8122419/01 EN . Table of contents 3

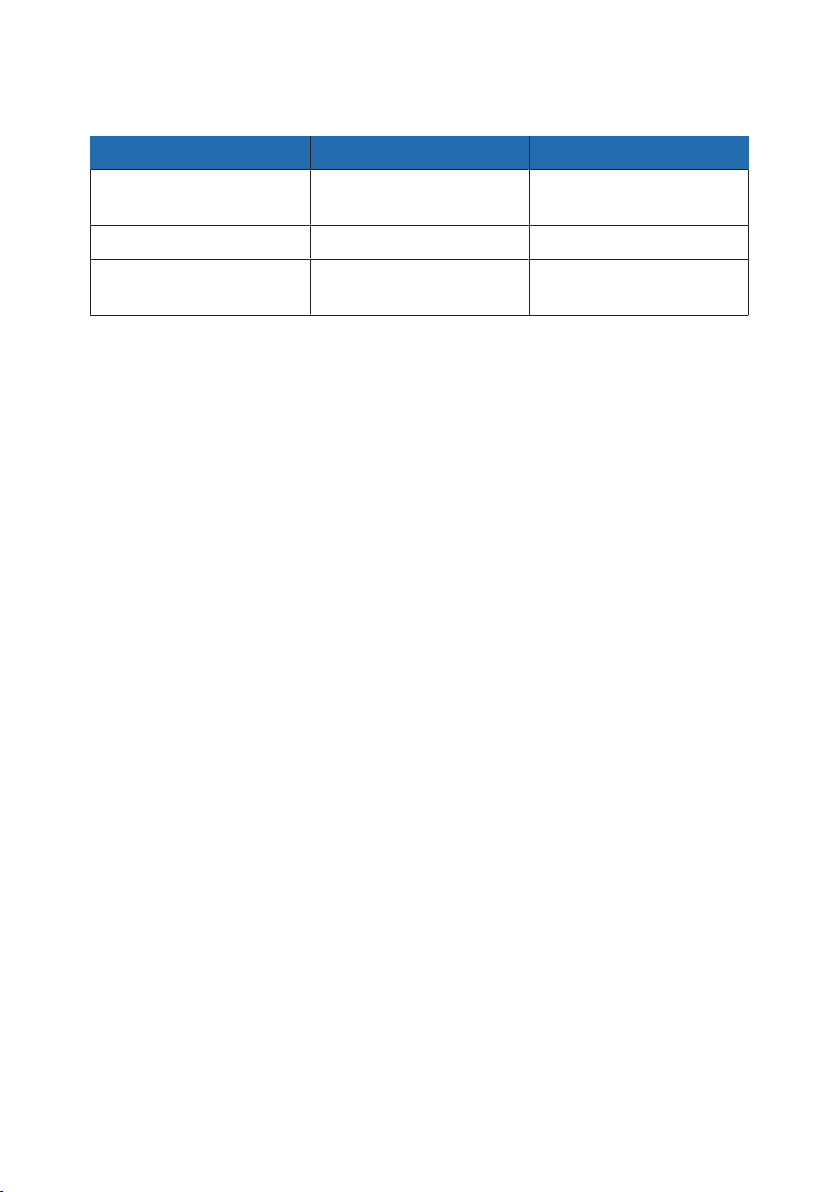

Table of contents

1 Introduction ................................................................... 5

1.1 Manufacturer ...........................................................................................5

1.2 Safekeeping .............................................................................................5

1.3 Notation conventions.............................................................................5

1.3.1 Hazard communication system.............................................................5

1.3.2 Information system.................................................................................6

1.3.3 Instruction system ..................................................................................7

1.3.4 Typographic conventions.......................................................................7

2 Security.......................................................................... 9

2.1 Appropriate use.......................................................................................9

2.2 Fundamental safety instructions.........................................................10

2.3 Personnel qualification .........................................................................12

2.4 Personal protective equipment ........................................................... 13

3 Product description.......................................................15

3.1 Function description and design .........................................................15

3.2 Nameplate ............................................................................................. 17

4 Packaging, transport and storage ................................ 18

4.1 Purpose ..................................................................................................18

4.2 Suitability, structure and production...................................................18

4.3 Markings.................................................................................................19

4.4 Transportation, receipt and handling of shipments ..........................19

4.5 Storage of shipments ...........................................................................21

5 Mounting...................................................................... 22

5.1 Electromagnetic compatibility .............................................................22

5.1.1 Wiring requirement of installation site ..............................................22

5.1.2 Wiring requirement of operating site .................................................23

5.2 Cable recommendation....................................................................... 24

5.3 Mounting and connecting the combi well ......................................... 24

6 Commissioning ............................................................ 33

6.1 Performing a dielectric test ..................................................................33

6.2 Performing comparison measurements.............................................33