TESTING

FOR

OVERHAUL

HOW

TO

DETERMINE

ENGINE

OVERHAUL

PERIOD

Cause

of

Low

Compression

Generally, the time at which an engine should be overhauled

is

determined

by

various conditions such as lowered engine

power output, decreased compression pressure, and increased

fuel and oil consumption. The lowered engine power output

is

not necessarily due to trouble with the engine itself, but

is

sometimes caused by improper oil, clogged filters or a faulty

carburetor.

The decrease in compression pressure is caused by many fac-

tors. It is, therefore, necessary to determine a cause or causes

on the basis

of

data produced by periodic inspection and

maintenance. Oil analysis on a seasonal basis is a good

means

of

monitoring engine internal wear. When caused by

worn cylinders or piston rings, the following symptoms will

occur: 1 Low engine power output

2 Increased fuel consumption

3 Increased oil consumption

4

Hard

engine starting

5 Noisy engine operation

These symptoms often appear together. Symptoms 2 and 4

can result also from improper fuel regulation

or

a faulty car-

buretor. They are caused also by defective electrical devices

such as the battery, starter

or

spark plugs. Therefore it is

desirable to judge the optimum engine overhaul time by the

lowered compression pressure caused by worn cylinders and

pistons plus increased oil consumption. Satisfactory combus-

tion

is

obtained only under sufficient compression pressure.

If

an engine lacks compression pressure, incomplete combus-

tion

of

fuel will take place even

if

other parts

of

the engine

are operating properly.

To

determine the period

of

engine

overhaul, it

is

important to measure the engine compression

pressure regularly.

At

the same time, the engine speed at

which the measurement

of

compression pressure is made

should be checked because the compression pressure varies

with engine rpm. The engine rpm can be measured at the

front end

of

the crankshaft.

NOTE:

To

test engine compression see the

ENGINE

ADJUSTMENT

section

of

this manual.

OVERHAUL

CONDITIONS

Compression pressure tends to increase a little in a new

engine until piston rings and valve seats have been broken in.

Thereafter, it decreases gradually with the progress

of

wear

of

these parts.

When decrease

of

compression pressure reaches the repair

limit, the engine must be overhauled.

The enginerequires overhaul when oil consumption

is

high,

blowby evident, and compression values are at minimum or

below. Engine compression should be

178

psi

(1260 Kpa) at

400 rpm With a limit 137

psi

(860 Kpa). Pressure should not

differ

by

more than 14

psi

(100 Kpa) between cylinders. See

ENGINE

COMPRESSION in this manual.

ENGINE

OVERHAUL

The following sections contain detailed information

relating to the major components and systems

of

the engine.

Included are disassembly and inspection instructions for the

guidance

of

suitable equipped and staffed marine engine ser-

vice and rebuilding facilities. The necessary procedures

should be undertaken only by such facilities.

Additional detailed information and specifications are

provided in other sections

of

this manual, covering the

generator, alternator, starter motor, engine adjustments,

cooling pumps, etc.

DISASSEMBLY

1.

Before disassembly and cleaning, carefully check for

defects which cannot be found after disassembly and

cleaning.

2. Clean the engine exterior.

3. Perform disassembly in a proper order using proper tools.

Keep disassembled parts in order. Apply oil when neces-

"sary. Take special care to keep the fuel system parts from "

intrusion

of

dust and dirt.

