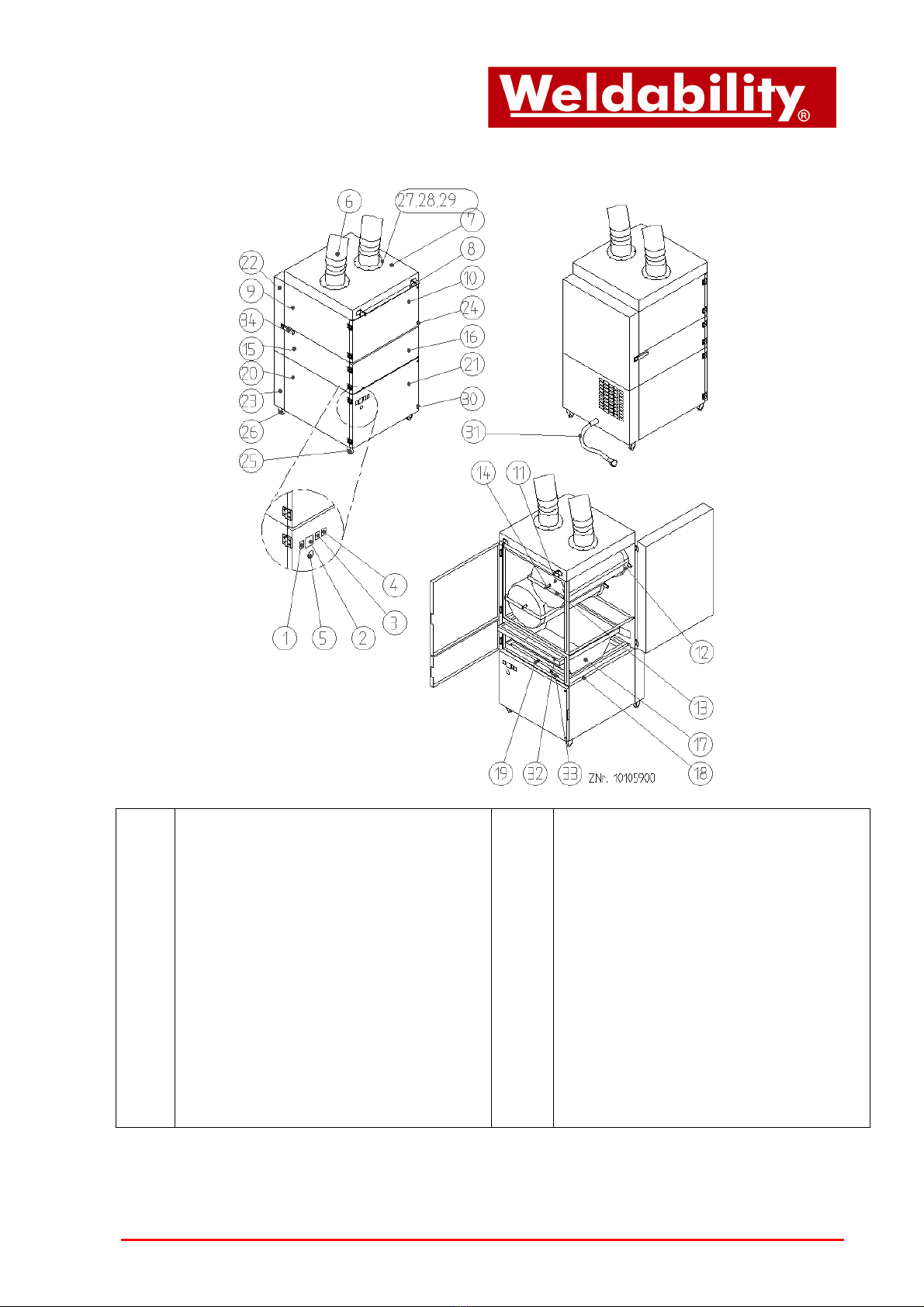

7 Maintenance and service

The accumulation of extracted particles on the filter cartridge will eventually lead to a reduction of

the suction / extraction performance.

The rate of accumulation and thereby the degrading of the filter cartridge (Pos.11) is monitored

electronically. In order to maintain the designed suction performance, the filter cartridge must be

cleaned when the red volume control lamp (Pos.4) illuminates and/or the signal horn (Pos.5)

sounds. (Refer to chapter 7.1: ”Cleaning of filter cartridge / Manual cleaning”)

The accumulated dust particles are blown off the filter by applying compressed air from the clean

side. The released filter cake will drop into the dust collecting bin (Pos.17). (Refer to chapter 7.3:

”Emptying of dust collector bin”)

The useful service life of the filter cartridge greatly depends on the operational environment. For this

reason, it cannot be predicted.

If the operating pressure of the filter unit should not be achieved after cleaning the filter cartridge,

the cartridge must be replaced. (Refer to chapter 7.4: ”Change of filter cartridge”)

Caution:

Stop the operation of the filter unit when changing the filter cartridge.

Exchange of the filter cartridge and the disposal of the element may be executed only in amply

ventilated environments and when using an appropriate protective respiratory mask!

We recommend to use a respiratory mask to DIN EN 141/143 - Protection class P3. It is also

recommended to use appropriate protective gloves.

Dispose of the filters according to the legal regulations. The polluted filter elements must be put in

an appropriate container (e.g. PE bag), bags are available as an option (see list of spare parts)! We

recommand to stockpile some PE bags in time.

The task of changing the filter elements should be executed by trained personnel only!

7.1 Cleaning of filter cartridge

When the red volume control lamp (Pos.4) illuminates and the signal horn (Pos.5) sounds, the filter

cartridge must be cleaned according to the following procedure:

•Disconnect the filter unit from the mains supply (Pull the plug) !

•Close the throttling flap at the suction hood.

•The front doors of the housing (pos.10 + 16 + 21) have to be closed.

•Open the cleaning access door (Pos.22) by releasing the overcentre lock (Pos.34).

•Evenly apply the air jet from the compressed air pistol (available as an option) to the filter

cartridge (Pos.11). (Refer to chapter 6.2. “ Compressed air supply”)

•Apply the air jet for ca. 5 – 10 minutes.

•Close the cleaning access door (Pos.22) and secure it with the overcentre lock (Pos.34).

•Open the throttling flap at the suction hood.

•Connect the filter unit to the mains supply.

•(Observe the information on the type plate!)

Caution:

Without the compressed air supply, the filter cartridge will be clogged, and its performance will

degrade rapidly. The unit will indicate a fault (Filter clogged/full) !

Do not manually shake or wash the filter element as this will damage the filter medium, and the

harmful waste particles will be returned into the workshop's atmosphere !