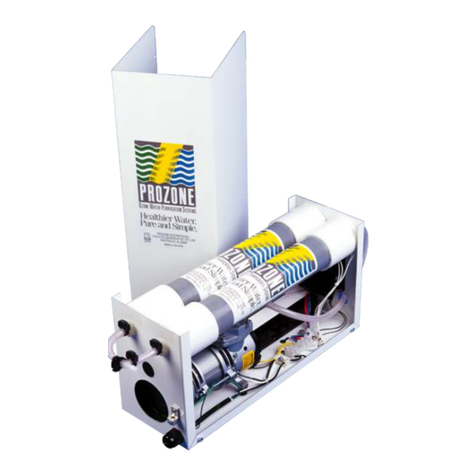

Prozone RCQD User manual

92-100105-05-00

INSTALLATION INSTRUCTIONS

FOR RCQD COILS

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OF THIS UNIT.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOL-

LOW THESE INSTRUCTIONS MAY RESULT IN IMPROPER

INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE

POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

refrigerant

f

2

TABLE OF CONTENTS

Model Number Explanation . . . . . . . . . . . . . . . . . . . . . . . 2

Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Airflow Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Coil Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 5

Codes/Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Vertical Upflow/Downflow. . . . . . . . . . . . . . . . . . . . . . . . . 6

Horizontal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Refrigerant Connections. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Horizontal Drain Pan Extension . . . . . . . . . . . . . . . . . . . . 7

TXV Sensing Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Condensate Drain Tubing . . . . . . . . . . . . . . . . . . . . . . . . 7

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Indoor Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Plenum Adapter Accessory . . . . . . . . . . . . . . . . . . . . . . . 8

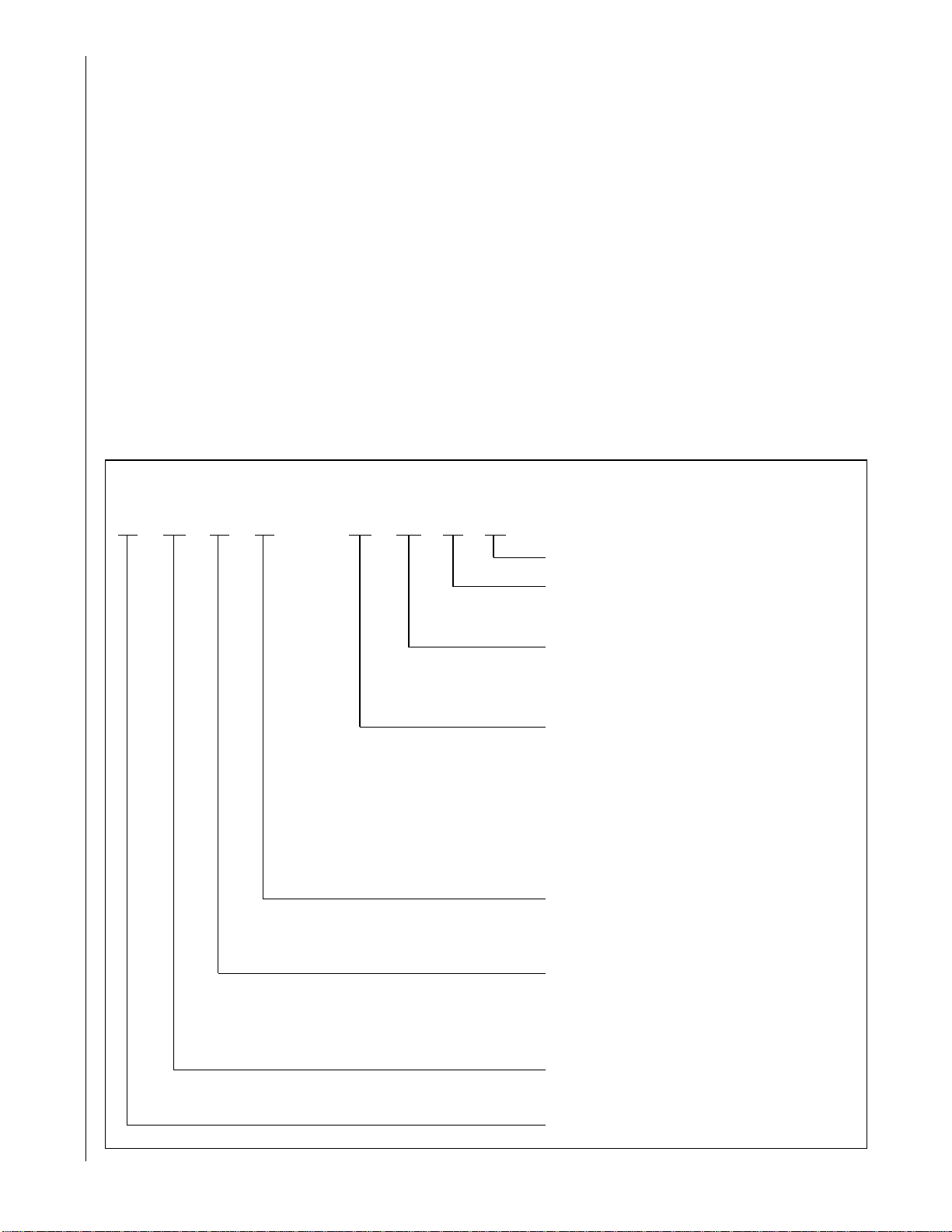

Sweat

Variation

A - 16 & 18 SEER Application

Coil Casing

17 = 17" [431.8 mm]

21 = 21" [533.4 mm]

24 = 24" [609.6 mm]

Nominal Capacity

24 = 24,000 BTUH

[7.03 kW]

