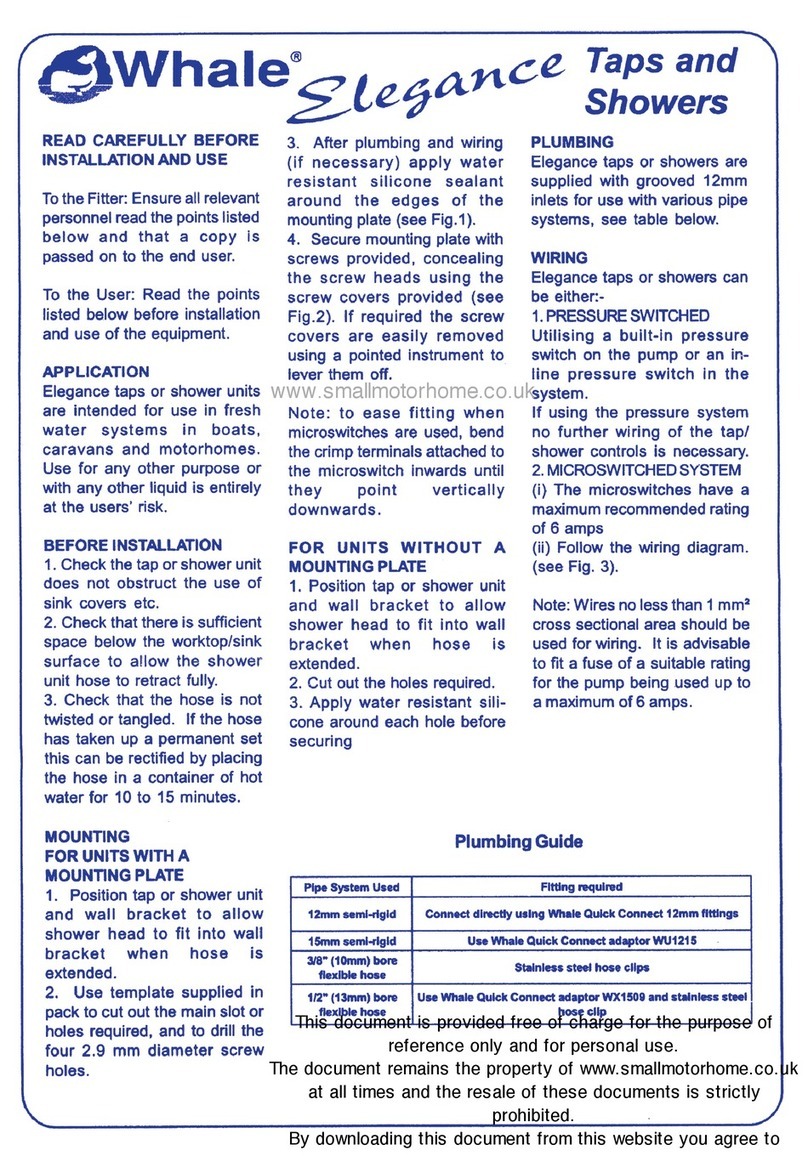

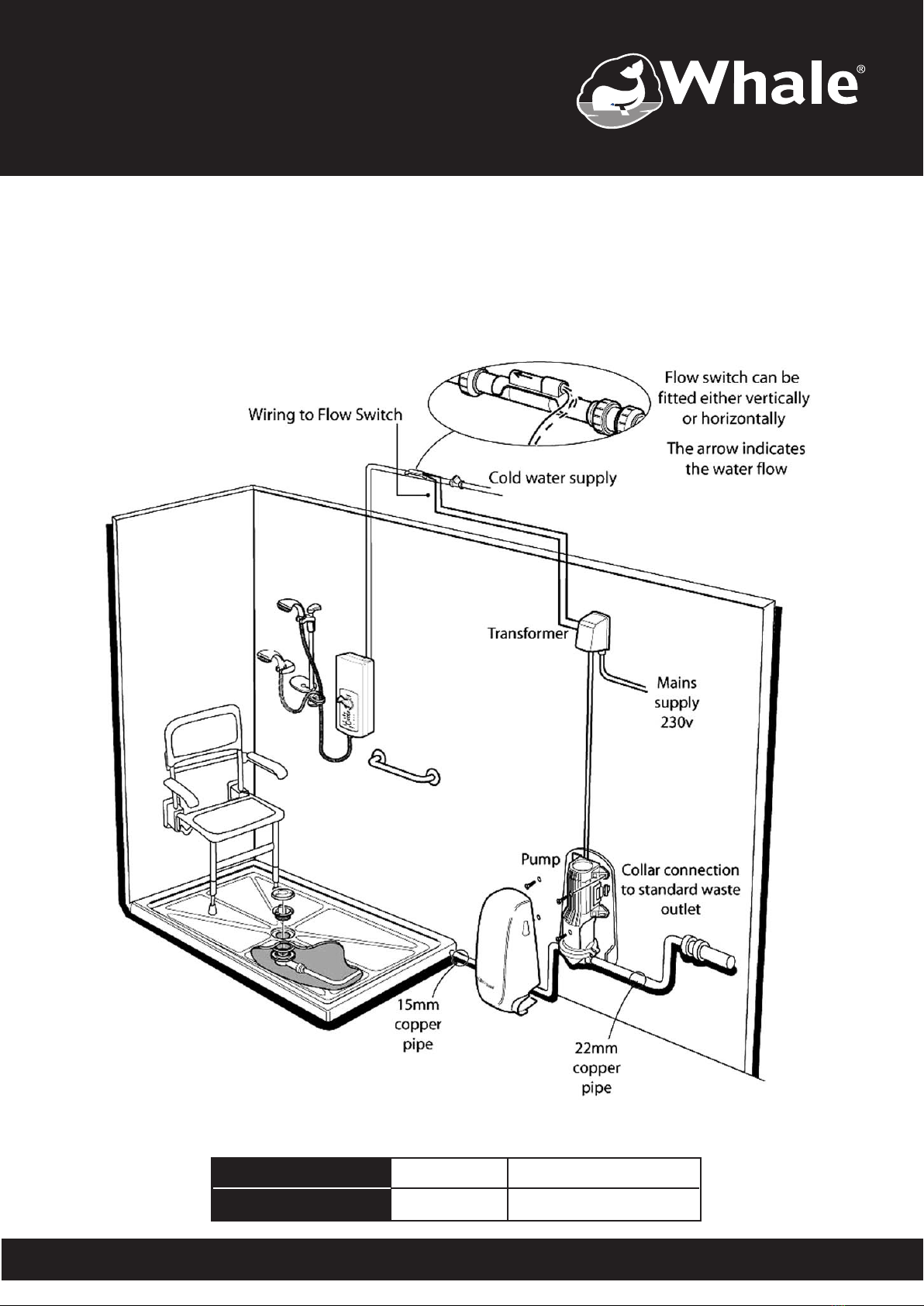

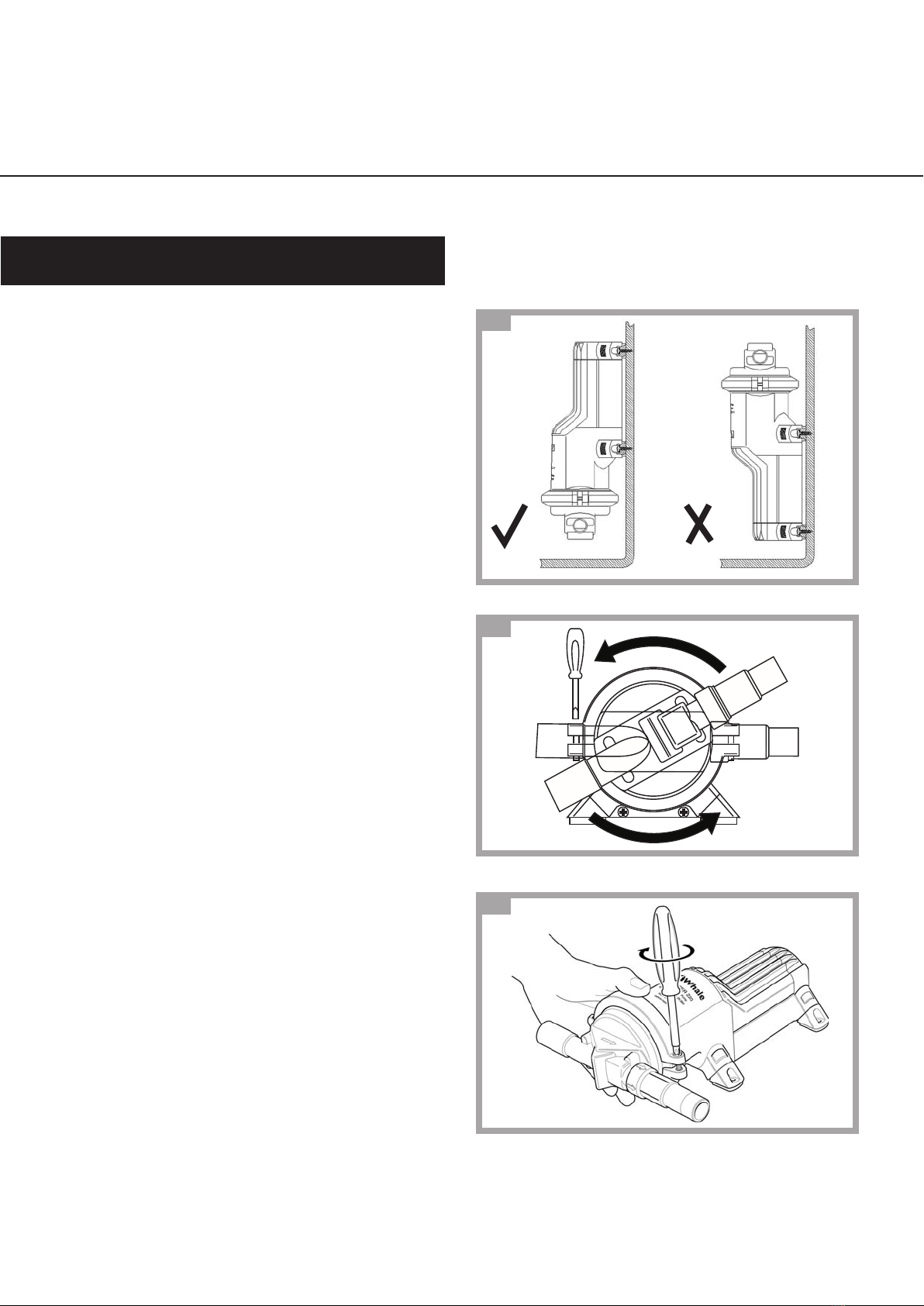

