Westerbeke 10.0KW-60Hz User manual

Other Westerbeke Inverter manuals

Westerbeke

Westerbeke 10.0KW-60Hz User manual

Westerbeke

Westerbeke Series 11 BTD User manual

Westerbeke

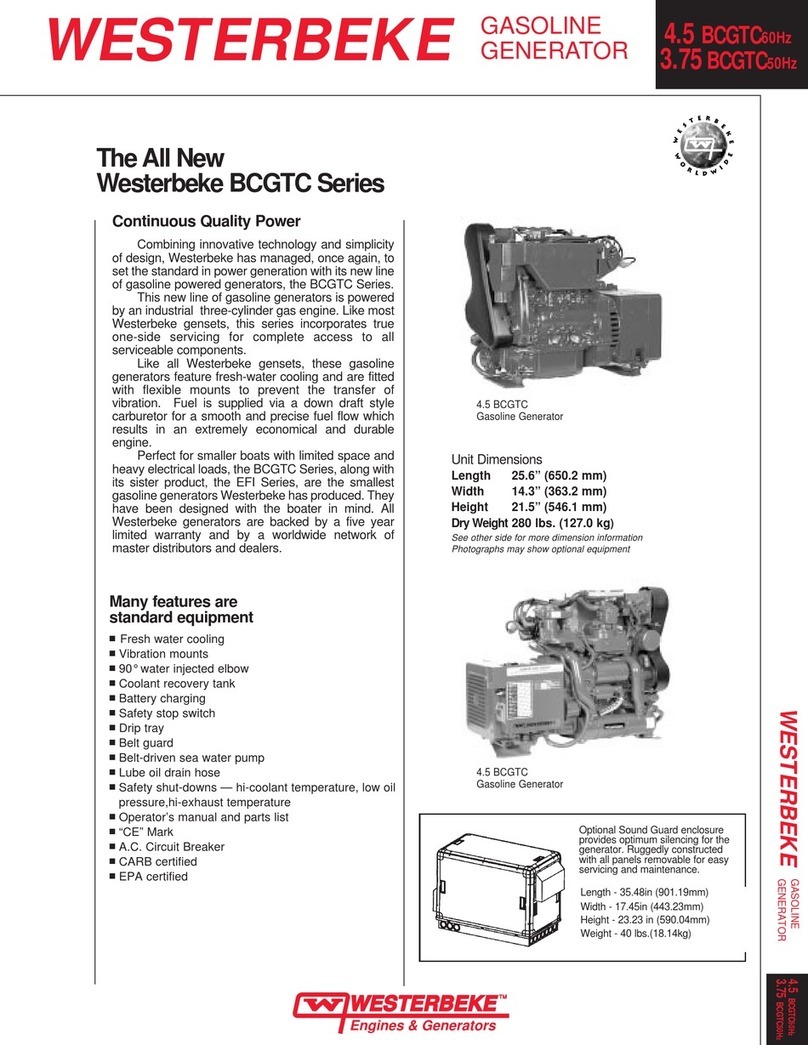

Westerbeke 4.5 BCGTC User manual

Westerbeke

