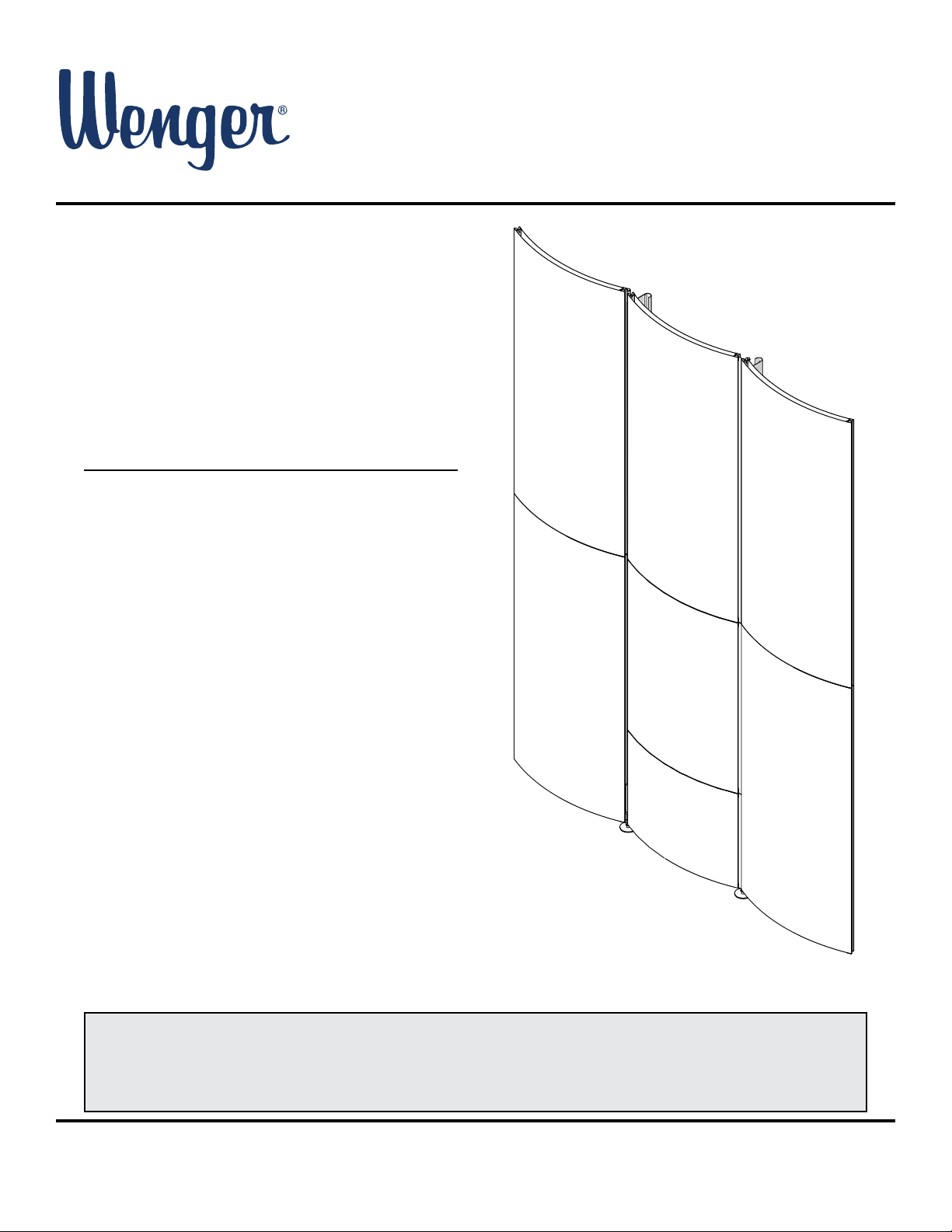

Installation Instructions

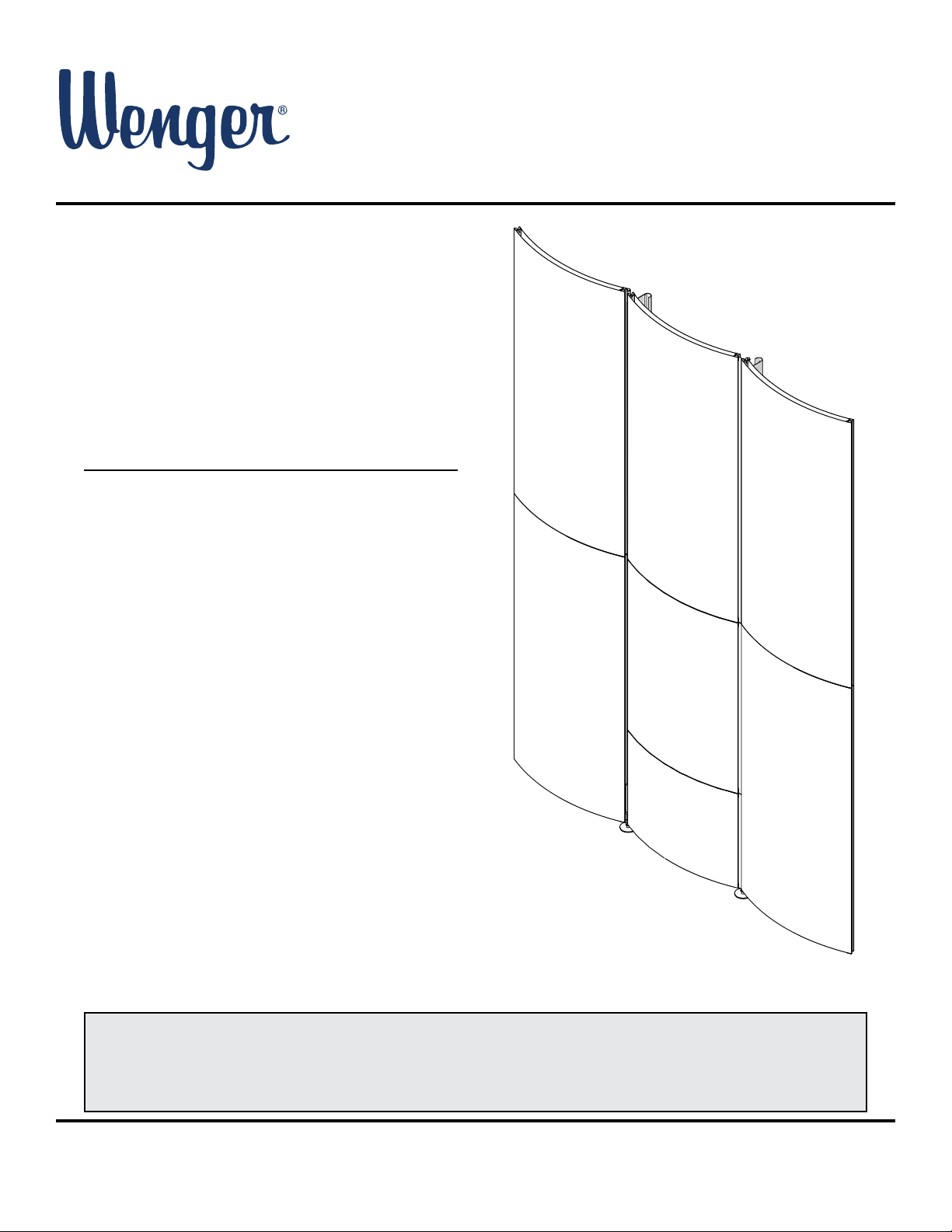

Diva

®

Acoustical Tower

©Wenger Corporation 2020 Printed in USA 2020-02 Part #185C755-05

Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448

Questions? Call.....USA: (800) 4WENGER (493-6437) • Worldwide: +1-507-455-4100 • wengercorp.com

Contents

Note: Please read and understand these instructions before installing.

Note: Review all of the Installation Drawings and Reference Drawings.

