WDT POOLKLAR Touch XL

Original Bedienungsanleitung in deutsch - Version (V1.1 –2012_01_09) 2/24

Inhaltsverzeichnis

1 Notes to this manual ................................................................................................... 4

1.1 scope of application............................................................................................... 4

1.2 Target group ........................................................................................................ 4

1.3 Keeping of the manual........................................................................................... 4

1.4 Further information ............................................................................................... 4

1.5 Used symbols ....................................................................................................... 4

2 Safety aspects............................................................................................................ 4

2.1 Intended use ........................................................................................................ 4

3 Delivery scope –Description ........................................................................................ 5

3.1 Delivery scope ...................................................................................................... 5

3.2 Transport damage................................................................................................. 5

3.3 Identification of the device ..................................................................................... 5

3.4 Device description................................................................................................. 5

4 Installation ................................................................................................................ 6

4.1 Place of installation ............................................................................................... 6

4.2 Tapping points for measuring water......................................................................... 6

4.3 Installation proposal .............................................................................................. 6

5 Commissioning........................................................................................................... 7

5.1 Setting of the Control parameters –see for this page 22 “Commissioning form” ........... 7

5.2 pH-Electrode ........................................................................................................ 7

5.3 Cleaning glass beads ............................................................................................. 7

5.4 Measuring water flow............................................................................................. 7

5.5 Dosing pump heads............................................................................................... 7

5.6 Chemicals ............................................................................................................ 7

5.7 Switch off at backwash and vacuuming .................................................................... 8

6 Electrical connections .................................................................................................. 8

6.1 To open and close the housing................................................................................ 8

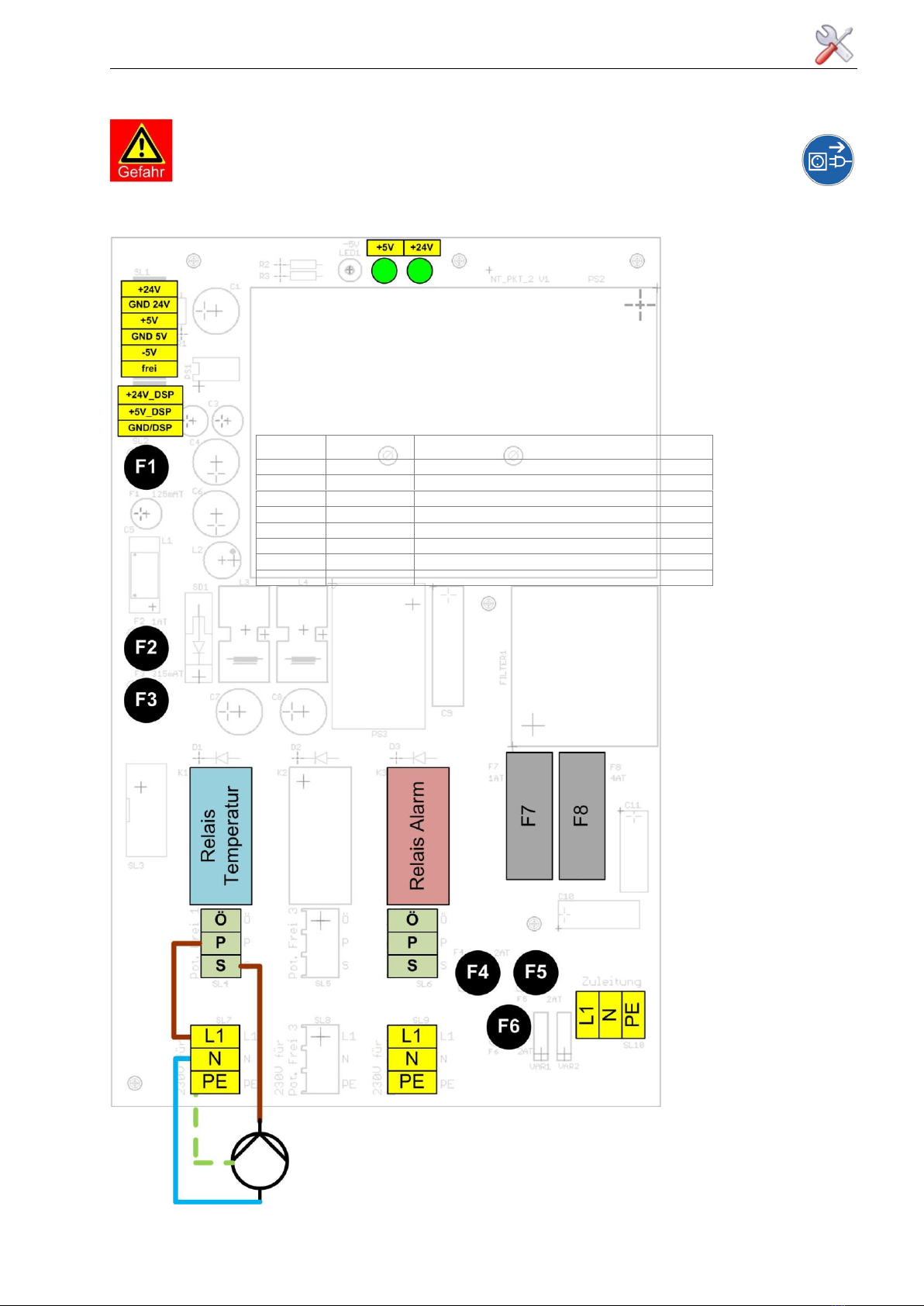

6.2 Wiring plan........................................................................................................... 9

6.2.1 The power board NT_PKT_2 –fuses, relay............................................................. 9

6.2.2 The I/O- Board IO_PKT_2...................................................................................10

6.2.3 The amplifier MV_PKT_2 ....................................................................................10

6.3 OPTIONS ............................................................................................................12

6.3.1 OPTION Temperature.........................................................................................12

7.3.2 OPTION Filter pressure.......................................................................................12

7 Operation of the Touch display ....................................................................................13

7.1 Operation Indication and Programmes ....................................................................14

7.1.1 Normal operation ..............................................................................................14

7.1.2 QuickInfo .........................................................................................................14

7.1.3 Dosing delay.....................................................................................................14

7.1.4 Start routine.....................................................................................................14

7.1.5 Alarm ..............................................................................................................14

7.2 Main menu ..........................................................................................................15

7.2.1 Main menuSettings ........................................................................................15