36 = 36,000 BTUH

[10.55 kW]

48 = 48,000 BTUH

[14.06 kW]

Design Series

Type of Coil

Q = High Efficiency AC/Heat Pump Coil

with Expansion Valve

Coil

TRADE NAME

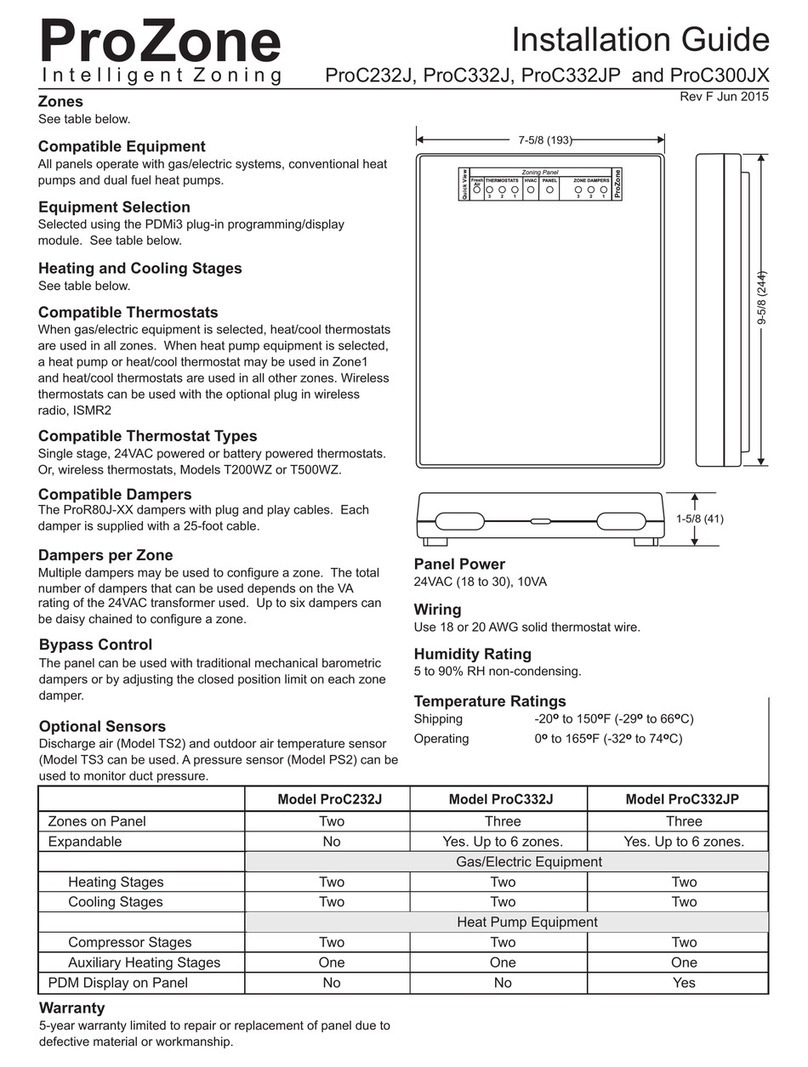

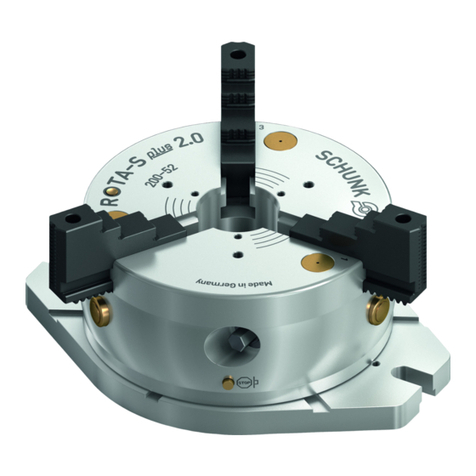

FIGURE 1

MODEL NUMBER EXPLANATION

RCQD—2417AS

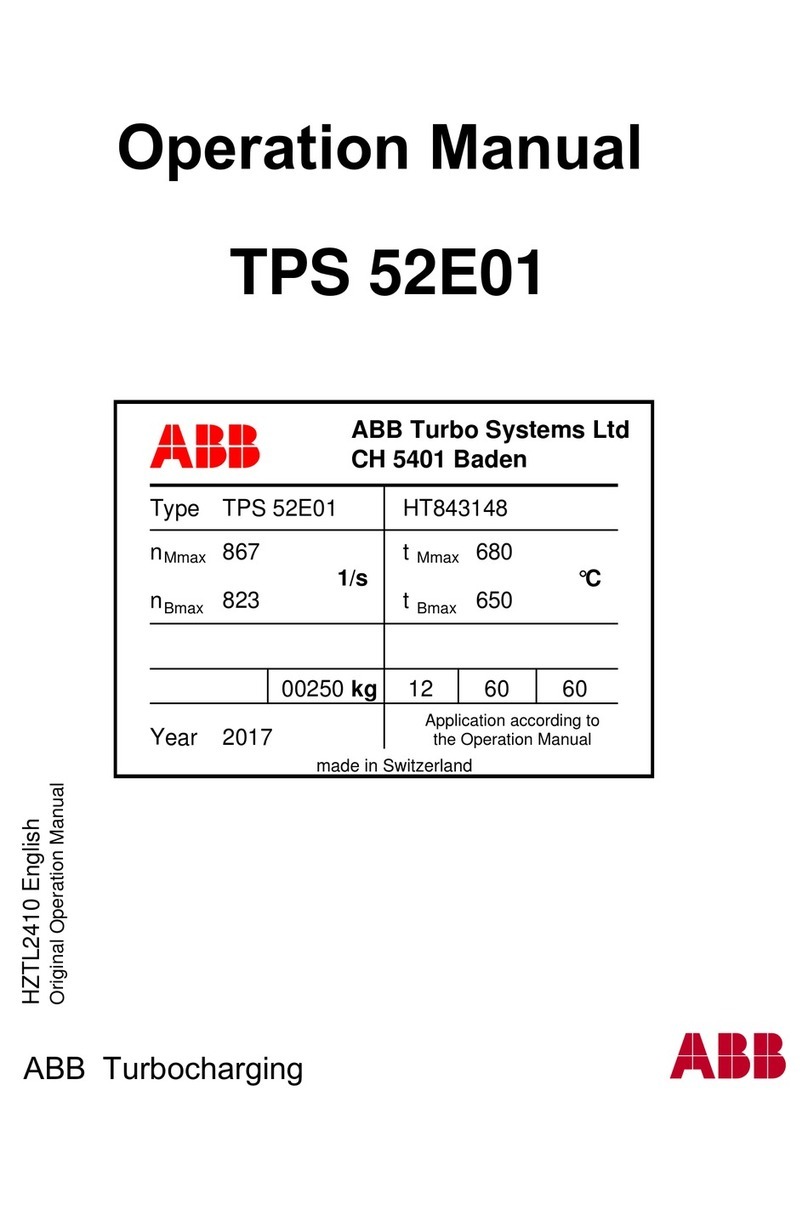

FIGURE 2

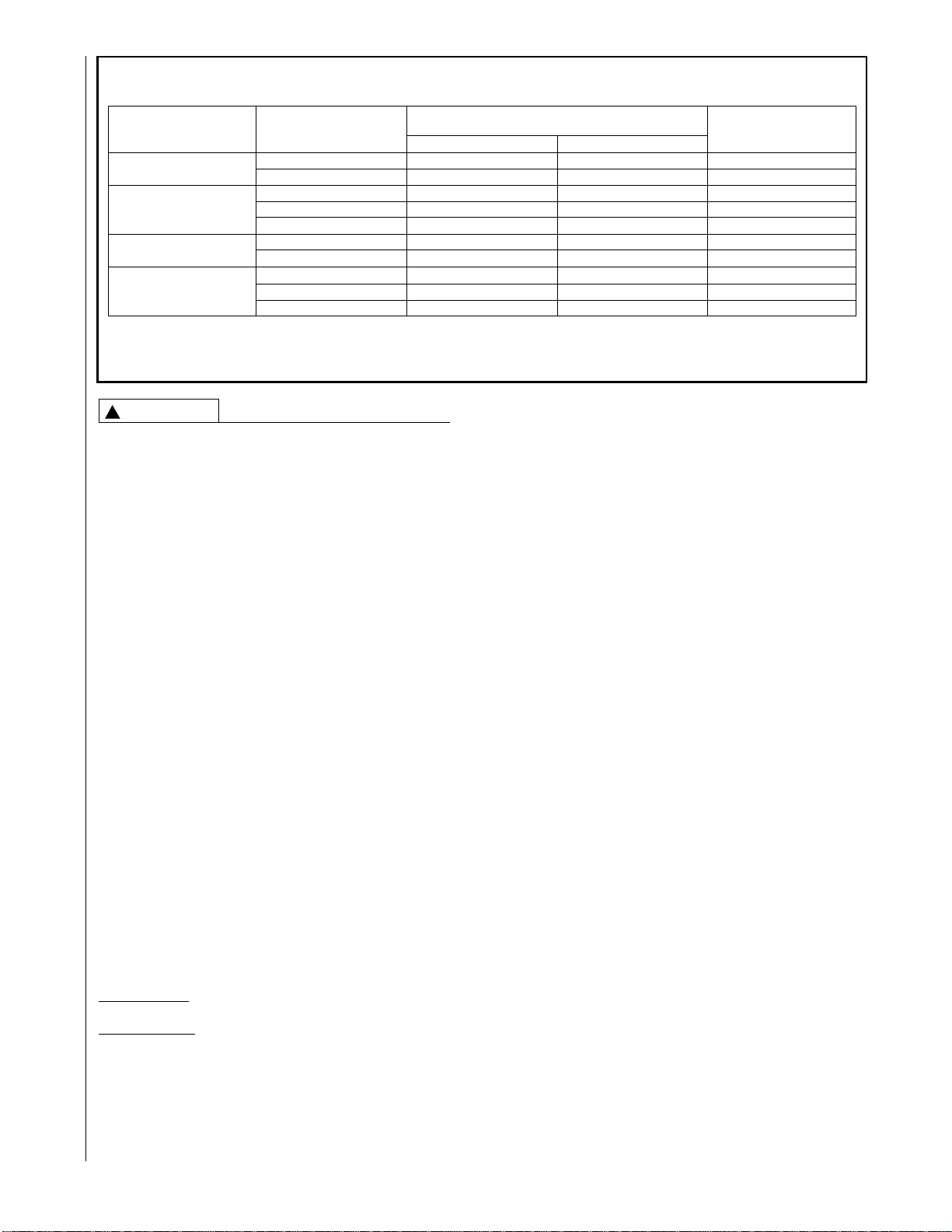

UNIT SPECIFICATIONS

3

3/4 NPT DRAIN

(SECONDARY)

3/4 NPT DRAIN

(PRIMARY)

3-3/8

A

B

SUCTION LINE

LIQUID LINE

1-51/64

C

7-5/8 5-5/8

22

AIRFLOW

FRONT VIEW

PLENUM WIDTH

SIDE VIEW

197/8

Coil

Model

Number

Connections Dimensions (in.) [mm] – Weight (lbs.) [Kg]

Sweat (in.) [mm]

ABC

Coil Weight

(lbs.) [Kg] Shipping Weight

(lbs.) [Kg]

Liquid Suction

I.D. I.D.

