Table of contents

Operating Instructions – MOVIGEAR® classic 3

Table of contents

1 General information.................................................................................................................. 5

1.1 About this documentation ...............................................................................................5

1.2 Other applicable documentation .....................................................................................5

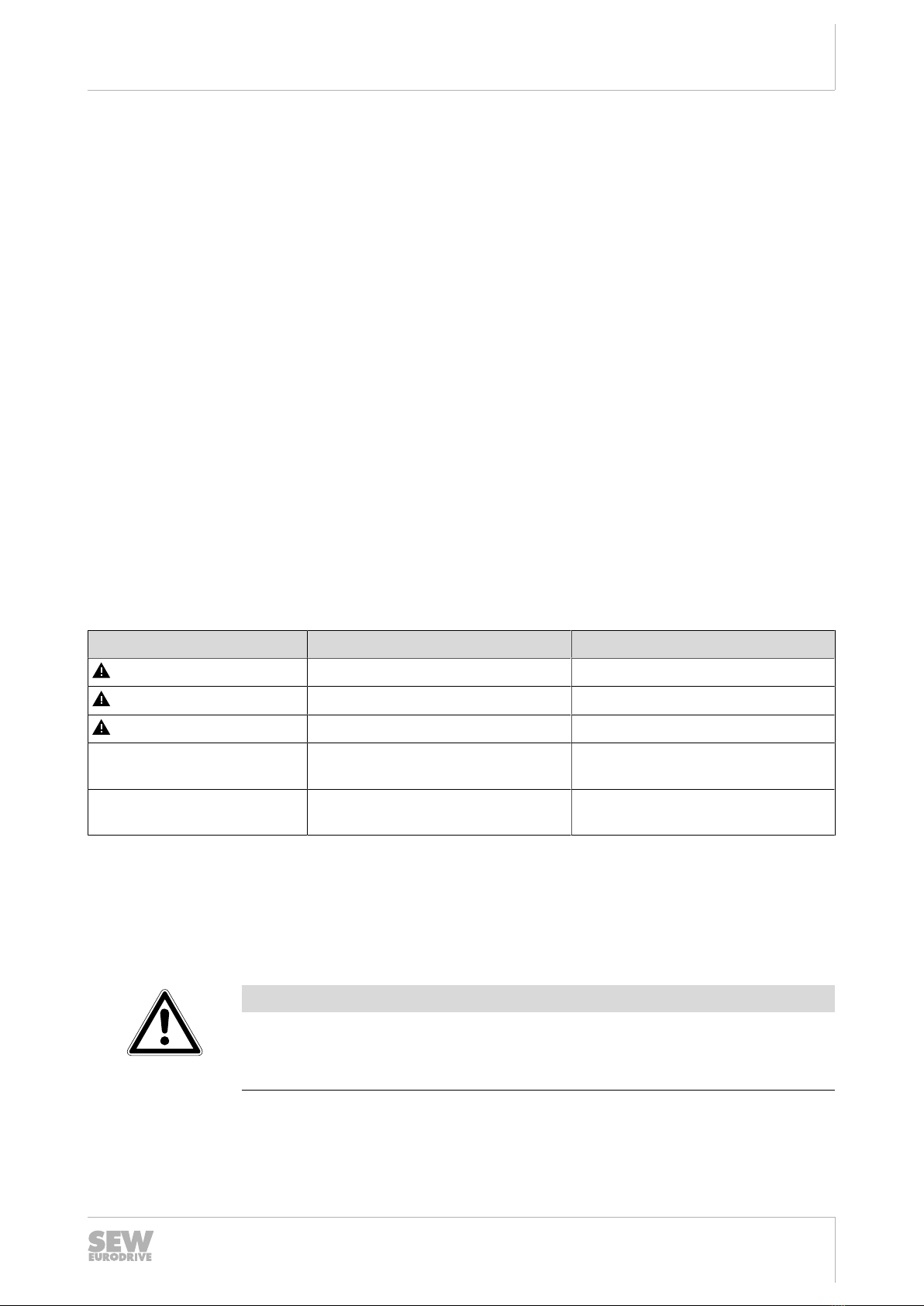

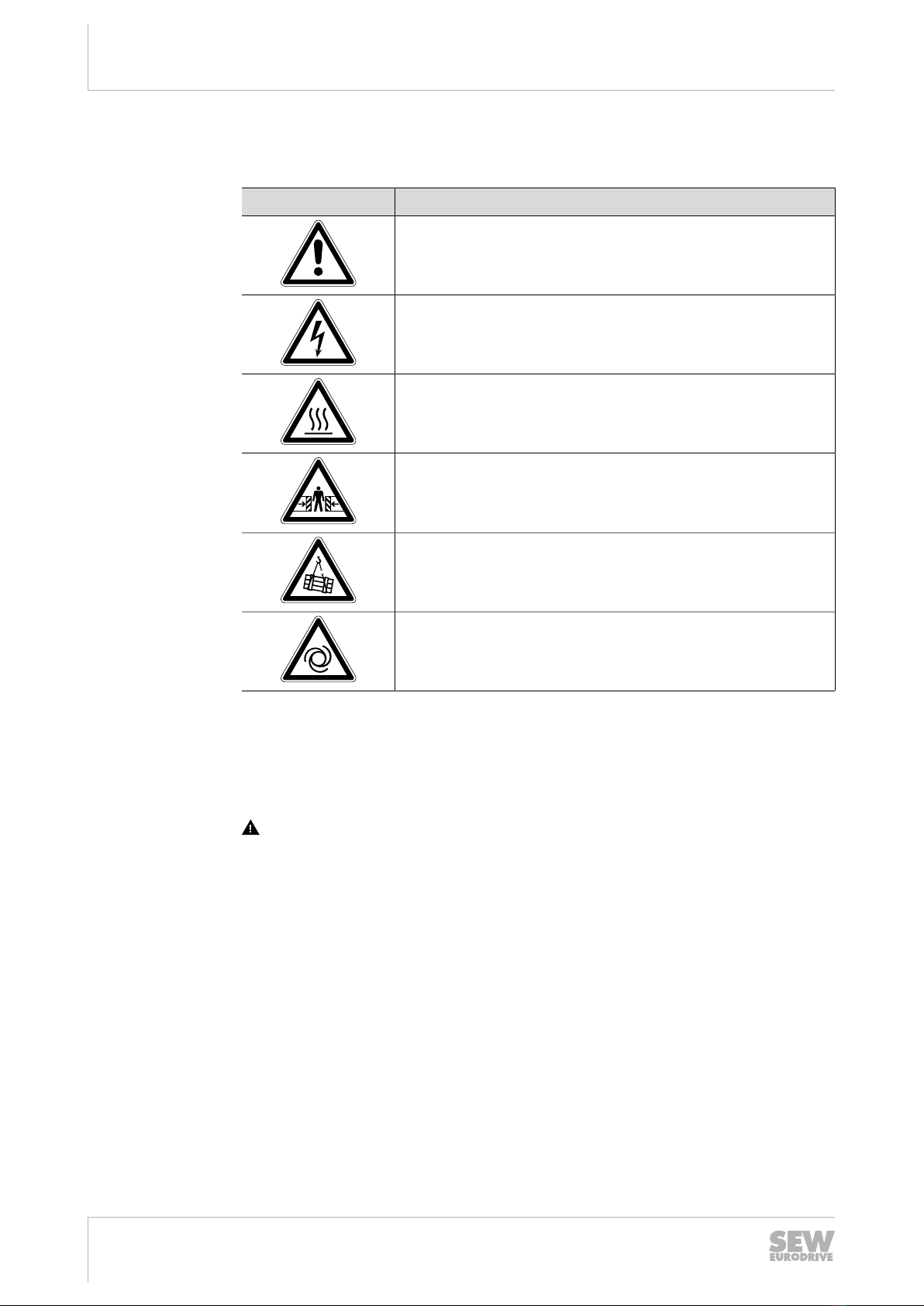

1.3 Structure of the safety notes ...........................................................................................5

1.4 Rights to claim under limited warranty ............................................................................6

1.5 Product names and trademarks......................................................................................6

1.6 Copyright notice ..............................................................................................................7

2 Safety notes .............................................................................................................................. 8

2.1 Preliminary information ...................................................................................................8

2.2 Duties of the user............................................................................................................8

2.3 Target group ...................................................................................................................8

2.4 Designated use ...............................................................................................................9

2.5 Transportation.................................................................................................................9

2.6 Installation/assembly.....................................................................................................10

2.7 Electrical connection .....................................................................................................11

2.8 Protective separation ....................................................................................................11

2.9 Startup/operation ..........................................................................................................12

2.10 Magnetic fields..............................................................................................................12

3 Unit structure .......................................................................................................................... 13

