Webasto Thermo 300.102 User manual

Thermo 300.102

Installation Instructions

for use with

The Detroit Diesel

Series 4000 Engine

Coolant Heater

TABLE OF CONTENTS

I

Table of Contents

1. Introduction

1.1 Scope and Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Meaning of Warnings, Cautions and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Additional Documentation to be Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 General Safety Regulations and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4.1 General Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. General Description

2.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Functional Description

3.1 Switching On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Heating Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Switching Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.4 Power Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4. Technical Data

4.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Thermo 300 Heater Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

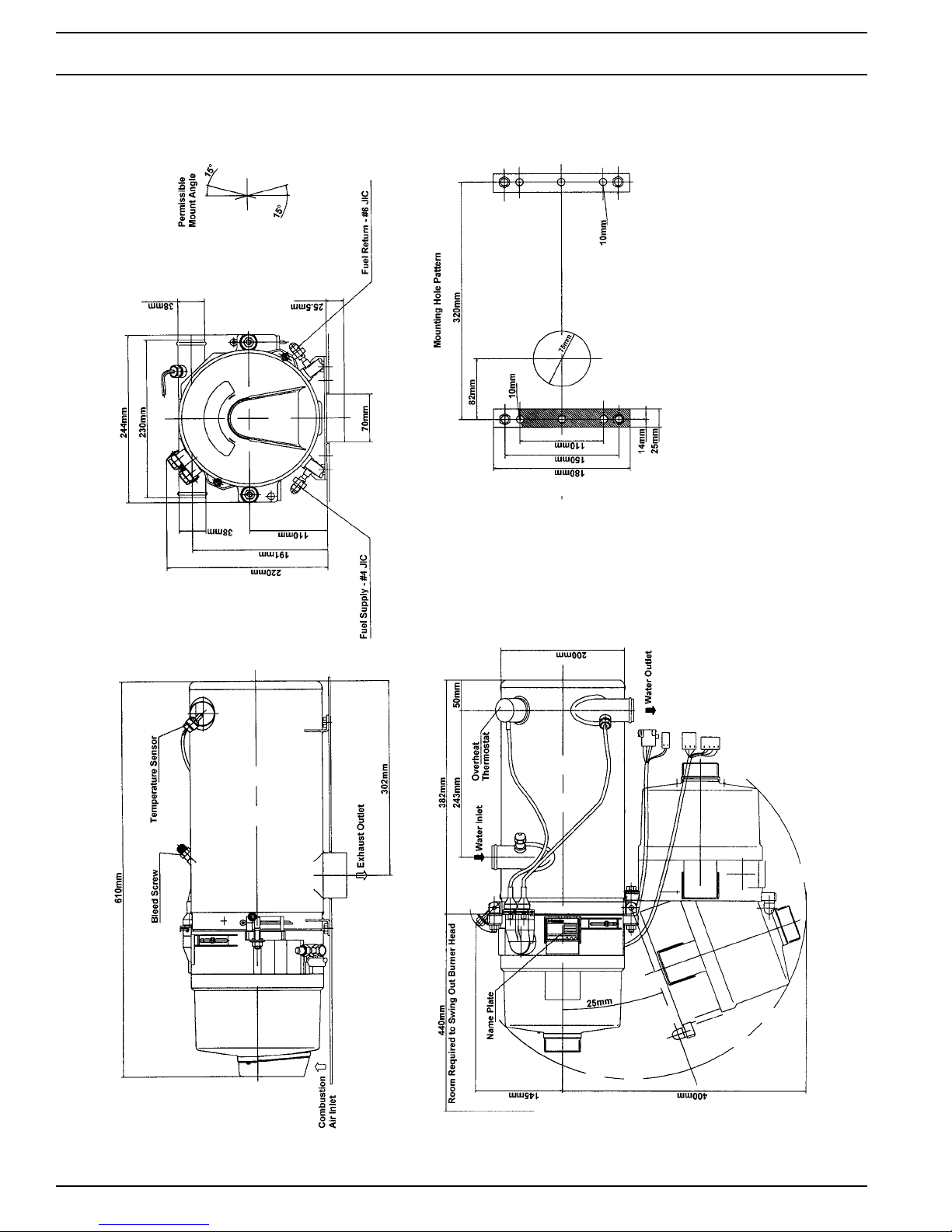

4.2.1 Thermo 300.102 Heater Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 U 4814 & U 4852 Coolant Pump Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.1 Coolant Circulation Pump U4814 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

