Section 520-10S-WI3-203 030-101591 Rev. B R

10 0806I3RB

front-panel LINE −I and +I pin jacks. The DROP −I and +I

pin jacks are disabled and provide no span current measurement

readings. See Figure 8 and Figure 16 for reference.

Span current is represented by the voltage measured across a

10-ohm resistor. A reading of 0.6Vdc equates to a measurement

of 60mA. For a reading of 57mA to 63mA, the voltage measured

across the −I and +I pin jacks will indicate 0.57Vdc to 0.63Vdc,

respectively.

4.2.2.5 CPE LOS Condition (Line Repeater Mode)

When configured as a line repeater, a loss-of-signal condition

from the CPE side (Side 2, Transmit to Network) causes the unit

to generate an AIS pattern toward the Network. Signal transmis-

sion on Side 1 (Receive From Network) remains unaffected.

Upon detecting a signal from the CPE side, the unit restores nor-

mal operation.

4.3 NIU Operation

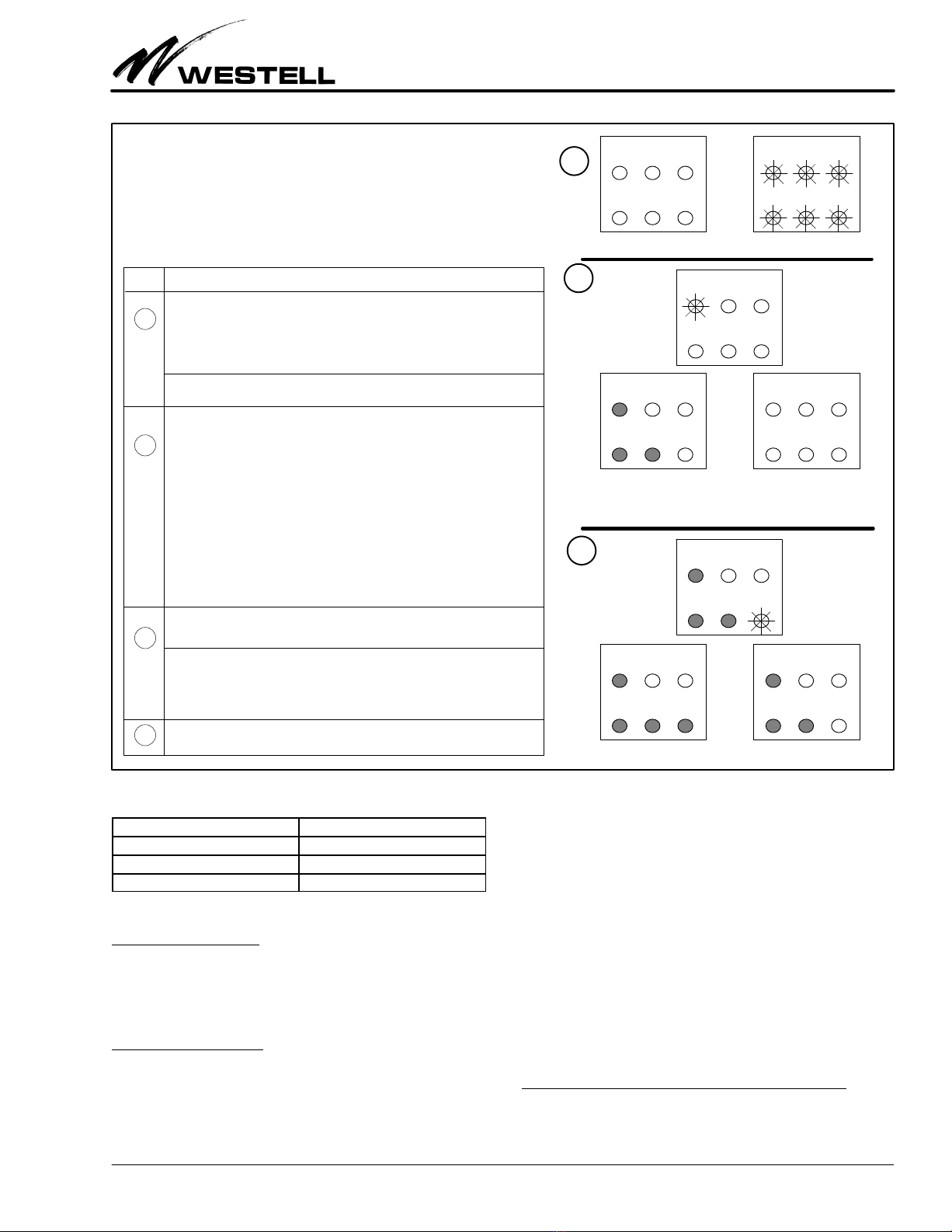

If the unit is to be configured as an NIU (i.e., option switches S1

and S2 set to the appropriate positions for the desired powering

mode, see Table 3).

