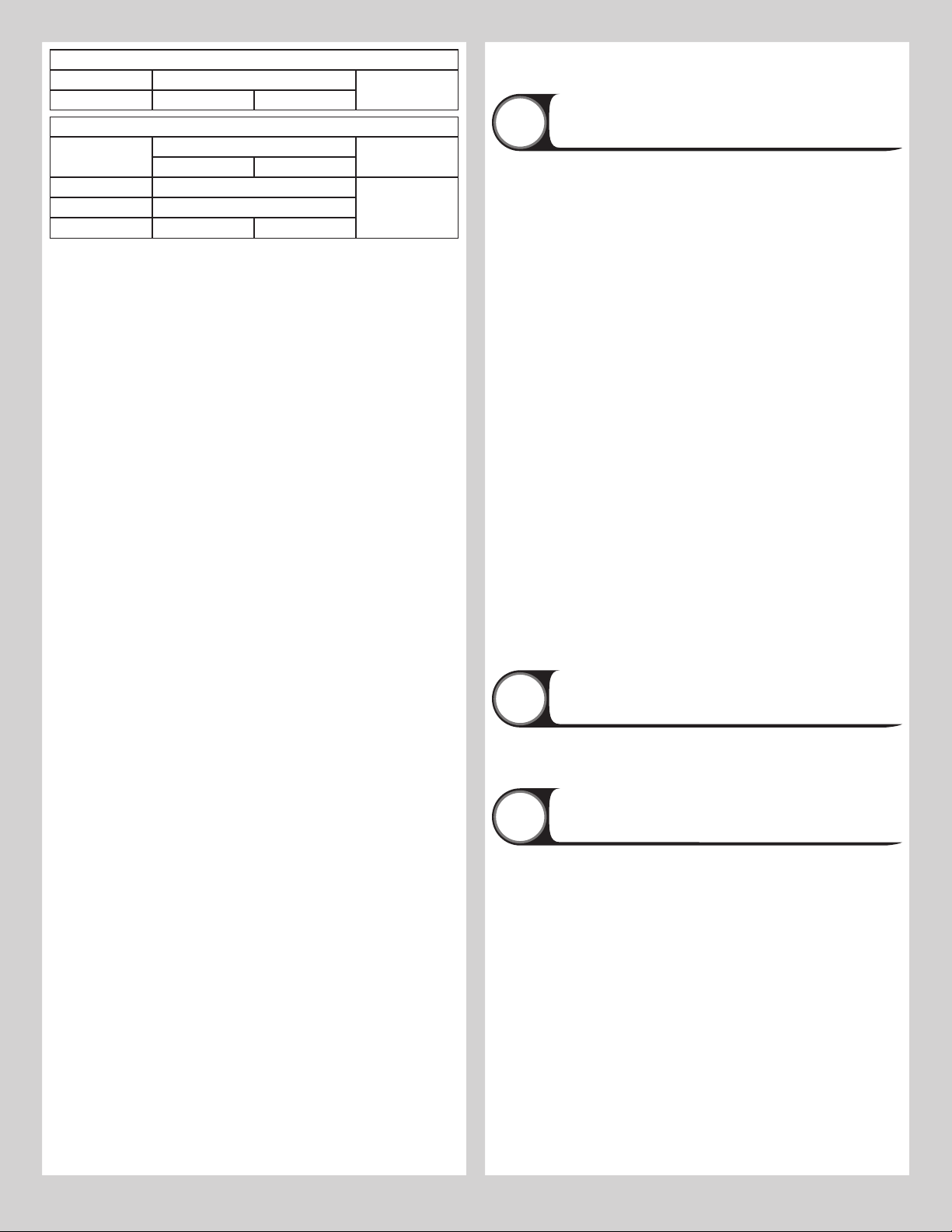

Door Height Spring Length Relaxed (Door

Open)

Spring Length Extended

(Door Closed)

7’ 0” 25” (635 mm) 67” (1702 mm)

7’ 6” 27” (686 mm) 72” (1829 mm)

7’ 9” 27” (686 mm) 73-1/2” (1867 mm)

8’ 0” 27” (686 mm) 75” (1905 mm)

Balancing Door

19

Lift door and check its balance. If door rises off floor more than 2 ft. under spring tension

alone, reduce spring tension by adjusting extension spring length, moving the “S” hook back-

ward (towards the rear back hangs) to a different hole in the horizontal track. If the door is

hard to rise or drifts down on its own, adjust extension spring length by moving the “S” hook

forward (towards the header) to a different hole in the horizontal track. A poorly balanced

door can cause garage door operator problems.