RCQD-2417AS 3/8 [9.53] 3/4 [19.05] 17-1/2 [445] 19-7/8 [505] 28 [711] 59 [27] 67 [30]

RCQD-3621AS 3/8 [9.53] 7/8 [22.23] 21 [533] 24-3/4 [629] 28 [711] 74 [34] 83 [38]

RCQD-3624AS 3/8 [9.53] 7/8 [22.23] 24-1/2 [622] 24-3/4 [629] 28 [711] 80 [36] 90 [41]

RCQD-4821AS 3/8 [9.53] 7/8 [22.23] 21 [533] 24-3/4 [629] 28 [711] 74 [34] 83 [38]

RCQD-4824AS 3/8 [9.53] 7/8 [22.23] 24-1/2 [622] 24-3/4 [629] 28 [711] 80 [36] 90 [41]

DIMENSIONS AND WEIGHTS DATA

“A” Minus One Inch

4

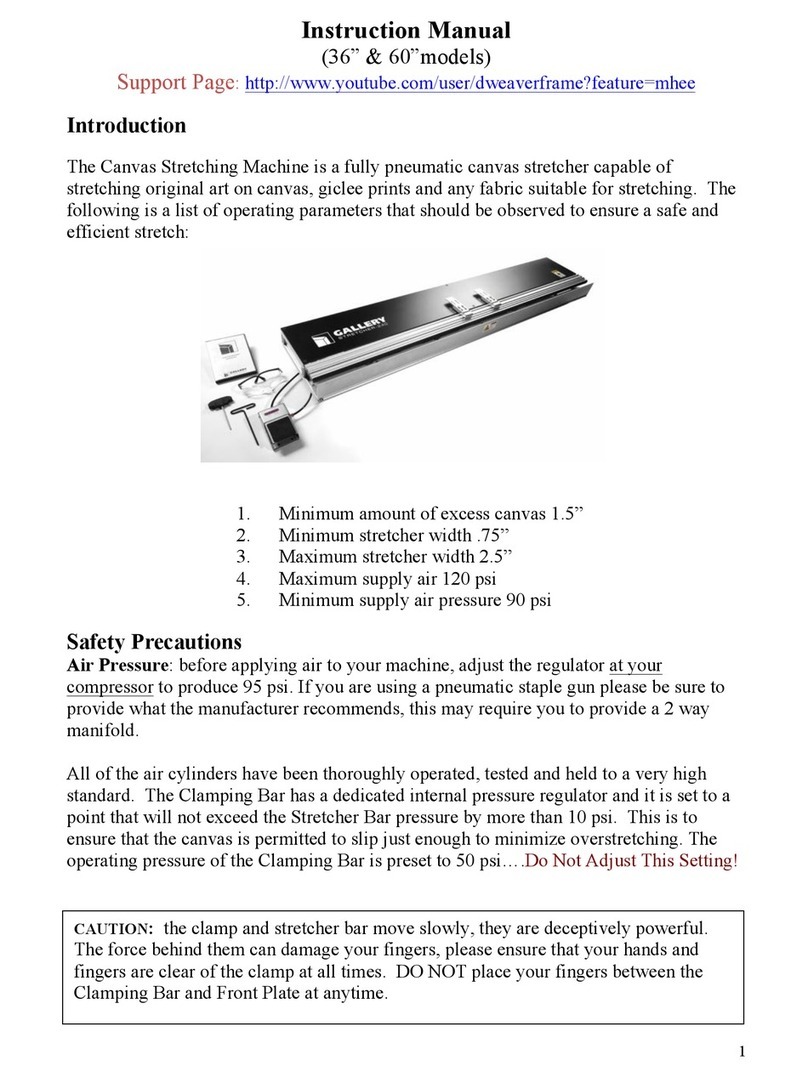

TABLE 1

COIL SPECIFICATIONS / AIRFLOW PRESSURE DROP

Model

Number

RCQD-

2417AS U-H 450/800 4.38 14/3 0.06 0.10 0.14 0.17 0.21 0.25 0.29

[212/378] [0.41] [.015] [.024] [.035] [.042] [.052] [.062] [.072]

3621AS U-H 720/1200 5.83 14/3 0.08 0.10 0.13 0.16 0.18 0.21

[340/566] [0.54] [.02] [.025] [.032] [.04] [.045] [.052]

3624AS U-H 720/1200 5.83 14/3 0.07 0.09 0.11 0.13 0.15 0.17

[340/566] [0.54] [.017] [.022] [0.27] [0.32] [0.37] [0.42]

4821AS U-H 960/1600 5.83 14/3 0.14 0.17 0.19 0.22 0.25 0.29 .032

[453/755] [0.54] [.035] [.042] [.047] [.055] [.062] [.072] [.08]

4824AS U-H 960/1600 5.83 14/3 .11 .13 .15 .17 .19 .23 .25

[453/755] [0.54] [.027] [.032] [.037] [.042] [.047] [.057] [.062]

HIGH EFFICIENCY COOLING COILS

Type

Air

Flow

➀

Approx.

Design

Air Flow

CFM [L/s]

Range

Face

Area

Sq. Ft.

[m2]

Fins-in.

