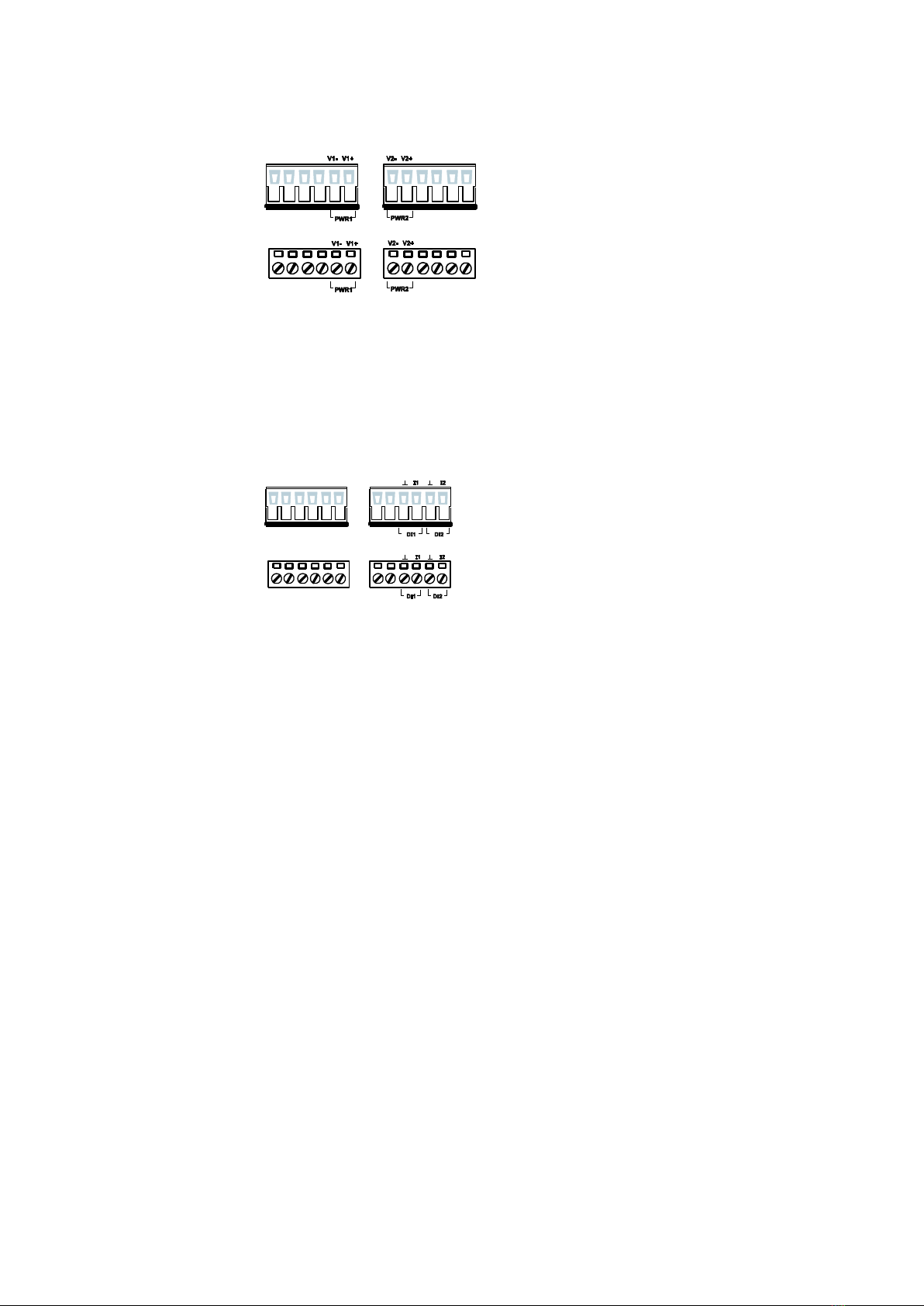

Wiring the Redundant Power Inputs

IE-SW-PL18M-Switches have two sets of power inputs - power input 1 and

power input 2 –located on the 6-pin terminal block connector on the top

panel of the device. See sketch below how to connect.

STEP 1: Insert the

negative/positive DC wires into

the V-/V+ terminals, respectively.

STEP 2: To keep the DC wires

from pulling loose, use a small

flat-blade screwdriver to tighten

the wire-clamp screws on the front

of the terminal block connector.

STEP 3: Insert the plastic terminal

block connector prongs into the

terminal block receptor, which is

located on the switch’s top panel.

Wiring the Digital Inputs

IE-SW-PL18M-Switches have two sets of digital inputs, DI 1 and DI 2. Each

DI consists of two contacts of the 6-pin terminal block connector on Switch´s

top panel, which are used for Switch´s two DC inputs. The top and front

views of one of the terminal block connectors are shown here.

