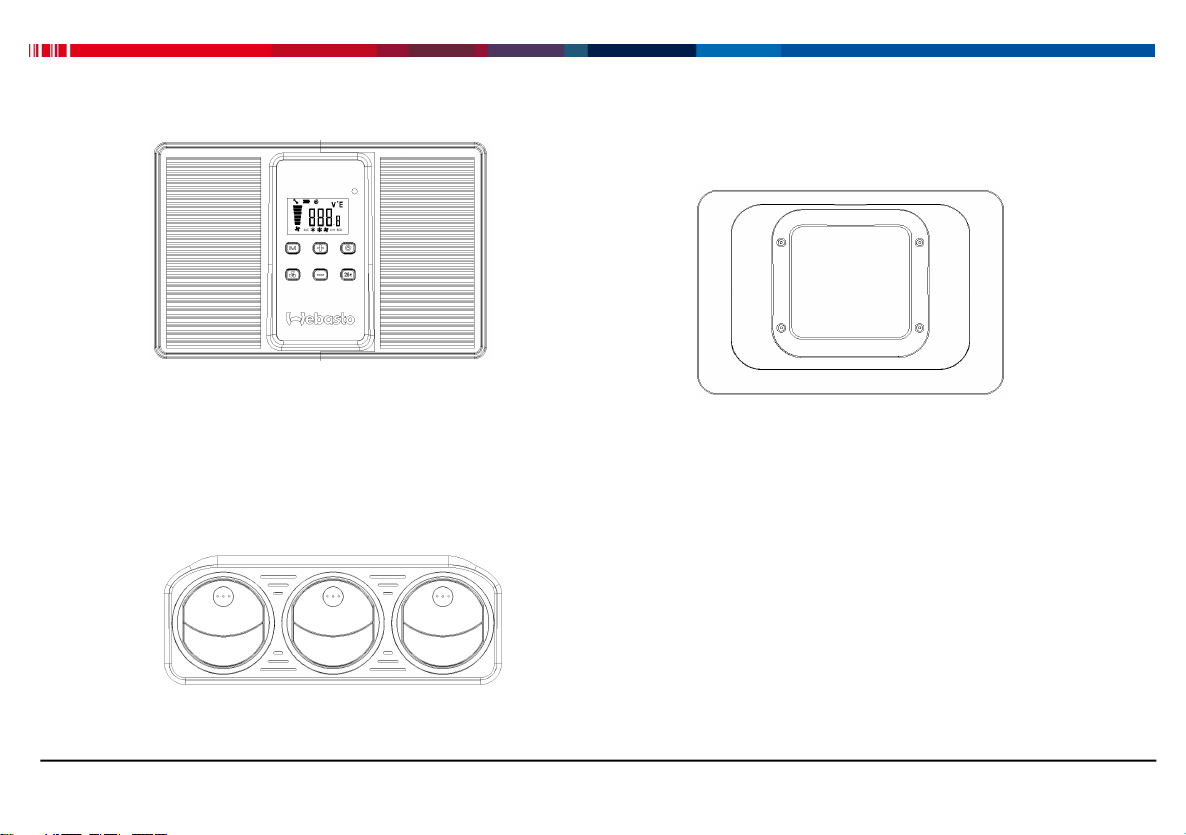

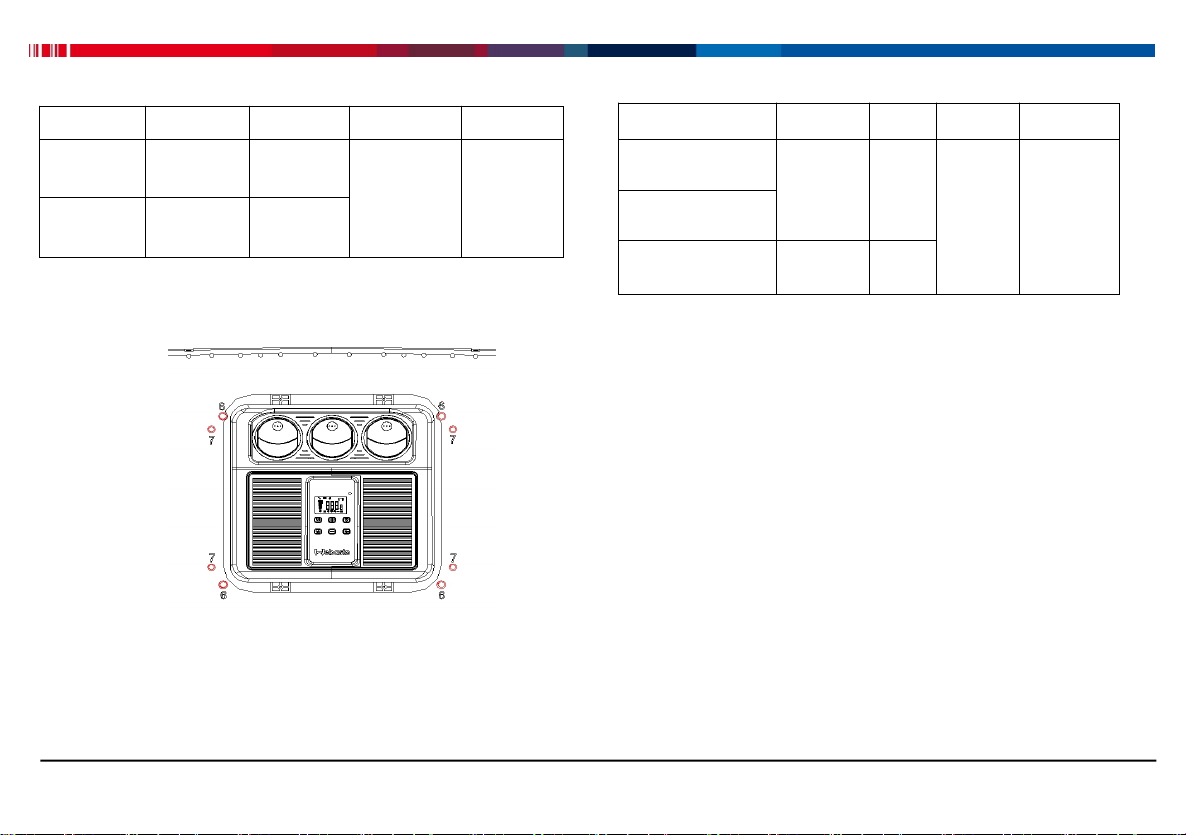

Control panel legend:

①On-Off button: Press this button to switch the Cool

Top 23 RT-E On or Off;

②Mode button: Push this button to switch among the

modes Auto, Eco, and Power.

③Airflow button: Each push on this button

corresponds to cycle through 5 different airflow levels;

④Auto 26 ℃:Press this button enables automatic

management towards 26℃;

⑤Temperature “+”button: Each pushing on this button

corresponds to the increase of 1℃of temperature;

⑥Temperature “-” button: Each pushing on this button

corresponds to the decrease of 1℃of temperature;

⑦Display window: Display temperature, airflow,

Voltage, error codes and ambient temperature.

⑧Infrared signal:Acceptance of infrared signal from

remote controller by users.

Low-voltage protection function

Settings: Long press on “26 ℃” button till screen

blinking, adjust low-voltage cutoff value (default value

is 20.5V, ranging 18-23V)via Temp“+” or “-” button,

and then long press on “26℃” button again for 5s.