6

NOTE: for a detailed explanation of the charging modes, please refer to our publication Theory

of Operation, document #AD-TD-0001-0.

BULK MODE

If the output current reaches its maximum (normally caused by a discharged battery), this will

cause the converter to go into Bulk Mode, which means the target output voltage will change

to 14.4 VDC and a timer will start. Although the converter is outputting 14.4 VDC, you will not

be able to read that on a voltmeter due to the voltage-current relationship. From the paragraph

above, as load current increases, output voltage decreases. The actual output voltage will not

rise until the load current is reduced, which happens naturally as the battery charges or if 12 VDC

appliances are turned off.

Bulk Mode will be maintained until the current draw drops to approximately ve Amps, or until

the timer reaches four hours (whichever happens rst). Then the target output voltage is changed

back to 13.6 VDC for Absorption Mode. Lights that are powered from the output may change

brightness slightly at that time.

FLOAT MODE

The third mode of charging is what is called the “oat” charge. This mode is designed to

provide a “trickle charge” to the battery after the system observes no signicant variations in

current draw over a long period of time. When in “oat” mode, the voltage will reduce from

13.6V to 13.2V and supply the “trickle charge” which helps to preserve the life of the battery

while keeping it charged and r

eady for use. A change in DC current will cause the converter to exit the mode and return to the

Absorption mode and then to Bulk mode if required.

Note: For a detailed explanation of the charging modes, please refer to our publication “Theory

of Operation”, document #AD-TD-0001-0.

LITHIUM TWO-STAGE SMART CHARGING

The two-stage “smart” charger continuously measures the battery voltage output and regulates

the amount of charge using two modes of operation: Bulk and Absorption mode.

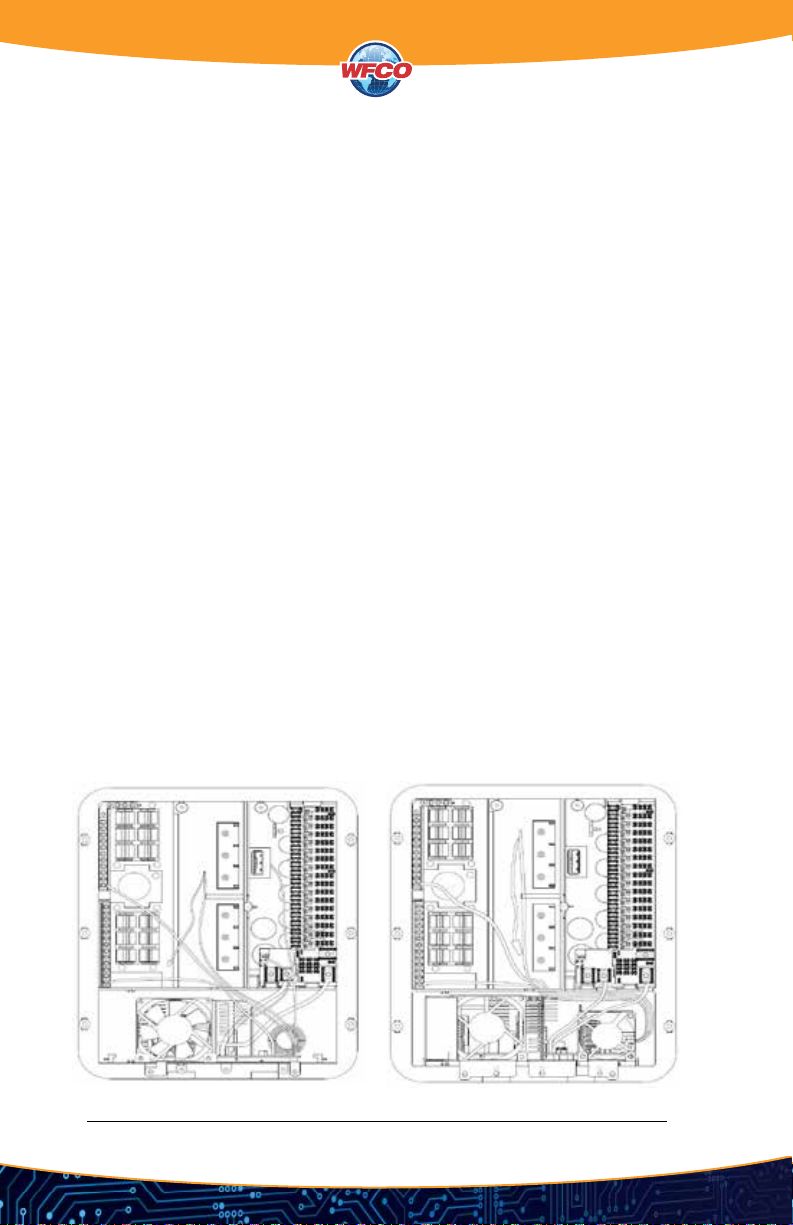

2-STAGE CONVERTER VOLTAGE OUTPUT MODES

Understanding output voltages of a two-stage converter.

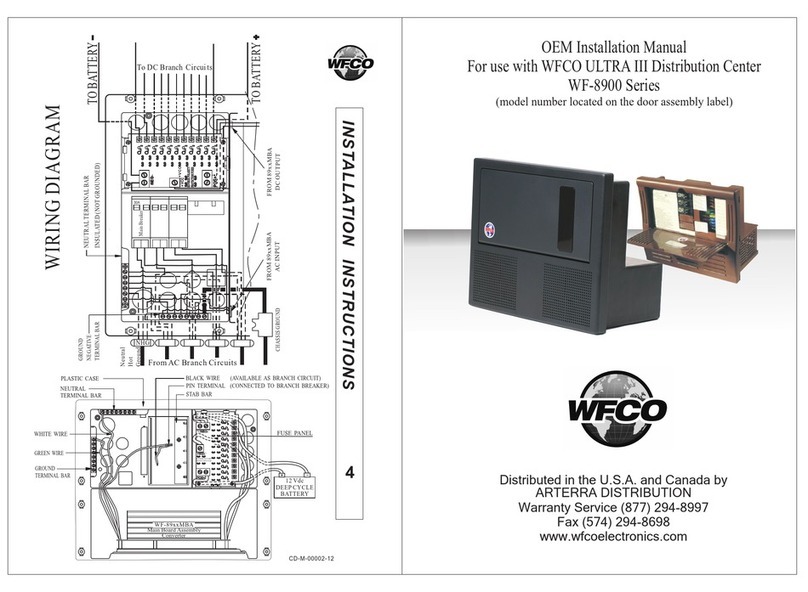

Figure 2