Overview

The IE-SW-VL16 Series of 16-port smart Ethernet switches provides an

economical solution for your Ethernet connections. As an added bonus, the

built-in smart alarm function helps system maintainers monitor the health of

your Ethernet network.

IE-SW-VL16 Series has an operating temperature range of 0 to 60°C (Standard

models) or optional a extended operating temperature range from -40 to 75°C

and is designed to withstand a high degree of vibration and shock. The rugged

hardware design makes IE-SW-VL16 Series perfect for ensuring that your

Ethernet equipment can withstand critical industrial applications, such as in

hazardous locations (Class 1 Division 2/ Zone 2), and complies with FCC,

TÜV, UL, and CE Standards.

Package Checklist

The IE-SW-VL16 Series is shipped with the following items. If any of these

items is missing or damaged, please contact your Weidmüller customer service

for assistance.

1 Ethernet Switch

Hardware Installation Guide

Protective caps for unused ports

Features

High Performance Network Switching Technology

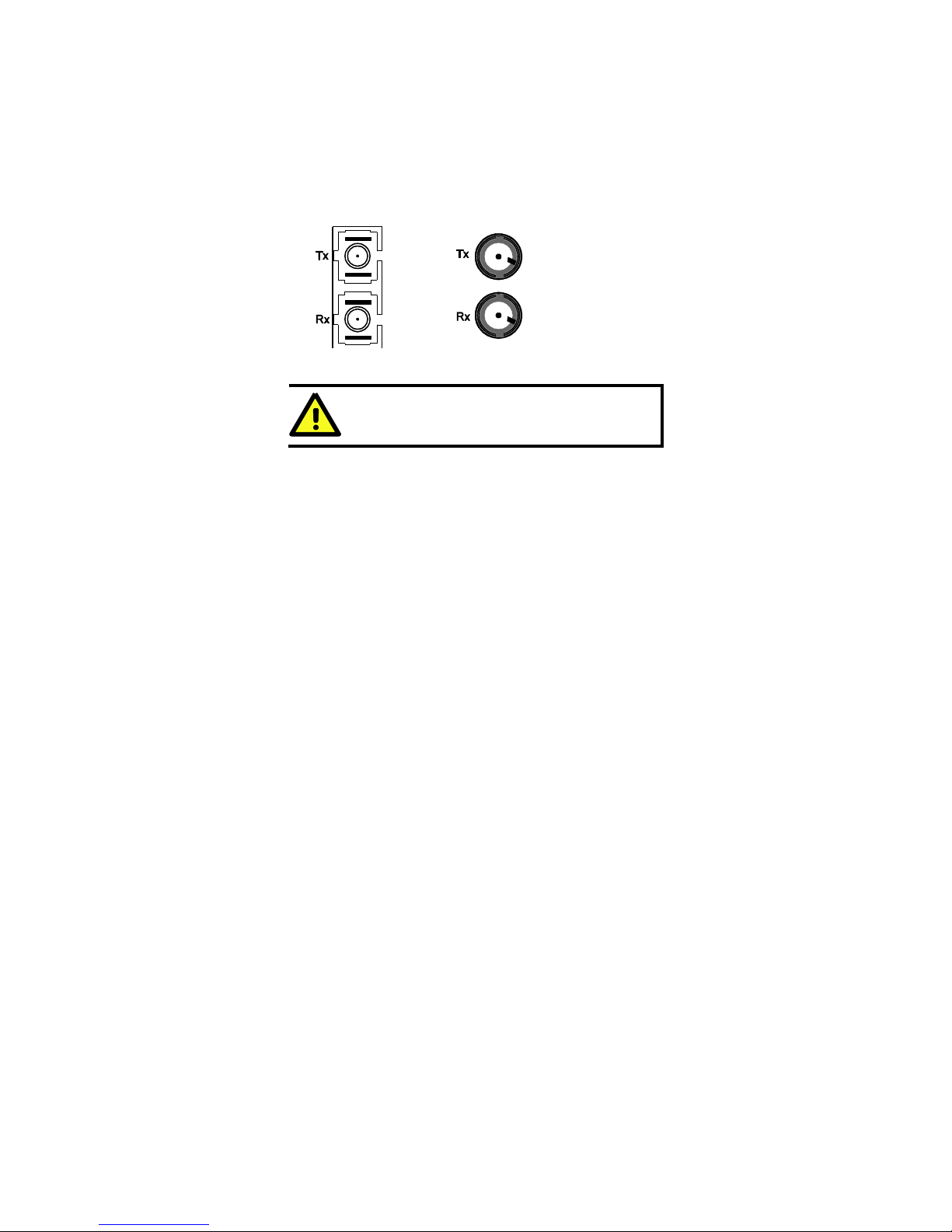

10/100BaseT(X) (RJ45), 100BaseFX (SC/ST type, Multi/Single mode)