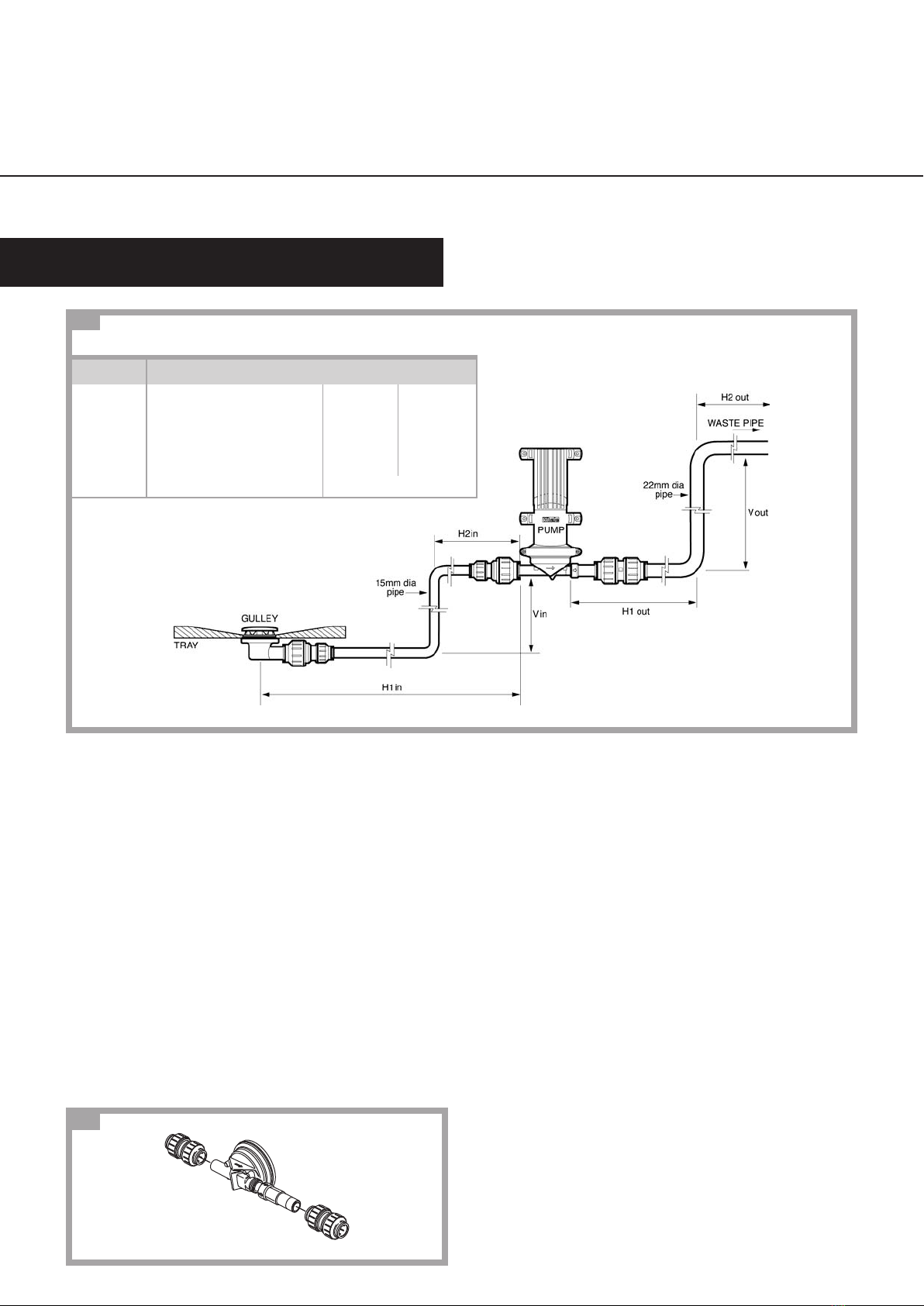

Fitting of Flow Switch and Filter

5.1 Install the flow switch and filter in the water

supply to the electric shower downstream of

any other connections to the water supply.

Ensure the flow switch is accessible

and mounted in a length of straight

unstressed pipe.

