Page7of14

© Copyright 2016 WESCO Industrial Products, Inc. Specifications subject to change. Not responsible for errors or omissions.

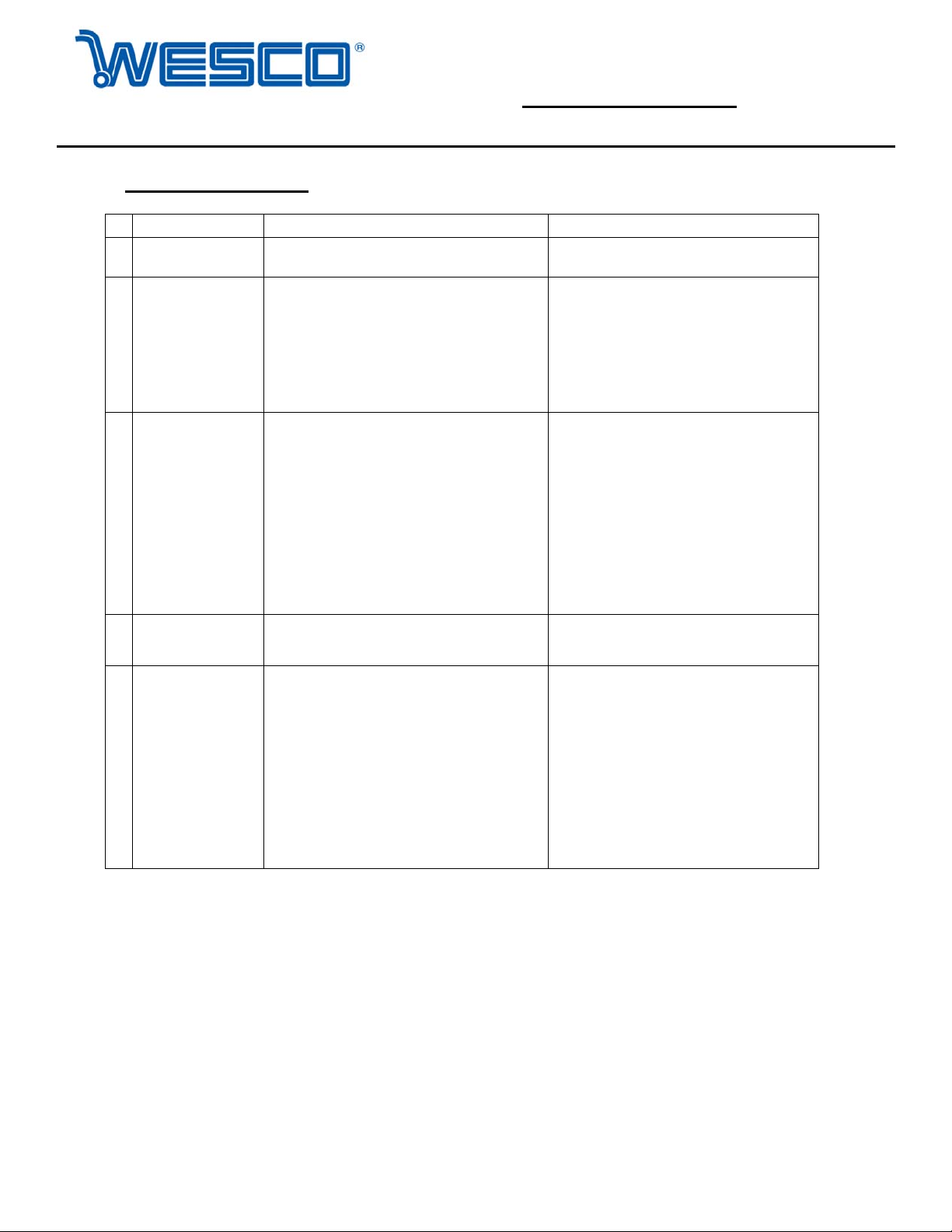

6. TROUBLE SHOOTING

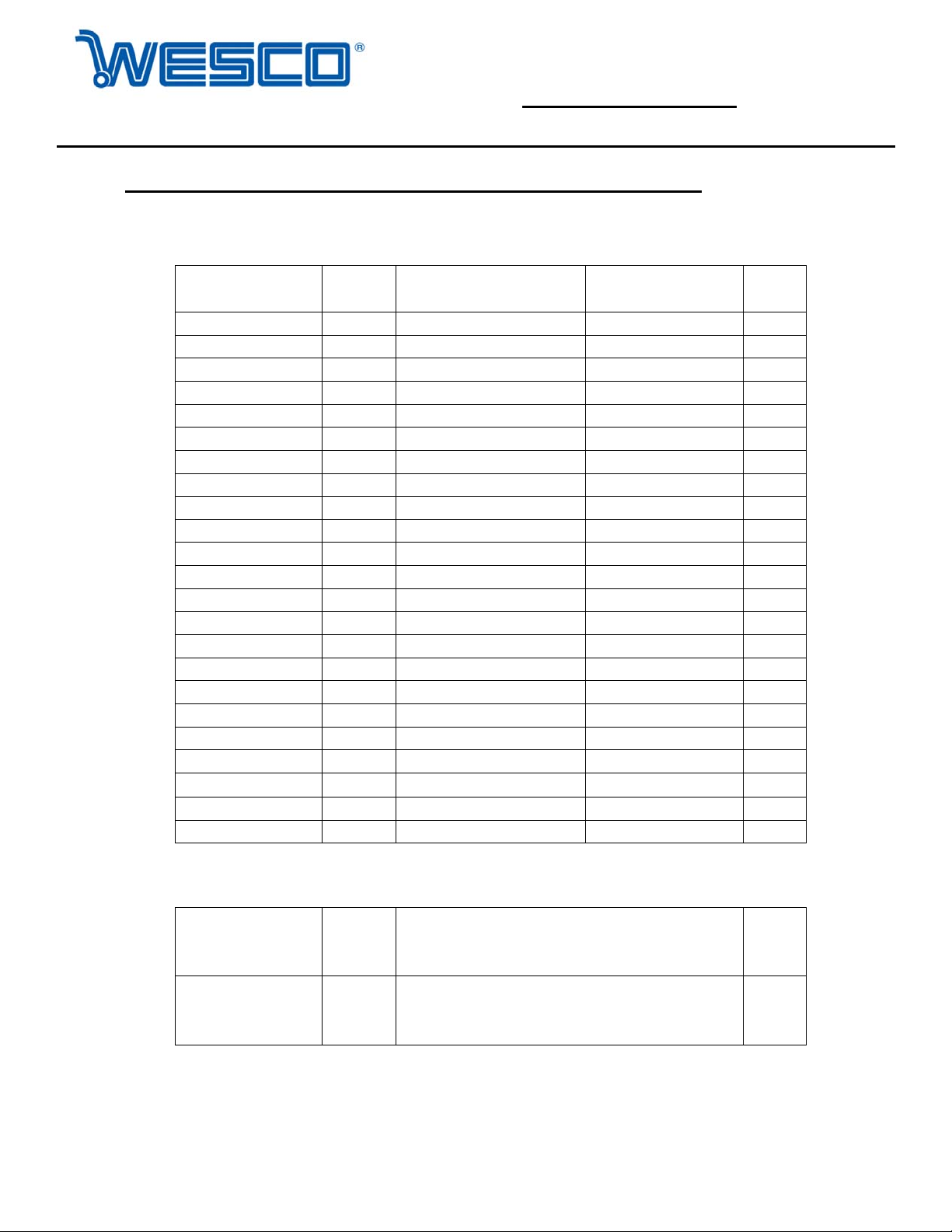

No Problem Causes Solutions

1 Forks cannot lift to

maximum height - There is not enough hydraulic oil. - Pour in hydraulic oil.

2

Forks cannot lift

up

- No hydraulic oil.

- The oil has impurities.

- The Adjusting Nut (104S) is too high,

keeping the pumping valve open.

- Air enters the h

draulic s

stem.

- Refill the hydraulic oil.

- Change the oil.

- Adjust the nut (104S) or screw (318S)

(see item 3.4)

- Remove the air.

see item 4.2

3 Forks cannot be

lowered

-The Piston Rod (328) or Pump Body

(322S) is deformed resulting from partial

loading slanting to one side or over-

loading.

-The fork was kept in a high position for

an extended amount of time. The piston

rod bore to arise in rusting and jamming

of the rod.

- The Adjusting Nut (104S) or Screw

(318S) is not in correct position.

- Replace the Piston Rod (328) or

Pump Body (322S).

