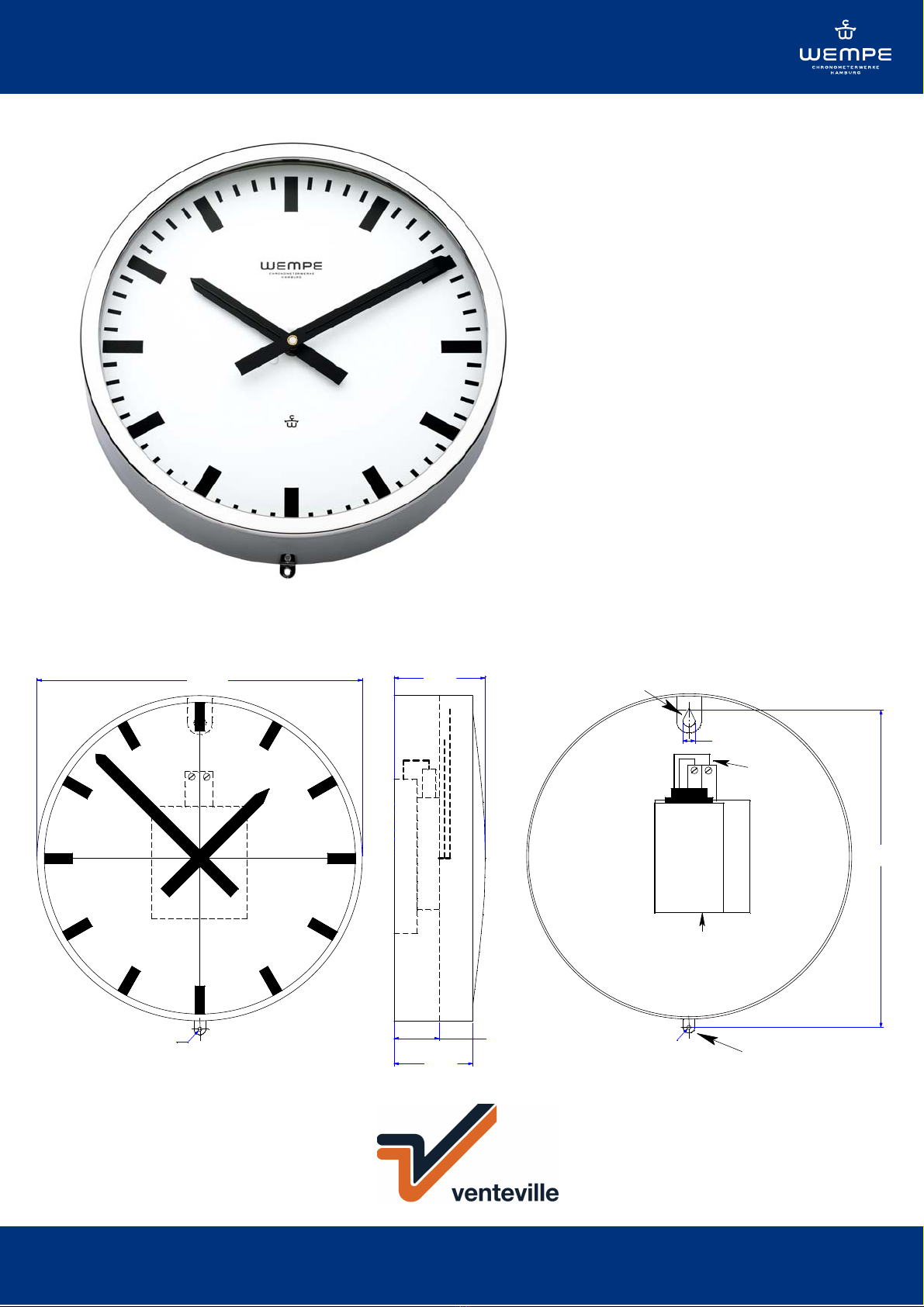

Schiffsuhr CHROM 232mm Mod. 20804/IP ENI v3

Marine clock CHROME 232mm Art.-no. CW850346

V0618

Assembly and commissioning instructions

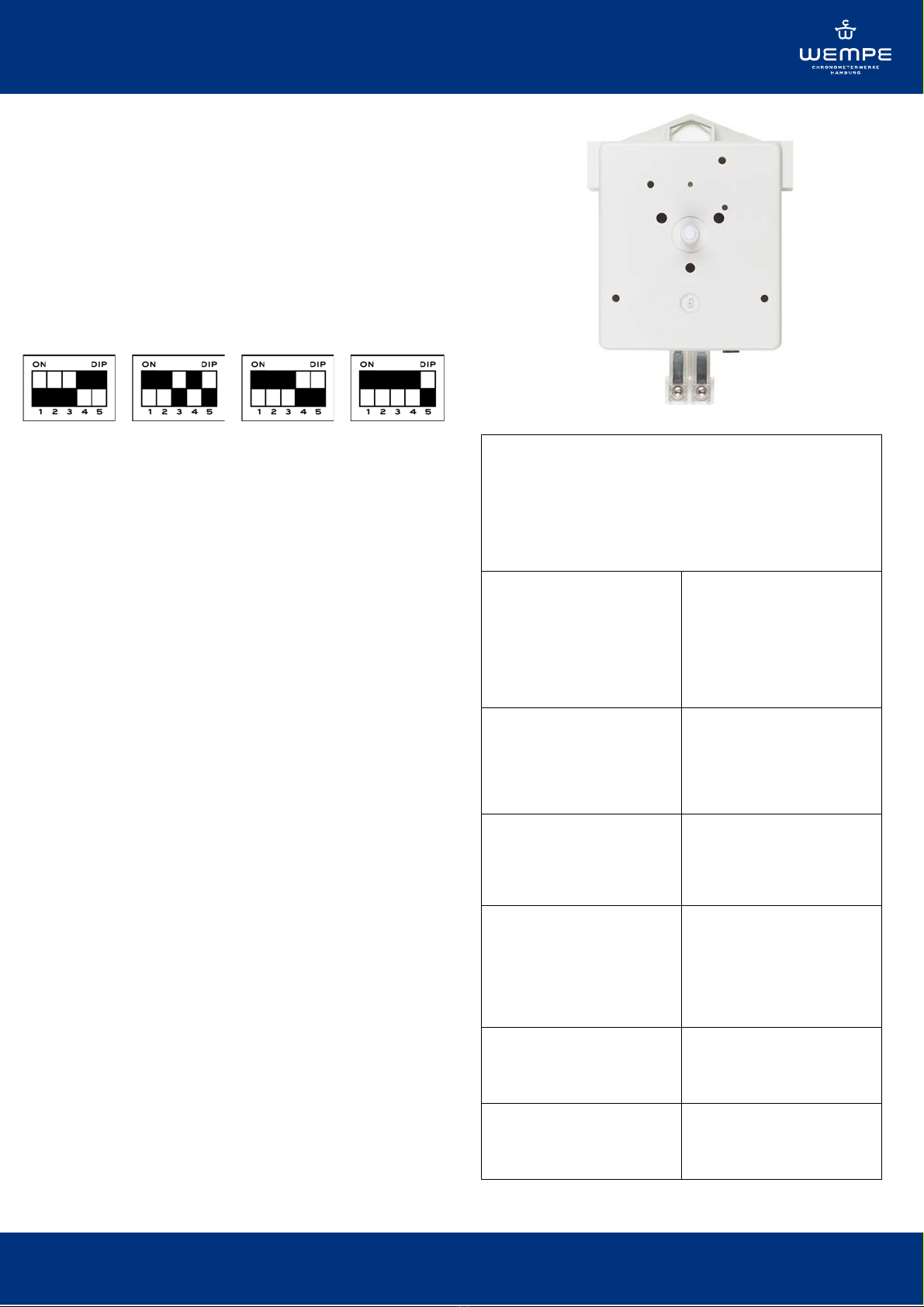

for secondary clock movements’ type: T

This state-of-the-art secondary clock movement can run on

polarizing minute impulses of 12, 24, 48 or 60V DC. It is

suitable for indoor clocks as well as for outdoor clocks with

protected hands with a diameter of 80cm at maximum. The

movement is maintenance-free.

