© 2022 www.teamWavelength.com 20

WLD SERIES LASER DIODE DRIVERS

IMON, PMON, and PDM allow for monitoring of laser diode

current and power intensity, depending on the selected

mode of operation. All three can be found on the terminal

block. IMON and PMON are duplicated on the input cable

(pinout in Table 9). The voltages at IMON, PMON, and PDM

are all referenced to the common terminal (COM) on the

input connector or the terminal block. A Molex 6-pin housing

(43645-0600) is the plug used for the input cable.

PIN # WIRE COLOR FUNCTION

1 Blue PGND

2 Orange VS

3 Red VDD

4 Black COM

5 White PMON

6 Green IMON

Table 9. Input Cable Color Code

• IMON provides a mechanism for externally monitoring

the laser diode current. IMON is available at all times

in both CC and CP modes. See Table 10 for IMON

transfer functions.

• PMON provides an external indication of the laser diode

intensity by measuring photodiode current. Since PD+

and PD- on the WLD33ND are shorted together in CC

mode, PMON will only monitor photodiode current in

CP mode. See Table 11 for PMON transfer functions

• PDM provides a mechanism for monitoring photodiode

current in either CC or CP mode. While PMON monitors

the feedback used by the control electronics to maintain

constant power of the laser, PDM is an external monitor

that is independent of the control electronics of the

WLD33ND. The transfer functions for PDM are the

same as PMON. PDM is accessible on the terminal

block.

FUNCTION MODE 200 mA

RANGE

2 A

RANGE

IMON CC / CP 106 mA / V 1.2 A / V

VSET CC 106 mA / V 1.2 A / V

Table 10. WLD33ND-EV laser diode current transfer

functions. Convert IMON and VSET voltage to laser diode

current.

FUNCTION MODE 200 A

RANGE

2 mA

RANGE

PMON CP 1 mA / V

PDM CC / CP 1 mA / V

VSET CP 1 mA / V

Table 11. WLD33ND-EV photodiode current transfer

functions. Convert PMON, PDM, or VSET voltage to

photodiode current.

The setpoint controls the output of the WLD33ND. The

setpoint voltage can be adjusted using the onboard

SET trimpot, applying an external setpoint voltage, or by

summing the two signals. The VSET SOURCE jumper

Figure 15 for its location). The sum of the external setpoint

voltage and the SET trimpot voltage can be adjusted

from 0 to 2.5 V. The transfer functions relating the VSET

voltage to the laser diode or photodiode current are given in

Table 10 and Table 11, respectively.

To use only the onboard SET trimpot, place the VSET

SOURCE jumper to the “T” position, and do not connect an

external voltage source to the SET terminal on the terminal

block. The SET trimpot will allow the setpoint to be adjusted

from 0 to 2.5 V.

To use an external voltage source summed with the setpoint

voltage from the onboard SET trimpot, place the VSET

SOURCE jumper to the “T” position. Connect an external

voltage source to the SET terminal on the terminal block.

The resulting setpoint voltage will be the sum of the voltage

dialed in using the SET trimpot, and the voltage applied to

the SET terminal.

To use only an external voltage source for the setpoint,

place the VSET SOURCE jumper to the “X” position and

connect the external setpoint voltage source to the SET

terminal on the terminal block. When the VSET SOURCE

jumper is in the “X” position, the voltage of the SET trimpot

on the WLD33ND-EV is ignored.

If an external voltage source is not available, but setpoint

adjustment needs to be external, a remotely located

potentiometer can easily be connected to the WLD33ND-EV

to adjust the setpoint. Connect the clockwise lead of the

potentiometer to the terminal position marked 2.5 on the

terminal block. Connect the counter-clockwise lead to the

COM terminal and connect the wiper to the SET terminal

and ensure that the VSET SOURCE jumper on the bottom

of the board is set to the “X” position. See Figure 18 for

external potentiometer

wiring.

