ECO FL User’s Guide (FL) Revision AN 4 June 2012 i

Table of Contents

1. Overview ........................................................................................................................... 1

1.1 Specifications ...................................................................................................................... 1

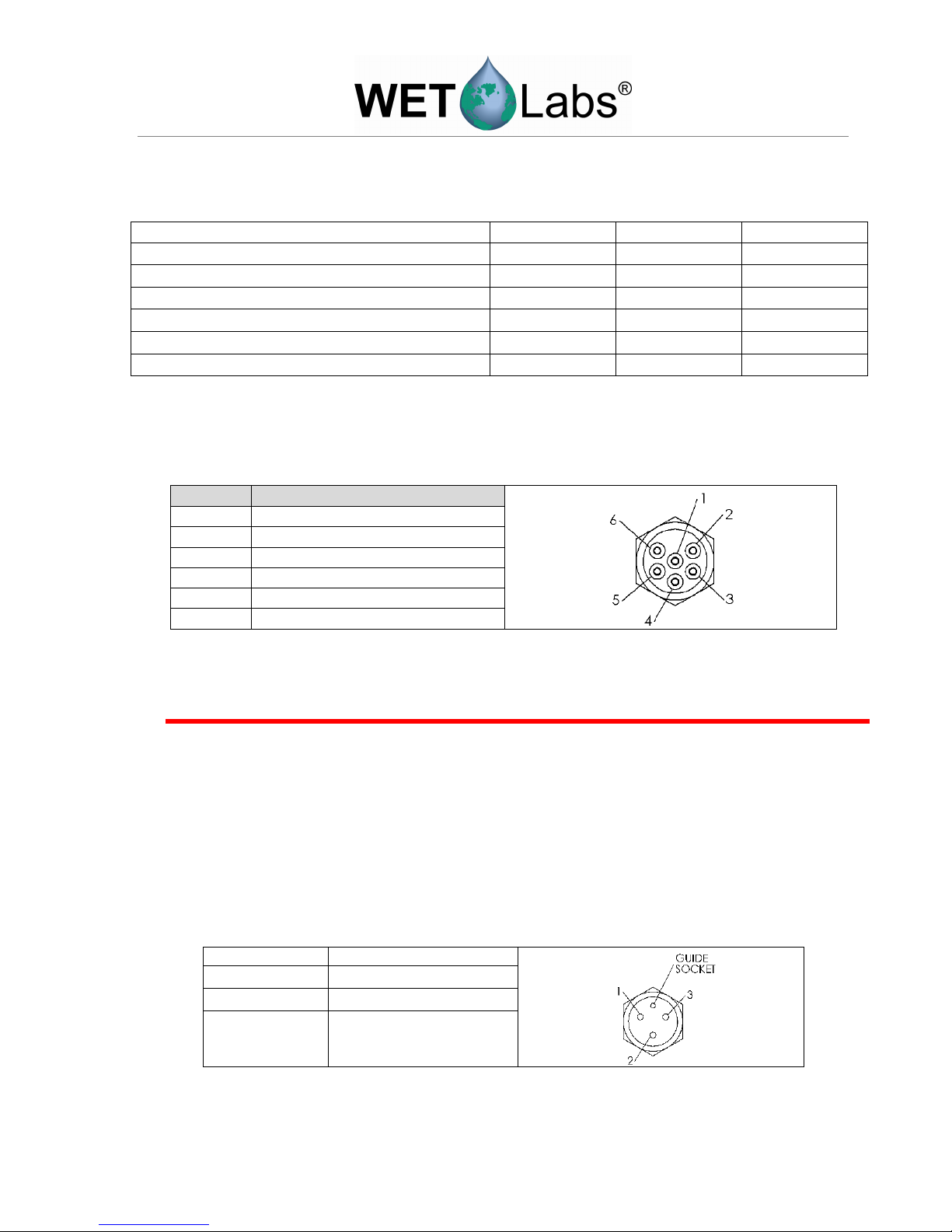

1.2 Connectors .......................................................................................................................... 2

1.3 Delivered Items .................................................................................................................... 3

1.4 Optional Equipment ............................................................................................................. 3

2. Theory of Operation ......................................................................................................... 6

3. Instrument Operation ....................................................................................................... 7

3.1 Initial Checkout .................................................................................................................... 7

3.2 Operating the Sensor for Data Output .................................................................................. 7

3.3 Bio-wiper™ Operation .......................................................................................................... 8

3.4 Deployment ......................................................................................................................... 9

3.5 Upkeep and Maintenance .................................................................................................... 9

4. FLB and FLSB: Using Internal Batteries....................................................................... 12

4.1 Removing End Flange and Batteries .................................................................................. 12

4.2 Replacing End Flange and Batteries .................................................................................. 13

4.3 Checking Vent Plug ........................................................................................................... 14

5. Data Analysis ................................................................................................................. 15

5.1 Scale Factor ...................................................................................................................... 15

5.2 Analog Response............................................................................................................... 15

5.3 Digital Response ................................................................................................................ 16

6. Characterization and Testing ........................................................................................ 17

7. Terminal Communications ............................................................................................ 18

7.1 Interface Specifications ...................................................................................................... 18

7.2 Command List.................................................................................................................... 18

8. Device and Output Files ................................................................................................ 19

8.1 Plot Header........................................................................................................................ 19

8.2 Column Count Specification ............................................................................................... 19

8.3 Column Description ............................................................................................................ 19

8.4 Sample Device File ............................................................................................................ 20

8.5 Sample Output Files .......................................................................................................... 21

Appendix A: Mounting Bracket Drawing .......................................................................... 22

WET Labs WEEE Policy ........................................................................................................ 23

WEEE Return Process ................................................................................................................. 23