IMPORTANT: WHENEVER ADJUSTING EXTENSION SPRING LENGTH FOR DOOR BALANCE,

ALWAYS OPEN THE DOOR TO THE FULLY OPEN POSITION AND RETURN THE LOCKING

PLIERS, AS SHOWN IN F3 TO THE HORIZONTAL TRACKS BELOW THE BOTTOM TRACK

ROLLERS.

If the door still does not operate easily, raise the door into the open position, return the lock-

ing pliers, and recheck the following items:

1.) Is the door level?

2.) Are the flag angles level and plumb?

3.) Does the distance between the flag angles equal door width plus 3-3/8” to 3-1/2”?

4.) Do the counterbalance lift cables have equal tension? Adjust by re-tieing the special knot,

if necessary.

5.) Make sure door is not rubbing on jambs.

IMPORTANT: IF DOOR STILL DOES NOT BALANCE PROPERLY, THEN CONTACT A TRAINED

DOOR SYSTEM TECHNICIAN.

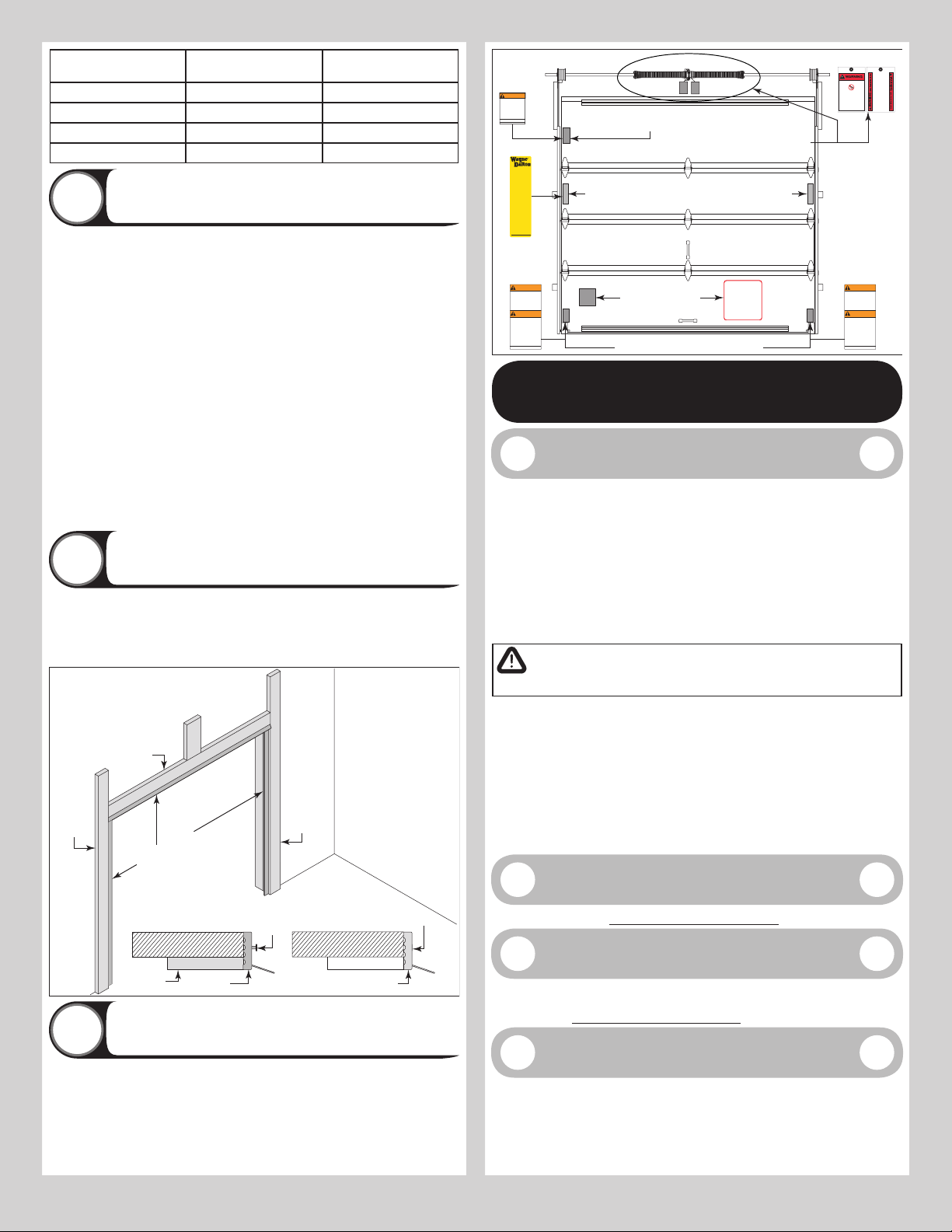

Attaching Weather Seal

20

Permanently attach the weatherstrips on both door jambs and header. The weatherstrips

were temporarily attached in Preparing the Opening, in the pre-installation section of this

manual.