STEP 1: Insert the negative

(ground)/positive DI wires into the ┴

/I1 terminals, respectively.

STEP 2: To keep the DI wires from

pulling loose, use a small flat-blade

screwdriver to tighten the wire-clamp

screws on the front of the terminal

block connector.

STEP 3: Insert the plastic terminal

block connector prongs into the

terminal block receptor, which is

located on the IE-SW-PL18M´s top

panel.

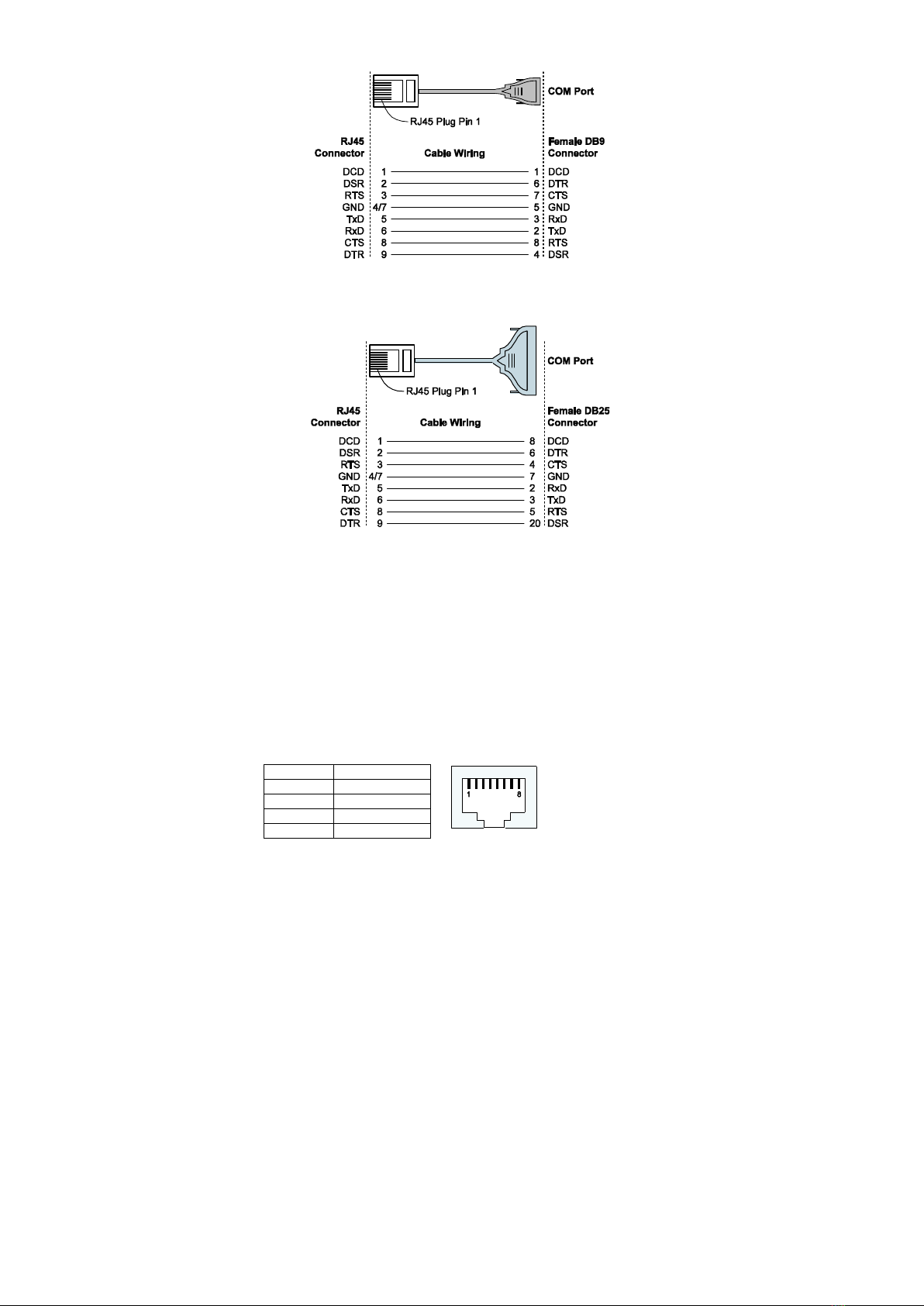

Communication Connections

All models of IE-SW-PL18M-Switches have one RJ45 console port (RS-232

interface), between 14 and 16 10/100BaseTX Ethernet ports. Some models

also have 2 100BaseFX (SC/ST-type connector) fiber ports.

In this section, we present two types of diagrams - Pinout Diagrams and

Cable Wiring Diagrams - to convey information about the ports and the

cables used to connect IE-SW-PL18M Series to other devices:

Pinouts—The meaning of the “Pinouts” diagrams is straightforward. The

diagrams simply display the type of signal passing through each of the port’s

pins.