Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

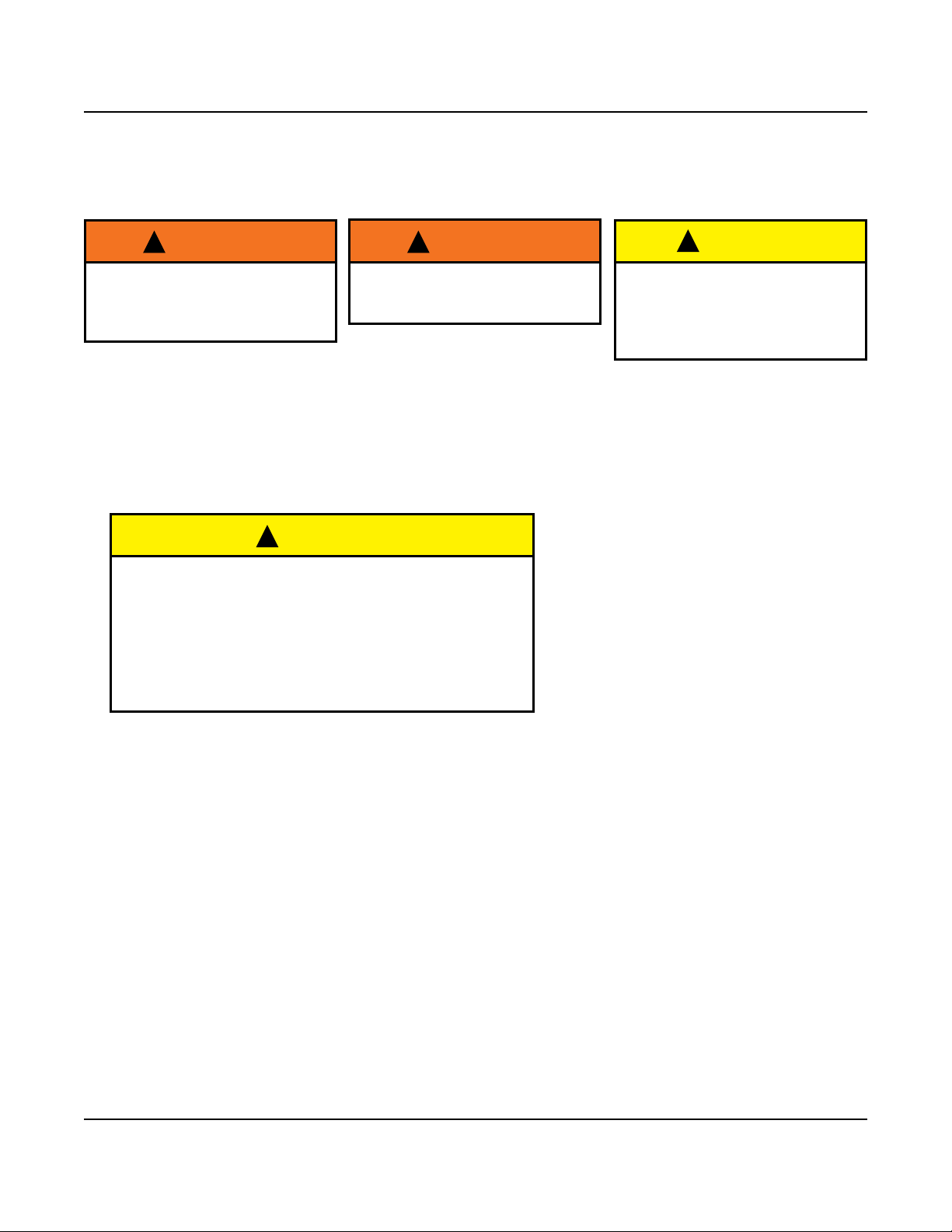

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