NOTE: When permanently attaching the weatherstrips to the jambs, avoid pushing the weath-

erstrips too tightly against the face of door.

Weather seals

Nail

Weather

Jamb Weather seal

Jamb

Header

Jamb

Nail

NOTE: Door not shown for clarity.

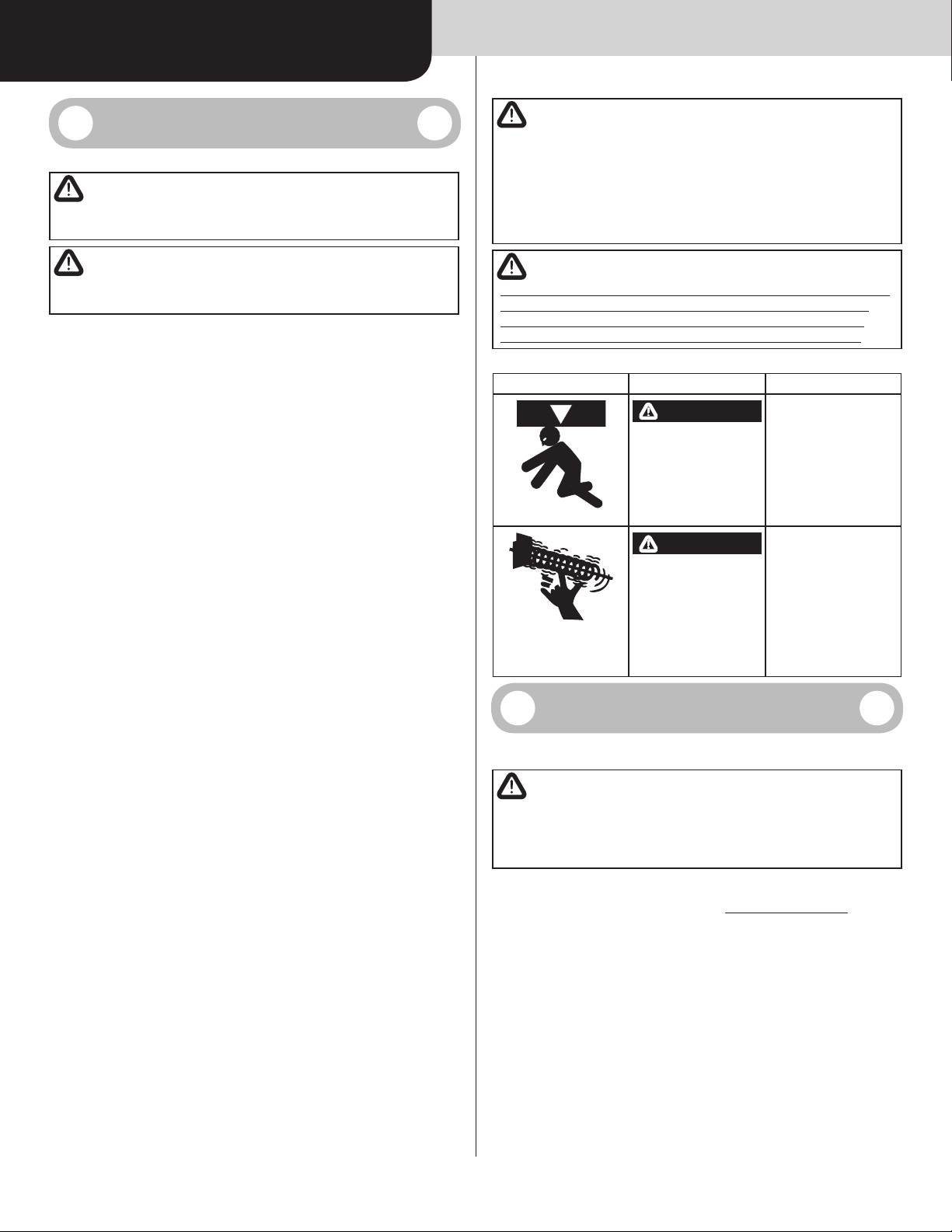

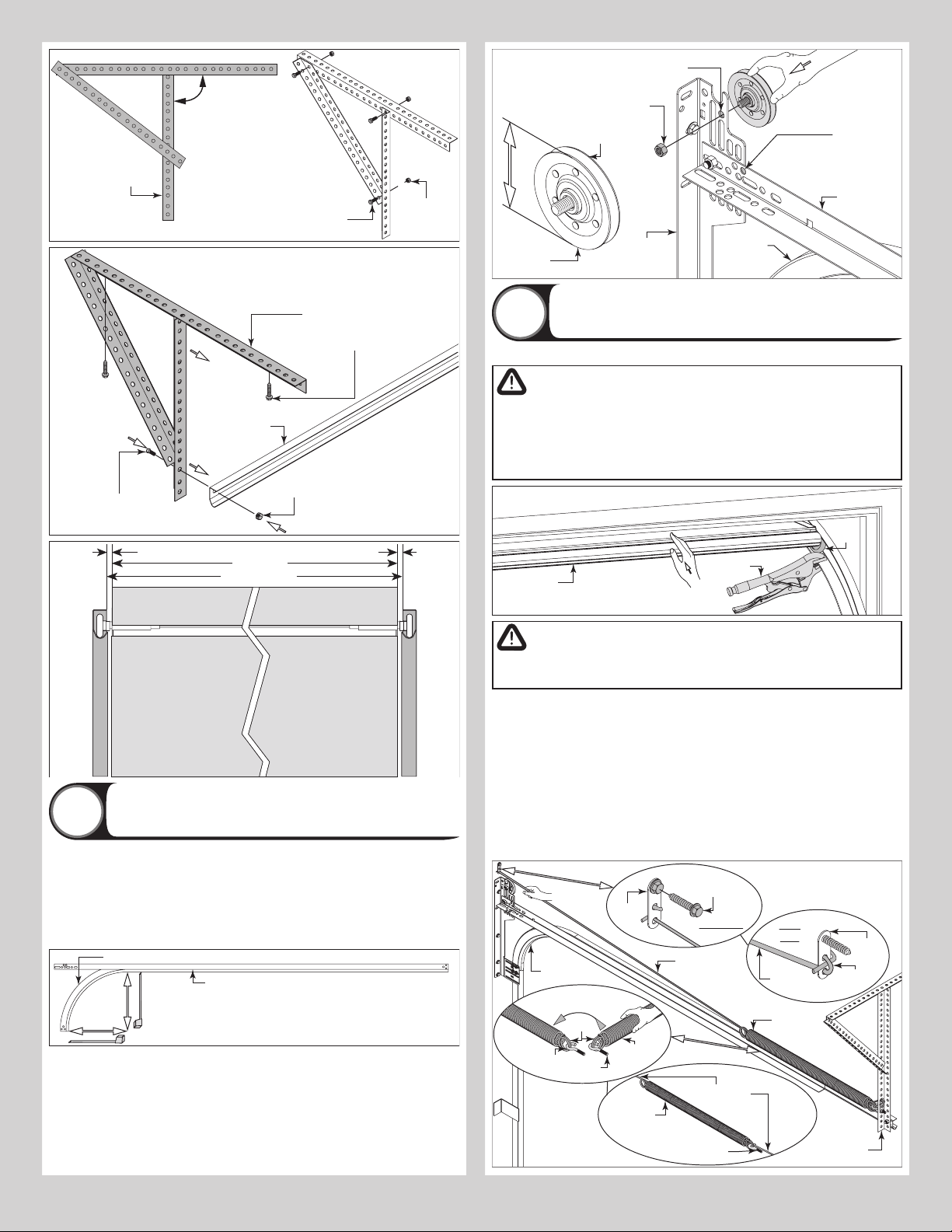

Label Placement

21

IMPORTANT: USING THE ILLUSTRATION, ATTACH THE APPROPRIATE LABELS TO THE AP-

PROPRIATE LOCATION ON THE SECTION, AS SHOWN.

NOTE: The Spring Warning tag(s) are factory attached (one per spring).

NOTE: Because of different configurations, some labels may require minor relocations.

HIGHSPRING TENSION CA NCAUSE

SERIOUSINJURY OR DEAT H.