Note: Three or more people are recommended to work together during assembly and installation.

Note: If you need additional information, contact Wenger Corporation using the information below.

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manufacturer ....................................2

Intended Use ....................................2

Installation ......................................2

Warranty ........................................2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

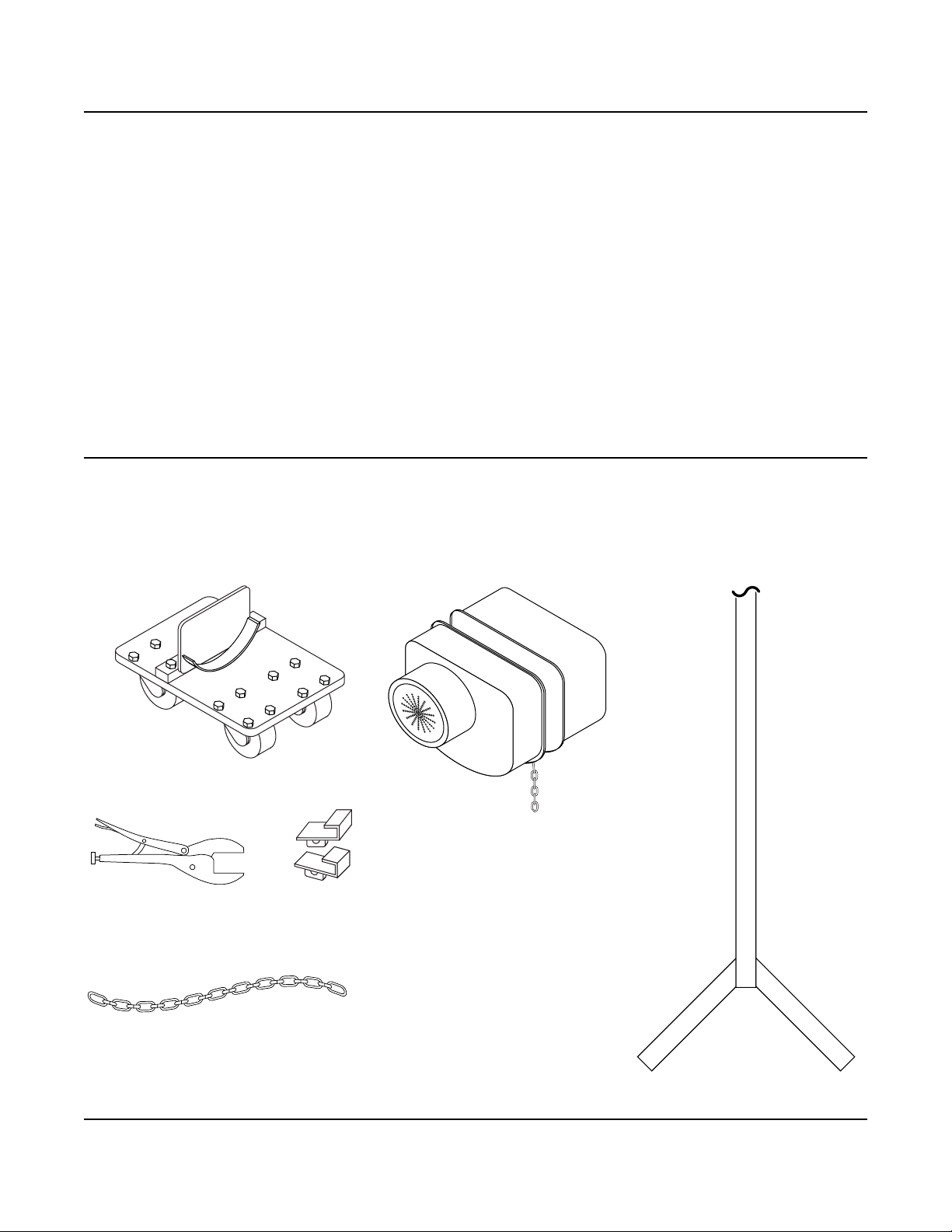

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rigging Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