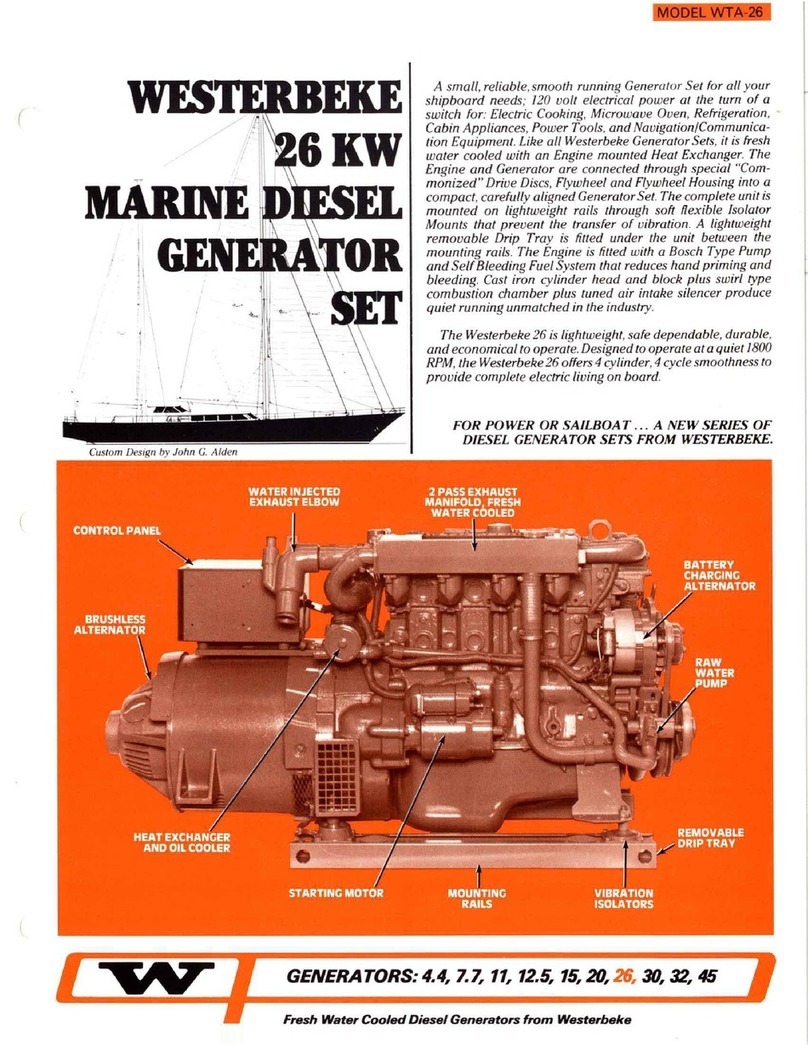

SERIAL

NUMBER

LOCATION~~

~

The engine serial

FiIl

in

the information

l";~0~Ob')..

~~\

'!umber

is

str;zmped

below for

referenc~_

~/

3-:>

II

znto

the engme block.

0~

f"'~

~

~I

'~

~

!~I(

I 1

I

\1

~~==~~~~

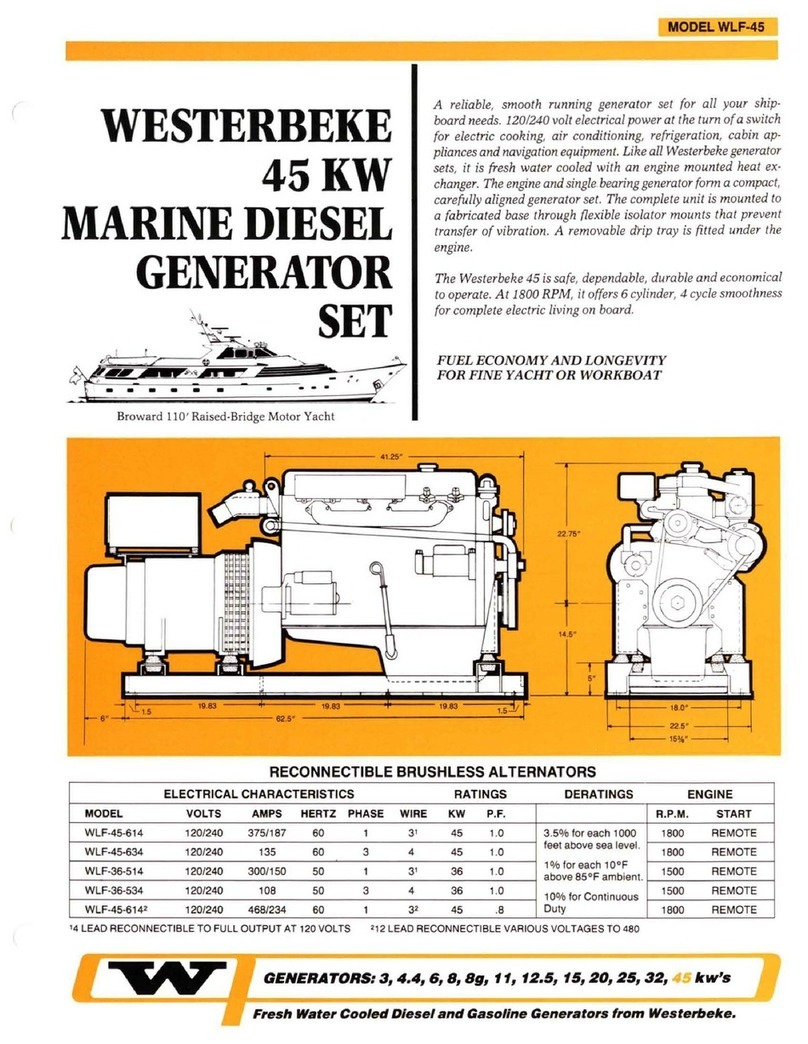

The engine model

number

and

"serial

numberare printed

on a decal on the

engine manifold.

The generator serial

number is stamped

on the top

of

the

generator housing.

An

additional decal

is located on the top

of

the

generator

housing.

Engines & Generators

3