Section VEL‐GX9‐20A 030‐300323 Rev. A R

61406IARAD4c

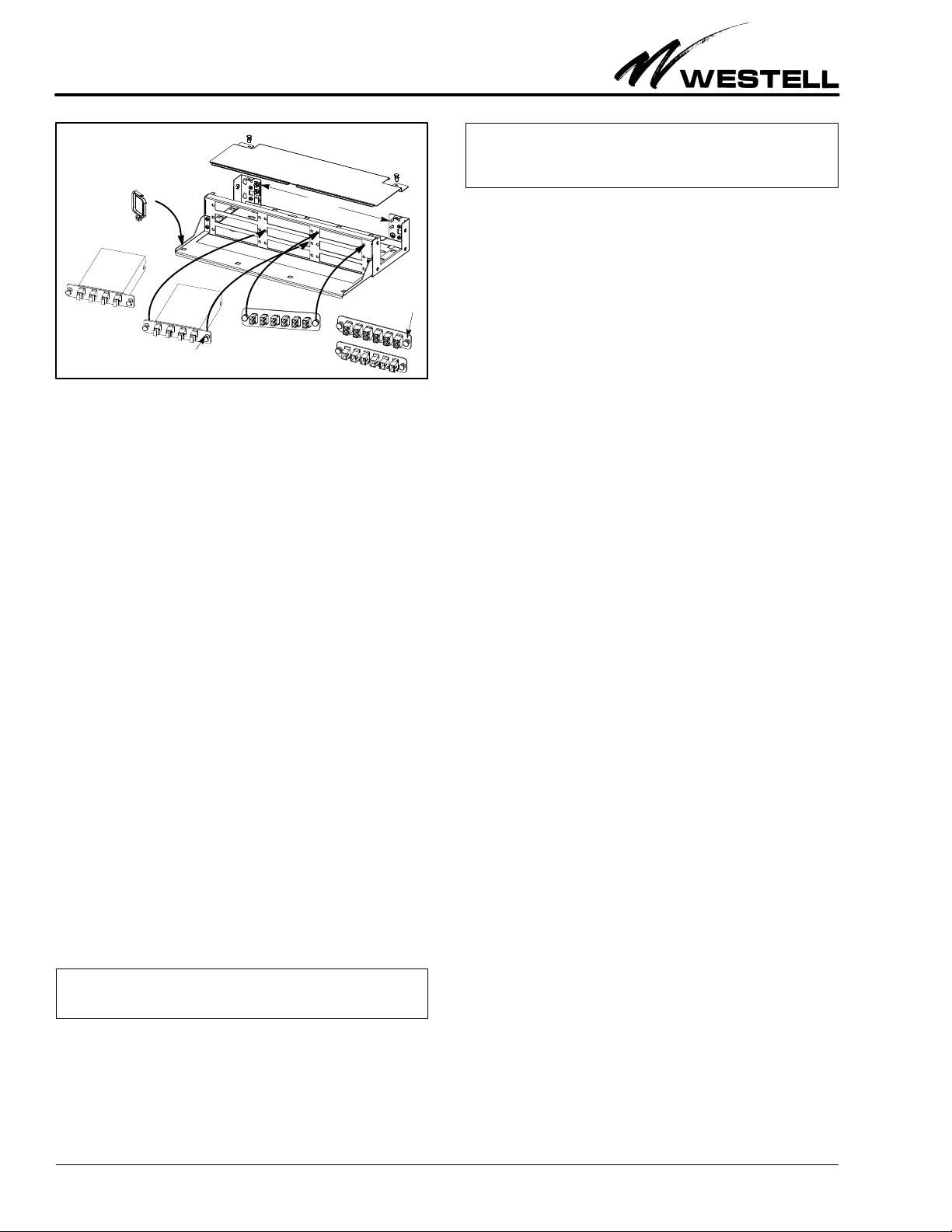

Figure 11. Inserting LGX Panels and Fiber Cassettes

Insert adapter panels and cassettes from the

front of the VELGX‐90. Align Ny‐latch push‐

pins with the mounting holes on both

sides of the LGX slot, then insert/press

push‐pins til they snap in place.

