030-101704 Rev. C R

Section VE2-848-CK6-20A

61006IARC

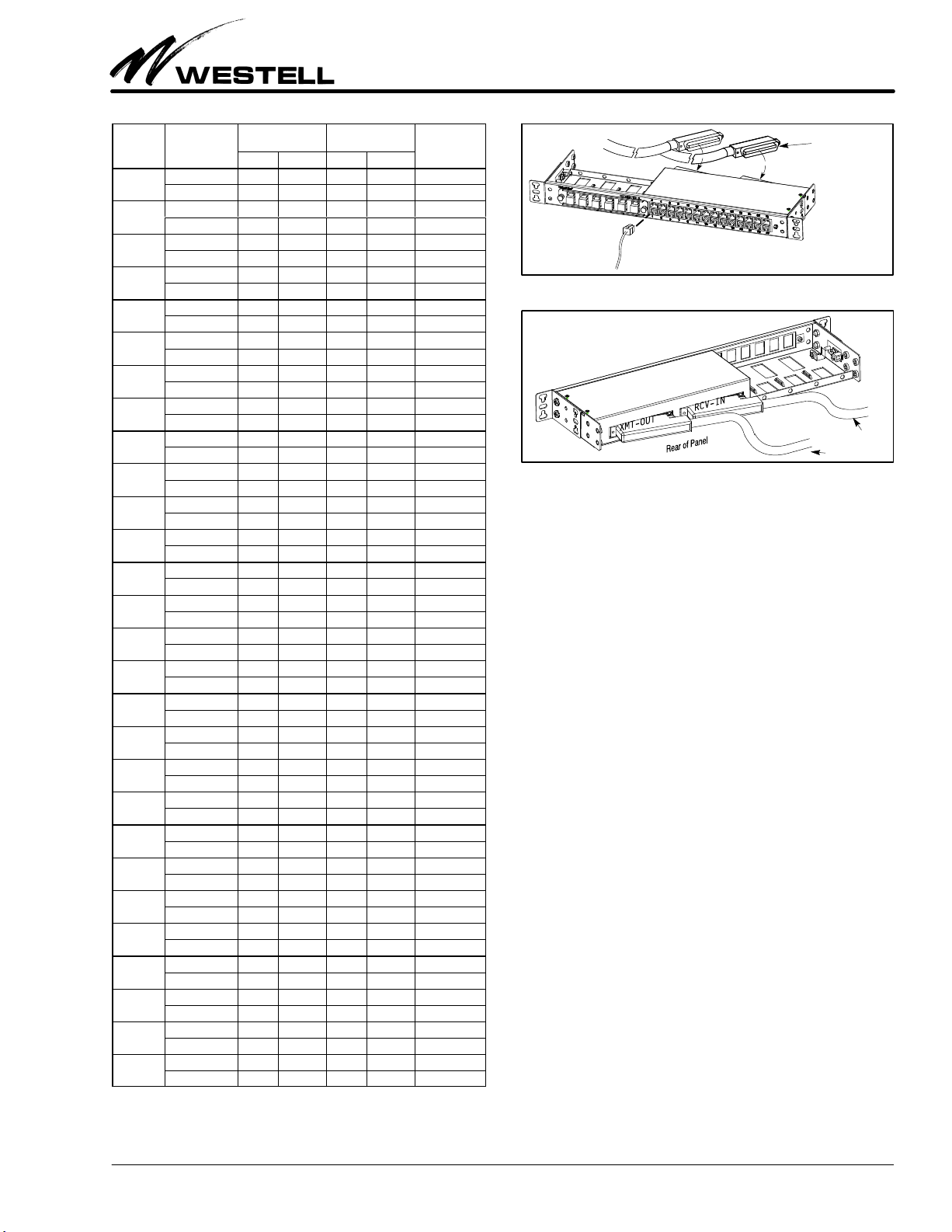

Figure 8. Installing Keystone-type Couplers into LGX Panel

Insert coupler of choice from

the rear of the LGX-type panel.

Depress tab and

insert into hole until

it snaps/locks into place.

Pull Nylatch fasteners

to remove LGX-type

after inserting couplers

Remove

rear of

covers from

blank hole

panel then re-install

LGX-type panel.