Rows

Deep 600

[283] 700

[330] 800

[378] 900

[425] 1000

[472] 1100

[519] 1200

[566] 1300

[614] 1400

[661] 1500

[708] 1600

[755] 1700

[802] 1800

[850] 1900

[897]

Static Pressure Drop Through Wet Cooling Coil [kPa] (Inches H2O) CFM [L/s]

➀H = Horizontal airflow, U = Upflow

5

TABLE 2

COIL APPLICATION

Coil Model

RCQD Type Air

Flow* Oil Gas

Furnace Width

inches [mm] Plenum Adapter

Upflow

2417AS

3621AS

4821AS

3624AS, 4824AS

U-H

U-H

U-H

U-H

U-H

U-H

U-H

U-H

U-H

U-H

14 [356]

21 [533]

17-1/2 [445]

21 [533]

17-1/2 [445]

24-1/2 [622]

21 [533]

RXBA-AC

21 [533]

21 [533]

24-1/2 [622]

17-1/2 [445] N/A

N/A

RXBA-AC

N/A

RXBA-AC

N/A

N/A

RXBA-AC

N/A

NOTES:

* U = UPFLOW

H = HORIZONTAL

PROPOSITION 65: THIS APPLIANCE CONTAINS

FIBERGLASS INSULATION. RESPIRABLE PARTI-

CLES OF FIBERGLASS ARE KNOWN TO THE STATE

OF CALIFORNIA TO CAUSE CANCER.

All Rheem products meet current Federal OSHA

Guidelines for safety. California Proposition 65 warnings

are required for certain products, which are not covered

by the OSHA standards.

California's Proposition 65 requires warnings for products

sold in California that contain or produce any of over 600

listed chemicals known to the State of California to cause

cancer or birth defects such as fiberglass insulation, lead

in brass, and combustion products from natural gas.

All “new equipment” shipped for sale in California will

have labels stating that the product contains and/or pro-

duces Proposition 65 chemicals. Although we have not

changed our processes, having the same label on all our

products facilitates manufacturing and shipping. We can-

not always know “when, or if” products will be sold in the

California market.

You may receive inquiries from customers about chemi-

cals found in, or produced by, some of our heating and

air-conditioning equipment, or found in natural gas used

with some of our products. Listed below are those chemi-

cals and substances commonly associated with similar

equipment in our industry and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO).

• Formaldehyde

• Benzene

More details are available at the websites for OSHA

(Occupational Safety and Health Administration), at

www.osha.gov and the State of California’s OEHHA

(Office of Environmental Health Hazard Assessment), at

www.oehha.org. Consumer education is important since

the chemicals and substances on the list are found in our

daily lives. Most consumers are aware that products pre-

sent safety and health risks, when improperly used, han-

dled and maintained.

I. INSPECTION

Immediately upon receipt, all cartons, and contents should

be inspected for transit damage. Units with damaged car-

tons should be opened immediately. If damage is found, it

should be noted on the delivery papers and a damage

claim filed with the last carrier.

• After unit has been delivered to job site, remove carton

taking care not to damage unit.

• Check the unit rating plate to be sure equipment match-

es what is required for the job specification.

• Read the entire instructions before starting the installa-

tion. This is particularly important if this is the first instal-

lation for this specific model series.

• Many installation steps done prior to setting the unit in

place can save time and simplify the installation.

II. GENERAL INFORMATION

CODES/REGULATIONS

Units should be installed in accordance with any local

code which may apply and the national codes. Latest edi-

tions are available from: “National Fire Protection

Association, Inc., Batterymarch Park, Quincy, MA 02269.”

These publications are:

• ANSI/NFPA Latest Edition (NEC) National Electrical

Code.

• NFPA90A Installation of Air conditioning and

Ventilating Systems.

• NFPA90B Installation of Warm Air Heating and Air

Conditioning Systems.

REPLACEMENT PARTS

Any replacement part must be the same as or an

approved alternate to the original part supplied. The man-

ufacturer will not be responsible for replacement parts not

designed to physically fit or operate within the design

parameters the original parts were selected for.

When ordering replacement parts, it is necessary to order

by part number and include the complete model number

and serial number from the unit rating plate. (See parts list

for unit component part numbers.)

WARNING

!