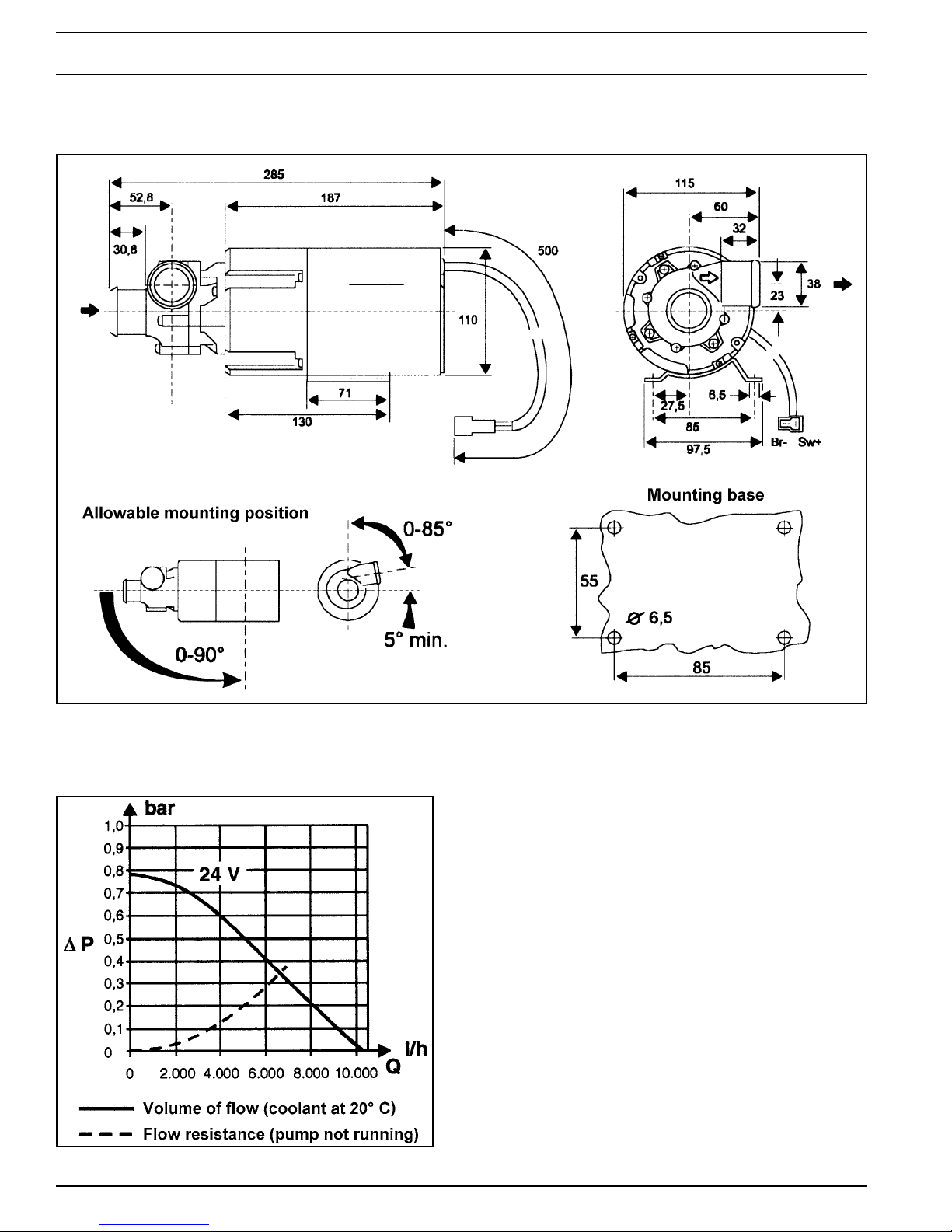

4.3.2 Coolant Circulation Pump U4852 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Installation

5.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Installation Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Mounting the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.4 Mounting the Coolant Circulation Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.5 Exhaust Pipe Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.6 Combustion Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.7 Plumbing into the Coolant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.7.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