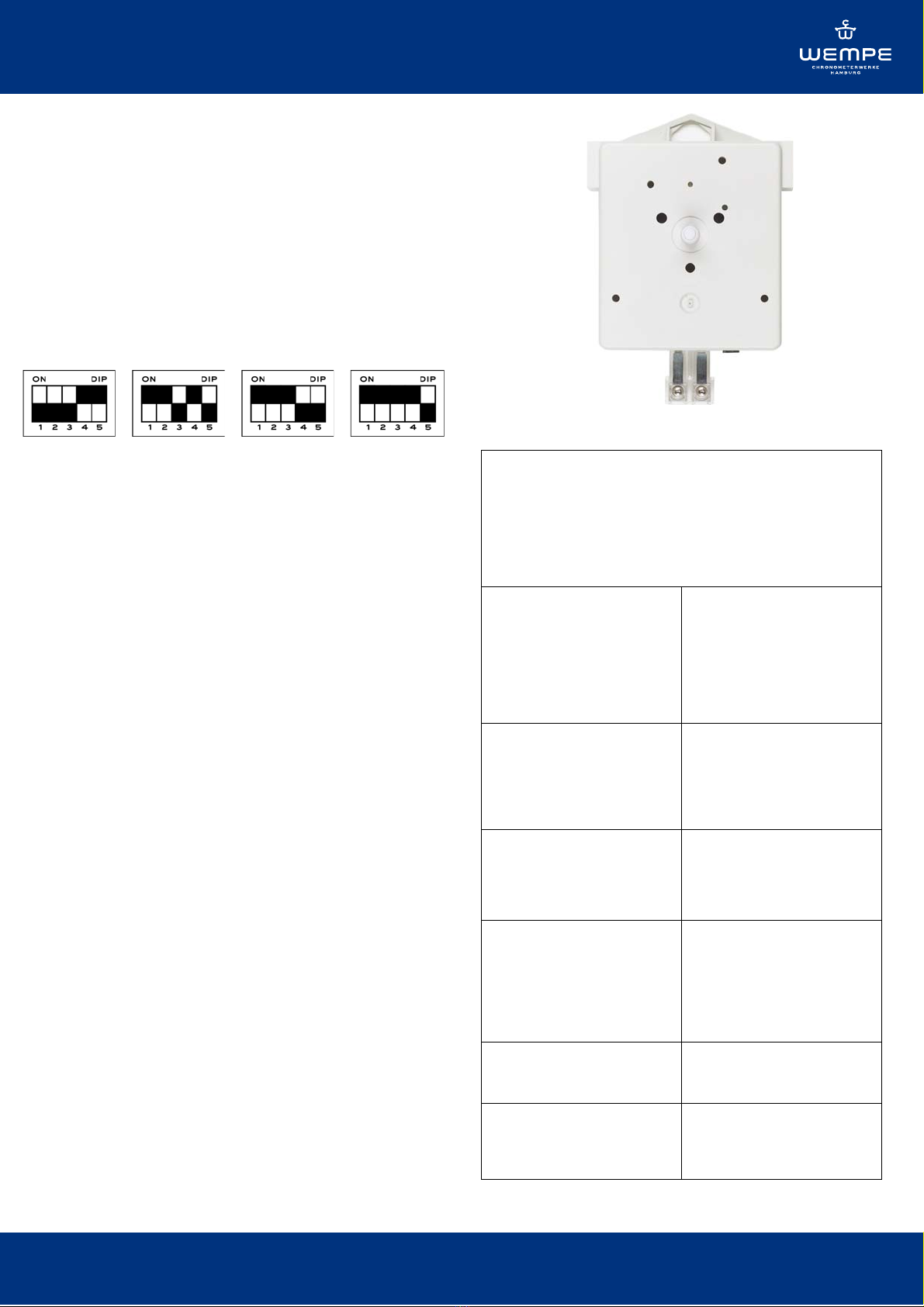

1. Operation voltage

The factory setting for the operation voltage is 24V DC.

Any other voltage can be set on the back of the movement

by means of a DIP-switch.

12V 24V 48V 60V

2. Clocks with a metal or plastic dial

Fix the movement to the dial with a 3-points fixation and

the enclosed pins (maximum thickness 3.5mm). There is

no particular operation position prescribed for the

secondary clock movement. Normally, the DIP-switch

should point downwards.

2.1 Clocks with transparent dials

The movement type TN-Lang has to be used for watches

with a dial made of acrylic glass (maximum thickness

12mm). The motion-work of this movement type is 36mm

long. Place the movement from the backside into the

centre hole of the dial with or without distance washers

(depending on the dial thickness), with the paperboard

washer and the rubber washer. Then place another rubber

washer from the front side on it and fix the movement by

means of the centre fixation screw.