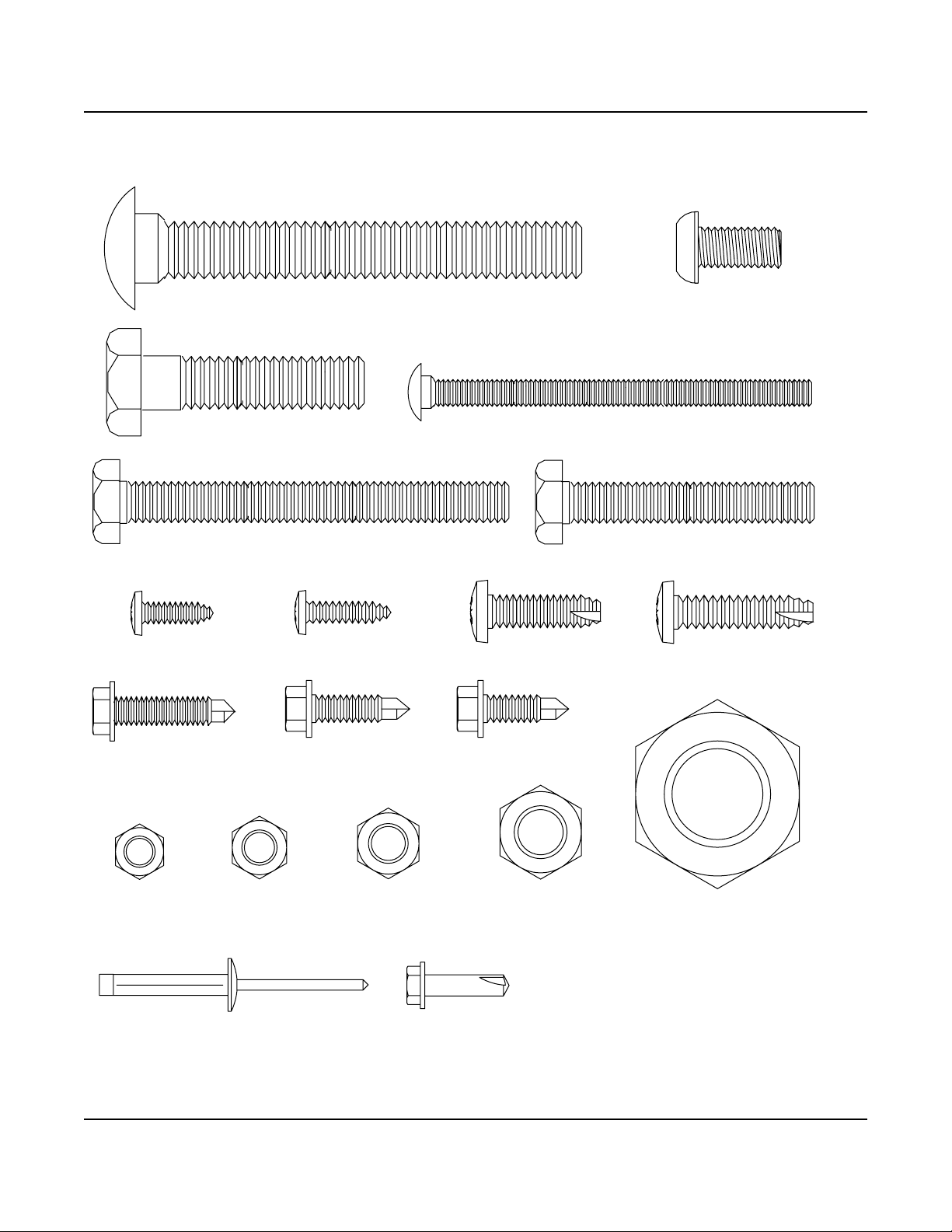

Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

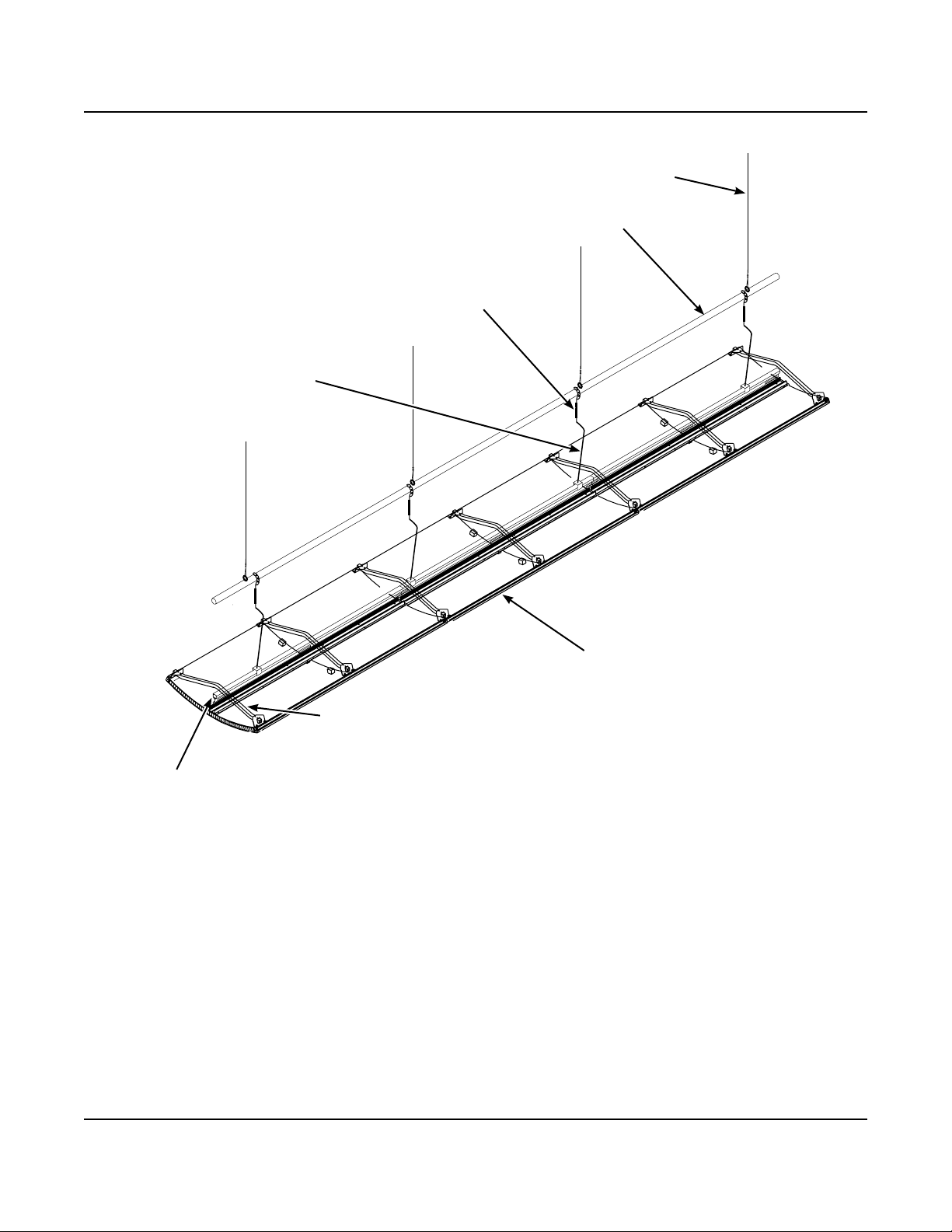

Ceiling Assembly Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ceiling Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assemble the Truss................................7