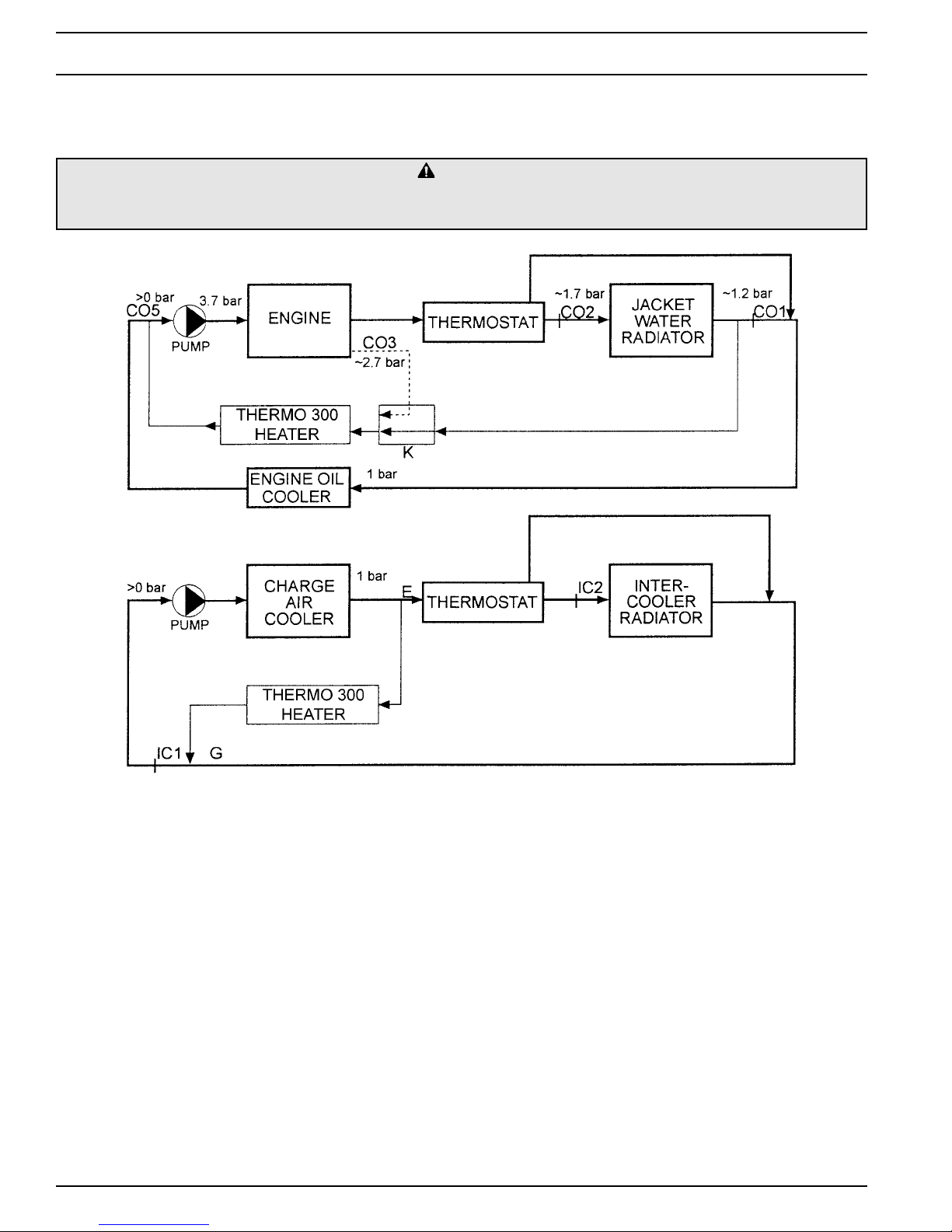

5.7.2 Supplemental Heating Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.7.3 Supply and Return Plumbing Connection Points . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.7.4 Example of a Heater Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.8 Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.8.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.8.2 Fuel Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.8.3 Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.9 Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.9.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.9.2 Timer and Switch Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.9.3 Timer and Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.9.4 Coolant Pump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

WEBASTO THERMO 300

TABLE OF CONTENTS WEBASTO THERMO 300

II

5.9.5 Wiring Diagram - with Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.9.6 Wiring Diagram - with 7-Day Digital Timer Model 1531 . . . . . . . . . . . . . . . . . . . 5-12

5.10 Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

6. Basic Troubleshooting

6.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Operational Malfunction Symptoms - Reading the Flash Code . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Reading a Malfunction Code with the Digital Timer Model 1531 Installed . . . . . 6-1

6.2.2 Malfunction Codes Stored in Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Operational Malfunction Code via Flash/ Malfunction Code . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4 Reading and Removing Malfunction Codes Stored in Memory with the Webasto

PC Diagnostics Kit and Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

8. Spare Parts List

8 Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

9. Warranty Policy

9.1 Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

List of Figures

2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

List of Tables

3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4-1 Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

WEBASTO THERMO 300 1INTRODUCTION

1-1

1. Introduction

1.1 Scope and Purpose

This manual is intended to support authorized Webasto

trained distributors, dealers and personnel in the

installation and servicing of Thermo 300 coolant heaters.

Webasto Thermosystems, Inc. does not recommend the

installation and servicing of Webasto products by

untrained, unauthorized personel or end-users.

Installations and servicing of Webasto products by

untrained, unauthorized personnel and end-users will

release Webasto Thermosystems, Inc. and Webasto

authorized distributors, dealers and personnel from

responsibility for damage to Webasto product or

collateral property and personal injury.

Any use, operation, installation, modification or

application of the product not described in Webasto

manuals, or subjecting the product to extreme or unusual

conditions beyond the limits of specified performance

characteristics is misuse of the product.

Failure to comply with all installation instructions is a

misuse of Webasto product. The same applies for

repairs without using genuine Webasto service parts.

This will void the coolant heaters “Official Marks of

Conformity.”

1.2 Meaning of Warnings, Cautions,

and Notes

Warnings, Cautions and Notes in this manual have the

following meaning:

1.3 Additional Documentation to be

Used

This manual contains all of the information and

procedures necessary for the installation of the

Thermo 300 heater.

The use of additional documentation is normally not

required. Vehicle specific installation guides (when

available) may be used as complimentary information

only.

1.4 General Safety Regulations and

Information

The general safety regulations for the prevention of

accidents and relevant operating safety instructions must

be observed at all times.