IEEE 802.3/802.3u/802.3x

Store and Forward switching process type, with 4K address entries

10/100M, Full/Half-Duplex, MDI/MDIX auto-sensing

Industrial Grade Reliablity

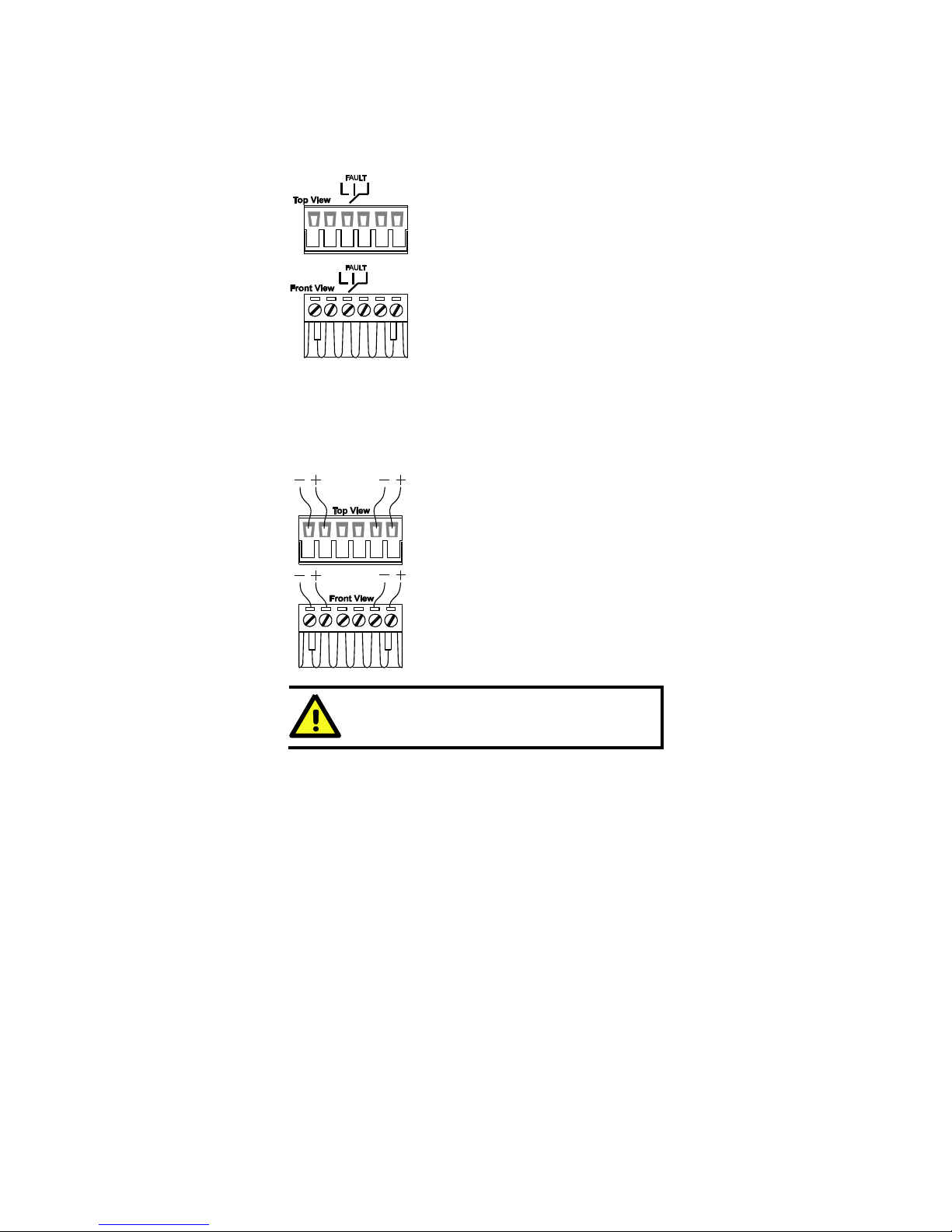

Power failure, port break alarm by relay output

Redundant dual DC power inputs

Rugged Design

Standard operating temperature range from 0 to 60°C or extended operating

temperature of -40 to 75°C for (-T) models

IP30, rugged high-strength case

DIN-Rail or panel mounting ability