Page 2of 28

CONTENTS

WARNINGS............................................................................................................................................................................................................................. 3

OPERATION ........................................................................................................................................................................................................................... 5

SETTING UP THE ECO-100 ........................................................................................................................................................................................ 6

Re-tighten Handway Assembly........................................................................................................................................................................... 6

Purge Air Supply Hose ............................................................................................................................................................................................. 6

BEFORE YOU BLAST......................................................................................................................................................................................................7

Pre-Blast Check. ...........................................................................................................................................................................................................7

Connecting Hoses .......................................................................................................................................................................................................7

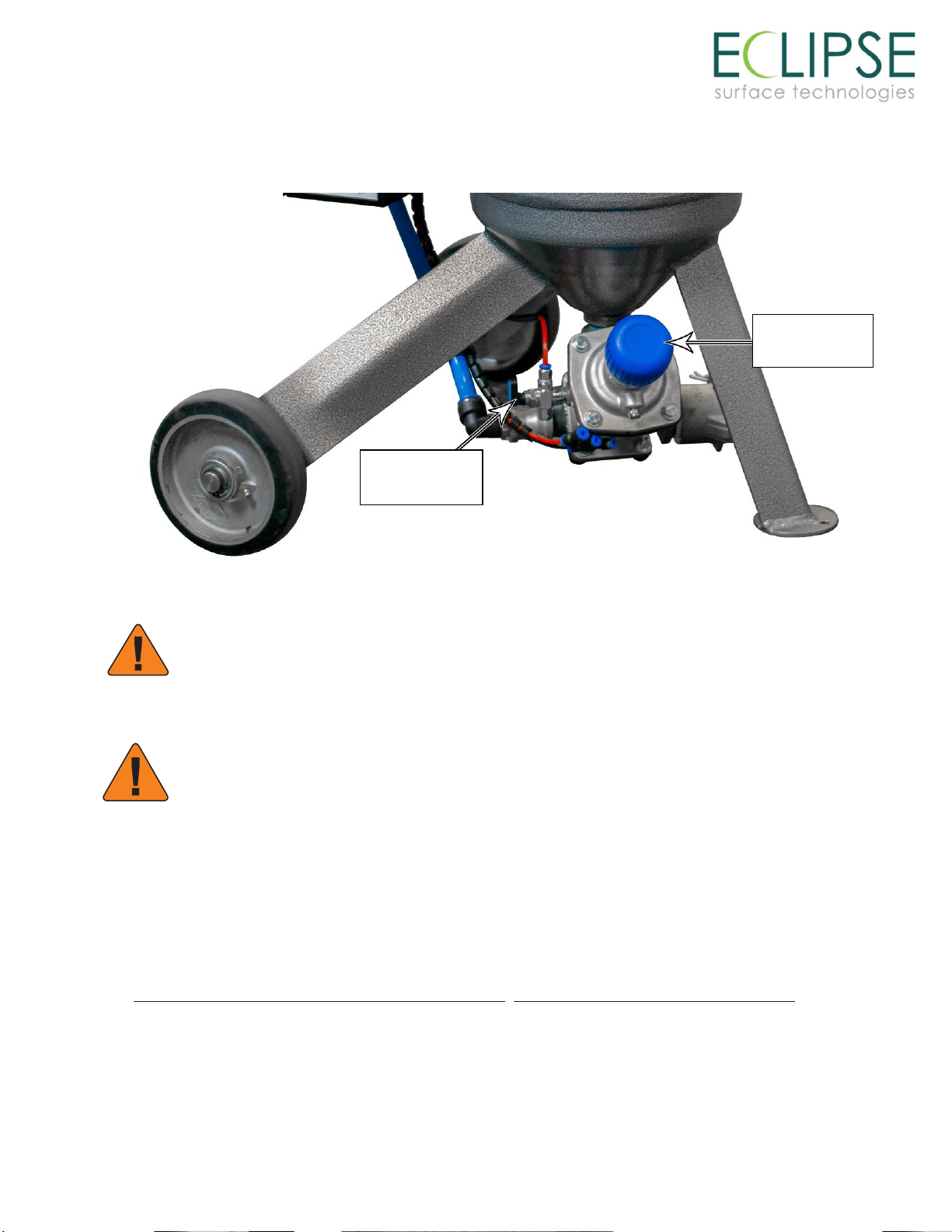

SETTING UP THE ECO-100 ........................................................................................................................................................................................ 8

BLASTING ............................................................................................................................................................................................................................. 10

Adding Abrasive ........................................................................................................................................................................................................ 10

Pressurizing the Abrasive Blaster...................................................................................................................................................................... 11

VAPOR BLASTING & WASHDOWN PROCEDURES..................................................................................................................................12

Water Supply Connection & Pump Pressure Relief Function............................................................................................................. 13

Siphon Tube (Water Connection)...................................................................................................................................................................... 13

Siphoning from a Water Bucket.................................................................................................................................................................. 13

Siphoning from Holding Tank ...................................................................................................................................................................... 13

Water Pump On/Off Control ................................................................................................................................................................................ 14

Using the Wash Down Feature........................................................................................................................................................................... 14

REFILLING THE ECO-100 ............................................................................................................................................................................................. 15

EMPTYING THE VESSEL............................................................................................................................................................................................... 15

Media Valve Drain Tube Procedure:................................................................................................................................................................... 15

SHUTTING DOWN............................................................................................................................................................................................................ 16

HANDWAY CLEAN OUT PROCEDURE..................................................................................................................................................................17

COMPRESSOR REQUIREMENTS............................................................................................................................................................................. 18

CONTROL PANEL DIAGRAM..................................................................................................................................................................................... 19

REPLACEMENT PARTS .................................................................................................................................................................................................20

Water Pump Replacement Parts ..........................................................................................................................................................................20

Pressure Vessel Parts List.........................................................................................................................................................................................21

TeraValve XL Parts List............................................................................................................................................................................................. 22

Auto Air Valve Parts List ......................................................................................................................................................................................... 23

TROUBLESHOOTING .....................................................................................................................................................................................................24

TECHNICAL SPECIFICATIONS .................................................................................................................................................................................26

WARRANTY ..........................................................................................................................................................................................................................27