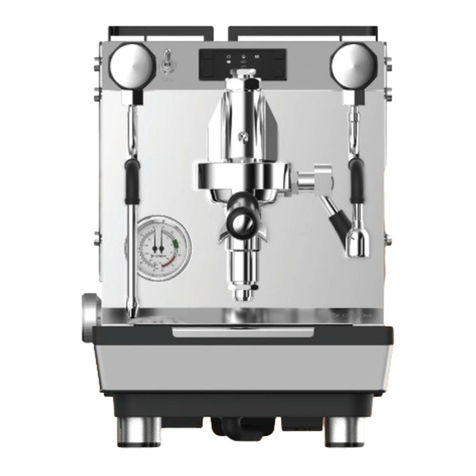

ONE

7

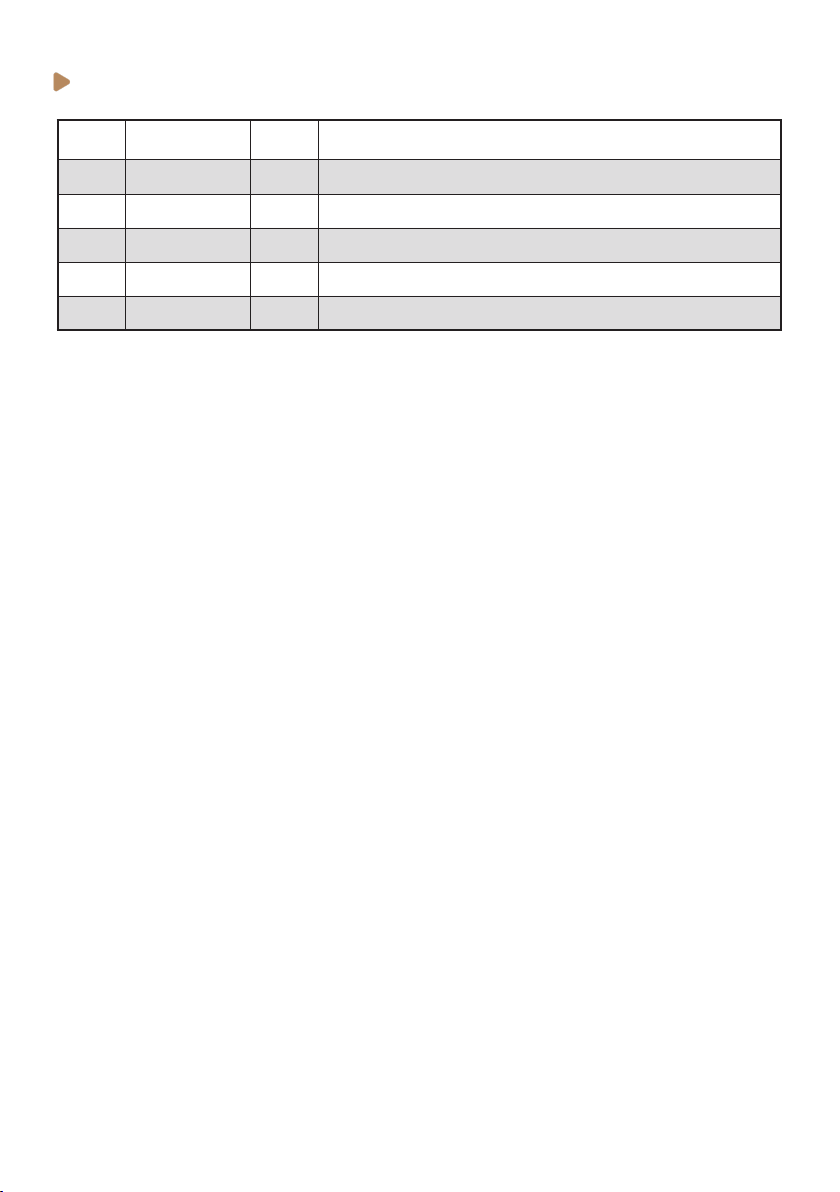

TECHNICAL SPECIFICATIONS

· Machine data

· Accessories

ONE 1B Dual ONE 2B Dual ONE 2B Dual

R-GSP

ONE 2B Dual

R-LFPP

EU Compliance codes: EAEB-I91F-13AP EEEB-I91F-13AP EEEB-I91G-13AP EEEB-I94G-13AP

US Compliance codes: EAJB-K91F-13BP EEJB-K91F-13BP EEJB-K91G-13BP EEJB-K94G-13BP

Temperature control: PID control PID control PID control PID control

Dispensing

control system: Manual Group lever Manual Group lever Manual Group lever

+ GSP

Manual Group lever

+ GSP + LFPP

Steam wand: 1 unit 1 unit 1 unit 1 unit

Hot water outlet: 1 unit 1 unit 1 unit 1 unit

Boiler system: 1 steam boiler

Dual boiler:

1 steam boiler

+ 1 group boiler

Dual boiler:

1 steam boiler

+ 1 group boiler

Dual boiler:

1 steam boiler

+ 1 group boiler

Boiler operating pres-

sure:

0.8 to 1.2 bar /

12-17 psi

0.8 to 1.2 bar /

12-17 psi

0.8 to 1.2 bar /

12-17 psi

0.8 to 1.2 bar /

12-17 psi

Steam boiler volume: 1.7L / 0.45 gal. 1.7L / 0.45 gal. 1.7L / 0.45 gal. 1.7L / 0.45 gal.

Group boiler volume: N/A 1.5L / 0.40 gal. 1.5L / 0.40 gal. 1.5L / 0.40 gal.

EU Power rating: 220-240V~ 50-

60Hz 1800W

220-240V~ 50-

60Hz 1800W

220-240V~ 50-

60Hz 1800W

220-240V~ 50-

60Hz 1800W

US Power rating: 110-127V~ 50-

60Hz 1300W

110-127V~ 50-

60Hz 1300W

110-127V~ 50-

60Hz 1300W

110-127V~ 50-

60Hz 1300W

Water connection: 3/8” Internal thread 3/8” Internal thread 3/8” Internal thread 3/8” Internal thread

Height, width, depth: 420, 300, 458mm /

17, 12, 18in.

420, 300, 458mm /

17, 12, 18in.

420, 300, 458mm /

17, 12, 18in.

420, 311, 458mm /

17, 12, 18in.

Machine weight: 30kg / 66 lb 35kg / 77 lb 35kg / 77 lb 35kg / 77 lb

Ambient noise: < 70 db < 70 db < 70 db < 70 db

For 1B

versions

2-spouts

portalter Filter basket Filter blind Tamper Brush Cleaning

tablets

Units 1 unit 1 of each 1 unit 1 unit 1 unit 1 unit

14 gr.

7 gr.

For 2B

versions

2-spouts

portalter

Filter

basket

Filter

blind Tamper Nozzle

Steam tap Brush Milk Jar Cleaning

tablets

Units 1 unit 1 of each 1 unit 1 unit 1 unit 1 unit 1 unit 1 unit

14 gr.

18 gr.

7 gr.