Front Tray Flange with hole for mounting

to panel’s inside wall flange

Screw to

Cable tie-down

Attach tray

the inside wall

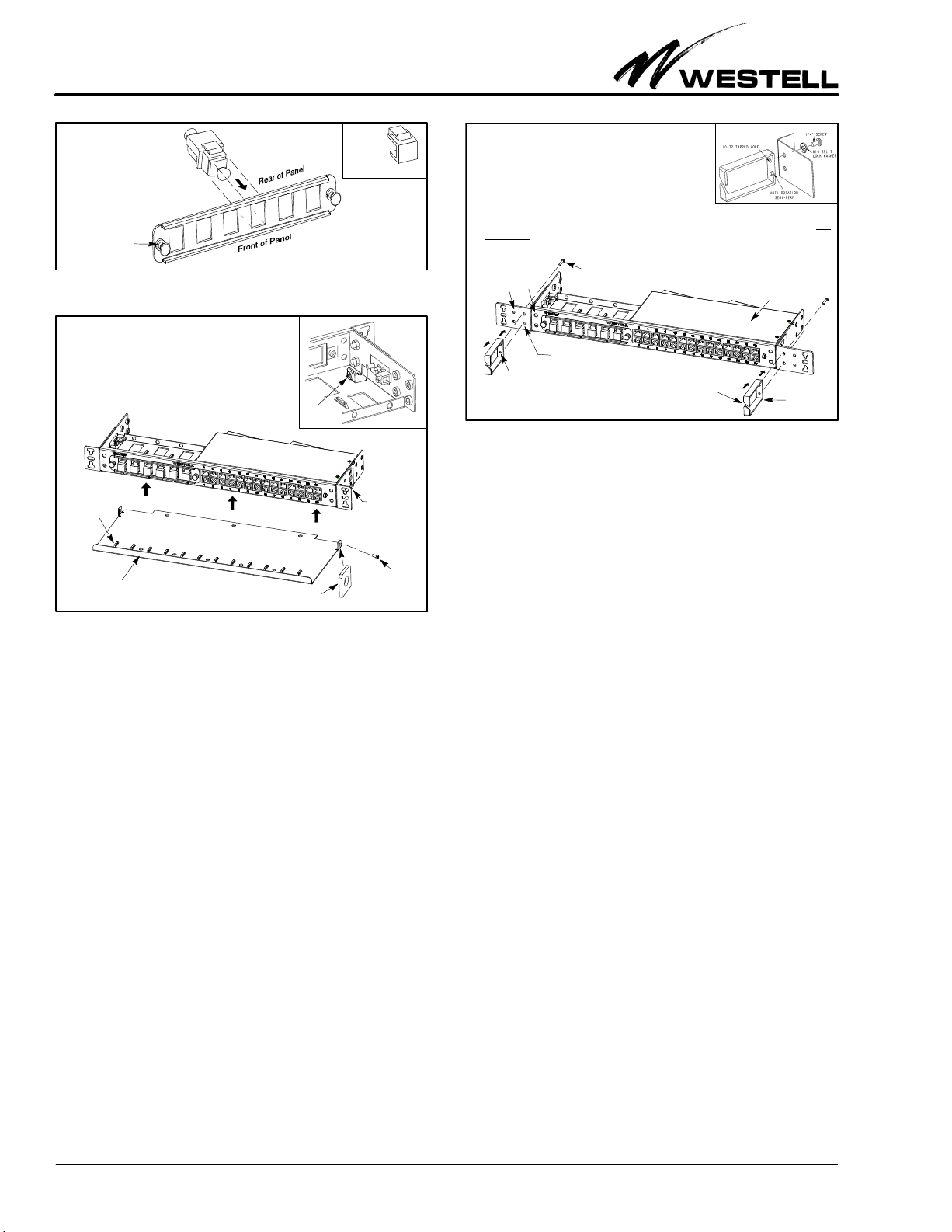

Figure 9. Installing Front Cable Management Tray

to flange on

1. Locate the two, small, vertical flanges at the inside of the panel

which are used to mount the front tray.

2. Align the front tray’s mounting flange holes with the correspond-

ing holes in the flanges located on the inside of the panel.

(see DETAIL A, rear

3. Insert the provided screws through both holes in the aligned

flanges, and tighten the screws.