DONOTadjust, repair or remove springs or parts to

whichsprings are connected, such as steel brack-

ets,cables, wood blocks, fasteners or other parts of

thecounterbalance system.

Adjustmentsor repairs must ONLY be made by a

traineddoor systems technician using proper tools

andinstructions.

DONOTremove, cover or paint over this tag. Prod-

uctuser should inspect this tag periodically for

legibilityand should order a replacement tag from

thedoor manufacturer, as needed.

©Copyright2010Overhead Door Corporation

102081 REV2 06/24/2010

DONOT REMOVE, COVER OR PAINT OVER

THISLABEL. PRODUCT USER SHOULD

INSPECTTHIS LABEL PERIODICALLY FOR

LEGIBILITYAND SHOULD ORDER A

REPLACEMENTFROM THE DOOR

MANUFACTURERAS NEEDED.

346214 NEW 11/19/2010

CALIFORNIAHEALTH AND SAFETY

CODESECTION 25249.6

DRILLING,SAWING, SANDING OR

MACHININGWOOD PRODUCTS GENERATES

WOODDUST, A SUBSTANCE KNOWN TO THE

STATEOF CALIFORNIA TO CAUSE CANCER.

AVOIDINHALING WOOD DUST OR USE A

RESPIRATOR OR OTHER SAFEGUARDS FOR

PERSONALPROTECTION.

WARNING

THISWOOD PRODUCT REQUIRES PROPER

FINISHING PRIORTO ANY DOOR HARDWARE BEING

APPLIED.BOTH INNER AND OUTER FA CESOF THE

SECTION(S),AS WELL AS ALL EDGE SURFACES

MUST BE PREPAREDAND FINISHED IN STRICT

ACC0RDANCETO THE DIRECTIONS GIVEN IN THE

INSTALLATIONINSTRUCTIONS AND OWNER’S

MANUAL UNDER “MAINTENANCE AND PAINTING

INSTRUCTIONS FOR ALLWOOD DOORS”.

IMPROPER STORAGE, IMPROPER TRANSPORTATION

AND/OR DELAYIN FINISHING, THAT ALLOWS FOR

THE EXPOSURE OFTHIS WOOD PRODUCT TO

MOISTUREAND/OR OTHER CONTAMINANTS, VOIDS

THE LIMITED WARRANTY.

IMPORTANT

316986

WARNING

WARNING

Lift handles/gripping points are required

on this door, located as spelled out in the

installation instructions, even if the door

is motor operated.

Failure to install and use these lift handles/

gripping points on this door can result in

serious injury to fingers and/or hands, if

placed in the opening between sections,

when the door is operated manually.

The adjacent bottom corner bracket and

all cable retention features including

milford pins, cotter pins, & clevis pins are

under HIGH SPRING TENSION.

Adjustments and repairs must only be

made by a trained door systems

technician, using proper tools and

instructions.

DO NOT REMOVE, COVER OR PAINT OVER

THIS LABEL.PRODUCT USER SHOULD

INSPECT THIS LABEL PERIODICALLY FOR

LEGIBILITY AND SHOULD ORDER A

REPLACEMENT FROM THE DOOR

MANUFACTURER AS NEEDED.

325304 REV3 06/26/12

©Copyright 2012,

OverheadDoor Corporation

WARNING

WARNING

Lift handles/gripping points are required

on this door,located as spelled out in the

installation instructions, even if the door

is motor operated.

Failure to install and use these lift handles/

gripping points on this door can result in

serious injury to fingers and/or hands, if

placed in the opening between sections,

when the door is operated manually.

The adjacent bottom corner bracket and

all cable retention features including

milford pins, cotter pins, & clevis pins are

under HIGH SPRING TENSION.

Adjustments and repairs must only be

made by a trained door systems

technician, using proper tools and

instructions.

DO NOT REMOVE, COVER OR PAINT OVER

THIS LABEL.PRODUCT USER SHOULD

INSPECT THIS LABEL PERIODICALLYFOR

LEGIBILITY AND SHOULD ORDER A

REPLACEMENT FROM THE DOOR

MANUFACTURER AS NEEDED.

325304 REV3 06/26/12

©Copyright 2012,

OverheadDoor Corporation

SAFETYINSTRUCTIONS

1. Operatedoor ONLY when it is properly

adjustedandfree of obstructions.

2. Ifa door becomes hard to operate,

inoperativeoris damaged, immediately

havenecessaryadjustments and/or repairs

madebya trained door system technician

usingpropertools and instructions.

