Quick Guide – Jointing

OsmaDrain 1 of 2

Customer Services:

0844 856 5152

Technical Advice:

0844 856 5165

Website:

www.wavin.co.uk

Email:

technical.design@wavin.co.uk

This Quick Guide is an extract from brochure (ref OD107) Osma Drainage, Product and Installation Manual.

The full document is available for download at www.wavin.co.uk

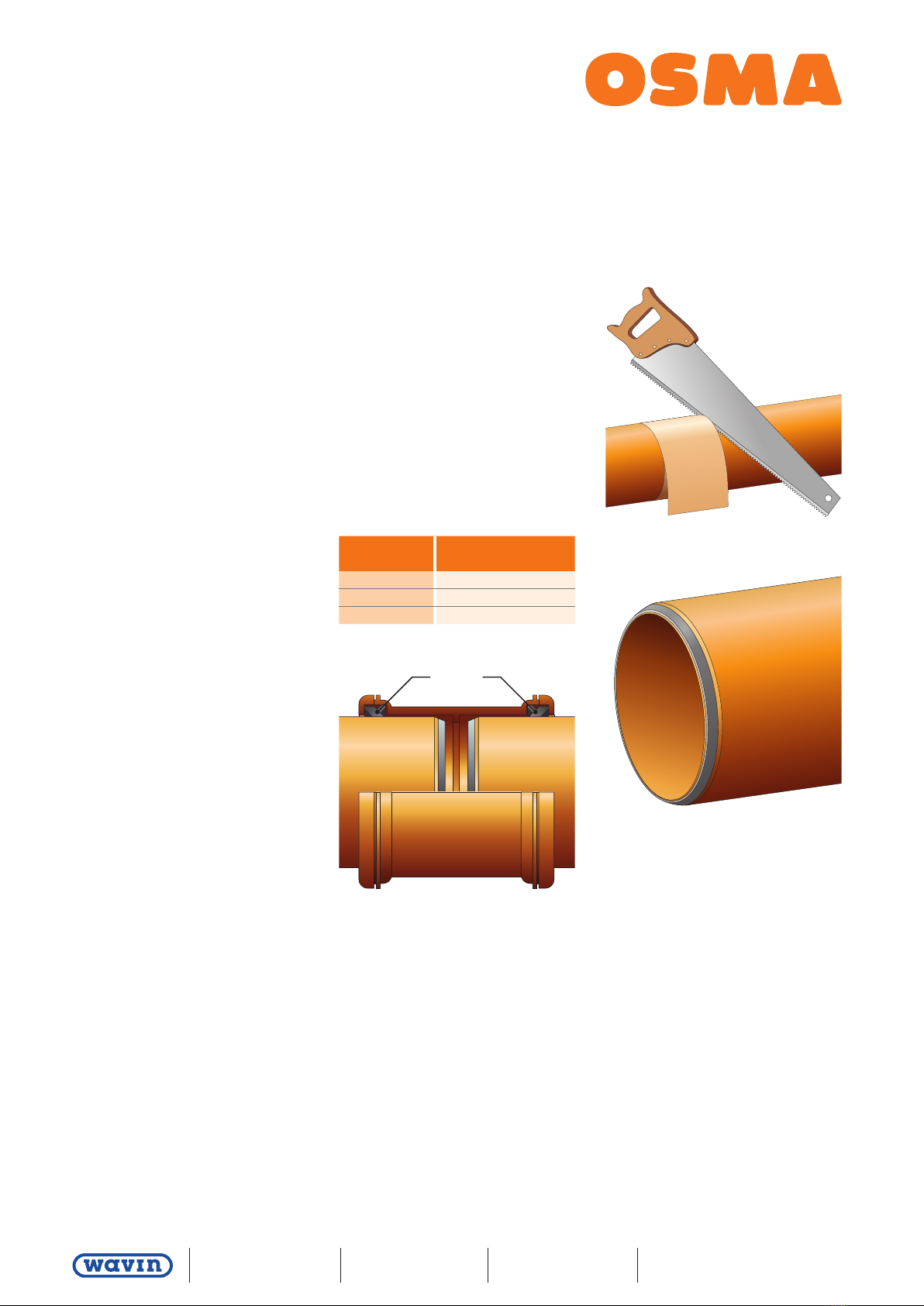

Preparing Pipe Ends

Pipes cut on site must be clean cut

at right angles to their horizontal axis.

Deburr the cut end with a scraper.

Depth of Entry Mark

Some plain ended fittings have a depth of

entry mark moulded on the spigot. This

depth of entry allows the pipe to expand

into the fitting socket by a minimum of

12mm. Insert the spigot into the socket

until the depth of entry mark is just visible.

All pipes (whether site cut or otherwise)

and other plain ended fittings must be

inserted to the full depth of the socket,

marked at the socket face, and then

withdrawn at least 12mm (See Figure.

10).