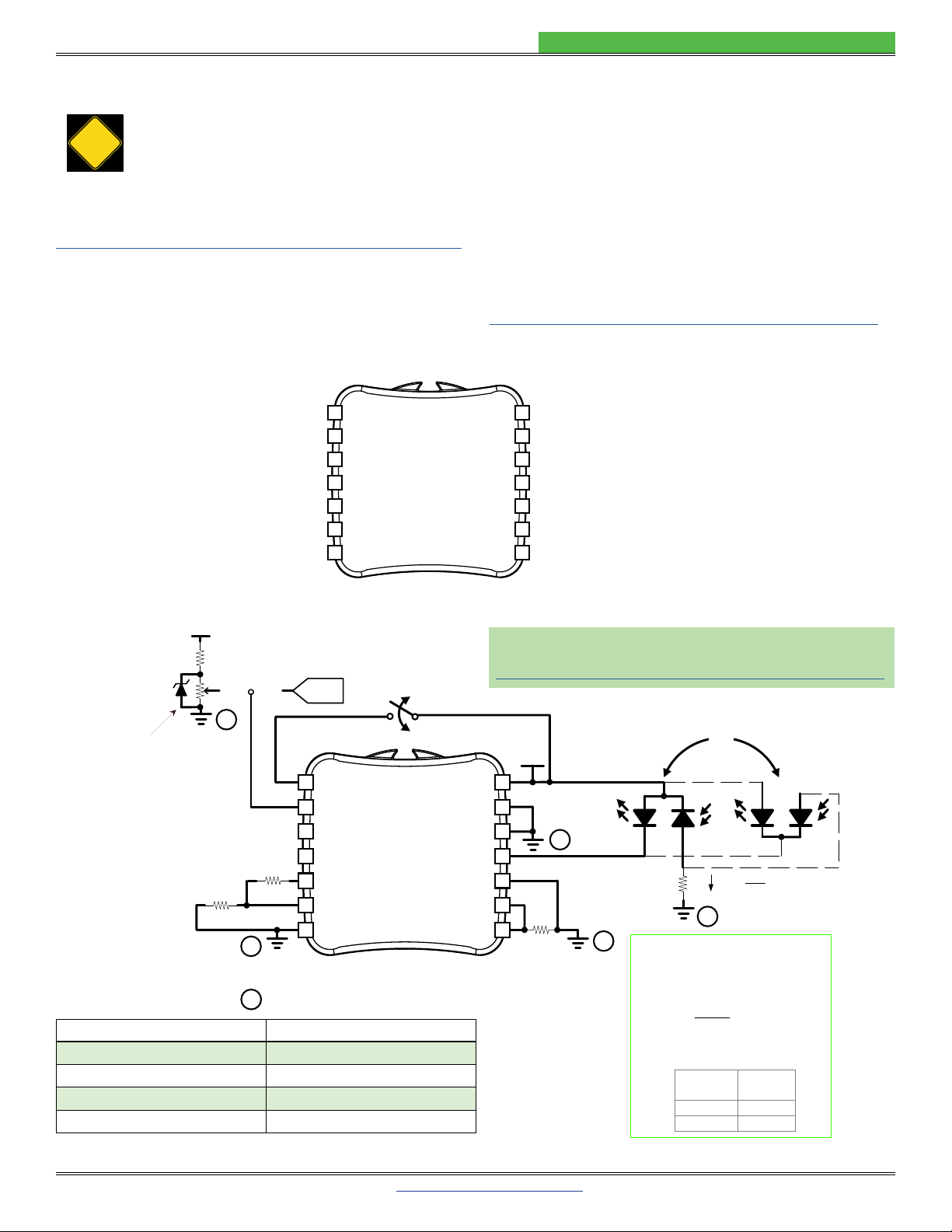

NOTE: The 2.5 V

output can source

1.5 mA with a 5 V input.

resistance to prevent it

loading down.

Figure 18. External

setpoint adjustment.

(-)

(+) FAN

PMON

SET

2.5

PDM

COM

IMON

W

CW

CCW