ÎDo not apply any external forces to the WEH®Product. Therefore, do not lean on the

(connected) WEH®Product, do not hang on the WEH®Product and do not climb on

the WEH®Product under any circumstances. In addition, refrain from hammering

on the WEH®Product or similar. Such force effects can lead to damage to property

and personal injury. Also make sure that the WEH®Product is protected from being

stepped on or run over in any way.

- The WEH®Product can become very hot or very cold due to the possible fluids

flowing through it, depending on the application and operating situation. In this

regard, observe the national and international regulations on occupational health

and safety to prevent injuries.

1�5 Definition of qualified personnel

- Qualified personnel, as defined by these instructions, are persons who, based on

their professional training, their knowledge (including the relevant standards and

regulations), experience and manual skills, can independently assess and properly

perform assigned work tasks (in conjunction with WEH®Products) and can thus

independently recognize and prevent potential dangers at an early stage.

2. INTENDED USE

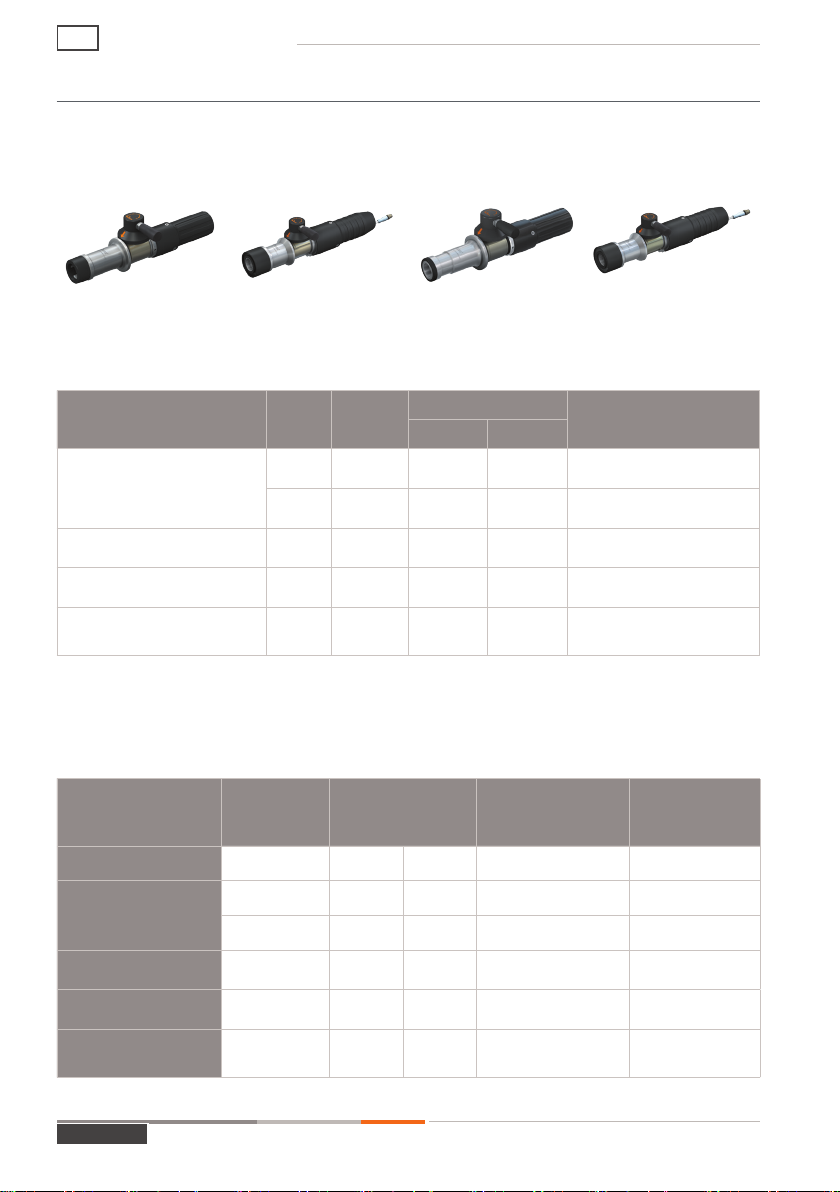

- The WEH®TK16 H2Fueling nozzle was specifically developed for quick refueling

vehicles with compressed gaseous hydrogen (CGH2).

- When used at sea or in the vicinity of the sea, increased salt and moisture content of

the air may cause faster wear and corrosion of the product. Please observe the spe-

cial maintenance instructions in Chapter 9.2 Maintenance intervals on page 25.

ÎAlways ensure that the WEH®Product is used only within the range of its intended

use. Please note in particular the technical data of the WEH®Product in Chapter 4 as

well as the marking on the WEH®Product itself.

- This WEH®Product is generally classified as pressure accessory in accordance

with Article 2 (5) of the Pressure Equipment Directive 2014/68/EU and is consid-

ered to be similar to piping. This WEH®Product may not be used as safety acces-

sory. Furthermore, it is pointed out, that this WEH®Product is designed and placed

on the market in accordance with the requirements of Article 4 (3) of the Pressure

Equipment Directive 2014/68/EU. The assessment with regard to a different classi-

fication can, however, be made on request.

Caution: Any use beyond the scope of application is considered as unintended use

and may result in personal injury and/or property damage.

MD-10214-L51-R2.0.0-03 Page 9

Operating instructions AE