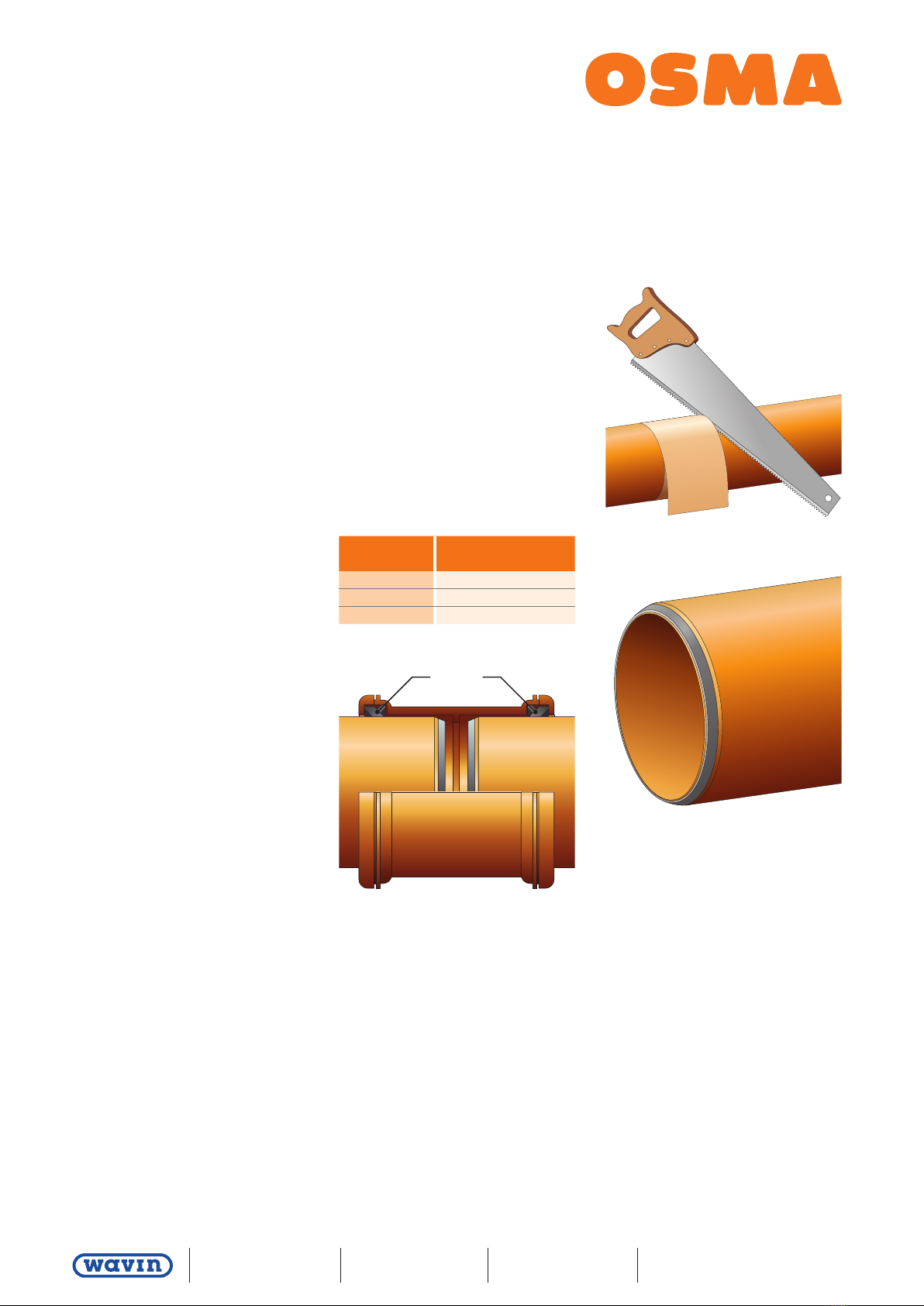

Ring Seal Joints

Pipe couplers and most bends and

junctions (in the 110mm and 160mm

sizes) are supplied with sockets on all

ends. These sockets are fitted with ring

seals which act as both a sealing and

expansion joint.

The correct sequence for ring seal jointing

is as follows:

1. Check that the pipe is correctly

prepared (See Pipe preparation,

Figure. 11a) and that the ring seal is

properly seated in its housing.

2. Make sure that both the pipe or fitting

spigot and ring seal socket are dry,

clean and free from grit or dust.

3. Lubricate evenly around the spigot

(NOT the socket) with OsmaDrain

Lubricant (4D392) (See Table 7).

4. Make sure that the components to be

joined are correctly aligned.

5. Push the spigot fully into the socket.

Mark the spigot at the socket face

and then withdraw the spigot by a

minimum of 12mm. If the spigot is

already marked with the depth of

entry, push it into the socket until the

depth of entry mark is just visible.

6. Do not cut back the straight leg

sections of Long Radius Bends

(4D/6D281) as only the spigot end

provided is suitable for jointing.

Figure 10: Ring Seal jointing

Figure 11a: Pipe preparation

Figure 11b: Pipe end

Ring Seal

1. Cut pipe square

2. Chamfer and deburr spigot end

Table 7: Lubricant allowance (for

guidance only) weights

Nominal

Size (mm)

Approximate No. of

joints (per 500g)

82 160

110 100

160 45