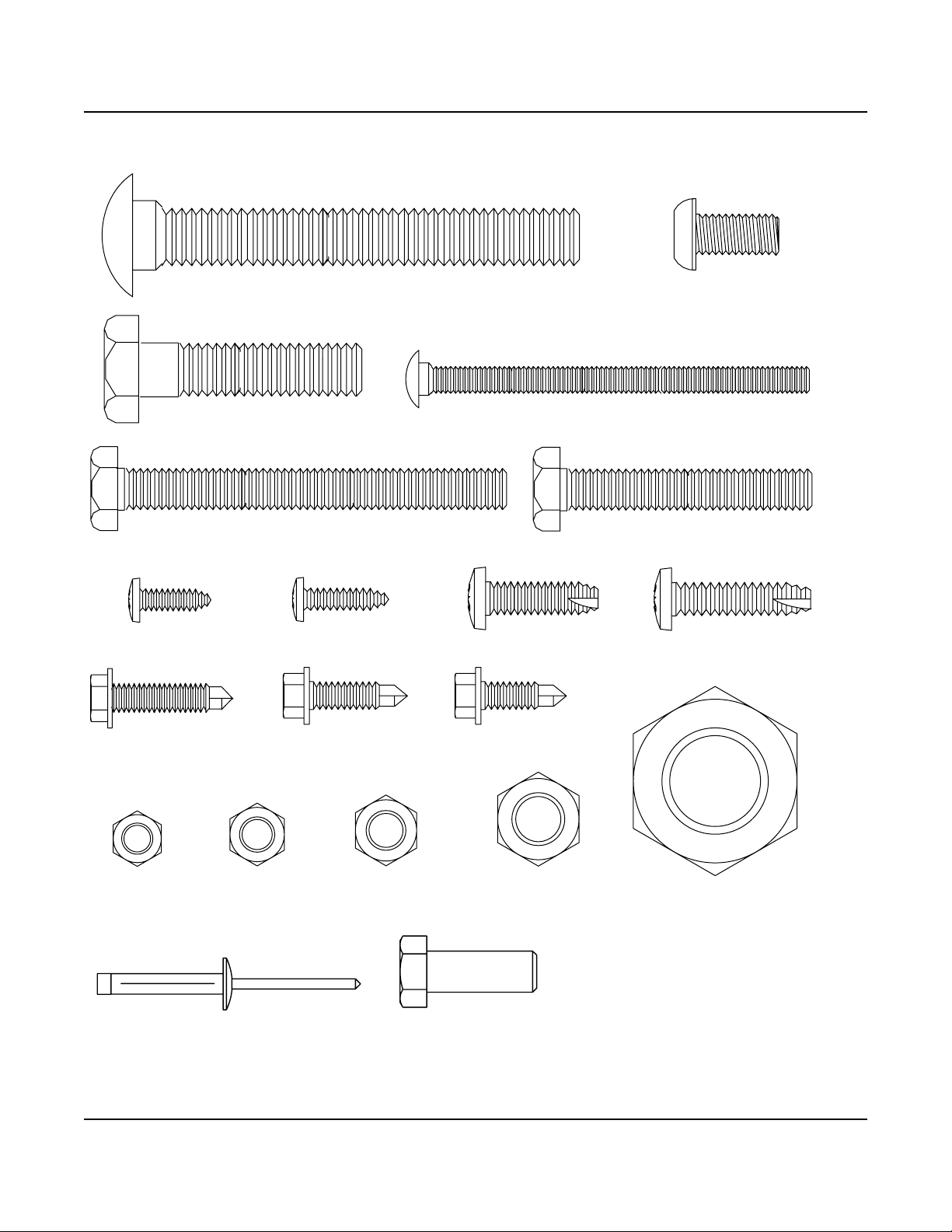

Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

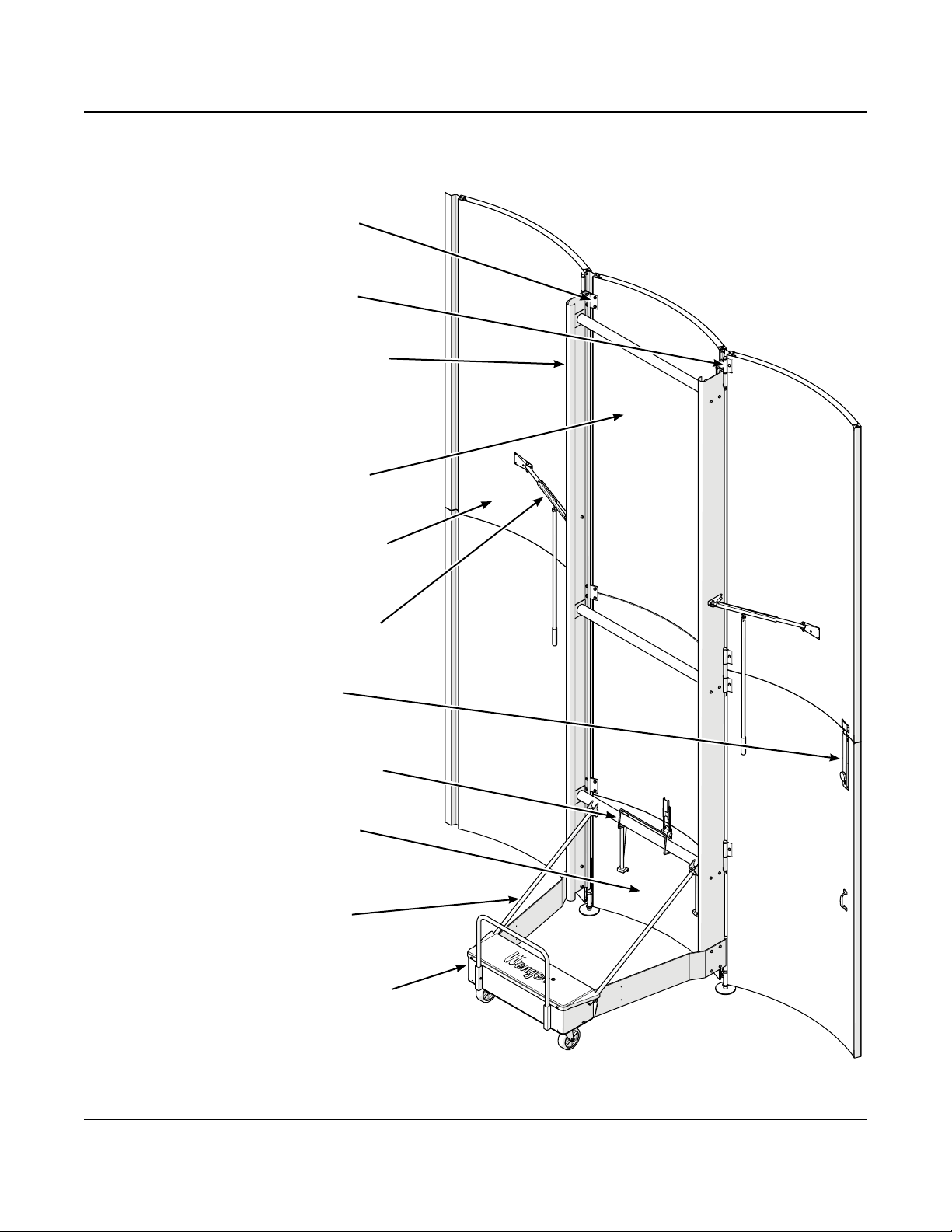

Tower Assembly Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tower Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assemble the Tower Frame .........................7