3. Assembly of the hands

Place the hour hand on the hour arbour. If necessary, the

liner of the hand has to be slightly squeezed. Then place

the minute hand on the minute arbour and tighten the pin

screw M2 of the liner. Please pay attention that there is

enough space between the hands. To check this, turn the

minute hand until the clock is set to 12 o’clock. If the

hands are correctly fixed and adjusted, they are now one

on top of the other. If not, you have to adjust the hands

once again.

4. Connection to the power supply

Fix the master clock cables to the 2-poles plug. Should

there be a difference of one minute between the master

and secondary clock after putting the clocks into operation,

turn the 2-poles plug by 180°.

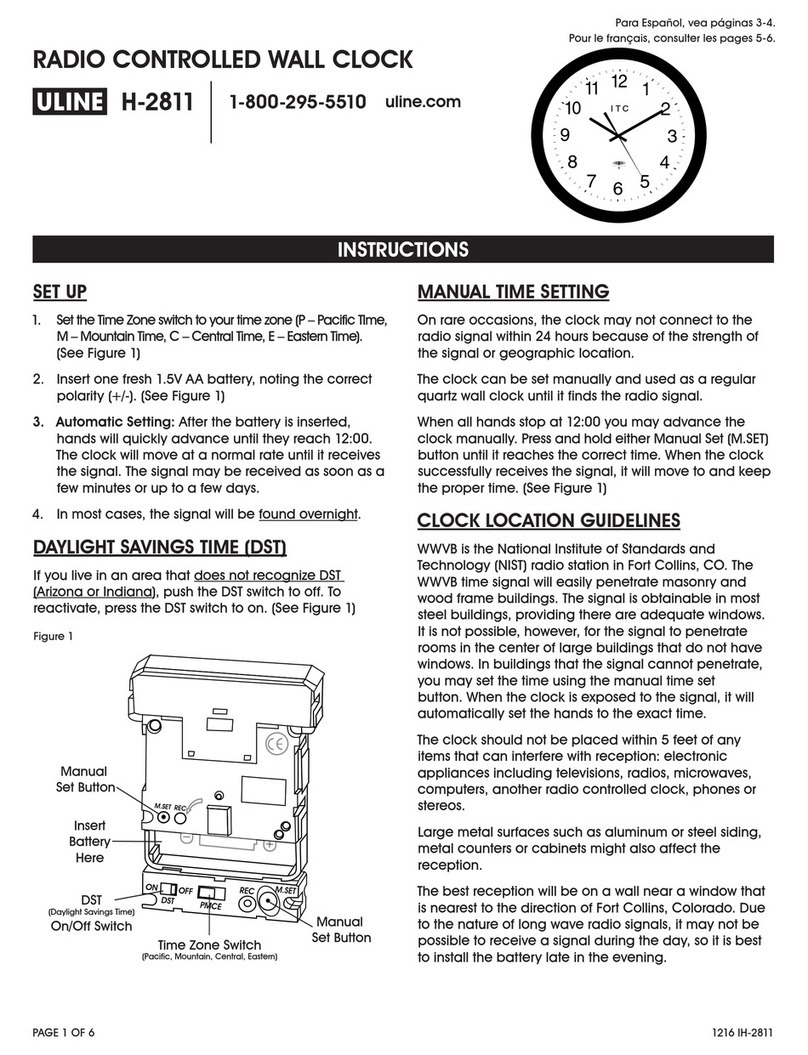

5. Setting of the hands

This can be done either manually by turning the minute

hand or by means of the setting bottom placed in a

countersink on the backside (using a screwdriver).

Technical data

Minutes slave clock movement type: T

up to 30 cm of dial diameter

for non-transparency dials

Planning information:

Electrical connection

For the operation and the transmitting of the minute impulse

is a two-wire line necessary.

Case

Width

Height

Height with SC in-series

adapter

Depth

Material

79,2 mm

92 mm

114 mm

21,5 mm

Synthetic material

Minute pointer shaft

Length from dial layer

Socket length

Diameter

Material

14 mm

4,4 mm

4 mm

Synthetic material

Hour pointer shaft

Length from dial layer

Diameter

Material

9 mm

6 mm

Synthetic material

Electrical values

Impulse-nominal voltage

Impulse current

Insulating resistance

Torque at Impulse-nominal

voltage

12, 24, 36, 48 ,60 Volt

12 mA at 12 V, otherwise 6

mA

800 Volt

150 cmp

Way of fastening

Three hole Spreading rivet, synthetic

material

Surrounding values

Protective system

Environmental temperature

Weight

IP 51

-25 °C to +70 °C

ca. 0,2 kg