4. Secure cables to tray with cable ties at the provided bridge-

forms or cable tie-downs.

view of VE-2848C-K6

for view of flange)

DETAIL A

Flange Rear View

secure tray

to panel

4. Repeat for each couple and cable.

2.5.5 Labelling Circuit Positions

A circuit identification card (label) is provided, inside a clear

plastic packet, for quick and easy circuit labelling and identifi-

cation. The ID card and packet hangs from the panel using the

provided, beaded, removable, cable tie.

3 ACCESSORIES

3.1 Coupler Types

VirtualEdgerpanels and adapter panels accept multiple cou-

pler types (listed below) that can be used or interchanged

within the panel. If desired, couplers can be purchased sepa-

rately using the part numbers shown in Table 4.

SRJ45/48 (Cat5e for Ethernet and DS1 services)

SBNC (for DS3 service)

SSC/LC (for fiber)

SAny Keystone-type coupler

3.2 Front Cable Management Tray

To facilitate cable management at the front of the

VE-2848C-K6, Westell offers a metallic Cable Management

Tray (Figure 9). This tray attaches to the unit as shown in

Figure 9. The tray is designed to allow jumpers and cables to

cross in front of the panel without putting unnecessary down-

1. Pick the set of holes (in panel or ear) to use to mount the D-ring.

2. If installing a D-ring to the holes provided on the right side of the

panel, first remove the protective connector box cover (to access

the rear of the top D-ring hole) from the panel by removing the two

screws on the top surface, one on the left side, and one on the rear.

If any cables are attached at the back side, disconnect them.

3. Align peg (semi-perf) at the back of the D-ring with the bottom

mounting hole in the panel or mounting ear; the peg prevents rotation of the D-ring when properly installed.

4. Align the top hole of D-ring hole with corresponding panel or ear hole and insert the provided screw, from

the back side, through the aligned set of holes (panel and/or ear hole and D-ring hole). Tighten screw.

5. Route cables through slit in the front side of the D-ring. Re-install box and cables, if removed.

igure 10. Installing Cable Management D-Rings to the Panel

D-ring

D-ring also can

be mounted here

Insert peg

(peg near bottom of D-ring Slit for

cable access

(optional)

of D-ring here

provides rotational stability)

Peg

D-ring mounting screw

(see

DETAIL A)

DETAIL A

(see DETAIL A)

Protective connector

box cover

ward force or strain on the couplers, when installed. The tray

also has bridge-forms or cable tie-downs to allow technicians to

dress and secure cables to the tray, if desired. The tray can be

mounted to the panels at two different depths to allow custo-

mization based on the amount of cables and jumpers running

across the panels. Use alone or with one or more D-rings de-

scribed in Paragraph 3.3 for a customized cable-management

solution.

3.3 Cable Management D-Rings

Optional, metallic D-rings (Figure 10), for installation at ei-

ther or both ends of a VirtualEdge panel, provide guidance and

support of the cables that run across the front of the panel to

the couplers. In the front of the D-ring, a diagonal slit allows

existing or newly-installed cables/jumpers to be easily inserted

into the ring, without re-feeding or re-routing, and the 3" ring

depth easily accommodates up to 24 or more cables. At the

back of the D-ring, a shallow peg serves as an anti-rotation de-

vice when properly inserted into the bottom hole of the dual

hole-set in the panel or mounting ear. The top, threaded, 10-32

hole at the back of the D-ring accepts the short screw (provided

with the D-ring) that is inserted or threaded from the rear side

of both the D-ring and mounting ear (or panel, if the panel

holes are used). Use one or more D-rings alone or with the tray

described in Paragraph 3.2 for a customized cable-manage-

ment solution.

3.4 Larger Cable Lacer (Towel) Bar

The panel comes equipped with a 16.56" wide, 2.34" deep, lacer

or towel bar installed on the front of the panel (as shown in

Figure 1) to allow cables to be laced around or hung from the

bar for proper support of the cables that connect to jacks or

couplers at the front of the panel. This bar can be used whether

the panel is wall or rack-mounted. Westell also offers an op-

tional, larger, lacer bar (see Table 4) for rack mounting only,

which is 4" deep and 19" wide, and which is installed on the pan-

el’s mounting ears (not on the panel itself). The larger bar can

be used with or without the smaller bar, or with or without op-

tional D-rings. Lace, hang, or tie-down cables around, from, or

at the lacer bar of choice, per company practice.