Assemble the Center Panels ........................8

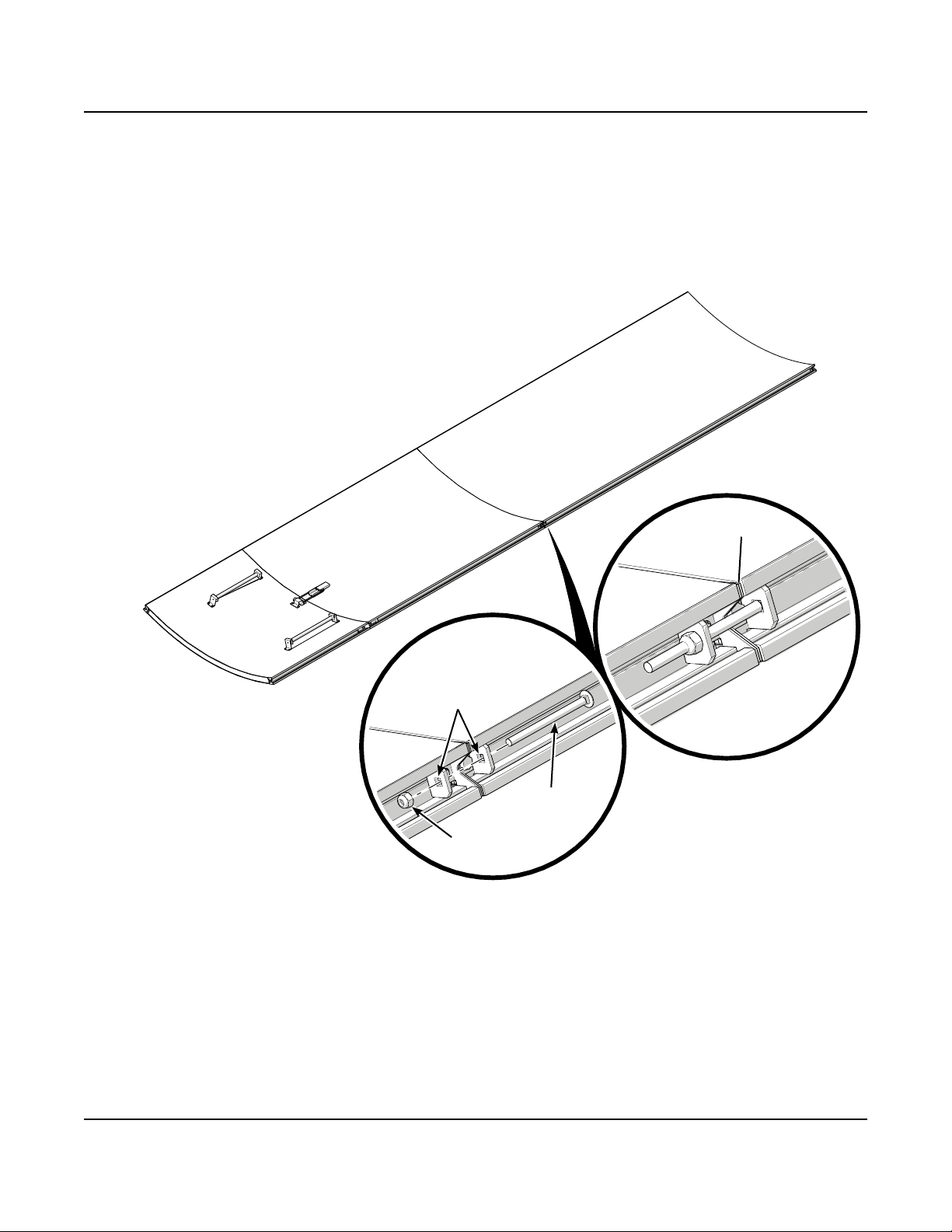

Attach Trim to the Center Panels .....................10

Separate Lower Filler Panel .........................11

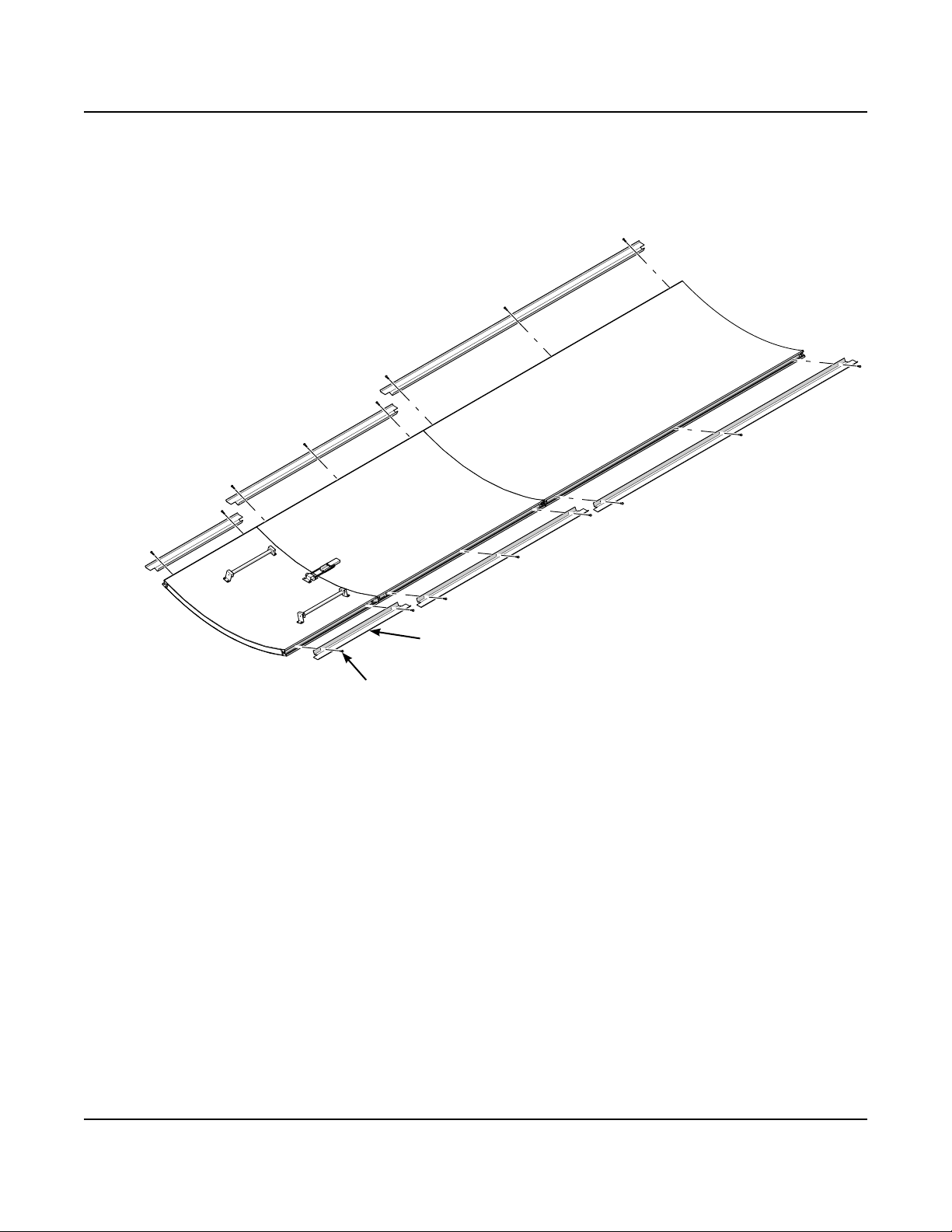

Attach Frame to the Center Panels ...................12

Attach Base .....................................14

Attach Wing Panels ...............................16

Attach Leveler Assembly ...........................18

Attach Wing Stays ................................19

Attach Slide Lock .................................21

Attach Door Pull Handle ............................22

Lifting Tower .....................................23

Install Counterweights .............................25

Attach Base Handle ...............................26

Store Lower Filler Panel ............................27

Attach Lower Filler Panel ...........................28

Moving Towers ...................................29

Decals, Numbers and Logos . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Final Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Visit the Diva Acoustical Shell web page at wengercorp.com for more information.