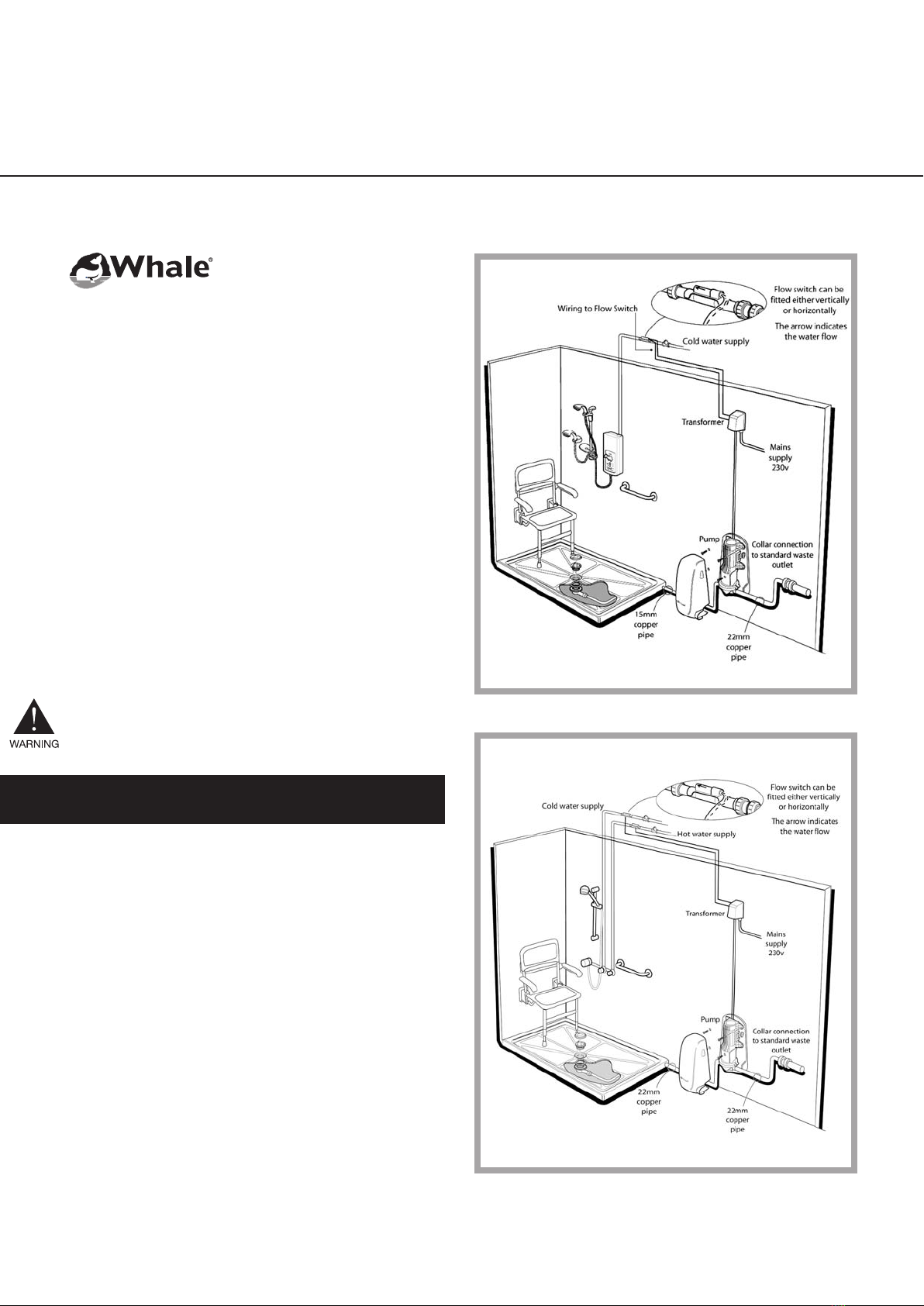

5.2 If a mixer valve is being used then an

additional flow switch and filter must be

installed in the hot water supply (Order Part

No. AK1570). The wires must be joined

together in parallel.

5.3 The flow switch is not polarity sensitive. Prior to

installation flush through the pipe to remove

any debris. Only use the push-fit fittings

supplied to connect the flow switch.

The arrow must be in the direction of water

flow. The flow switch may be mounted in any

orientation.