While in the Local Provisioning mode, the PWR/RPTR Provi-

sioning LED will flash. (See Figure 8 also).

PWR/ If the unit is to be configured to operate as an NIU and

RPTR while the PWR/RPTR LED is flashing, simply let the

4-second timer time out (i.e., do not press the MLB

button). The PWR/RPTR LED will be off and the unit

will automatically be set for the NIU mode. Then unit

will then sequence to the next LED option − CLOS

ID.

4.3.1 CLOS ID Provisioning − NIU Mode Only

The unit, when configured as an NIU, can be optioned for one

of the following responses upon detecting a CPE loss of signal:

1) to send an AIS toward the Network; 2) to send a Customer

Disconnect Indication (CDI) toward the Network or 3) to enter

Loopback.

To provision the unit for the proper CLOS ID response, option

switch S4 (segments A and B) must first be set to the appropriate

positions (see Figure 16). When S4-A and S4-B are set and while

the CLOS ID LED is flashing, press the front-panel MLB button

within the 4-second time frame. If pressed, the CLOS ID LED

illuminates and the unit sequences to the next Provisioning LED

− ESF Only. If the MLB button is not pressed during the 4-sec-

ond time frame, the CLOS ID option is disabled and the unit

then sequences to the next Provisioning LED − ESF Only.

- NOTE -

If the CLOS ID option is disabled, upon detecting a loss of signal

from the CPE end, the unit simply terminates.

4.3.2 ESF Only Provisioning − NIU Mode Only

- NOTE -

When configured as an Office or as a Line Repeater, the ESF Only

option is not applicable. This feature is available only while in the

NIU mode.

When configured for the NIU mode, the unit can be configured

to respond to SF or ESF codes or respond to ESF codes only.

ESF While the ESF Only LED is flashing, simply press

Only MLB button once to configure unit to detect ESF sig-

nals only. The ESF Only LED illuminates and

sequence to the next LED − NET REGEN.

To configure the unit to detect either SF or ESF codes,

simply let the 4-second timer time out (i.e., do not

press MLB button). ESF Only LED is OFF and the

unit sequences to the next LED − NET REGEN.

- NOTE -

When configured for detecting both SF or ESF codes, the unit

responds to the standard SF or ESF inband loop-up codes 11000 or

0001 0010 1111 1111 and standard loop-down codes 11100 or 0010

0100 1111 1111. If configured for ESF Only, the unit only responds

to the standard ESF DL codes 0001 0010 1111 1111 (loop-up) or

0010 0100 1111 1111 (loop-down).

4.3.3 NET REGEN Provisioning − NIU Mode Only

- NOTE -

When configured as an Office Repeater, Network-side Regeneration

(NET REGEN) is always enabled. Therefore the next Provisioning

LED to flash in the Office Repeater mode, is the CPE REGEN LED.

When configured as a line repeater, the Network and CPE-side

Regeneration (NET and CPE REGEN) options are always enabled

and those LEDs are illuminated. Therefore, the next Provisioning

LED to flash in the Line Repeater mode is the LPBK T.O. LED.

In the NIU mode, the unit can be configured to enable or dis-

able the Network-side Regenerator. When CPE to NET

REGEN is enabled, the unit places a signal regenerator in the

RCV From CPE (Side 2) transmission path. When NET RE-

GEN is disabled, the unit removes the regenerator in the RCV

From CPE (Side 2) transmission path and the unit is passive.

NET While the NET REGEN LED is flashing, to enable

REGEN Network-side regeneration, simply press MLB button

once. The NET REGEN LED illuminates then se-

quences to the next LED − CPE REGEN.

If Network regeneration is not required, simply let the

4-second timer time out. The NET REGEN LED is off

and the unit sequences to the next LED − CPE RE-

GEN.

4.3.4 CPE REGEN Provisioning − NIU Mode Only

In the NIU mode, the unit can be configured to enable or dis-

able the CPE-side Regenerator. When the NET to CPE

REGEN is enabled, the unit places a CPE-side signal regenera-

tor in the RCV from NET (Side 1) transmission path. When

NET to CPE REGEN is disabled, the unit removes the regen-

erator in the RCV from NET (Side 1) transmission path and

the unit is passive.

CPE While the CPE REGEN LED is flashing, to enable

REGEN CPE−side regeneration, simply press MLB button

once. The CPE REGEN LED illuminates then se-

quences to the next LED − LPBK T.O.

If CPE-side regeneration is not required, simply let the

4-second timer time out. The CPE REGEN LED is off

and the unit sequences to the next LED − LPBK T.O.

- NOTE -

With the CPE REGEN feature enabled, the signal regenerator

recovers signals from the CPE and regenerates the DS1 signal

towards the Network at a 0dB level.