The specific safety regulations applicable to this manual

are highlighted in the individual chapters by Warnings,

Cautions and Notes.

1.4.1 General Safety Notes

The heater may only be installed in vehicles, with a

minimum coolant capacity of 2.6 US Gal. (10 litres).

The heater must not be installed in the passenger

compartments of the vehicle. Should the heater be

installed in such a compartment, the installation box must

be sealed tight against the vehicle interior. There must

be sufficient ventilation of the installation box from the

exterior in order not to exceed a maximum temperature

of 140 °F (60 °C) in the installation box. Excessive

temperatures may cause malfunctions.

NOTE:

This heading is used to highlight and draw specific

attention to information.

CAUTION

This heading is used to highlight that

non-compliance with instructions or procedures may

cause damage to equipment.

WARNING

This heading is used to highlight that

non-compliance with instructions or procedures may

cause injuries or lethal accidents to personnel.

WARNING

Due to the danger of poisoning and suffocation, the

heater must not be operated in enclosed areas, such as

garages or workshops, without an exhaust venting

system, not even if the start-up is activated by the timer

or remote start device.

At filling stations and fuel depots the heater must be

switched off as there is a potential danger of explosions.

Where flammable fumes or dust may build up (e.g. in the

vicinity of fuel, coal, wood, cereal grain deposits or

similar situations) the heater must be switched off to

prevent explosions.

1INTRODUCTION WEBASTO THERMO 300

1-2

In the vicinity of the coolant heater, a temperature of

185 °F (85 °C) must not be exceeded under any

circumstances (e.g. during body paint work). A violation

of this temperature limit may cause permanent damage

to the electronics.

When checking the coolant level, proceed in accordance

with the vehicle manufacturer’s instructions.

The coolant in the heating circuit of the heater must

contain a minimum of 10% of a quality brand glycol

based anti-freeze.

Extracting combustion air from the vehicle interior is not

permissible under any circumstance.

The exhaust line outlet is to be positioned below the

vehicle floor, to the nearest possible location of the

vehicle’s left side. Exhaust pipes must be routed so that

exhaust fumes will not penetrate into the vehicle’s

interior.

The function of any parts vital for vehicle operation must

not be impaired. Condensation accumulation in the

exhaust line must be directly drained. A condensation

drain hole may be provided as required.

Electrical lines, switch gear, and control gear of the

heater must be located in the vehicle so that their proper

function cannot be impaired under normal operating

conditions.

The coolant heater may only be operated within the

specified operating voltage range designated by type.

The coolant heater may only be operated with the

specified fuel (Diesel 1, Diesel 2, Arctic grade, Kerosene

and certain military spec. fuels).

For the routing of fuel lines, the following important

regulations must be adhered to:

• Fuel lines are to be installed in such a way that they

remain unaffected by torsional stresses created by

vehicle and engine movement. They must be

protected against mechanical damage. Fuel lines

must be securely fastened to the vehicle every 12

inches (30 cm.) or less along the total length from

heater to fuel tank. Fuel-carrying parts are to be

protected against excessive heat and are to be

installed so that any dripping or evaporating fuel can

neither accumulate nor be ignited by hot components

or electrical equipment.

• In buses, fuel lines are not to be located in the

passenger area or in the driver’s compartment.

Fuel supply must not be by means of gravity or

pressurization of the fuel tank.

• The fuel tank must either be equipped with a vent

cap or be ventilated in another way (ventilation line).

• The operational state of the heater, i.e. an indication

“On” or “Off”, must be clearly visible to the operator.

