1

Indicator Technical Manua

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................................. 2

Safety .......................................................................................................................................... 2

Features ...................................................................................................................................... 3

Specifications .............................................................................................................................. 3

DISPLAY & ANNUNCIATORS ........................................................................................................ 4

Weight Display ............................................................................................................................ 4

Annunciators ............................................................................................................................... 4

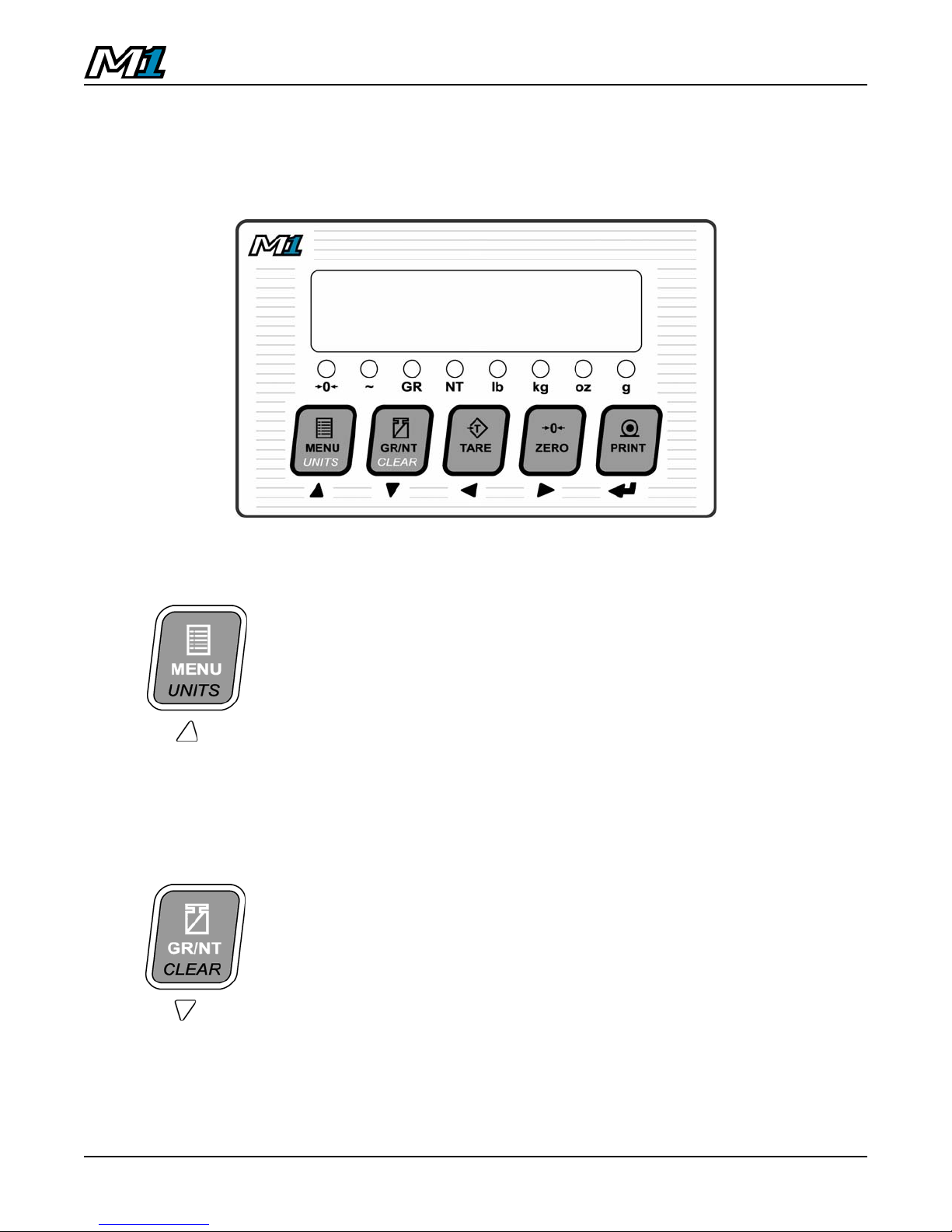

KEYPAD & SCALE FUNCTIONS.................................................................................................... 6

INSTALLATION ............................................................................................................................... 8

Pre-Installation ............................................................................................................................ 8

Opening the M1 Enclosure.......................................................................................................... 8

Load Cell Wiring .......................................................................................................................... 9

Communications Wiring (RS 232)............................................................................................. 10

Remote Switch Wiring............................................................................................................... 11

Battery / Battery Replacement .................................................................................................. 11

Closing the M1 Enclosure ......................................................................................................... 12

Mounting Instructions ................................................................................................................ 12

START-UP..................................................................................................................................... 13

TIME & DATE ................................................................................................................................ 13

CALIBRATION MODE................................................................................................................... 14

Calibration Keys ........................................................................................................................ 14

Entering Calibration Mode......................................................................................................... 14

Navigating Calibration Parameters ........................................................................................... 15

Editing Calibration Parameters ................................................................................................. 15

Exit & Save Calibration ............................................................................................................. 15

CALIBRATION PARAMETERS..................................................................................................... 16

Scale Calibration Sub-block 1.x ................................................................................................ 16

Zero and Motion Settings Sub-block 2.x ................................................................................... 17

Tare Settings Sub-block 3.x ...................................................................................................... 18

Scale Filtering Settings Sub-block 4.x....................................................................................... 19

Serial Communications Sub-block 5.x ...................................................................................... 20

Serial Communications Sub-block 5.x (Continued) .................................................................. 21

Ticket Formatting Sub-block 7.x................................................................................................ 22

Additional Scale Functions Sub-block 8.x................................................................................. 23

Scale Diagnostics Sub-block 9.x............................................................................................... 24

QUICK SCALE CALIBRATION ..................................................................................................... 25

REMOTE DISPLAY MODE ........................................................................................................... 26

USER MENU ................................................................................................................................. 28

SEALING THE INDICATOR (LEGAL FOR TRADE) ..................................................................... 29

TROUBLESHOOTING & ERROR MESSAGES............................................................................ 30