6

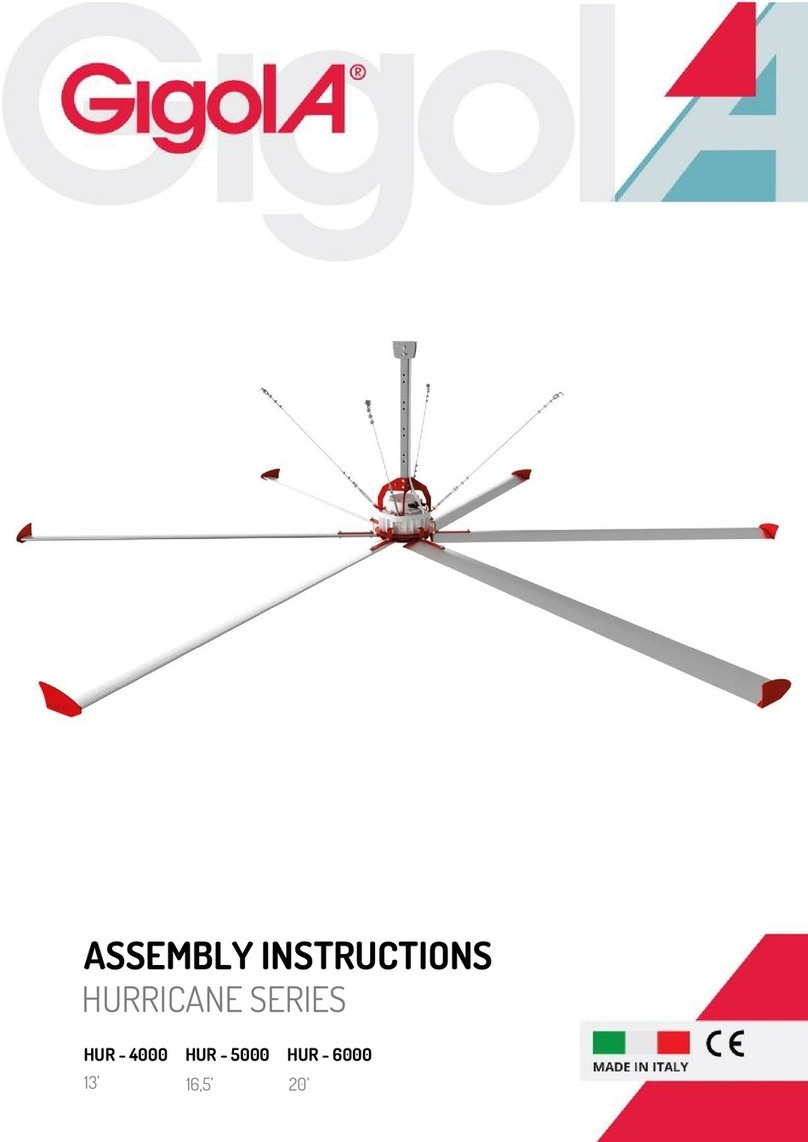

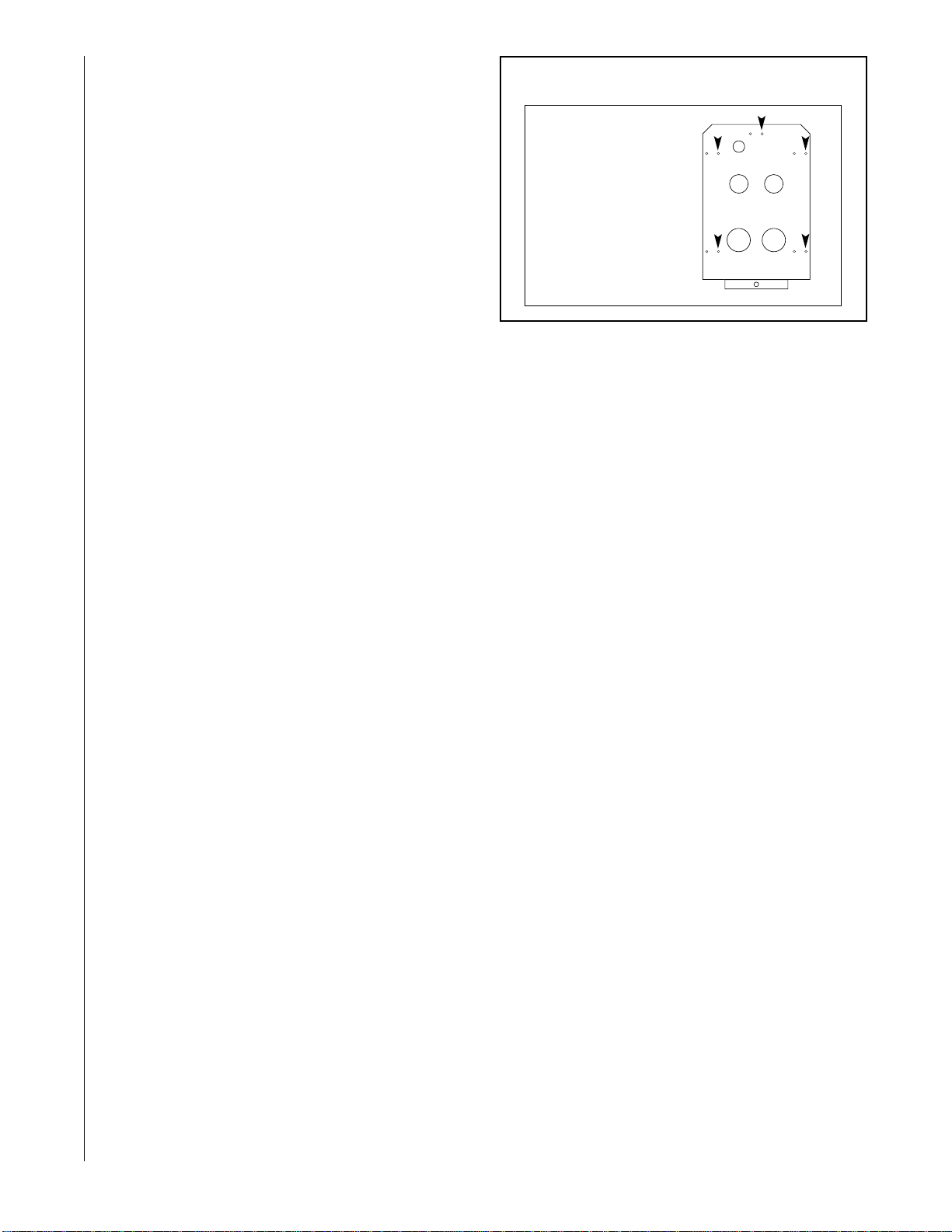

FIGURE 4

HORIZONTAL RIGHT INSTALLATION

III. INSTALLATION

COIL INSTALLATION

WHEN INSTALLING A UNIT WITH COOLING COIL OVER

A FINISHED CEILING AND/OR LIVING SPACE, INSTAL-

LATION OF A SECONDARY FIELD FABRICATED DRAIN

PAN UNDER THE ENTIRE UNIT, TO AVOID DAMAGE TO

CEILING, IS RECOMMENDED.