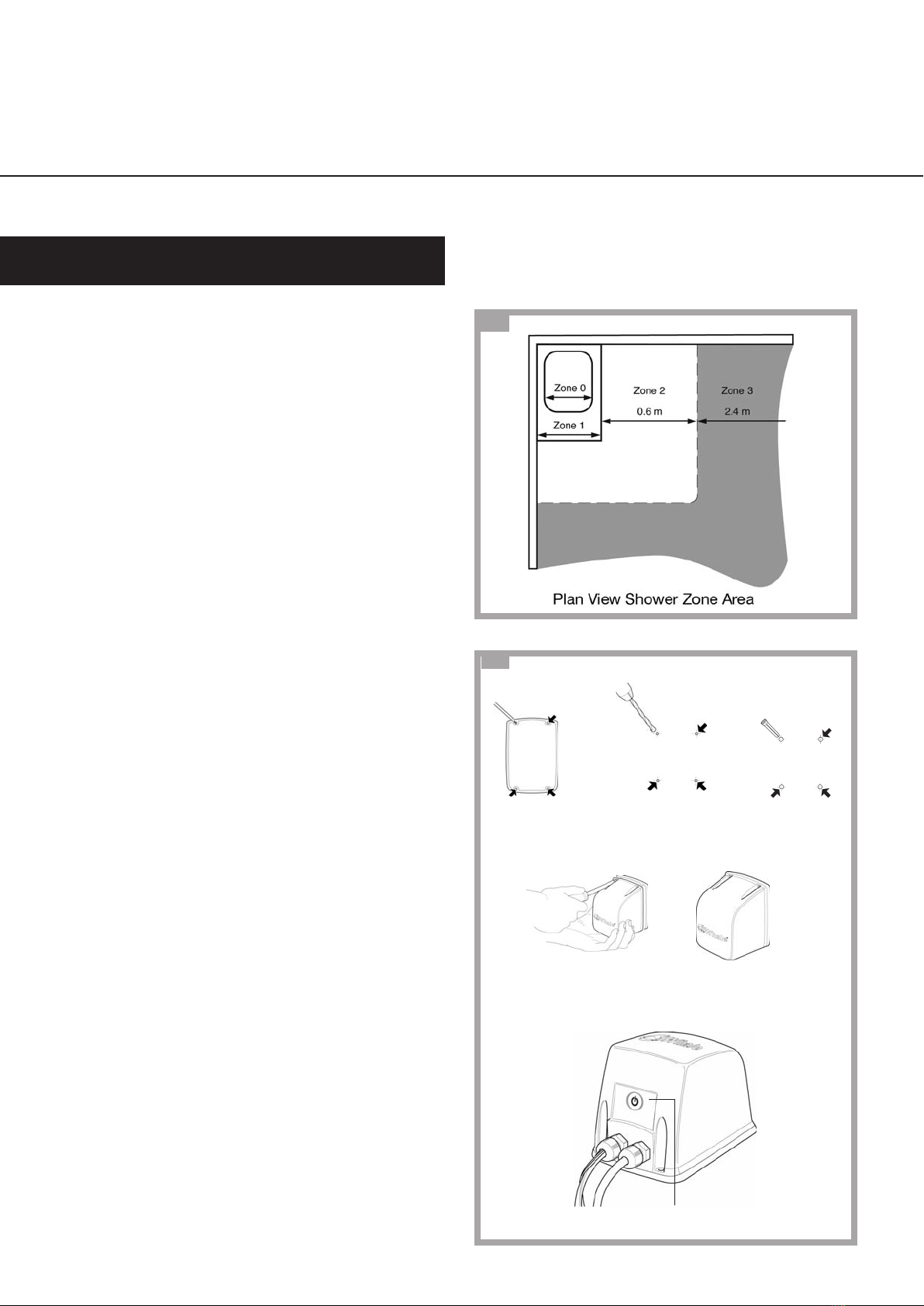

6.1 Electrical connections are as shown.

6.2 Mains supply to the transformer should be

made using a 5 amp fused spur.

6.3 Flow switch connections to the transformer

bell-wire are not polarity sensitive and can be

made using the electrical connector block

supplied.

6.4 The transformer 24v RED and BLACK cable

supply to the pump should be terminated

using the crimp connectors supplied. Connect

to the pump RED and BLACK male crimps.

The polarity of the connection must be correct

for the pump to operate.