2GENERAL DESCRIPTION

2-1

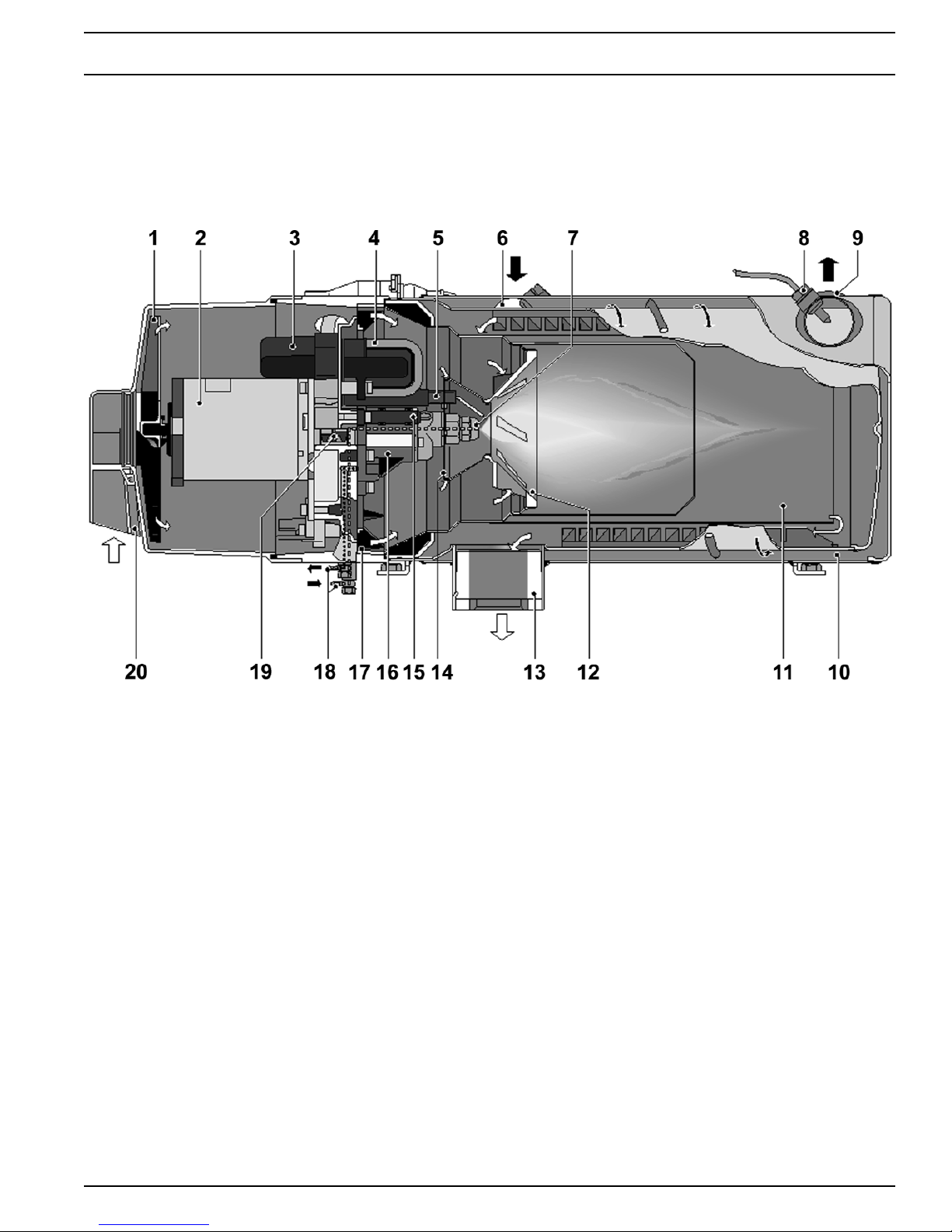

1 Combustion air fan

2 Motor

3 Electronic control unit

4 Electronic ignition coil

5 Ignition electrodes

6 Water pipes

7 Fuel nozzle

The Webasto Thermo 300 heater has been designed for use on large displacement diesel engines where a

high degree of operational flexibility is desired.

Additionally, the Thermo 300 heaters supplied to Detroit Diesel Corporation have been optimized to meet the

specific requirements of the Series 4000 Detroit Diesel engine.

The Webasto Thermo 300 heater is designed to:

1. Preheat Engine block of liquid cooled engines to help ensure reliable starting in cold weather and to reduce cold

start wear and emissions (white smoke).

2. Boost heating levels with the engine running. The heater will boost the charge-air cooling system in cold weather

when an engine is running at light loads or idling while helping to eliminate white smoke and fuel accumulation in

the vehicle exhaust system.

2. General Description

2.1 General Description

Fig. 2-1: Major Components of the Thermo 300 Coolant Heater

8 Temperature sensor

9 Overheat Thermostat

10 Heat exchanger

11 Combustion chamber

12 Combustion air swirler

13 Exhaust pipe

14 Photo disc

15 Flame detector

16 Fuel pump w/ solenoid valve

17 Combustion air adjusting shutter

18 Fuel supply/ return pipes

19 Coupler

20 Combustion air intake

WEBASTO THERMO 300

2GENERAL DESCRIPTION WEBASTO THERMO 300

2-2

WEBASTO THERMO 300 3FUNCTIONAL DESCRIPTION

3-1

3. Functional Description

Activation and deactivation is by means of a

• switch

• timer

dependent on the type of installation.

For monitoring operation an operating indicator light is provided.

Switch off initiates the rundown procedure (see ”Switch off”).

The heaters may be

• operated with power save for reduced fuel consumption (see circuit diagram)

• equipped or retrofitted with nozzle preheating for extreme low temperatures.

3.1 Switching On

Upon switching on, an operating indicator light will illuminate.

Combustion air fan, fuel pump and circulation pump start operation. (If fitted and temperature is < 0 °C (< 32 °F)

nozzle preheating is also activated).

After approximately 12 seconds a high voltage ignition spark is generated at the electrode tips. Approximately 1

second later the solenoid valve in the fuel pump opens and the nozzle sprays fuel into the combustion chamber to be

ignited by the spark at the electrode tips. A photo control device detects a flame in the combustion chamber and

deactivates the ignition system (Combustion process is self-sustaining).

3.2 Heating Operation

After reaching operating temperature the control unit takes over to provide controlled operation by activation and

deactivation of the burner in order to maintain a nearly constant temperature of the heat exchanger.

