Instruction Manual

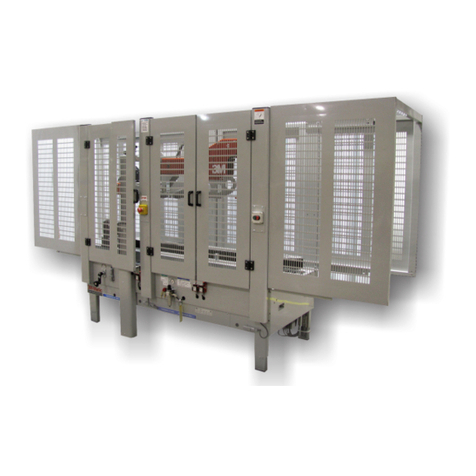

700r-s Stainless Steel, Random Case Sealer, Type 10500

This instruction manual is divided into two sections as follows:

Section IIncludes all information related to installation, operation and parts for the case sealer.

Section II Includes specific information regarding the AccuGlide™ SST 2 Inch Taping Heads.

Table of Contents Page

Section I– 700r-s Stainless Steel Random Case Sealer

Intended Use ................................................................................................................................... 1

Equipment Warranty and Limited Remedy ...................................................................................... 2

700r-s Contents............................................................................................................................... 2

Important Safeguards ...................................................................................................................... 3 - 7

Specifications .................................................................................................................................. 8 - 10

Installation and Set-Up .................................................................................................................... 11 - 15

Receiving and Handling ...................................................................................... 11

Machine Set-Up.................................................................................................. 11 - 14

Packaging and Separate Parts ................................................................. 11 - 12

Infeed Conveyor Assembly ....................................................................... 13

Centering Guides ...................................................................................... 13

Machine Bed Height.................................................................................. 14

Outboard Tape Roll Mounting ................................................................... 14

Bumper Supports ...................................................................................... 15

Box Size Capacity of Case Sealer............................................................. 15

Electrical Connection and Controls ........................................................... 15

Initial Start-Up of Case Sealer................................................................... 15

Operation......................................................................................................................................... 16 - 21

Operating "Warnings" ......................................................................................... 19

Machine Switches and Controls.......................................................................... 17 - 18

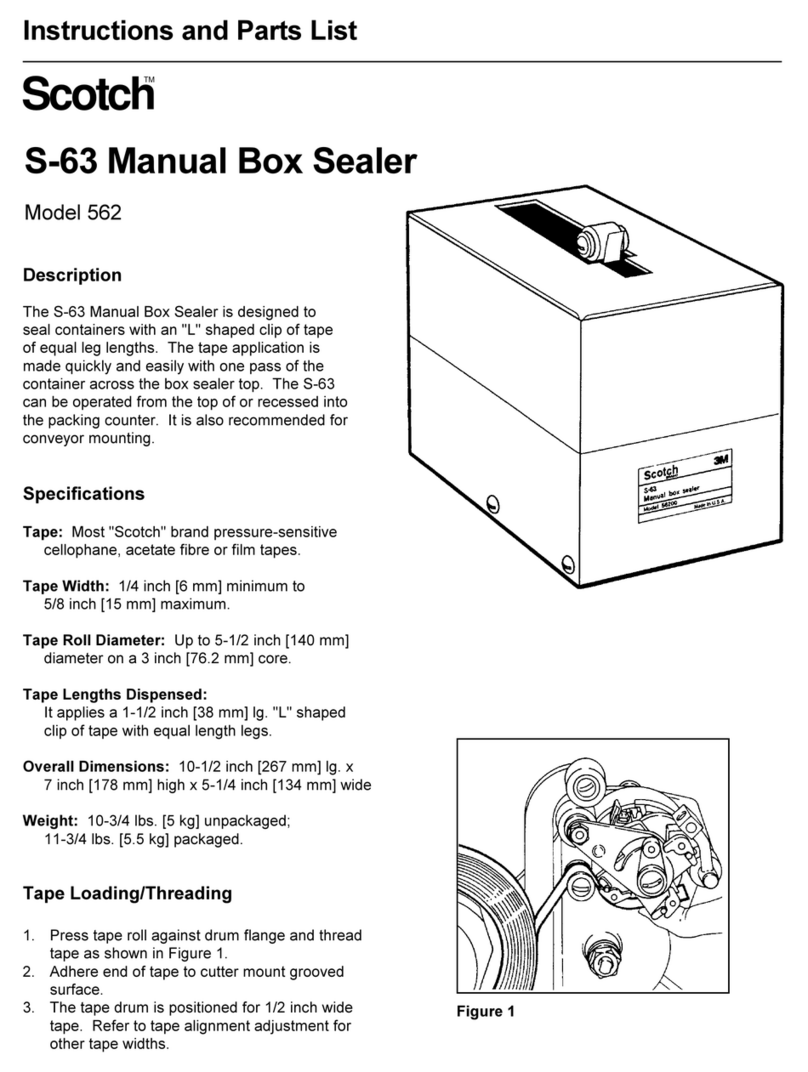

Tape Loading/Threading..................................................................................... 20

Theory of Operation............................................................................................ 20 - 21

Box Sealing ........................................................................................................ 21

i

(Table of Contents continued on next page)