Mark the Stage Area ...............................8

Attach the Hanger Arms to the Batten .................9

Attach the Hanger Arms to the Truss Assembly ..........12

Assemble a Ceiling Row Panel.......................14

Attach the Truss Assembly to the Ceiling Panel Row......16

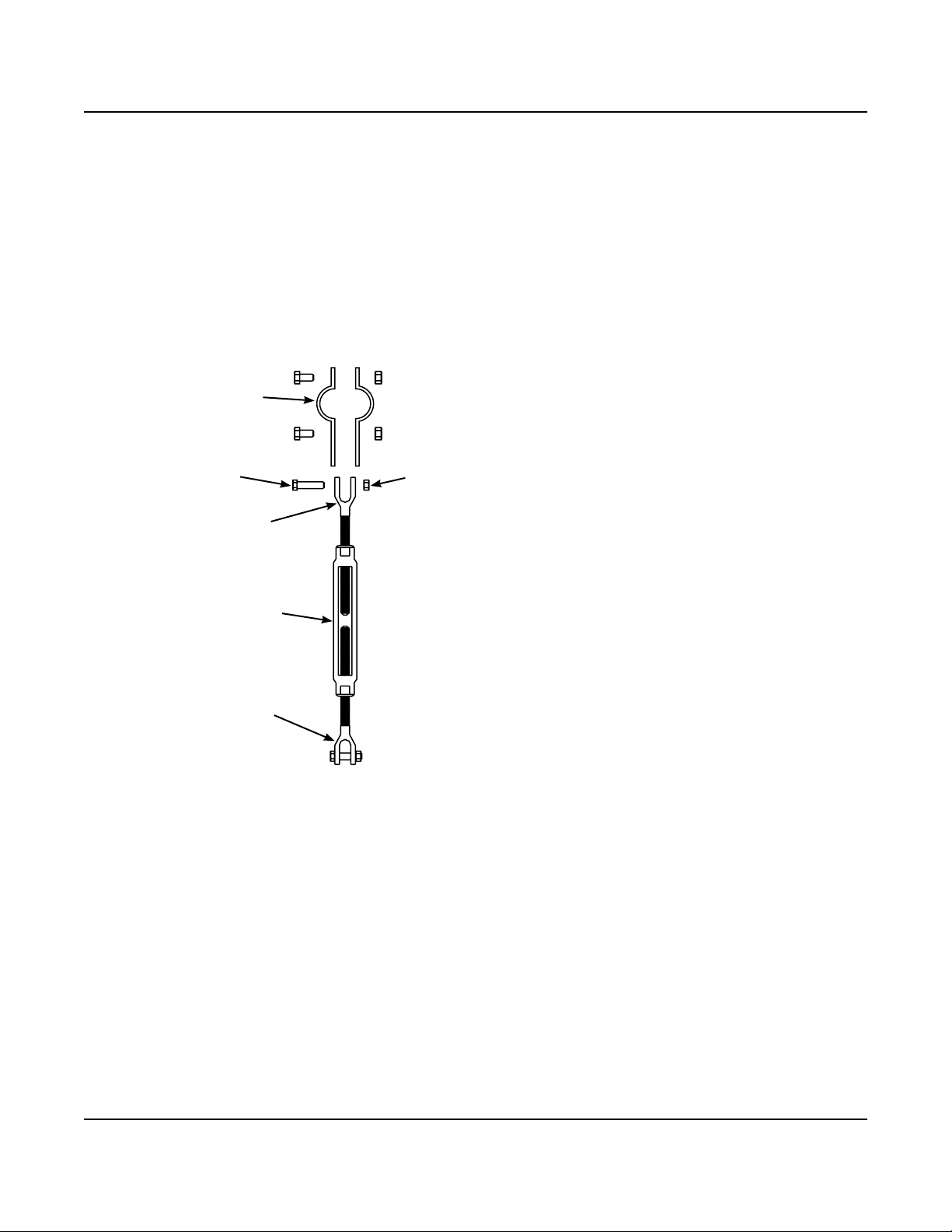

Assemble the Bowstring to the Truss ..................18

Apply Tension to the Bowstring.......................20

Install the Ceiling Stays.............................21

Fly the Ceiling Assembly............................23

Level the Ceiling Assembly ..........................24

Set the Ceiling Stay Performance Angle................25

Install the Ceiling Catch ............................27

Light Fixture Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Inspection .......................................28

Lieto LED Light Fixture Installation ....................28

Lieto LED Light Fixture Electrical Connection. . . . . . . . . . . . 29

LightFixtureConguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

InitialConguration ................................30

ConguretheDMXcatConnection ....................31

Lieto LED Light Fixture Communication ................31

DMXAddressInformation ...........................32

LED Power Settings Chart ..........................32

Troubleshooting...................................32

Light Fixture Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adjustment and Aiming .............................32

Photometrics .....................................33

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Lieto LED Light Fixture Electrical Schematic

(Diva Acoustical Ceiling) ........................36

Decals, Numbers and Logos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Final Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation Instructions

Diva

®

Acoustical Ceiling

©Wenger Corporation 2020 Printed in USA 2020-05 Part #185C756-05

Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448

Questions? Call.....USA: (800) 4WENGER (493-6437) • Worldwide: +1-507-455-4100 • wengercorp.com

Contents

Note: Please read and understand these instructions before using or setting up.

Note: Review all of the Installation Drawings and Reference Drawings.

Note: It is recommended that three or more people work together during the assembly.

Note: If you need additional information, contact Wenger Corporation using the information below.

Visit the Diva Acoustical Shell web page at wengercorp.com for more information.