A rise in temperature above the upper switching point makes the solenoid valve in the fuel pump shut off the fuel

supply and initiates the rundown procedure. The flame extinguishes, the combustion air fan and the circulation pump

continuing their operation. After approximately 90 seconds rundown is completed with deactivation of the combustion

air fan.

The circulation pump remains in operation during the control idle period. The operating indicator light is on.

3.3 Switch Off

Switching off the heater stops combustion. The operating indicator light goes out and the rundown procedure

commences.

The combustion air fan and circulation pump are deactivated after approximately 90 to 120 seconds.

Reactivation of the heater during rundown is permitted.

3.4 Power Save

With the power save feature on, the control temperatures of the heating circuit are kept low.

This results in a reduced heat radiation loss when limited heating performance is required (e.g. in heat hold

operation) and reduces fuel consumption.

3FUNCTIONAL DESCRIPTION WEBASTO THERMO 300

3-2

WEBASTO THERMO 300 4TECHNICAL DATA

4-1

4. Technical Data

4.1 General Information

Where no threshold values are specified, technical data are understood to include standard tolerances for heater

units of ± 10% at ambient temperature of + 20 °C (+ 68 °F) and at nominal voltage.

Electrical components:

Control unit, fan and circulation pump motors, solenoid valve, igniter box, heater cartridge, nozzle pre-heater and

timer are 24V components. Temperature limiter, flame sensor, temperature sensor and switches are voltage

independent components.

Heater

Type

Mark of conformity

Heater design principle

Heat output kW/h (BTU/h)

Fuel

Fuel consumption kg/h (US. Gal/h)

Rated nominal voltage V

Operating voltage V

Nominal power consumption W

(without circulation pump)

Permissible operating ambient °C (°F)

temperature range

(heater, control unit, circulation pump)

Permissible storage temperature °C (°F)

Permissible operating pressure bar (psi)

of coolant system

Heat exchanger capacity l (US. Gal)

Minimum capacity of circuit l (US. Gal)

CO2in exhaust at nominal voltage Vol.-%

Dimensions of heater length

width

height

Weight kg (lb.)

Thermo 300

DW 300.

~ S229

High pressure fuel atomizing nozzle

30 (104,000)

Diesel #1, Diesel #2, Arctic grade and Kerosene

3.3 (1.2)

24

20 ... 28

110

- 40 ... + 60 (- 40 … + 140)

+ 85 max. (+ 185)

0.4 ... 2.0 (06 … 29)

1.8 (0.475)

10.00 (2.64)

10 + 0.5 related to 500 m above S.L.

610 mm (24.01 in.)

246 mm (9.69 in.)

220 mm (8.66 in.)

19 (41.88)

NOTE:

The allocation of circulation pumps to heater units must be in accordance with coolant resistances.

4.2 Thermo 300 Heater Data

Table 4-1: Thermo 300 Heater Data

4TECHNICAL DATA WEBASTO THERMO 300

4-2

4.2.1 Thermo 300.102 Heater Dimensions

Fig. 4-1 Thermo 300.102 Heater Dimensions

WEBASTO THERMO 300 4TECHNICAL DATA

4-3

Circulation pump

Volume flow l/h (US. Gal/min)

Nominal voltage V

Operating voltage range V

Nominal power consumption W

Dimensions of coolant pump length

width

height

Hose connection O.D.

Weight kg (lb.)

U 4814

5200 (22.9) against 0.15 bar

24

20 ... 28

104

221 mm (8.7 in.)

100 mm (3.94 in.)

105 mm (4.14 in.)

38.0 mm (1.5 in.)

2.1

U 4852

6000 (26.4) against 0.4 bar

24

18 ... 32

209

285 mm (11.22 in.)

115 mm (4.52 in.)

110 mm (4.33 in.)

38.0 mm (1.5 in.)

2.7

NOTE:

The allocation of circulation pumps to heater units must be in accordance with coolant resistances.

4.3 U 4814 & U 4852 Coolant Pump Data

Table 4-2: U 4814 & U 4852 Coolant Pump Data

4.3.1 Coolant Circulation Pump U4814 Dimensions

Fig. 4-2 Coolant Circulation Pump U4814 Dimensions

4TECHNICAL DATA WEBASTO THERMO 300

4-4

4.3.2 Coolant Circulation Pump U4852 Dimensions

Fig. 4-3 Coolant Circulation Pump U4852 Dimensions

Fig. 4-4 Pump U4852 Operating Data

WEBASTO THERMO 300 5INSTALLATION

5-1

5. Installation

5.1 General Information

Webasto will take you step by step through the installation process to ensure successful operation for years to come.

The installation must be performed in accordance with the installation instructions provided in this manual.

IMPORTANT! The proposed heater installation must be approved by Webasto Thermosystems.

5.2 Installation Location

The heater and circulation pump are to be integrated into the coolant system (or into a separate heating circuit, if

applicable) of the vehicle. The heater should be installed as low as possible in the coolant system to assure static

bleeding of the heater and the circulating pump.

