Contents

CONTENTS

ABOUT THE MANUAL ..................................................................................... 6

ABBREVIATIONS AND DEFINITIONS .......................................................................... 6

NUMERICAL REPRESENTATION ............................................................................... 6

DOCUMENTS ...................................................................................................... 6

1 MAIN CHARACTERISTICS.......................................................................... 7

2 INTERFACE DESCRIPTION......................................................................... 8

2.1 CHARACTERISTICS OF THE CAN INTERFACE......................................................... 8

2.2 CONNECTOR ................................................................................................ 8

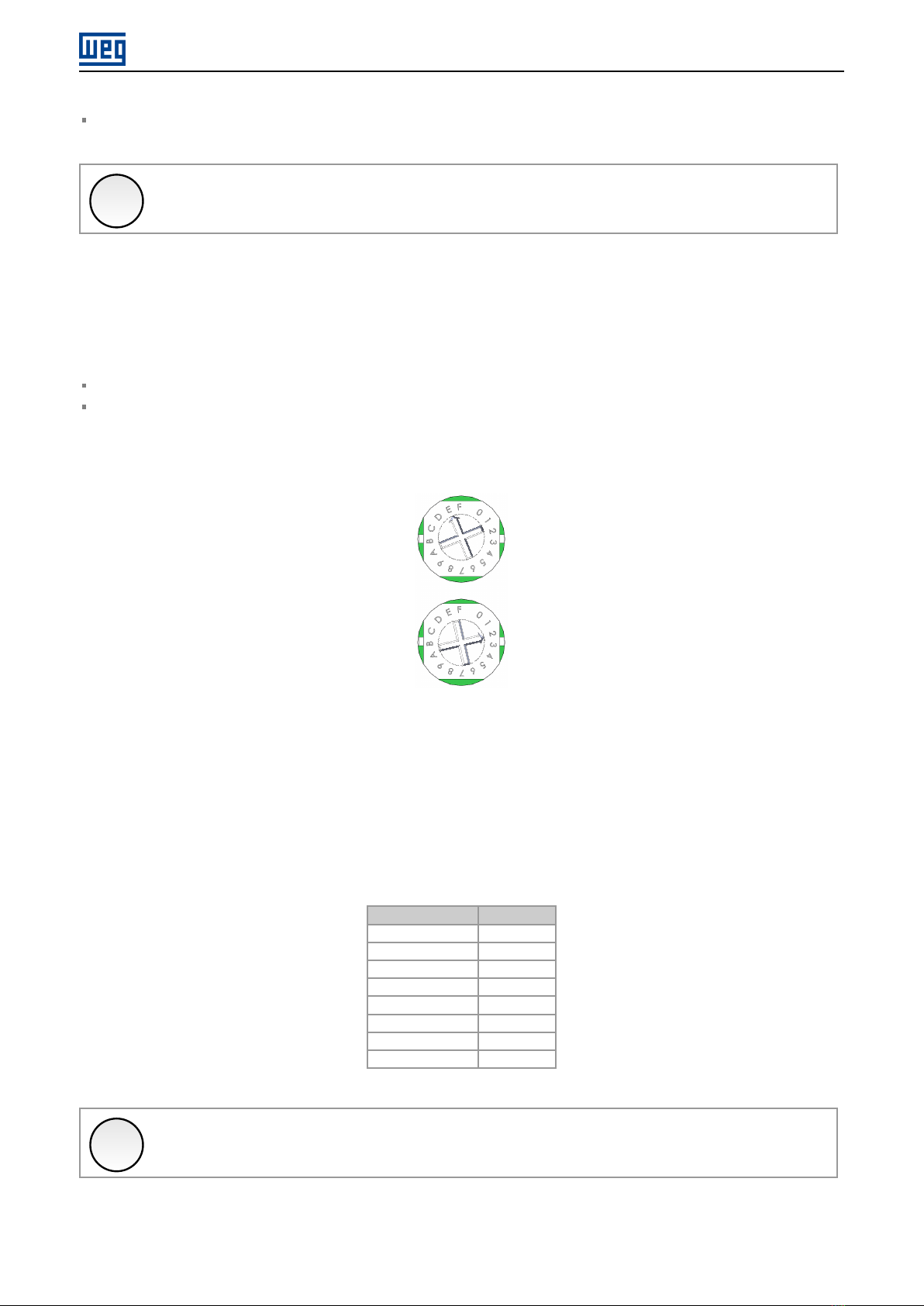

2.3 ADDRESS .................................................................................................... 8

2.4 BAUD RATE .................................................................................................. 9

2.5 TERMINATING RESISTOR ................................................................................. 10

2.6 INDICATION LED ............................................................................................ 10

3 CANOPEN NETWORK INSTALLATION ...................................................... 11

3.1 BAUD RATE .................................................................................................. 11

3.2 ADDRESS IN THE CANOPEN NETWORK ............................................................... 11

3.3 TERMINATION RESISTOR ................................................................................. 11

3.4 CABLE ........................................................................................................ 11

3.5 CONNECTION TO THE NETWORK ....................................................................... 12

4 S STATUS...................................................................................................... 13

S4 COMMUNICATION ............................................................................................ 13

5 C CONFIGURATION................... .................................................................. 15

C2 COMMUNICATION ............................................................................................ 15

6 OPERATION IN THE CANOPEN NETWORK .............................................. 16

6.1 ACCESS TO THE DATA ..................................................................................... 16

6.2 CYCLIC DATA ................................................................................................ 16

6.3 ACYCLIC DATA .................................................................................. ............ 16

6.4 COMMUNICATION OBJECTS - COB ..................................................................... 16

6.5 COB-ID ....................................................................................................... 17

6.6 EDS FILE ..................................................................................................... 17

7 OBJECT DICTIONARY................................................................................. 18

7.1 DICTIONARY STRUCTRE .................................................................................. 18

7.2 DATA TYPE ........................................................................................... ........ 18

7.3 COMMUNICATION PROFILE - COMMUNICATION OBJECTS ........................................ 18

7.4 MANUFACTURER SPECIFIC OBJECTS.................................................................. 19

8 COMMUNICATION OBJECTS DESCRIPTION ........................................... 20

8.1 IDENTIFICATION OBJECT ................................................................................. 20

8.1.1 Object 1000h - Device Type ................... .................................................... 20

8.1.2 Object 1001h - Error Register..................................................................... 20

8.1.3 Object 1018h - Identity Object .................................................................... 21

8.2 SERVICE DATA OBJECTS - SDOS ........................................................................ 21

8.2.1 Object 1200h - SDO Server........................................................................ 21

8.2.2 SDOs Operation......................................................................... ............ 22

8.3 PROCESS DATA OBJECTS - PDOS ...................................................................... 23