TABLE OF CONTENTS

Introduction…………………………………………………………………………………. 1

Installation Strategies…………………………………………………………….. 2

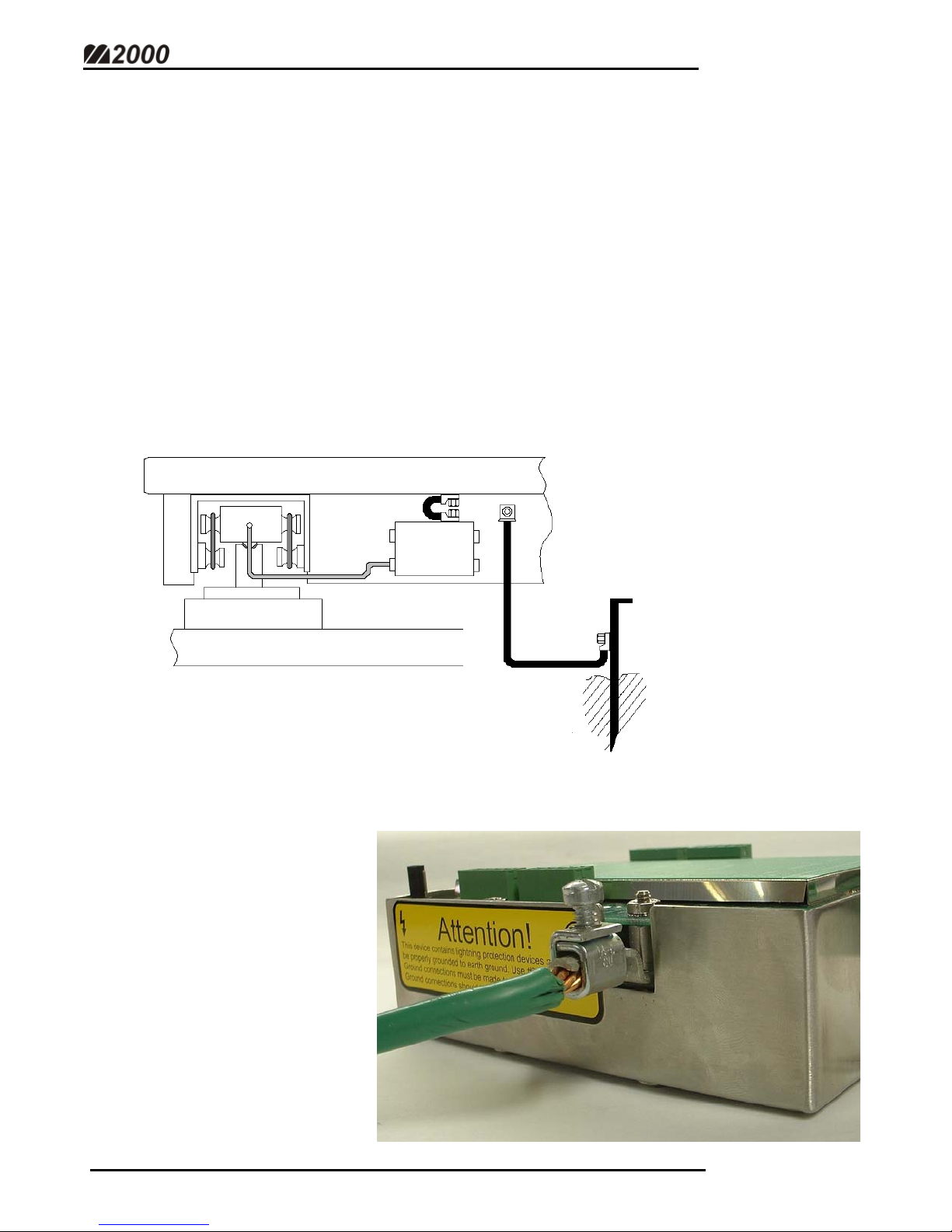

System Grounding……………………………………………………………….. 3

Getting Started…………………………………………………………………………… 4

Setting the DLC ID Jumper……………………………………………………… 5

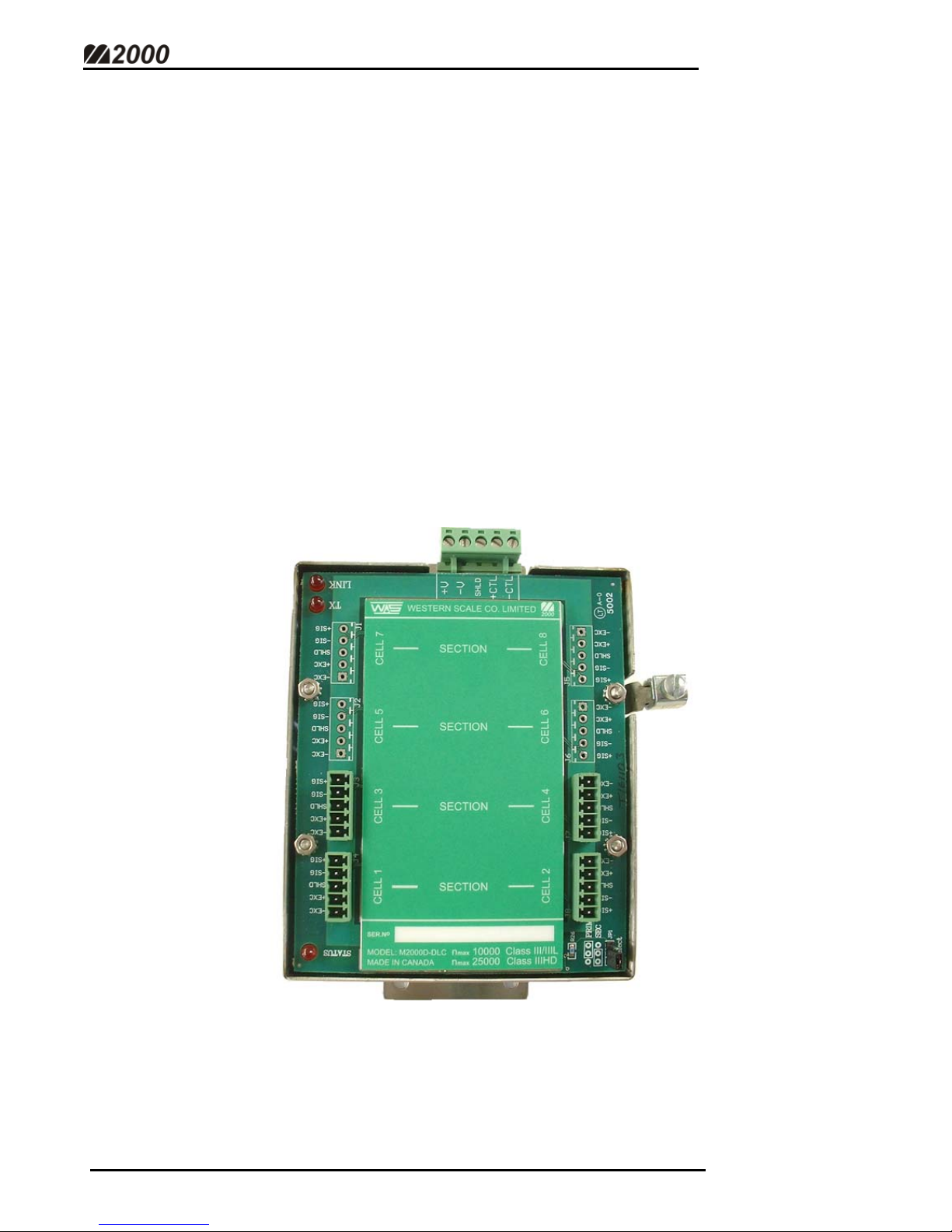

Wiring Loadcells to the DLC Smart Box………………………………………… 6

Wiring DLC Smart Boxes to the M2000D Indicator…………………………….. 7

Other Wiring to the M2000D Indicator………………………………………….. 9

Powering Up the Indicator for the First Time…………………………………… 10

LEDs on Power Up……………………………………………………………… 10

Calibration Mode……………………………………………………………………….. 11

Entering Into Calibration Mode…………………………………………………. 11

Entering Calibration Commands………………………………………………… 11

Setting Graduation Size…………………………………………………………. 12

Setting Scale Capacity………………………………………………………….. 12

Setting Calibration Units………………………………………………………… 12

Allocating Sections……………………………………………………………… 13

Deadloading the Scale…………………………………………………………… 13

Spanning a Scale with a Test Weight…………………………………………… 14

Exit Calibration Mode…………………………………………………………… 14

Navigating the M2000………………………………………………………………….. 15

Select a Section or Cell…………………………………………………………. 16

Quick Select Method (For Sections)…………………………………………….. 17

Sectional Adjustment……………………………………………………………. 17

Example…………………………………………………………………. 18

Corner & Side-to-Side Adjustments…………………………………………….. 18

Serial Communications………………………………………………………………….. 19

Data Bits…………………………………………………………………………. 19

Baud Rate……………………………………………………………………….. 19

Parity…………………………………………………………………………….. 20

String Formats for Continuous Output………………………………………….. 20

Serial Handshaking……………………………………………………………… 21

Com Port String Output Mode…………………………………………………... 21

Configuring Com Ports to Transmit in RS422 Mode…………………………… 21

Transmission Delay for Com1 & Com2………………………………………… 22

M2000D System Specifications…………………………………………………………. 23

Appendix A - M2000 Parameters……………………………………………………….. 24

Appendix B - M2000D Specific Parameters……………………………………………. 26

Appendix C – Error Messages………………………………………………………….. 27