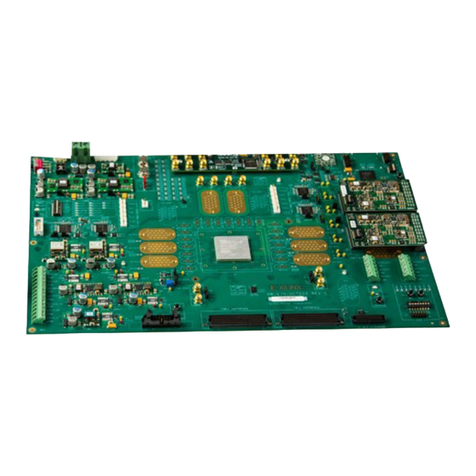

The WTC3243 is a linear temperature controller that delivers

(TEC), or unidirectional current to resistive heaters.

The fundamental operating principle is that the controller

adjusts the TEC drive current in order to change the

temperature of the sensor that is connected to the thermal

load. The goal is to make the voltage across the sensor match

the setpoint voltage, and then keep them equal in spite of

changes to ambient conditions and variations in thermal load.

The controller measures the load temperature by driving a

current through the temperature sensor and measuring the

voltage drop across it. It may be useful to remember that you

do not directly adjust the setpoint temperature. Rather, you

adjust a voltage signal that represents the sensor voltage at

the desired temperature setpoint.

While the output is enabled the controller continuously

compares the setpoint voltage and the actual sensor voltage.

adjusts the output current—thereby driving the TEC or heater

Once the actual sensor voltage equals the setpoint voltage,

the controller makes minor adjustments to the output

the drive current accordingly.

The controller includes features that help protect the load

from damage, and also make it more versatile in a wide array

Operating Instructions — WTC3243 + EVAL BOARD on

page 12.

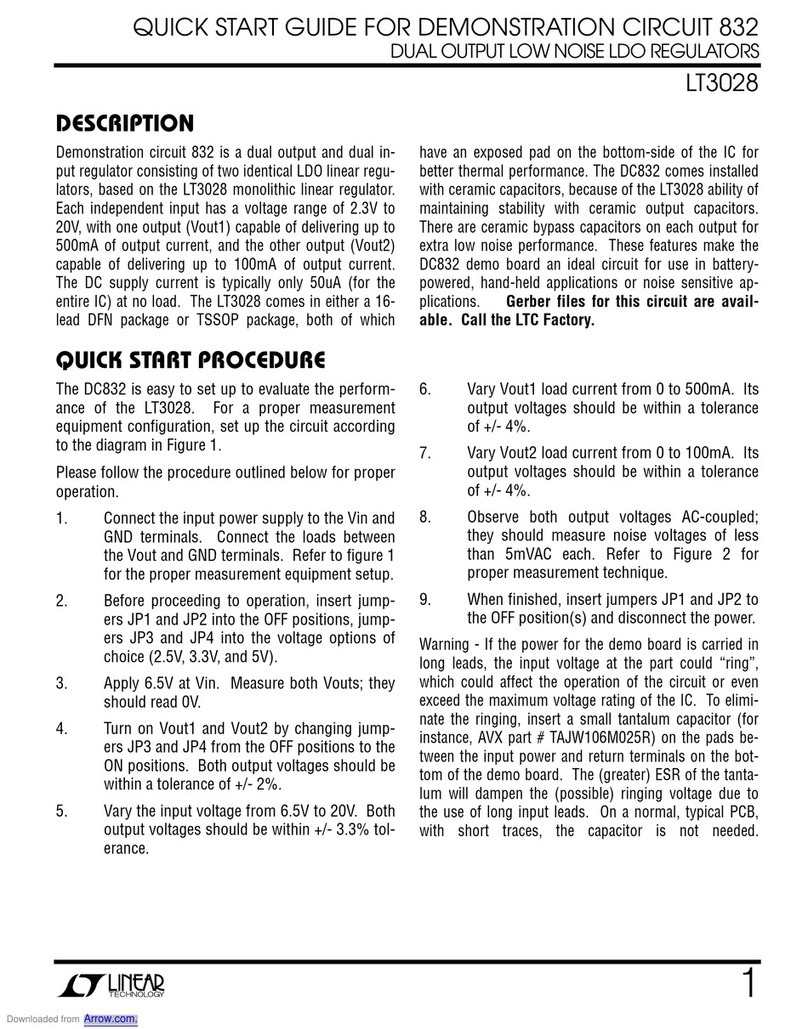

• Current limit: Independent heating and cooling current

limits avoid over-driving and damaging the TEC or heater.

