Blueview FWTU-2835T-112-24 User manual

1(7)

FWTU-2835T-112-24

Features

- Raw materials imported from Germany;

- The product is resistant to chlorine and salt corrosion;

- Ra 90+;

- Brightness keeps the same due to constant current design;

- Long run with less power feed;

- High quality FPC, easy to shape;

- High brightness and efficiency;

- Can not be cut during mounting, support customization;

Suitable for shallow water places such as swimming

pools and fountains.

Bending radius:

120°

3300-3500K 961100

CCT

Ra

>90

LM/W W/mLM/m

11.5224V DC

Voltage

FWTU-2835T-112-24

FWTU-2835T-112-24 112pcs /m 10.0m 10.0m

- Fix with mounting clips. - Must use the isolated power supply

- Input: AC90-265V 50/60HZ

- Output: DC24V

Optical & Electrical Parameters

Model No.

2835 DC 24V 3Years IP68

Installation LED Driver

Version: C1.2

Other Parameters

-20~+55 °C -20~+70 °C

LED QTY Working Temperature Storage Temperature

No Brightness Difference

(single feed)

Model No. Standard

Packing Length

NOTE:

-

-

-

-

-

-

The above data was measured under standard conditions and actual data may be different. We would update data without further notice.

The luminous flux was tested while the corresponding-color products were lightened.

UL max run refers to operating length at UL class II @100W.24V.

Luminous flux values were measured accordance to IES LM-80-08. LED chips with tolerance range of +/- 10%.

Each maximum-run requires a dedicated power feed from the driver. Do not exceed the recommended maximum run length. Max run may exceed Class 2 limits.

Actual wattage may be different from the calculated wattage due to voltage drop while using.

2(7)

FWTU-2835T-112-24

Compliance & Regulatory Approvals

Performance

LED chip data measured in accordance to IES LM-80-08.

Photometric & Colorimetry data measured in accordance to IES LM-79-08, in Blueview ‘s TUV Innovation Lab.

•

•

Standard: EN 60598-2-21: 2015; EN 60598-1: 2015; EN 62471: 2008; EN 62493:2015; EN 62031: 2015+A1: 2013+A2: 2015

Standard: EN IEC 55015: 2019; EN IEC 61000-3-2: 2019; EN 61000-3-3:2013+A1: 2019;EN 61547: 2009

Standard: IEC 62031:2018

Standard: UL 2108 E354137-Low-voltage Lighting Systems, Power Units, Luminaires and Fittings

Standard: IEC62321

CE LVD

CE EMC

CB

UL LISTED

RoHS

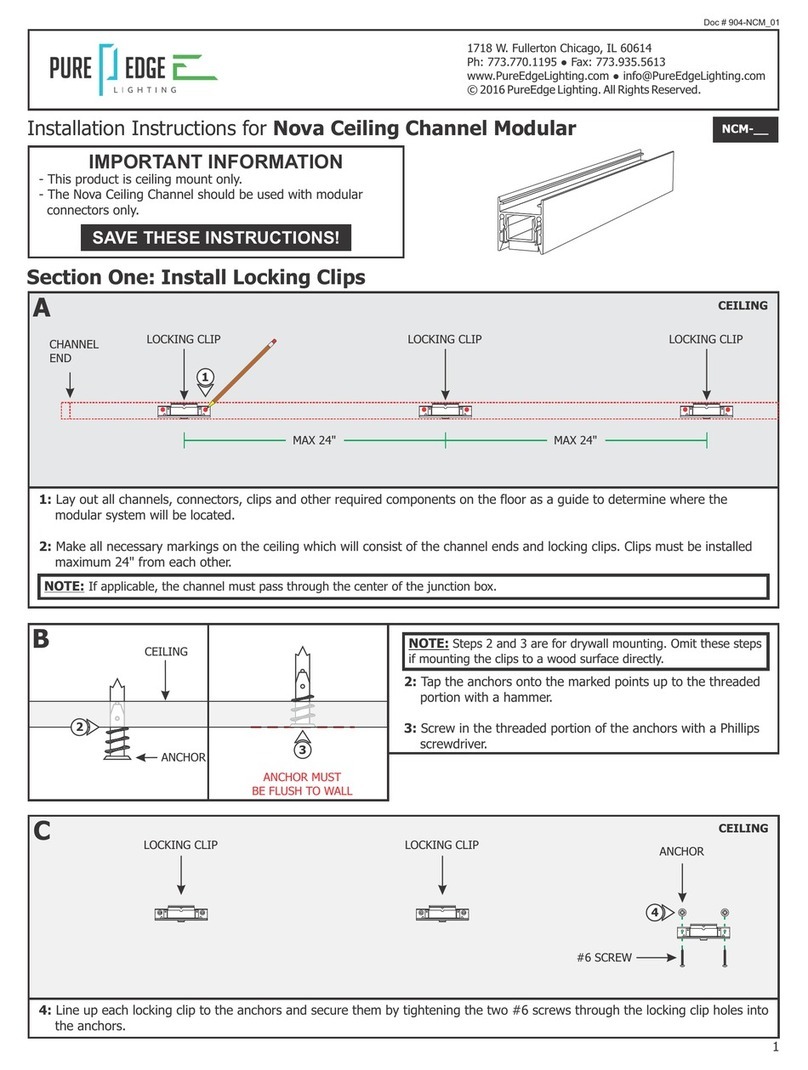

Unit: mm [inch]

Profile Drawings

-

-

-

-

-

Actual efficacy value is determined by the specific LED driver (power supply). An estimated efficacy value can be calculated as follows: Luminous intensity

divided by average power consumption.