Ny‐latch

fastener (push‐pin)

LGX‐type

fiber cassettes

LGX adapter panels

(6, 8, and 12 coupler

models available)

Fiber management

D‐clip

Ny‐latch

fastener (push‐pin)

Ground

posts

2.5.2 Installing Optional Fiber Cable Clamp(s)

An optional, rubber‐padded, fiber cable clamp may be ordered

and installed at either or both rear corners of the VELGX‐90.

The expandable clamp accommodates single or groups of ca

bles of various sizes. Contact Westell for further details.

2.5.3 Installing Optional Adapter Panels and Couplers

The VELGX‐90 panel supports 9 LGX‐type adapter panels,

fiber cassettes, or JDSU BrightJacks. Order and install option

al LGX‐type adapter panels, fiber cassettes, or JDSU

BrightJacks per the specific application, company practice, or

service desired. Follow the steps below to install the cassettes,

couplers and adapter panels in the VELGX‐90.

1. Call Westell to order the fiber cassettes, couplers or LGX‐

type panels of choice for the application (see Table 3).

2. If and as necessary, populate any blank LGX panels per

company practice by installing the desired or any different

couplers into their proper or designated Keystone posi

tions in the field‐provided LGX‐type adapter panels.

3. Remove the VELGX‐90's top cover, for easy panel access.

4. Align the two, plastic, Nylatch fasteners (push‐pins) locat

ed on each side of the fiber cassette, LGX adapter panel

or JDSU BrightJack with the holes at both sides of the se

lected, empty, LGX‐type cut‐out position at the front of

the VELGX‐90. Insert the push‐pin fasteners into the

holes, and press them until they click, snap, or lock in

place. Verify the adapter panel is securely attached to the

panel (see Figure 11).

‐ EXTRA PUSH‐PINS FOR LGX PANEL NOTE ‐

For convenience, two extra Nylatch easy‐on/easy‐off push‐pins are pro

vided in a bag of parts shipped with the VELGX‐90.

5. Connect fiber (pigtails/fan‐outs) at the installed LGX

adapter panels and/or fiber cassettes as needed and make

all installer connection per company practice.

6. Use the circuit ID card to identify all coupler positions.

7. Repeat for all adapter panels to be installed.

‐ LGX‐SIZED CASSETTES NOTE ‐

If LGX‐sized cassettes or trays are installed in the VELGX‐90 panel, fol

low the manufacturer's instructions for installer connections at the tray

or cassette.

2.5.4 Labelling Circuit Positions

A circuit identification card (label) and a clear plastic packet

is provided for quick and easy circuit labelling and identifica

tion. Complete and fill in the card per company practice.

3 CUSTOMER & TECHNICAL SERVICES

3.1 Customer Service & Technical Assistance

If technical or customer assistance is required, contact Westell

by calling or using one of the following options:

Voice: (800) 377‐8766

For additional information about Westell, visit the Westell

World Wide Web site at http://www.Westell.com.

3.2 Part Numbers

This equipment is identified by a product number

(A90‐VELGX90), which consists of three parts: the issue letter

of the equipment (A), the assembly type (90), and the specific

model number (VELGX90). Each time a change is made to the

product which changes the form, fit, or function of the product,

the issue letter is incremented or advanced by one. Be sure to in

dicate the issue level as well as the model number when making

inquiries about the equipment.

4. WARRANTY & REPAIRS

4.1 Warranty

Westell warrants this product to be free of defects at the time of

shipment. Westell also warrants this product to be fully function

al for the time period specified by the terms and conditions

governing the sale of the product. Any attempt to repair or

modify the equipment by anyone other than an authorized Wes

tell representative will void the warranty.

4.2 Repair and Return

Westell will repair or replace any defective Westell equipment

without cost during the warranty period if the unit is defective

for any reason other than abuse, improper use, or improper

installation. To return defective equipment, first request a Re

turn Material Authorization (RMA) number from Westell by

calling or using one of the options shown below. Once an RMA

number is obtained, return the defective unit (freight prepaid),

along with a brief problem description, to the address we will

provide to you when you contact us.

Voice: (630) 375‐4457

Replacements will be shipped in the fastest manner consistent

with the urgency of the situation. Westell will continue to repair

or replace faulty equipment beyond the warranty period for a

nominal charge. Contact Westell for details.