• for

prototyping and benchtop applications the temperature

setpoint can be adjusted with the onboard trimpot on the

evaluation board. When the controller is integrated into an

automated control system, the temperature setpoint can

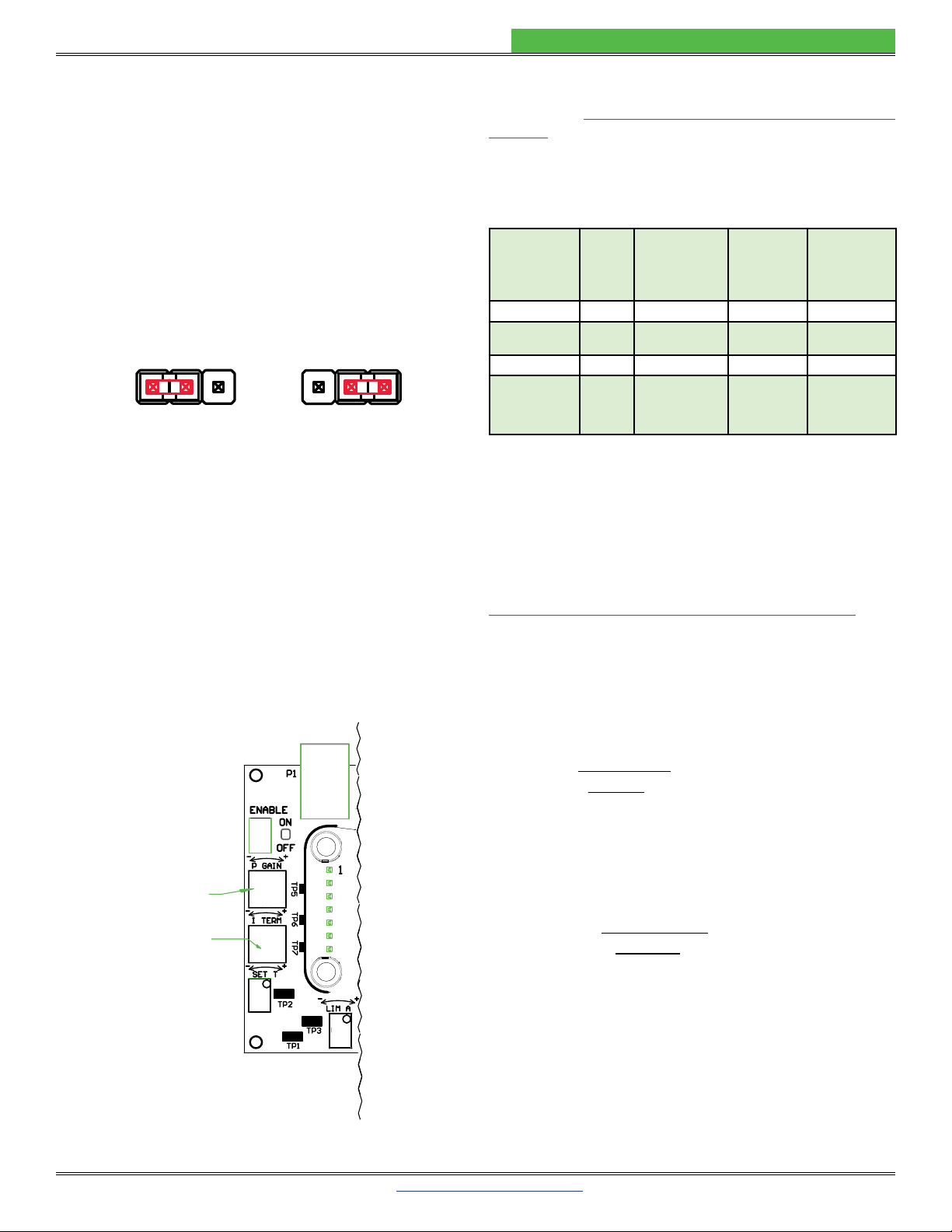

• Local Enable on WTC3293 Evaluation Board: the

on whenever power is applied to the unit.

• Control loop: the controller employs a smart Proportional-

Integrating control loop to adjust the drive current. The

proportional term is user-adjustable, and when properly

minimal overshoot and ringing.