Do not install products in the conditions that exceed the listed ambient temperature. Exceeding the maximum ambient temperature may damage LED chips,

reduce the total lamp life, luminous intensity output, and/or adversely impact color consistency.

Operating temperature was measured under the minimum and maximum ambient temperature environment.

Cutting segments are marked on the profiles below.

If the product power is greater than 15W, auxiliary heat dissipation appliances must be added.

Note:

For LED quantity less than 160leds/m with standard power, we recommend to use 20AWG parallel wire/sheathed cable with wire length less than 20cm, user need to reduce the

max run when the wire length more than 20cm.

For LED quantity more than 160leds/m with standard power, we recommend to use 18AWG parallel wire/sheathed cable in single feed, or 20AWG parallel wire or sheathed cable

in both ends with wire length less than 20cm. Users need to reduce the max run properly when the wire length more than 20cm.

Above conditions are only applicable to products with the PCB width of 10mm or more, for other width needs to be evaluated separately.

•

•

•

3(7)

FWTU-2835T-112-24

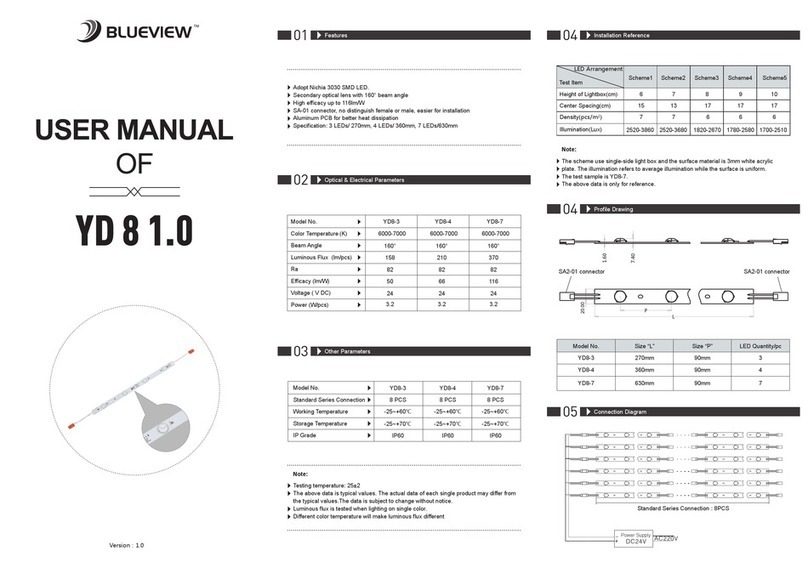

AVERAGE BEAM ANGLE(50%):116.1°

C 0 /180,118.1°

Unit:cd

C 90/270,114.1°

Luminous Intensity Distribution Diagram Average Illumination

Note: above data tested with FWTU-2835T-112-24 , for other data,please consult sales rep.

Flux Out: 585.1lm

Height Eavg, Emax Beam Angle:107.23° Diameter

0.5m

1.0m

1.5m

2.0m

2.5m

3.0m

3.5m

4.0m

4.5m

5.0m

393.3,1202lx

98.31,300.4lx

43.69,133.5lx

24.58,75.10lx

15.73,48.06lx

10.92,33.38lx

8.026,24.52lx

6.145,18.77lx

4.855,14.83lx

3.933,12.02lx

135.71cm

271.42cm

407.13cm

542.85cm

678.56cm

814.27cm

949.98cm

1085.69cm

1221.40cm

1357.12cm

Reliability test

Water

environment

test

Blueview

Blueview

Third-party

Third-party

Project Category Test conditions

Please refer to the report for details

Immerse the sample into an ordinary pool, immersed depth 100cm

Please refer to the report for details

Immerse the sample in artificial seawater solution (pH 7.5~8.0), immersed depth 10cm

Outcome

Pass

Testing agency

Artificial seawater test

Seawater immersion test

IP test(3m)

Immersion test

FWTU-2835T-112-24

Recommended power supply upon working length

Operating Length

1.0m 10.73W 0.25% 0.49%

1.13% -0.32%

3.14% -0.32%

6.17% -0.16%

10.17% -0.16%

12.45% 0.16%

3.0m

5.0m

7.0m

9.0m

10.0m

31.80W

52.73W

73.66W

93.84W

104.40W

Single feed

Single feed

Single feed

Single feed

Single feed

Single feed

Total Power Head-to-tail Current Drop RateHead-to-tail Voltage Drop Rate Single/Double feed

4(7)

FWTU-2835T-112-24

Packaging information

Carton Size (mm) Meter/Reel Reel/Carton Gross Weight (kg)Product Size L*W (mm)

Model No. Net Weight (kg)

10000*12.5 10 11.00 (1±10%) 16.50 (1±10%)15390*390*325FWTU-2835T-112-24

NOTE:

• The above quantity and weight are only for the illustrated packaging method. There will be differences in the quantity and weight with other packaging methods.