Westerbeke SBEG Series User manual

Westerbeke

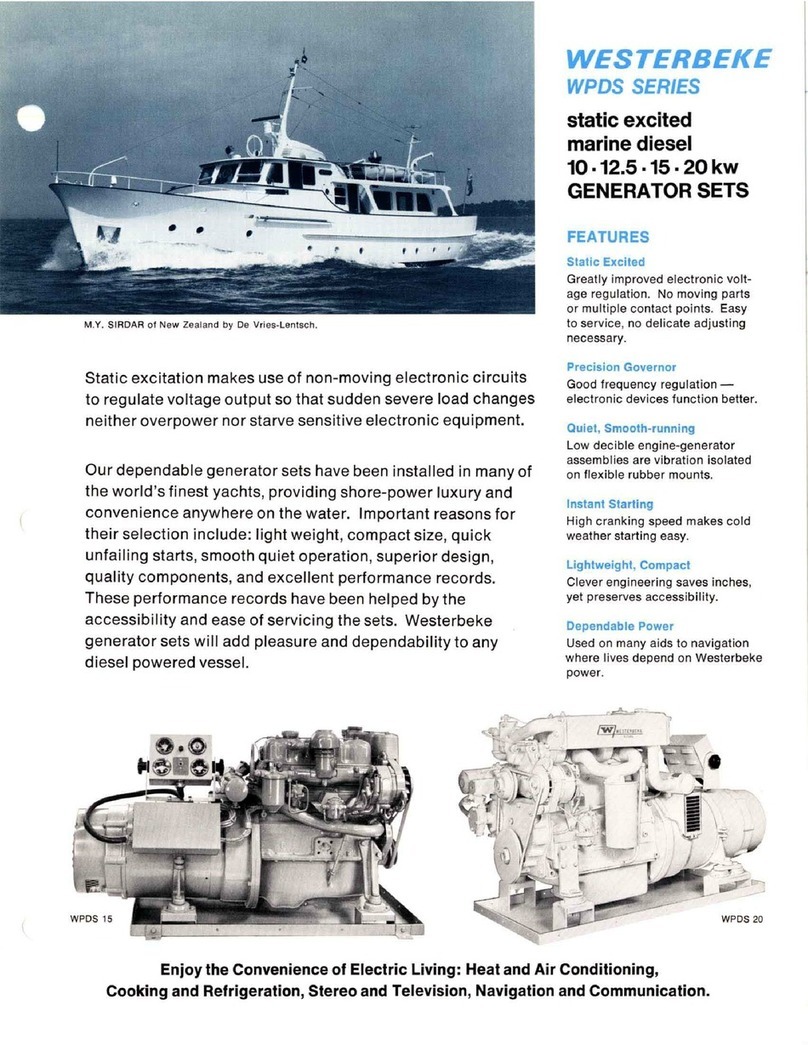

Westerbeke WPDS SERIES Manual

Westerbeke

Westerbeke 10.0 EGTD User manual

Westerbeke

Westerbeke 5.0Kw BCDR User manual

Westerbeke

Westerbeke BCD 4.4KW User manual

Westerbeke

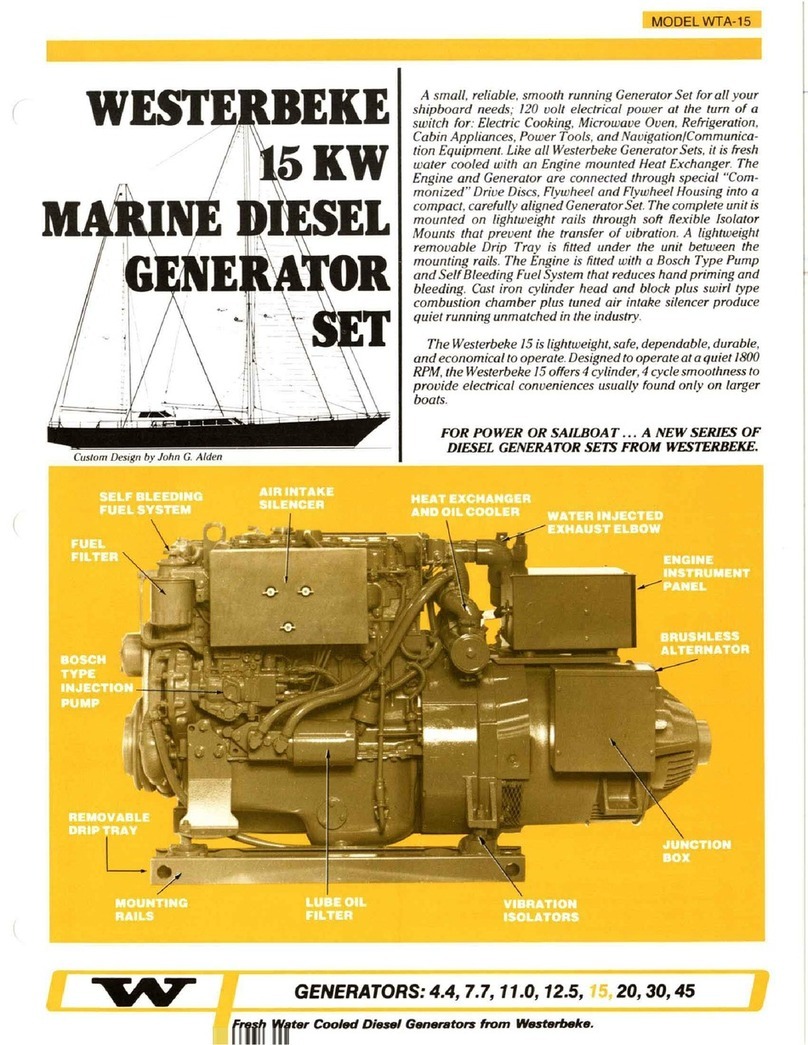

