2

Contents

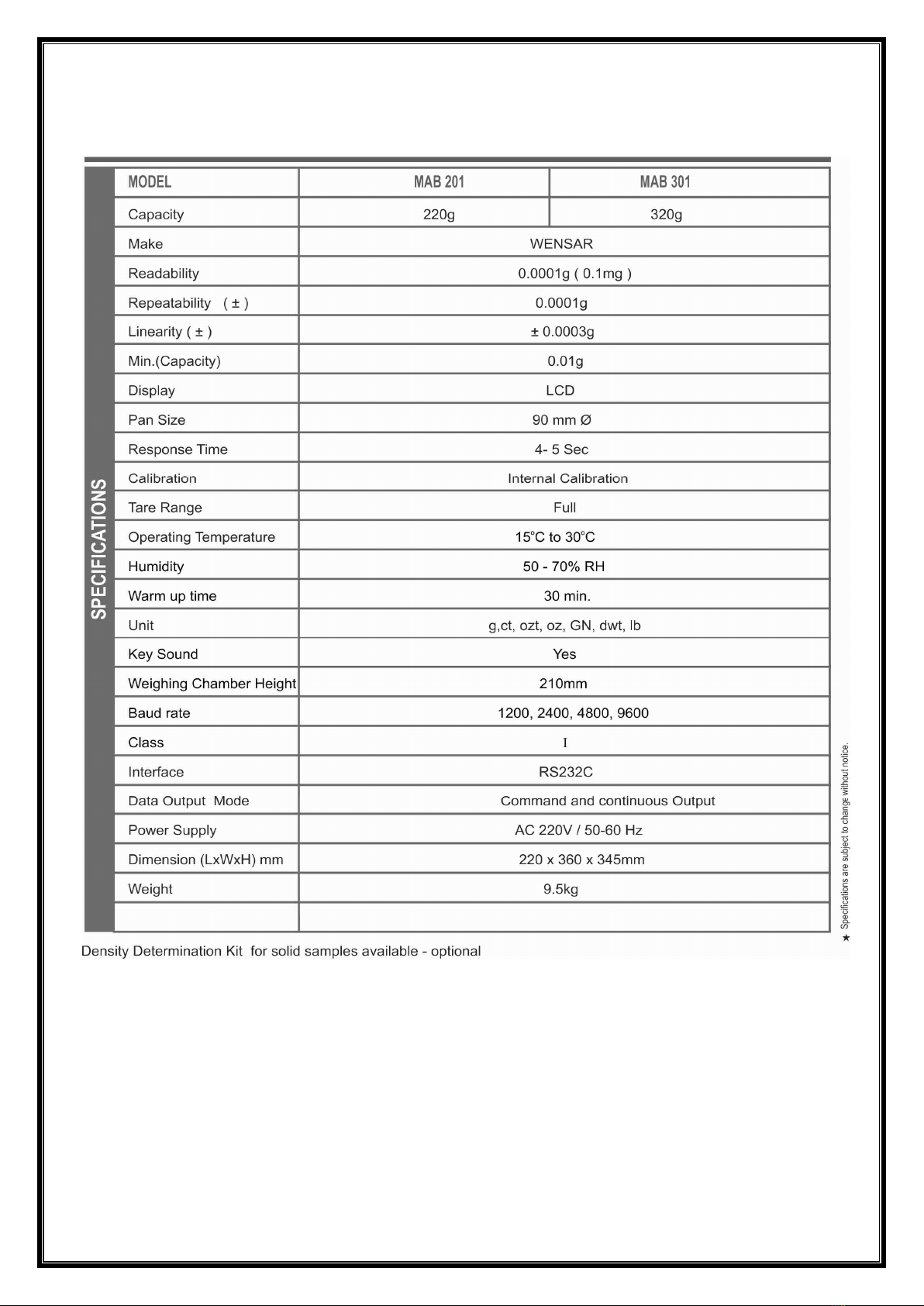

1 Technical data ................................................................................................................................... 4

2 Introduction ...................................................................................................................................... 4

2.1 Proper Use ................................................................................................................................. 5

2.2 Improper Use............................................................................................................................. 5

2.3 Control of inspection, measuring and test equipment .............................................................

3 Precautions .......................................................................................................................................

4 Transportation and Storage..............................................................................................................

4.1 Acceptance check ......................................................................................................................

4.2 Packing ......................................................................................................................................

5 Unpacking, Setup and Commissioning ............................................................................................. 7

5.1 Installation Site, Location of Use ............................................................................................... 7

5.2 Unpacking / Installation ............................................................................................................ 7

5.3 Mains connection ...................................................................................................................... 8

5.4 Connection of peripheral devices ............................................................................................. 8

5.5 Initial Commissioning ................................................................................................................ 8

5. Adjustment ................................................................................................................................ 8

5.7 Calibration ................................................................................................................................. 8

5.7.1 Internal calibration: ........................................................................................................... 8

5.7.2 Internal calibration: ........................................................................................................... 8

Basic Operation................................................................................................................................. 9

.1 [Power On/OFF] ........................................................................................................................ 9

.2 TARE ........................................................................................................................................ 10

.3 CAL - [calibration with external weight] ................................................................................. 10

.4 UNIT- [multifunctional key] ..................................................................................................... 10

.4.1 Weighing unit selection [weighing mode] ....................................................................... 10

.5 Print function [print mode] ..................................................................................................... 10

. Pieces counting function [counting mode] ............................................................................. 10

.7 Underfloor weighing ............................................................................................................... 11

7 Density determination (Hydrostatic weighing) .............................................................................. 11

7.1 Density determination of solids .............................................................................................. 12

7.2 Determining density of liquids ................................................................................................ 12

7.3 Influencing magnitudes and error sources ............................................................................. 12

8 Display Information / Error messages ............................................................................................ 12