The heater is to be installed in a clean and dry environment, usually a separate compartment, accessible for service,

typically towards the rear of the vehicle. The heater may also be located in the engine compartment. The

installation enclosure must provide adequate ventilation for combustion air requirements [4 in² (20 cm²)]. When

installing the heater, make certain that the clearances required for accessing the unit for servicing are observed (e.g.

removal of the combustion chamber). See figure 4-1, page 4-2.

5.3 Mounting the Heater and Enclosure

1. Locate spot to mount heater, refer to fig 5-4, page 5-6

2. Drill holes as needed for size refer to fig ?? page 4-5

NOTE:

This manual does not cover all possible installation variants. For special applications, use this manual as a guideline

only. For further information concerning installations for special applications, contact Webasto Thermosystems

directly at 1-800-555-4518.

WARNING

Due to the danger of poisoning and suffocation, the heater must not be installed in either the drivers compartment or

in the passenger area of vehicles.

5INSTALLATION WEBASTO THERMO 300

5-2

5.5 Exhaust Pipe Connection

Rigid exhaust pipe is recommended in installations where the use of an exhaust deflector is not suitable. The

exhaust pipe must have a minimum internal diameter no less than 2 3/4” (70mm) and a length no greater than 16’

(5m). The pipe may have several bends totaling no more than 270° overall. Do not cut and weld pipe to make 90°

angled corners. Always form sweeping corners and smooth transitions when forming bends in exhaust pipes.

1. Install exhaust deflector on heater exhaust outlet or install exhaust pipe.

2. Route the exhaust system so that the possibility of discharged exhaust gases entering the vehicle is prevented.

3. Direct the discharge opening of the exhaust system in such a way as not to be pointed in the direction of travel,

and so located that the possibility of clogging caused by snow, mud or debris is prevented.

4. Any condensation water collecting in the exhaust pipe must be discharged. If necessary, drill a drain hole at the

lowest point to allow drainage.

WARNING

Due to the danger of poisoning and suffocation, exhaust pipes are to be installed and routed in a manner that does

not permit the possibility of exhaust gases entering the vehicle where people are present. Carefully read and

understand all information pertaining to the installation of the exhaust system.

NOTE:

Webasto approved flexible exhaust tubing is available from your Webasto Thermosystems supplier under part

number 479721.

CAUTION

Route the exhaust system away from vehicle components that may be damaged by heat e.g., brake lines, electrical

wiring, coolant hoses and fuel lines.

5.6 Combustion Air Supply

Never draw combustion air from inside the passenger area of a vehicle, or from areas where fumes and gases can

accumulate.

Where the heater is installed in a sealed compartment, adequate ventilation for combustion air requirements

[4 in² (20 cm²)] must be provided.

Combustion air can be drawn from a remote (protected) area in order to provide a clean air supply. For installations

requiring remotely drawn combustion air, use approved ducting with an unrestricted internal diameter no less than 2

1/4” (55mm) and a length no greater than 16’ (5m). The ducting may have several bends totaling no more than 270°

overall. Approved combustion air ducting can be ordered through Webasto under part number 88729A.

To connect combustion air intake ducting [2 1/4” (55mm)] to the heater, several types of fittings are available that

snap directly onto the combustion air inlet port of the heater.

WARNING

Due to the danger of poisoning and suffocation, never draw combustion air from inside the driver and passenger

areas of the vehicle or from areas where hazardous fumes and gases can accumulate. Carefully read and

understand all information pertaining to the installation of the combustion air intake system.

CAUTION

Combustion air ducting and components must be non-restrictive. Do not connect to existing vehicle air ducting or

filtration systems.

WEBASTO THERMO 300 5INSTALLATION

5-3

For a straight connection, order a straight adapter under part number 101377 and snap it onto the combustion air

inlet and attach air ducting.

In the event there is insufficient room for a straight attachment, a 90° snap-on fitting (P.N. 101404) and an adapter

ring (P.N. 82315A) are available. Simply snap them onto the combustion air inlet of the heater and attach ducting.

For installations where ducting is not required, the heater is factory equipped with a splash deflector that simply snaps

onto the combustion air inlet.

NOTE:

Webasto approved flexible combustion air ducting is available from your Webasto Thermosystems supplier under

part number 88729A.

5.7 Plumbing Into the Coolant System

5.7.1 General Information

The coolant circulating pump must be mounted as low as possible in the vehicle’s cooling system. A minimum of

10% of a good quality antifreeze should be maintained in the cooling system at all times. Heater and water pump fit

1.5” (38 mm) I.D. heater hose meeting SAE 20 R3 specifications. Silicone hose requires special hose clamps.

Refer to “Supplemental Heating Schematic - Jacket Water and Intercooler Coolant Heaters” under section 5.7.2 for

information regarding plumbing the coolant heater into the coolant system.

WARNING

Burn risk! When working on the coolant system, allow the engine to cool down and open the radiator cap carefully.