RCQD- coils can be applied in various upflow and horizon-

tal flow configurations. (See Figure 3. Refer to Table 2 for

approved applications).

FOR HORIZONTAL APPLICATIONS, THE HORIZONTAL

DRAIN PAN MUST BE LOCATED UNDER THE INDOOR

COIL. FAILURE TO PLACE THE PAN UNDER THE COIL

CAN RESULT IN PROPERTY DAMAGE.

FIGURE 3

FACTORY SHIPPED COIL INSTALLATION

UPFLOW

HORIZONTAL LEFT

CAUTION

!

CAUTION

!

VERTICAL UPFLOW AND

HORIZONTAL LEFT INSTALLATION

(SEE FIGURE 3)

1. For vertical or horizontal left installation, no modifica-

tion from current factory configuration is required.

2. Seal the gap around the refrigerant lines with the per-

magum provided in the parts bag.

NOTE: The coil is shipped from factory for the vertical or

horizontal left position. The coil must be converted for use

in horizontal right position.

VERTICAL DOWNFLOW

IMPORTANT: The RCQD-series coil is not approved for

vertical downflow applications.

SEVERE CONDENSATE BLOWOFF CAN OCCUR IF THE

RCQD COIL IS APPLIED IN A VERTICAL DOWNFLOW

APPLICATION.

CAUTION

!

7

HORIZONTAL LEFT INSTALLATION

All RCQD-series coils are shipped for vertical and horizon-

tal left applications. Conversion is required for horizontal

right applications.

HORIZONTAL RIGHT INSTALLATION

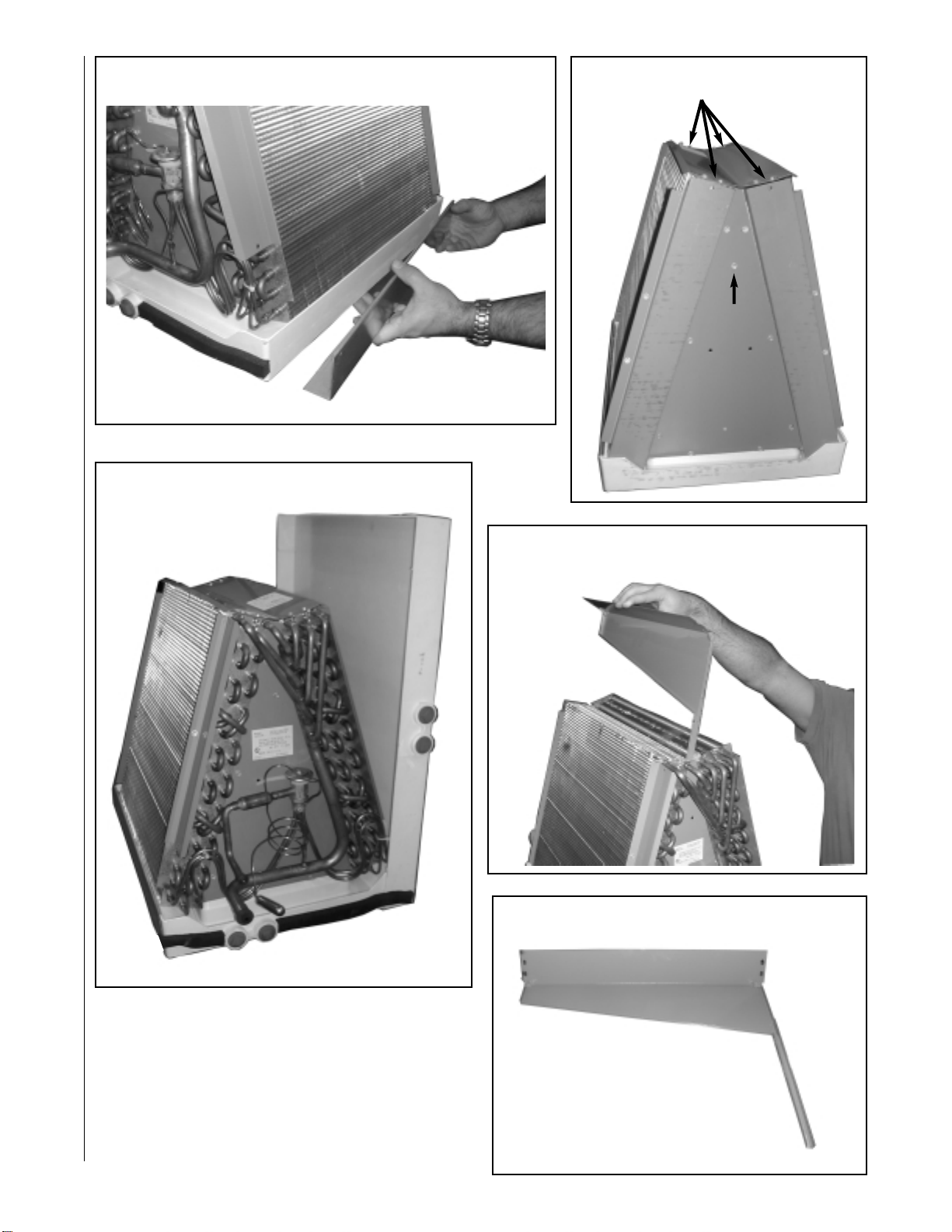

(SEE FIGURE 4)

THE FOLLOWING COIL MODIFICATIONS MUST BE IMPLEMENTED:

1. Remove the entire front panel assembly by removing

all necessary screws.

2. Remove the refrigerant access panel from the front

panel and reinstall it with the right-hand side mounting

holes (see Figure 5).

3. Switch the positions of the left condensate plate and

right blank plate on the front panel.