3. DONOT stand or walk under a moving door,

orpermitanybody to stand or walk under

anelectricallyoperated door.

4. DONOT place fingers or hands into open

sectionjointswhen closing a door. Use lift

handles/grippingpointswhen operating

doormanually.

5. DONOT permit children to operate garage

doorordoor controls.

6. Dueto constant extreme spring tension,

DONOTattempt any adjustment, repair or

alterationtoany part of the door,

especiallytosprings, spring brackets,

bottomcornerbrackets, red colored

fasteners,cablesor supports. To avoid

possiblesevereor fatal injury, have any

suchworkperformed by a trained door

systemtechnicianusing proper tools and

instructions.

7. Onelectrically operated doors, pull down

ropesmustbe removed and locks must be

removedormade inoperative in the open

(unlocked)position.

8. Topsection of door may need to be

reinforcedwhenattaching an electric

opener. Check door and/or opener

manufacturer’s instructions.

9. VISUALLYinspect door and hardware

monthly for worn and/or broken parts.

Check to ensure door operates freely.

10.Te stelectric opener’s safety features

monthly, following opener manufacturer’s

instructions.

11.NEVER hang tools,bicycles, hoses, clothing

or anything else from horizontal tracks.

Track systems are not intended or designed

to support such extra weight.

Placelabel at a readable height on door. DO NOT

remove,cover or paint over this label. Product

usershould inspect this label periodically for

legibilityand should order a replacement label

fromthe door manufacturer as needed.

324100 REV7 09/16/2013

Qualitygarage doors since 1954

WayneDalton

2501S. State Hwy 121 Bus., Suite 200

Lewisville,TX 75067

Forservice, call (800) 827-3667

www.Wayne-Dalton.com

Copyright2013WayneDalton, a

DivisionofOverheadDoor Corp.

Residential warning label, The warning label will

either be on the right or the left end stile.

Bottom section warning labels

Residential Dust label

(For California Residents Only)

Wood label

important notice

Torsion spring tag(s)

(one per spring)

MAINTENANCE

Cleaning Your Garage Door

IMPORTANT: DO NOT USE A PRESSURE WASHER ON YOUR GARAGE DOOR!

An annual inspection of all the surfaces of your garage door(s) will reveal the extent of weath-

ering and the possible need for refinishing. When the finish becomes eroded or thin, clean

and prime any areas showing deterioration. Then completely refinish the door, according to

the directions, listed below, or the manufacturer’s label directions. Proper finishing of the

wood substrates to protect your door(s) from the effects of moisture and sunlight is vital in

extending the service life and beautifying your garage door(s).

The interior and exterior surfaces, as well as all edges must be properly primed, painted and

maintained, to protect and beautify your door. These finishing instructions are intended to

achieve both objectives for your wood doors(s).

NOTE: Be sure to clean behind weatherstrips on both sides and top of door.

CAUTION

NEVER MIX CLEANSERS OR DETERGENTS WITH BLEACH.

GLASS CLEANING INSTRUCTIONS

Clean with a mild detergent solution (same as above) and a soft cloth. After cleaning, rinse

thoroughly.

ACRYLIC CLEANING INSTRUCTIONS

Clean acrylic glazing with nonabrasive soap or detergent and plenty of water. Use your bare

hands to feel and dislodge any caked on particles. A soft, grit-free cloth, sponge or chamois

may be used to wipe the surface. Do not use hard or rough cloths that will scratch the acrylic

glazing. Dry glazing with a clean damp chamois.

NOTE: Do not use any window cleaning fluids, scouring compounds, gritty cloths or solvent-

based cleaners of any kind.

Painting Your Garage Door

Refer to Instruction Insert “Field Painting Wood Door Sections”.

Maintaining The Finish

On Your Garage Door

If the finish is beginning to fade, the door may require a field applied top clear coat. Depend-

ing on environment and usage, this may be necessary after 1 to 3 years of use. Refer to

Instruction Insert “Field Painting Wood Door Sections”.

Operation And Maintenance

OPERATING YOUR GARAGE DOOR: Before you begin, read all warning labels affixed to

the door and the installation instructions and owner’s manual. When correctly installed, your

Wayne Dalton door will operate smoothly. Always operate your door with controlled move-

ments. Do not slam your door or throw your door into the open position, this may cause dam-

age to the door or its components. If your door has an electric opener, refer to the owner’s

manual to disconnect the opener before performing manual door operation below.

10