CAUTION

The coolant pump(s) must be operating and a continuous unobstructed coolant path provided during heater

operation. Overheating of the heater will quickly develop if coolant flow is interrupted.

NOTE:

Heater hose must meet SAE 20 R3 specifications. Silicone hose requires special hose clamps. Hose clamps must

be tightened to 45 lb/in. (5 Nm) torque.

5INSTALLATION WEBASTO THERMO 300

5-4

Fig. 5-1: Supplemental Heating Schematic

5.7.2 Supplemental Heating Schematic - Jacket Water and Intercooler Coolant Heaters (fig. 5-1)

CAUTION

The coolant pump(s) must be operating and a continuous unobstructed coolant path provided during heater

operation. Overheating of the heater will quickly develop if coolant flow is interrupted.

CO2: OEM Connection - Engine Outlet to Jacket Water Radiator

B: Supply to Jacket Supplemental Heater - Connect to OEM Plumbing

CO1: OEM Connection - Engine Inlet from Jacket Water Radiator

CO5: Return from Jacket Supplemental Heater - Connect to Engine (30 mm)

E: Supply to Intercooler Supplemental Heater - Connect to Engine (1 in. NPT)

IC2: OEM Connection - Engine Outlet to Intercooler Radiator

G: Return from Intercooler Supplemental Heater - Connect to OEM Plumbing

IC1: OEM Connection - Engine Inlet from Intercooler Radiator

CO3: Supply to Jacket Supplemental Heater - Preheating Mode - Connect to Engine (2 X 20 mm)

K: Ball valve or Solenoid Activated Valve - Required if both Supplemental Heating and Preheating Modes are

Desired

Dashed Lines = Preheat Mode

Bold Lines = Engine Coolant Circuit

Thin Lines = Supplemental Heating Mode

* All presures listed without radiator pressure cap @ 1900 RPM - pressure with radiator cap on will be 1 bar higher.

WEBASTO THERMO 300 5INSTALLATION

5-5

Fig. 5-3: Engine

WARNING

Burn risk! When working on the coolant system, allow the engine to cool down and open the radiator cap carefully.

NOTE:

Heater hose must meet SAE 20 R3 specifications. Silicone hose requires special hose clamps. Hose clamps must

be tightened to 45 lb/in. (5 Nm) torque.

5.7.3 Supply and Return Plumbing Connection Points (Charge Air Cooler)

5INSTALLATION WEBASTO THERMO 300

5-6

Fig. 5-4: Example of Heater Installation

5.7.4 Example of a Heater Installation

Thermo 300 in Enclosure

WEBASTO THERMO 300 5INSTALLATION

5-7

5.8 Fuel System

5.8.1 General Information

The fuel is drawn from the vehicles fuel tank through a fuel standpipe. This standpipe can be utilized on vehicles with

a spare threaded port as shown in figure 5-5. The Webasto heater utilizes 37° flare JIC fuel connection fittings. The

fuel supply line fitting is a JIC #4 and the return line is a JIC #6.

5.8.2 Fuel Supply

IMPORTANT!

Keep the submerged end of fuel standpipe at least 2” from bottom of fuel tank.

The fuel standpipe and fuel line must be installed according to these instructions to insure proper heater operation.

Fig. 5-5: Fuel Standpipe Installation

CAUTION

Whenever the fuel tank is situated higher than the Webasto heater, the top of the fuel tank must not be more than

500 mm (20 in.) above the heater.

NOTE:

The Thermo 300 heater is equipped with a self priming fuel pump. Priming the fuel system or fuel filters is generally

not necessary.

1. Cut fuel standpipe to length, approx. 2” off fuel tank bottom.

NOTE:

After fuel standpipe has been cut to length, remove burrs from opening.

On Haulage Trucks

Use an open port NEAR the bottom of that fuel tank, at least 2” above bottom.

On Mining, Drill Rigs, Marine, and other Off-highway applications that have large fule tanks use a spare

port that is at least 2” from the bottom of the tank.

If the fuel tank is small enough to be able to use the standpipe follow the directions listed below for installation guide.

Image not available

This manual suits for next models

1

Table of contents

Popular Electric Heater manuals by other brands

Somogyi Elektronic

Somogyi Elektronic home FK 3 instruction manual

Harvia

Harvia HH6 Instructions for installation and use

Truma

Truma Ultraheat S 3004 P operating instructions

Creda

Creda TPRIII 500MT Installation and operating instructions

Kingfisher

Kingfisher NE15EPC manual

Comfort Glow

Comfort Glow CEH154 Homeowner's manual

MrHeater

MrHeater MHE150FAT Operating instructions and owner's manual

Life Smart

Life Smart LS-3WTR-MEN13 user manual

prime3

prime3 TEH21 user manual

Optimus

Optimus H-4439 Instruction manual and owner's guide

Rointe

Rointe ecodesign SYGMA Installation and user manual

Gude

Gude GH 15 EV Translation of original operating instructions