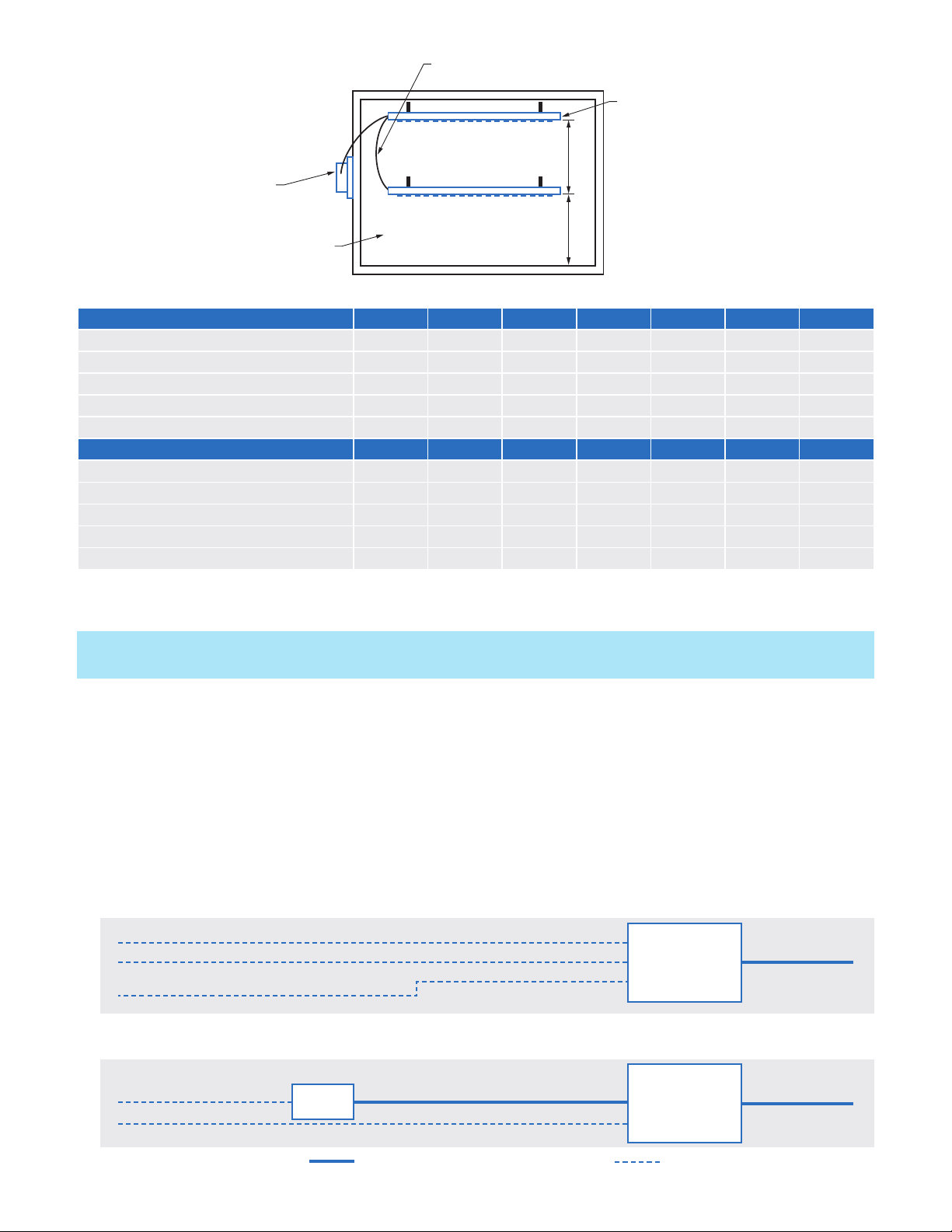

FIGURE 5 Bottom view of PB-CP control panel

FIGURE 4 Left view of PB-CP control panel

DUAL BAR SYSTEM WIRING INSTRUCTIONS

For applications where two linked BARs are required, follow the wiring instructions listed below. Accessories

Required: 3 x Ring Terminals per (2) BAR system.

Remove the white cover plate with the Plasma Air logo from BAR #1 exposing its ring terminals.

1. Snip the control panel connector off the end of the wiring from BAR #2 and attach the new ring terminals to the

loose wire ends.

2. Lay the new ring terminals from BAR #2 on

top of the exposed ring terminals on BAR #1.

3. Reattach the cover plate on BAR #1. Connect

BAR #1 to the Control Panel using the

standard factory connector.

OPERATION

1. When power is supplied to the Plasma BAR

Control Panel and the switch is in the "on"

position, the Plasma BAR ionization assembly

will be activated with the supply fan.

2. The Plasma BAR ionization unit is self

balancing and does not require any type of

adjustment.

3. The benefit of the Plasma BAR ionization

system is realized only when the supply fan

is running. Therefore, to achieve improved

air quality, interlock the Plasma BAR Control

Panel to be activated with the supply fan.

MONITORING CIRCUIT

The Plasma BAR Control Panel includes a

monitoring circuit to verify operation status. The

circuit consists of a relay with isolated normally

open contacts. The contacts remain open

whenever the ionization system is not powered

or if there is a fault in the equipment. Whenever

the ionizer is energized and producing ions, the

normally open contacts close and the green

ion indicator light will illuminate. Connect

the monitoring control wires of the Building

Automation System (BAS) to the dry contacts on

the unit. (See Figure 4 & 5).

TROUBLESHOOTING & MAINTENANCE

The Plasma BAR ionizer should be inspected annually to ensure optimal performance. If any dust has built up on

the tip of the ionizing needles, this can be removed using a simple cotton swab or compressed air. The control

panel requires no maintenance of any kind.

1. If the Plasma BAR ionization unit is not working, check that: The control panel power switch is in the "on"

position, the supply fan is running and the green ion indicator light is illuminated.

2. The power input connections to the control panel are properly connected. Verify all connections are correct

and securely tightened. Reconnect any loose wires.

3. Test the BAS alarm dry contacts using a multimeter set to continuity mode (Ohms symbol). If the multimeter

buzzes the circuit is continuous and operation is normal. If it does not buzz the circuit is broken. Verify other

steps and contact support if needed.

4. If the control panel internal fuse is blown, wait 2 minutes to allow the unit to automatically reset the fuse. Turn

on the power to the control panel. If the fuse blows again, return the control panel to the factory for service.

SEQUENCE OF OPERATION

1. For units that are interlocked with the supply fan control, the BAS controls the start/stop of the air conditioning

unit supply fan.

2. After a one minute time delay on a call for supply fan operation, the BAS monitors the ionization system via the

control panel.

3. Open contacts indicate a fault; closed contacts indicate normal operation.

3540 Toringdon Way Suite 200, Charlotte, NC 28277

phone 1 866 508 1118 www.plasma-air.com info@plasma-air.com

200080-C

© 2023 All rights reserved

GREEN LED

IONIZATION

LIGHT

(MAY APPEAR

SLIGHTLY DIFFERENT

THAN PICTURED)

ON/OFF

SWITCH

12 VOLT DC

IN/OUT PIN

(2.1mm pin)

DRY CONTACTS

FOR BAS

MONITORING

24 VOLT AC

POWER INPUT

CONNECTION