9

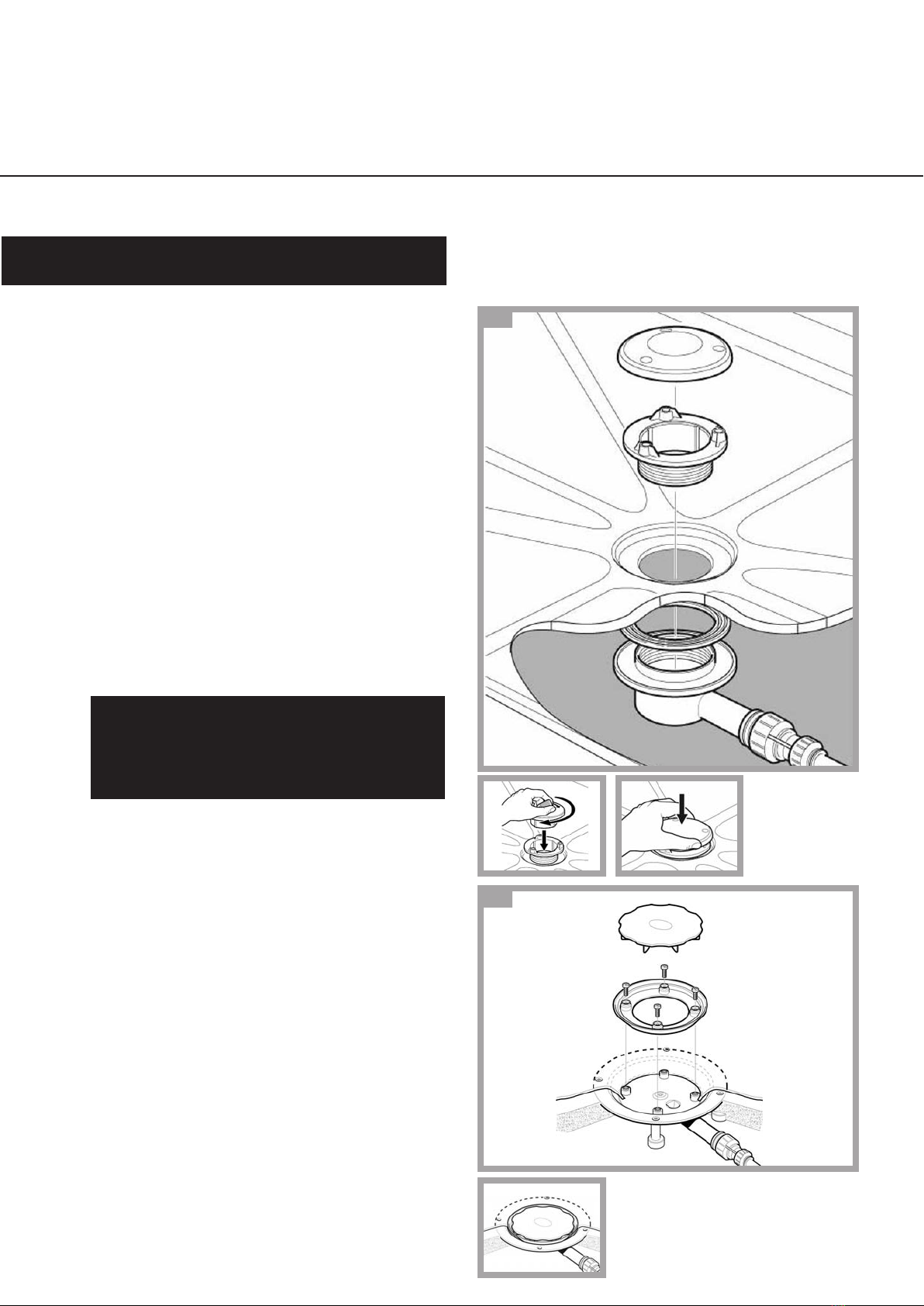

Flow Switch Connect

Electrical Connections 1.11

1.10

Flow Switch Operation

The flow switch is operated by a float with an

internal magnet housed in the copper pipe. In a

plastic housing on the outside of the pipe is a

magnetic reed switch. When the water flows

the float pushes against a spring. At above 1.5

litres/minute the magnet moves sufficiently to

activate the magnetic reed switch. When the

contacts are joined this signals the transformer

to switch power to the pump.

Note: The electric motor in the pump creates a strong

magnetic field which can hold the magnetic reed

switch open or closed. We recommend the flow

switch is not placed within 1 meter of the pump.