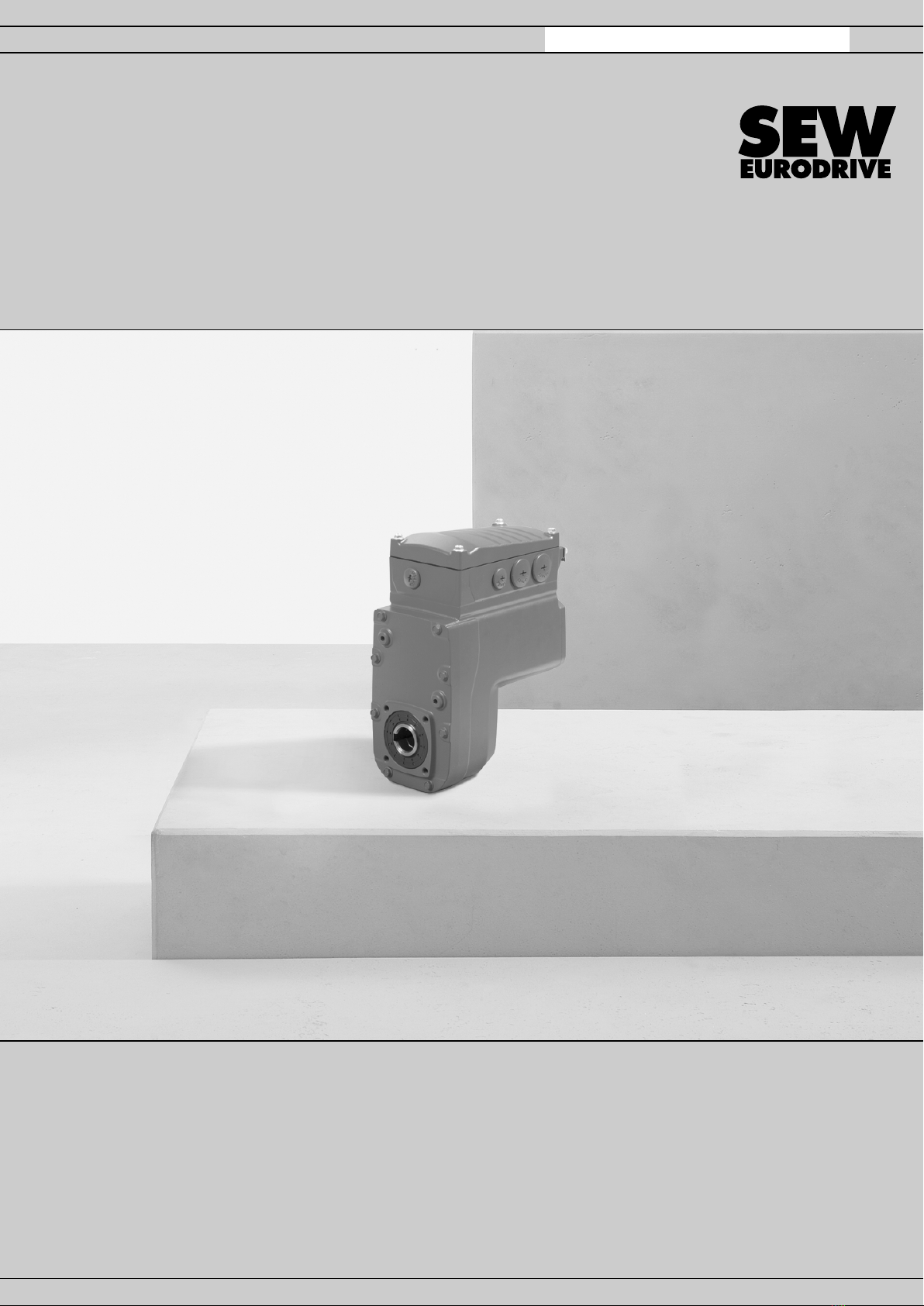

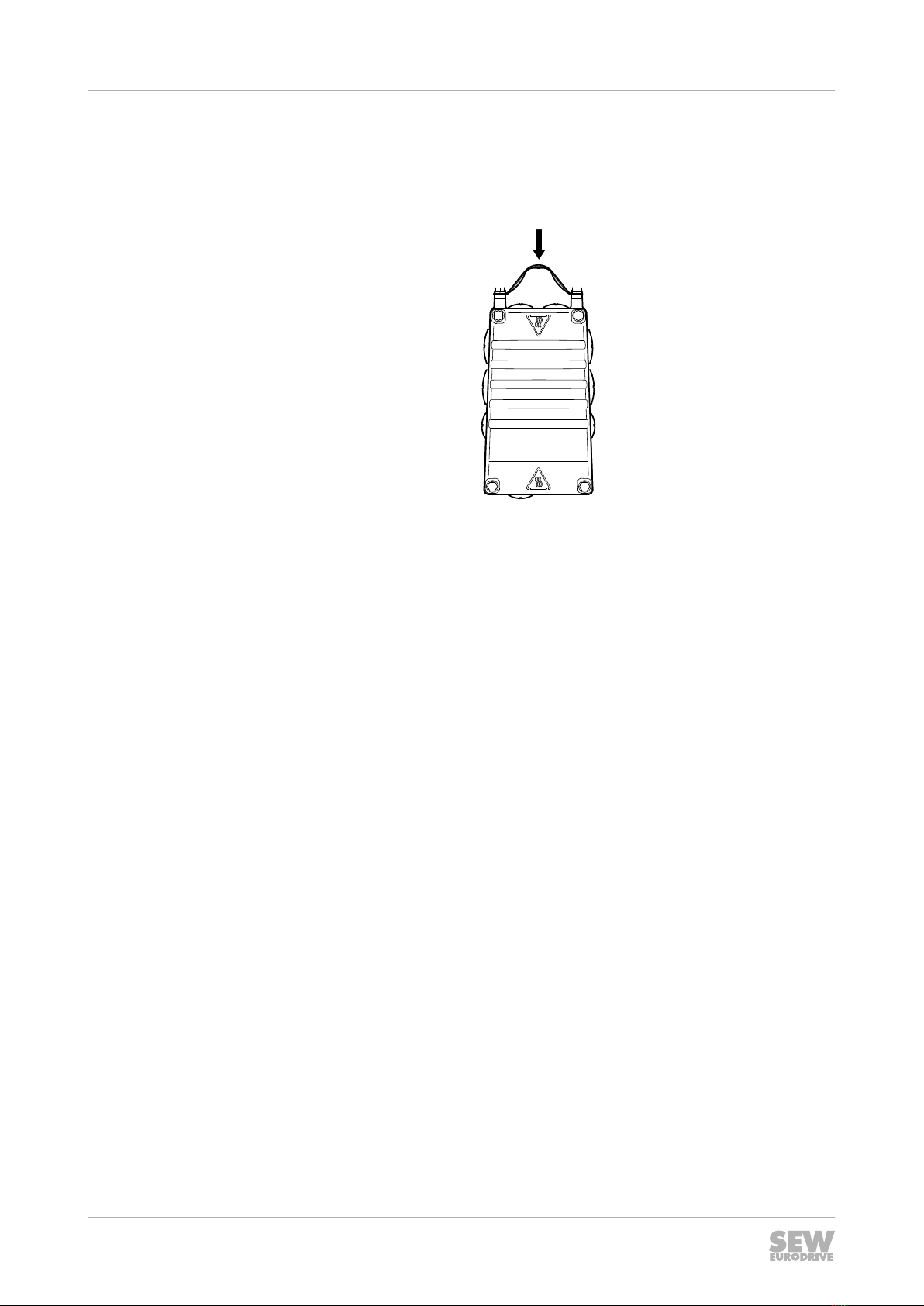

3.1 MOVIGEAR® classic drive unit.....................................................................................13

3.2 Shaft types ....................................................................................................................14

3.3 Housing mounting .........................................................................................................15

3.4 Threads for protective cover .........................................................................................16

3.5 Cable entry position ......................................................................................................16

3.6 Nameplate position .......................................................................................................17

3.7 Example nameplate and type designation of drive unit ................................................18

3.8 Cover and connection box ............................................................................................19

4 Mechanical installation .......................................................................................................... 20

4.1 Installation notes ...........................................................................................................20

4.2 Required tools and resources .......................................................................................21

4.3 Installation requirements...............................................................................................21

4.4 Setting up the drive unit ................................................................................................22

4.5 Shaft-mounted gear unit with keyway ...........................................................................27

4.6 Shaft-mounted gear unit with TorqLOC® (customer shaft without contact shoulder) .32

4.7 Shaft-mounted gear unit with TorqLOC® (customer shaft with contact shoulder) .......39

4.8 Shaft-mounted gear unit with TorqLOC® – disassembly, cleaning, lubrication ............44

4.9 Installing the protective cover .......................................................................................46

4.10 Torque arm ...................................................................................................................48

4.11 Tightening torques ........................................................................................................49

5 Electrical installation.............................................................................................................. 52

5.1 Equipotential bonding ...................................................................................................52

5.2 Equipotential bonding at the connection box ................................................................53

5.3 Installation instructions..................................................................................................54

25805134/EN – 07/2018