2.3. INSTALLING THE PLAY DETECTOR

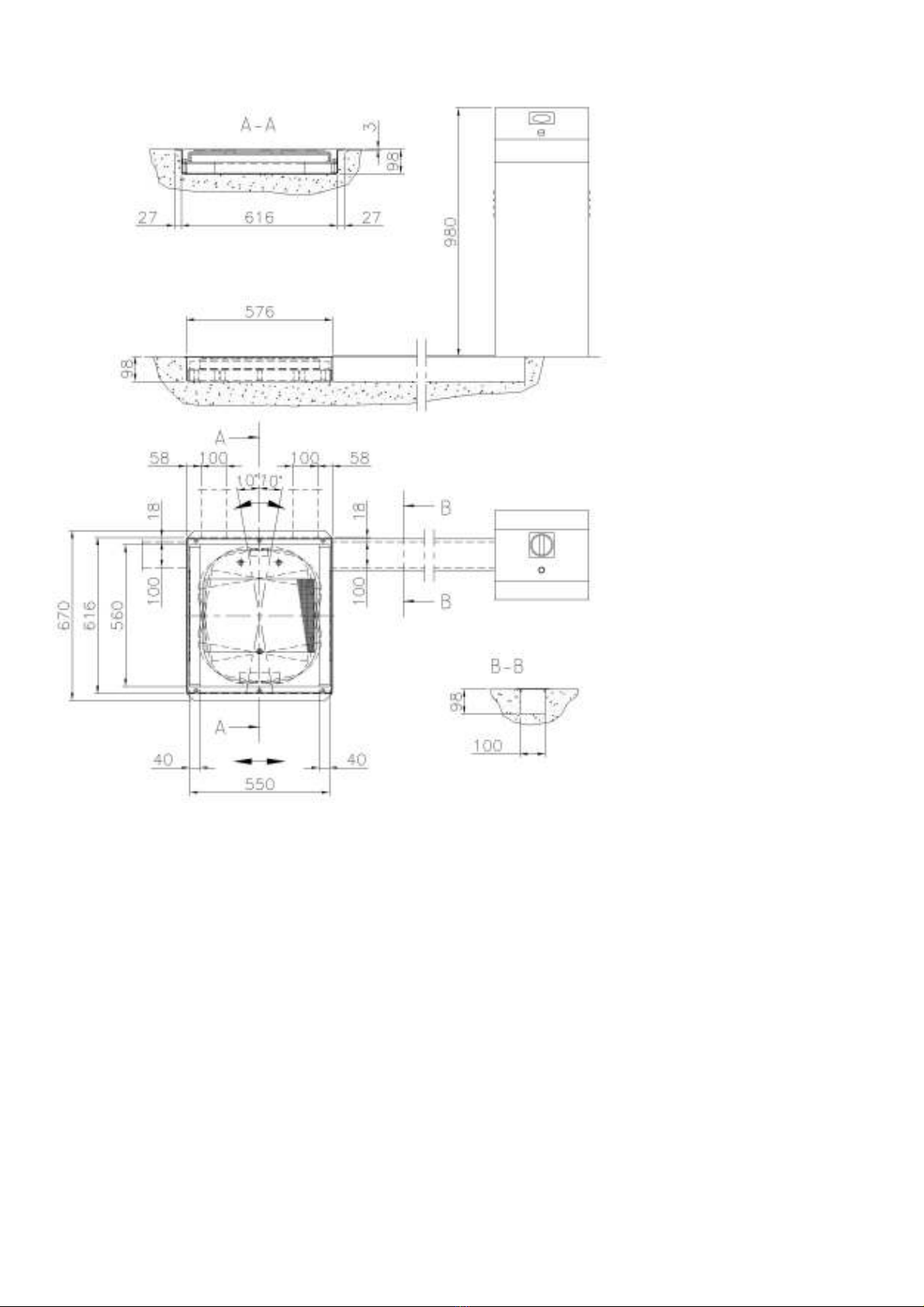

Prepare the recess where set the plates of the play detector and the canal for the connections

(see PLAY DETECTOR DIMENSIONS).

After inspecting the shipment, the play detector can be moved plate by plate by handles, using 2

persons in order to reduce the weight lifted for each of them.

Place platform in the recess.

Place the control box with handlamp and selector + movement pushbuttons to previste distance

from the play detector plate and to prepare to connect to the main central unit.

Take out the electric cables rubber hoses (see to prepare the connection with end bornes in the

control box.

Pass the hydraulic rubber hoses, that you have prepared of the correct length for the installation

(see pictur HOSES LENGTH) from the canal to the central unit. Connecter the hoses to the

electro valve. Make sure all nipless are securely fastened with copper washers.

ICAUTION TAKE CARE OF ELECTRIC CABLES

The personnel assigned to perform these operations should make sure

no extraneous persons are standing in the way of move-

me nt.

2.4. CONNECTION TO POWER MAINS

Before connecting the electric system, make sure that:

the power supply plant is equipped with the protection devices required by current

standards in the country where the machinery is installed.

·the power supply line has the following cross-section:

Voltage 400V, three-phase minimum 1,5 mmq

Voltage 230V, three-phase minimum 1,5 mmq

Voltage 230V, single-phase minimum 2,5 mmq

·the voltage oscillations are within the tolerance range set forth by the specifications.

It is up to the user to ascertain that the power mains comply with international and local

safety standards. The Manufacturer is not responsible for damage due to “Non-Confor-

mity” of the electrical system. The manufacturer will not be liable for any malfunctioning cau-

sed by disturbance from other equipment.

It is essential to make the “EARTH CONNECTION”, using a 0,03A differential switch, and

checking its correct functioning (W) by means of an appropriate measuring device.

2.5. TAKING THE PLAY DETECTOR OUT OF SERVICE

In order to facilitate disposal of the different play detector components, they should be sorted

into categories. Consider the units to be special waste that must be disposed of by specialized

companies in compliance with current regulations.

10