4. Slide the coil outside of the coil box.

5. Remove the vertical bracket on the right side of the

vertical drain pan (see Figure 6).

6. Remove the horizontal drain pan and place it on the

right side of the coil (see Figure 7).

7. Re-install the vertical bracket on the left side of the

vertical drain pan.

8. Remove all screws from the top of the air stop (see

Figure 8).

9. Remove the center drain trough by removing the

screw located at the back triangular plate (see Figure

8). Ensure glue stop on the bottom of the drain trough.

10. Rotate the center drain trough 180°, front to back (see

Figure 9).

NOTE: Failure to properly rotate the center drain

trough may permit condensate water to blow off the

cooling coil.

11. Apply permagum supplied in parts bag to underside of

drain trough (see Figure 10) in four corners.

12. Re-install the center drain trough and secure it by

tightening the screw through the hole located on the

front triangular plate. Reinstall the top air stop.

13. Replace the coil assembly into the coil box (be sure to

align the vertical brackets properly with the side rail),

taking care not to tear insulation.

14. Locate TXV sensing bulb and slide it through the uni-

versal grommet on the access panel.

15. Reinstall front panel.

16. Seal the gap around the refrigerant lines with the per-

magum provided in the parts bag.

REFRIGERANT CONNECTIONS

Keep the coil connections sealed until refrigerant connec-

tions are to be made. See the Installation Instructions for

the outdoor unit for details on line sizing, tubing installation,

and charging information.

Install refrigerant tubing so that it does not block service

access to the front of the unit.

Use a brazing shield to protect the cabinet’s paint from

being damaged by torch flames.

Coil is shipped with a low (5 - 10 PSIG) pressure charge of

dry nitrogen. Evacuate the system before charging with R-

410A refrigerant.

TXV SENSING BULB

IMPORTANT: Do not perform any brazing with the TXV bulb

attached to the line.

After brazing operations have been completed, clamp the TXV

bulb securely on the suction line at the 2 o’clock position with

the strap provided in the parts bag.

Insulate the TXV sensing bulb and suction line with the provid-

ed pressure sensitive insulation (size 4” x 7”) and secure with

provided wire ties.

NOTE: TXV sensing bulb should be located on a horizontal

section of suction line, just outside of coil box.

CONDENSATE DRAIN TUBING

Consult local codes or ordinances for specific requirements.

IMPORTANT: When making drain fitting connections to drain

pan, use a thin layer of teflon paste, silicone or teflon tape and

install hand tight.

IMPORTANT: When making drain fitting connections to drain

pan, do not overtighten. Overtightening fittings can split pipe

connections on drain pan.

• Do not reduce drain line size less than connection size pro-

vided on condensate drain pan.

• All drain lines must be pitched downward away from the unit

a minimum of 1/8” per foot of line to ensure proper drainage.

• Do not connect condensate drain line to a closed or

open sewer pipe. Run condensate to an open drain or

outdoors.

• The drain line should be insulated where necessary to

prevent sweating and damage due to condensate form-

ing on the outside surface of the line.

• Make provisions for disconnecting and cleaning of the

primary drain line should it become necessary. Install a

2 in. trap in the primary drain line as close to the unit as

possible. Make sure that the top of the trap is below

connection to the drain pan to allow complete drainage

of pan (see Figure 5).

FIGURE 5

REFRIGERANT ACCESS PANEL

NOTE: WHEN CON-

VERTING TO HORIZON-

TAL RIGHT INSTALLA-

TION, USE THE RIGHT-

HAND SIDE MOUNTING

HOLES IN THE REFRIG-

ERANT ACCESS

PANEL

8

FIGURE 6

VERTICAL BRACKET

FIGURE 10

PERMAGUM APPLICATION

FIGURE 9

ROTATE DRAIN TROUGH

FIGURE 7

DRAIN PAN PLACEMENT

FIGURE 8

AIR STOP

SCREWS SCREW

REMOVAL

DRAIN

TROUGH

SCREW

9

FIGURE 11

CONDENSATE DRAIN TRAP

DO NOT OPERATE UNIT WITHOUT

CONDENSATE DRAIN TRAP.

UNIT MUST BE SLOPED

TOWARD DRAIN CONNECTION.

DO NOT OVERTIGHTEN DRAIN FITTING

UNIT

2''

• Auxiliary drain if used should be run to a place

where it will be noticeable if it becomes operational.

Occupant should be warned that a problem exists if

water should begin running from the auxiliary drain

line.

• Test condensate drain pan and drain line after instal-

lation is complete. Pour several quarts of water into

drain pan, enough to fill drain trap and line. Check to

make sure drain pan is draining completely, no leaks

are found in drain line fittings, and water is draining

from the termination of the primary drain line.

V. ACCESSORIES

PLENUM ADAPTER ACCESSORY

RXBA-AC

This plenum adapter accessory is for installation on

cased indoor cooling and heat pump coils. This allows a

nominal size cased coil to be installed on the next small-

er size gas or oil furnace. NOTE: This accessory is for

installation on coil casings to fit gas or oil furnaces

only - this accessory must not be used on electric

furnaces or heat pump air handlers. Consult the instal-

lation instructions packaged with the accessory for prop-

er installation. The RXBA-AC (upflow) can be ordered

factory installed by designation as “with adapters” in the

coil model number.

PLENUM ADAPTER ACCESSORY

RXBA-AE

This plenum adapter accessory is for use with the 24-1/2"

wide cased indoor cooling and heat pump coils. This

allows a 24-1/2” wide cased coil to be installed on a 28”

wide oil furnace. This is a field installed accessory only.

10

11

12 CM 1004

Table of contents

Other Prozone Industrial Equipment manuals