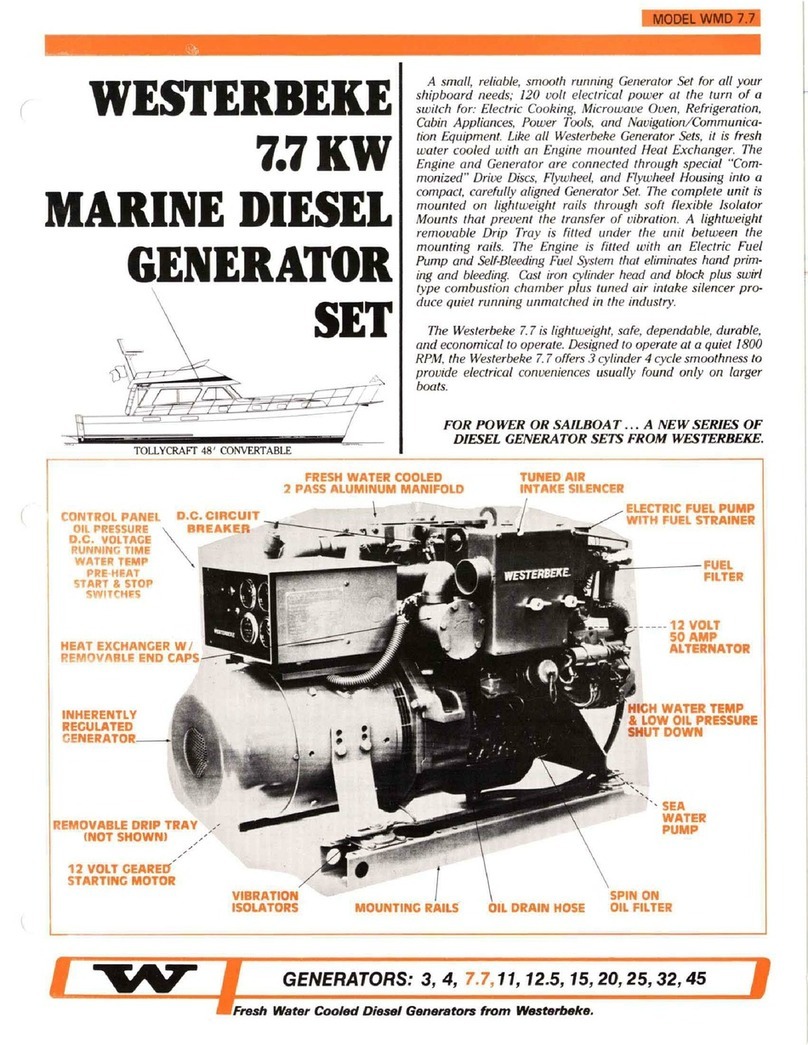

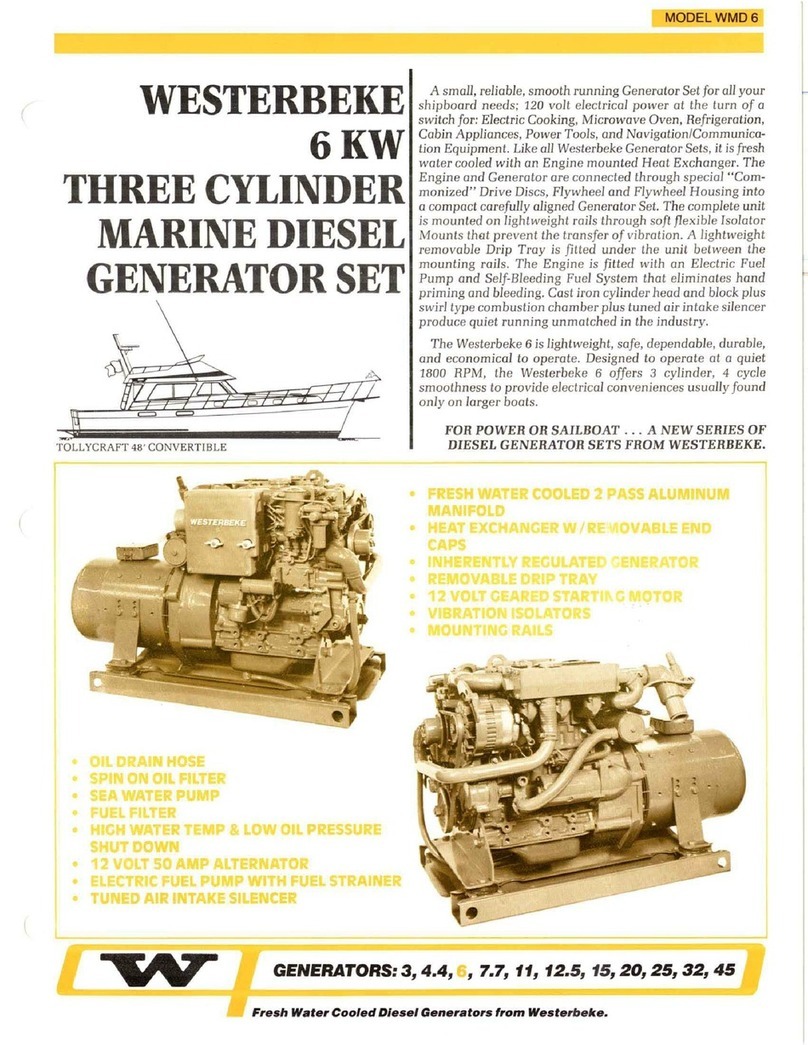

Westerbeke 4KW-7.7KW-11KW-12 5KW User manual

Westerbeke

Westerbeke 4.5 BCGB-614 User manual

Westerbeke

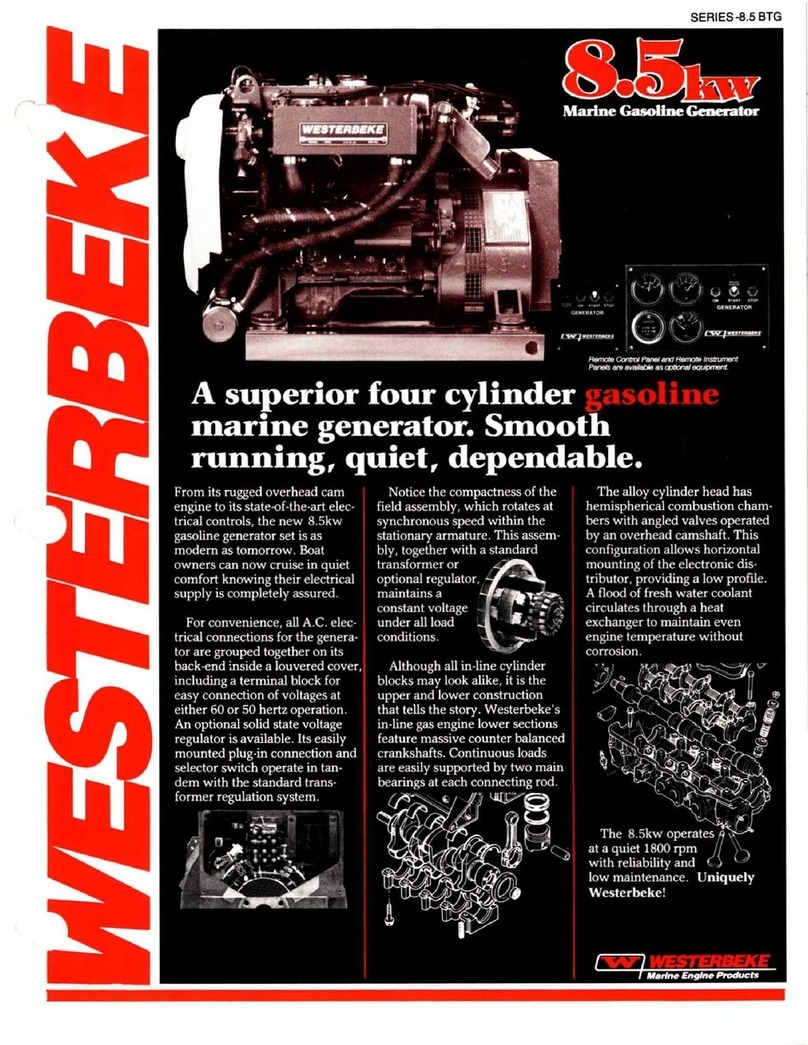

Westerbeke 8.5 BTG User manual