Installation

Cutter Electric drillLED power supply Screw Clips

Packaging Information

Label the reel;

Seal the carton box; Use packing belt to pack. Add

edge protectors if necessary.

Put reel, accessory bag and

desiccant together into static

shielding bag;

Seal and label the static

shielding bag;

Label the box;

Put the packed static shielding

bag into carton box;

5(7)

FWTU-2835T-112-24

Mounting Method

After draining the water in the swimming pool, clean the

mounting surface and mark the mounting position.

Fix the clips at the mounting position with screws.

Make sure the luminous surface is flat, then light on to test.

Mounting Position

Mounting position 1

Mounting position 2

Mounting position 3

Mounting position 4

6(7)

FWTU-2835T-112-24

Attentions before installation

- Check whether the power line is screwed into the terminal firmly, and it is better not to pull it out by hand.

- Before installation, check that the product parameters are consistent with the requirements (Seeing product specifications or product labels)

- Load voltage, current, power and power supply should be matched with the product.

- Follow the instructions of wiring diagram (first connect the load and then the power supply) to avoid short circuit.

- Make sure the correct connection of positive and negative poles between products and power supply. Otherwise, the light will not be on.

- The wiring terminal must be provided with effective waterproof and anti-corrosion treatment.

Common Faults and Troubleshoot

Quick Guide

Problems

All LEDs can not light on.

LEDs can not light on partly.

Brightness of LED is

inconsistent tor insufficient.

LED flicker.

Automatic power protection from the open or short

circuit in output of the power supply. Fix the short circuit problem.

Correctly connection.

Replace with more powerful power.

Make sure the working voltage of the product within ±5% of

standard voltage, or keep balance by circuit power consumption.

Reduce the quantities of the product in series connection

to meet requirement.

Wrong connection of power supply.

Some switching mode power supplies are not powered.

Power supply line error.

Mistaken wire connection of some of products

Power overloaded.

Connection point fault. Remove bad connection point.

Replace a new power supply.

Please follow the instructions

Power supply circuit excessive consumption.

Excessive quantities in series connection of the product

Switching power supply failure.

Wrong Installation or use of products

Reasons

No electric supply.

Solutions

Warning

- Do not disassemble or retrofit the light. Do not touch the surface of the light with a sharp object.

- Do not do live-line working during installation,especially for high voltage product.

- Do not use any organic chemical solvents.

- Use neutral glass adhesive to fix this product and it needs to be dried 4 hours in the open environment after operation.

- Treat the ends and the circuit connection points that are not connected to the main line with insulation,waterproof, and anti-corrosion in the installation.

- Use 18AWG (0.75mm² cross-sectional area) or thicker core wire to avoid adverse consequences caused by overheating, if the power cable need to lengthen.

- Make sure the input voltage meets the requirements and lines are connected correctly before lighting on.

- This product is for signage, and do not use as general lighting.

- Use 1 mm² cross-sectional area or thicker core wire to avoid adverse consequences caused by overheating, if the power cable need to lengthen.

- Make sure the input voltage meets the requirements and lines are connected correctly before lighting on.

- Series connection within the max run.

- The length of the power cable between the power supply and the led strip should not exceed 2 meters. Otherwise, large circuit loss will lead to inconsistent brightness.

- Installation, maintenance and repair should be operated by a qualified technician.

- For non replaceable light sources: the light source of this luminaire is not replaceable; when the light source reaches its end of life the whole luminaire shall be replaced.

- Do not connect the rope light to the supply while it is in the packing or wound onto a reel.

- Do not use the rope light when covered or recessed into a surface.

- The external flexible cable or cord of this luminaire cannot be replaced; if the cord is damaged, the luminaire shall be destroyed.

- For operation only with safety isolating transformer.

- This product needs to be cleaned regularly during use, and cannot be cleaned with oily, strong alkaline, strong acid and other chemical cleaners.

isolated power supply

7(7)

FWTU-2835T-112-24

Statements and Recycling

- Repair should be operated by a qualified technician, if the external circuit or main line of this product is damaged.

- The parameters given in this manual are typical values and for reference only.

- All illustrations and drawings in this manual are for reference.

- This product is subject to change without notice.

Statements:

- LED lighting products belongs to electronic products, please do recycling treatment according to the relevant WEEE directives.

Recycling:

BLUEVIEW ELEC-OPTIC TECH CO.,LTD

□ Tel: +86-28-8148 0011

□ Fax: +86-28-8148 1258

□ Web.: www.blueviewled.com

□ Email: [email protected]

□ Add.: No. 1000, Section 2, Konggang 2nd Road, Shuangliu, Chengdu 610207, Sichuan, CHINA

Table of contents

Other Blueview Lighting Equipment manuals