-Keep the fork in the lowest position if

not using, and pay more attention to

lubricate the rod.

-Adjust the Nut (104S) or Screw (318S)

(see item 3.3)

4 Leaks - Sealing parts worn or damaged.

- Some part cracked or worn down.

- Replace with the new parts.

-Replace with the new part.

5 Forks lowers

without the

release valve

working

-Impurities in the oil prevent the release

valve from closing.

-Some part/s of hydraulic system are

cracked or bored.

- Air enters the hydraulic system.

-Sealing parts worn or damaged.

-The Adjusting Nut (104S) or Screw

(318S) is not in the correct position.

-Replace with new oil.

-Inspect and replace the damaged

part/s.

-Remove the air. (See item 4.2)

-Replace with the new parts.

-Adjust the nut (104S) or screw (318S).

(See item 3.2)

NOTE: DO NOT ATTEMPT TO REPAIR THE PALLET TRUCK UNLESS YOU ARE TRAINED

AND AUTHORIZED TO DO SO.

Stainless Steel Pallet Truck

(Part # 272152)

Instruction Manual

ATTENTION: TO INSURE SAFE AND EASY USE OF YOUR WESCO PALLET

TRUCK, READ THESE INSTRUCTIONS ENTIRELY BEFORE USING.

Industrial Products, Inc.