Westerbeke

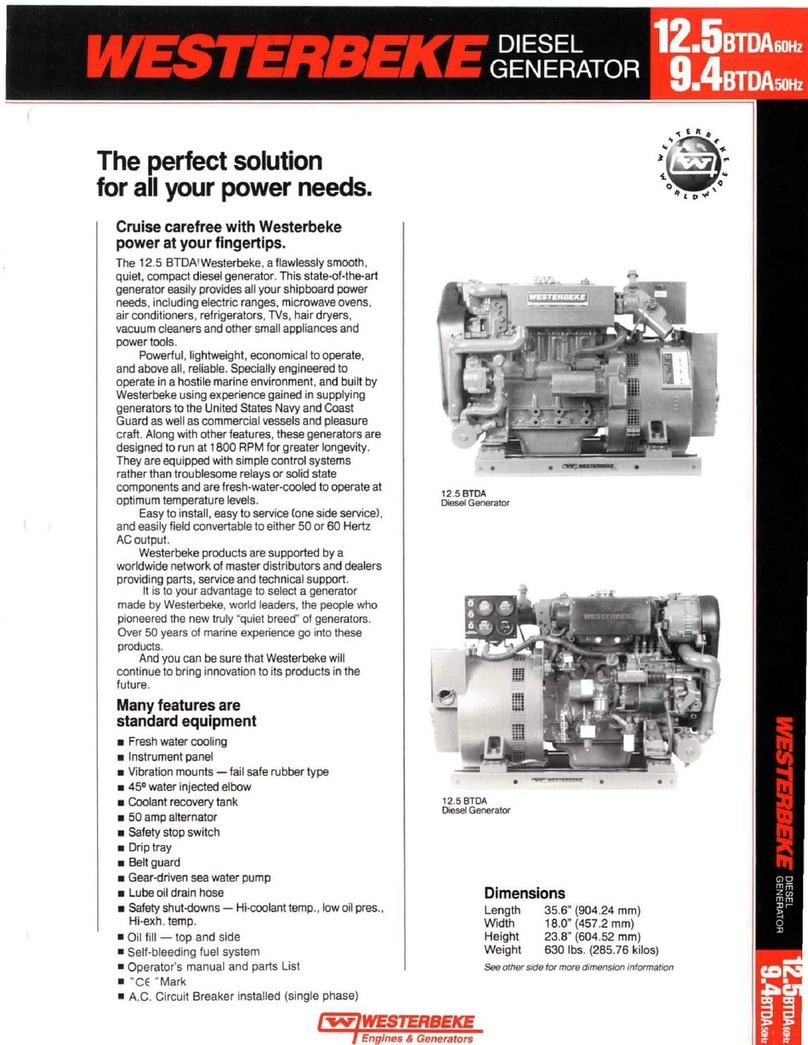

Westerbeke 12.5 BTDA Manual

Westerbeke

Westerbeke 7.0KW BCG-60HERTZ User manual

Westerbeke

Westerbeke 6.4 KW-50Hz SBEG User manual

Westerbeke

Westerbeke WMD6 User manual

Westerbeke

Westerbeke BT 8 User manual

Westerbeke

Westerbeke 3.5 SBCG User manual

Westerbeke

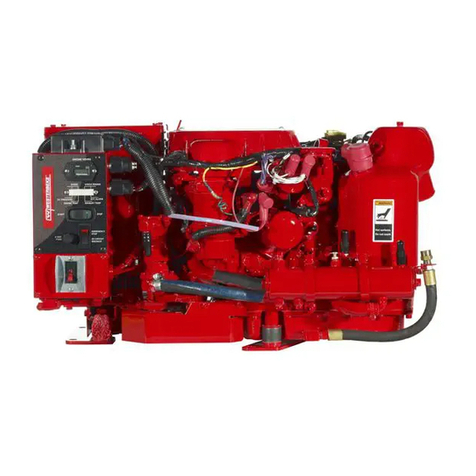

Westerbeke 15.0BTD60-HERTZ User manual

Westerbeke

Westerbeke 3.5KW SBCG-60Hz User manual

Westerbeke

Westerbeke 8 BCDT-614 User manual

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual