Westerbeke 7.0KW BCG-60HERTZ User manual

Other Westerbeke Inverter manuals

Westerbeke

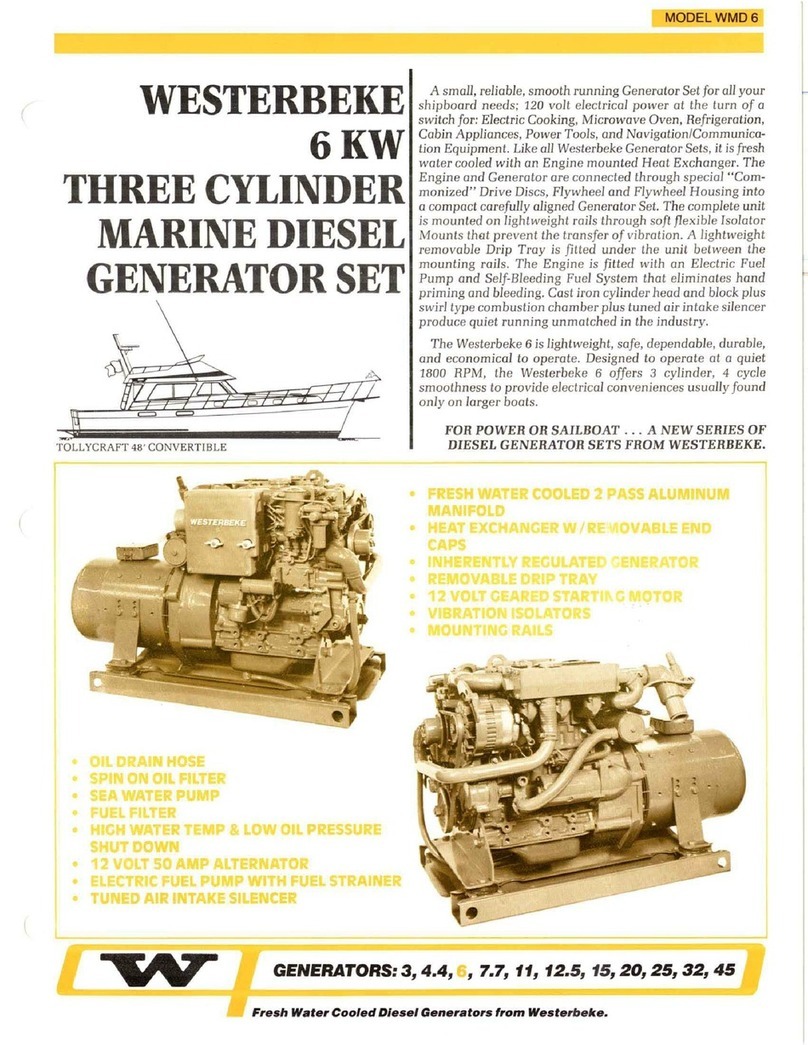

Westerbeke WMD6 User manual

Westerbeke

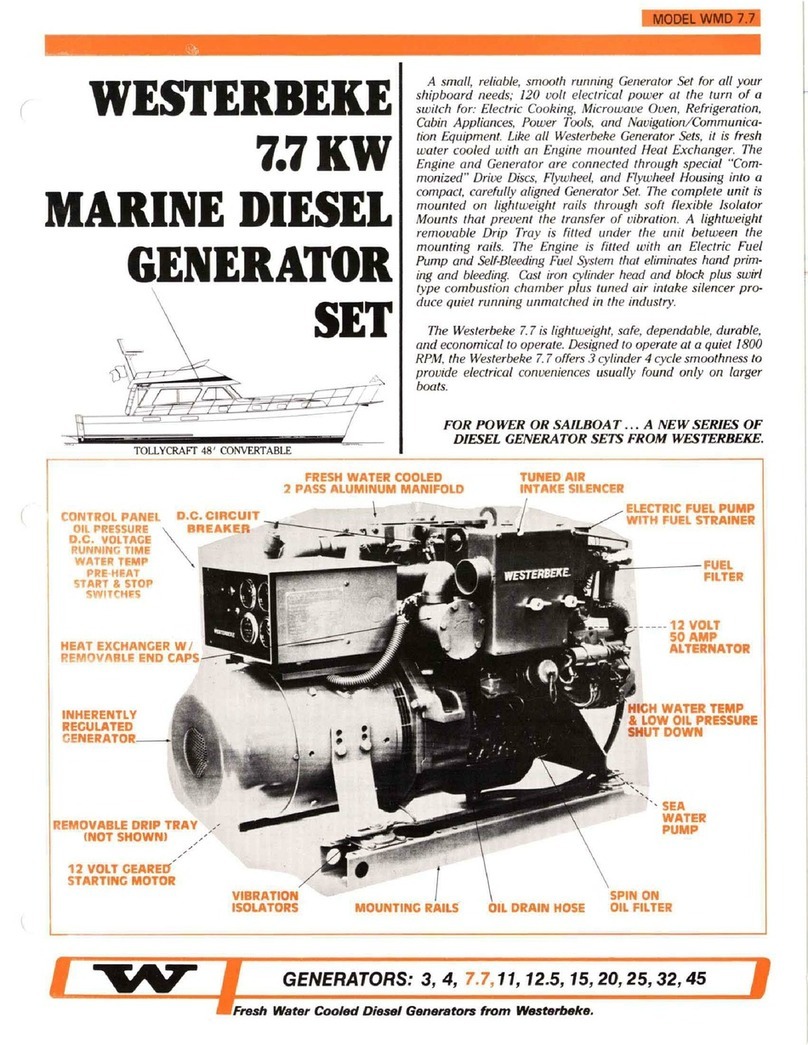

Westerbeke WMD 7.7 User manual

Westerbeke

Westerbeke 8 BCDT-614 User manual

Westerbeke

Westerbeke 9.0 BCG User manual

Westerbeke

Westerbeke 6.5 MCG 60HZ User manual

Westerbeke

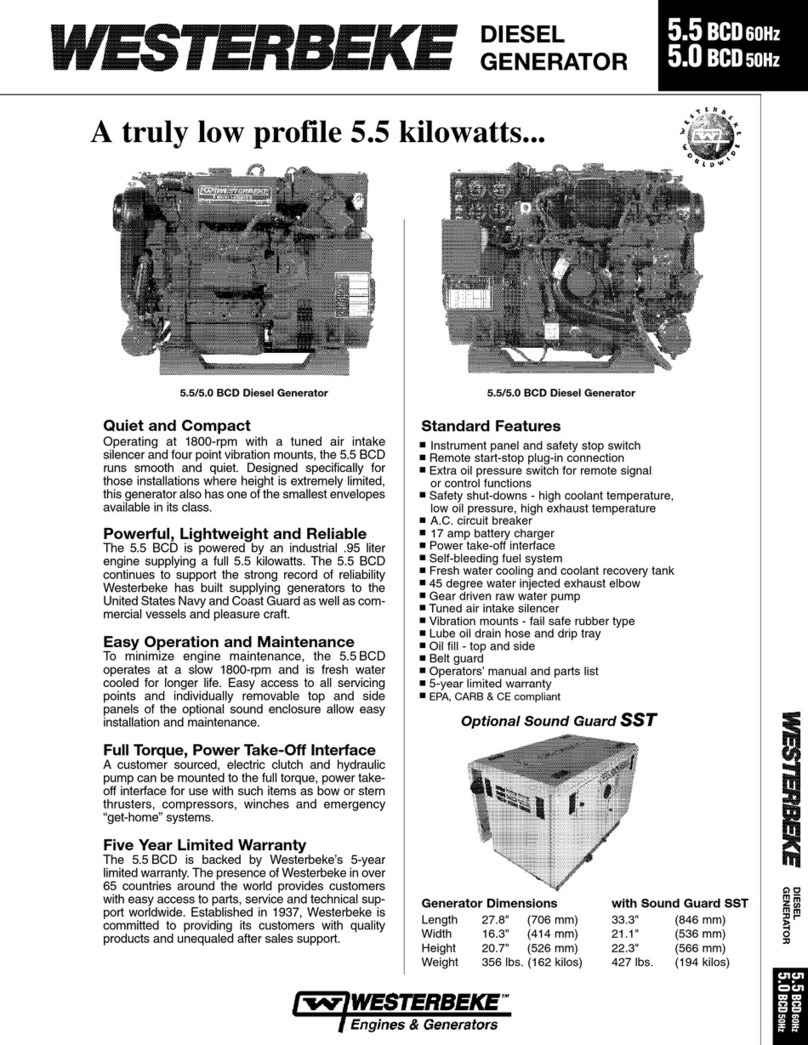

Westerbeke 5.5 kw EDC 60 HZ User manual

Westerbeke

Westerbeke BT 8 User manual

Westerbeke

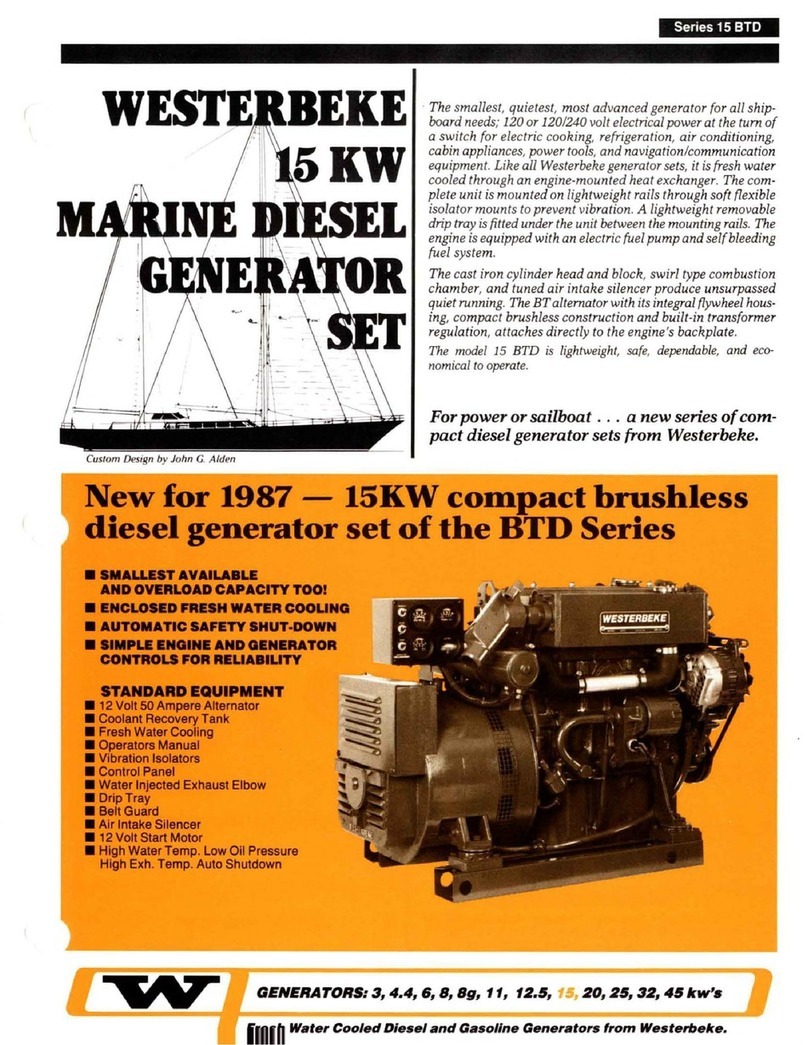

Westerbeke 15 BTD-614 User manual

Westerbeke

Westerbeke 8.0KW - 60Hz EDT User manual

Westerbeke

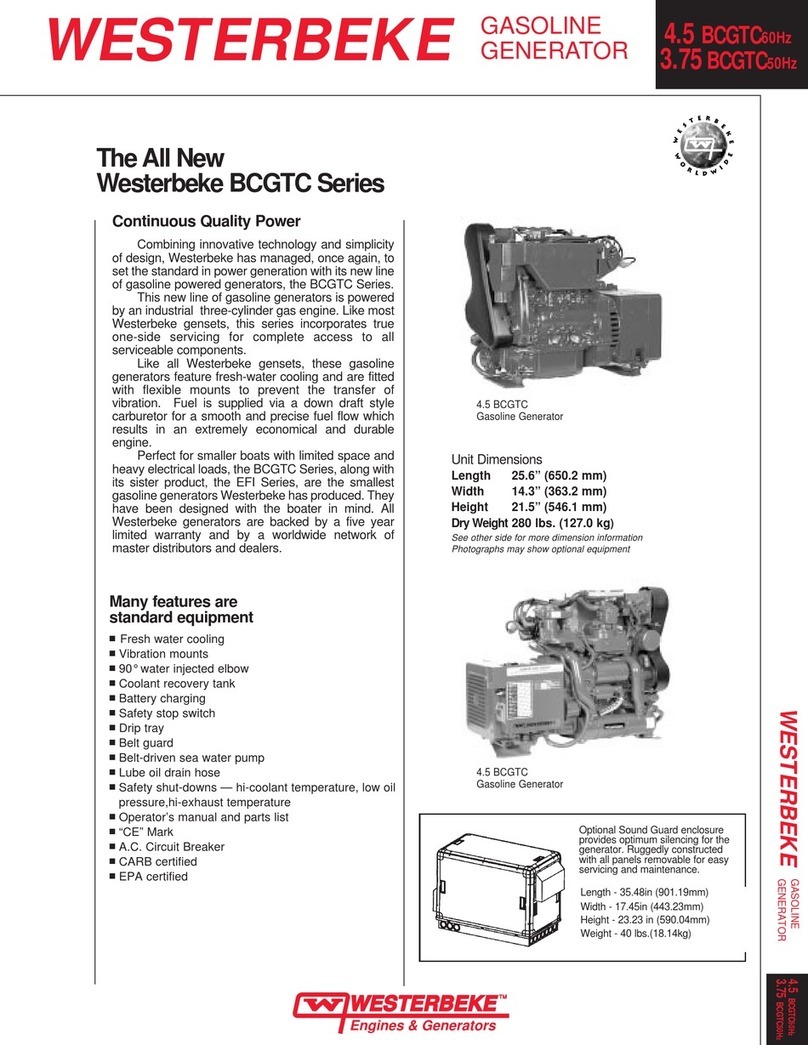

Westerbeke 4.5 BCGTC User manual

Westerbeke

Westerbeke 12.5 BTD-614 User manual

Westerbeke

Westerbeke 10.0KW-60Hz User manual

Westerbeke

Westerbeke BTG-9KW User manual

Westerbeke

Westerbeke 6.4 KW-50Hz SBEG User manual

Westerbeke

Westerbeke 10.0KW-60Hz User manual

Westerbeke

Westerbeke 8.0 KW BCGTC - 50 Hz User manual

Westerbeke

Westerbeke 4.5 BCGB-614 User manual

Westerbeke

Westerbeke 10.0KW-60Hz User manual

Westerbeke

Westerbeke 3.8 BCDT-612 User manual

Westerbeke

Westerbeke BCGA-60HZ User manual

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual