Whelen Engineering Company Delta Independence User manual

Other Whelen Engineering Company Light Fixture manuals

Whelen Engineering Company

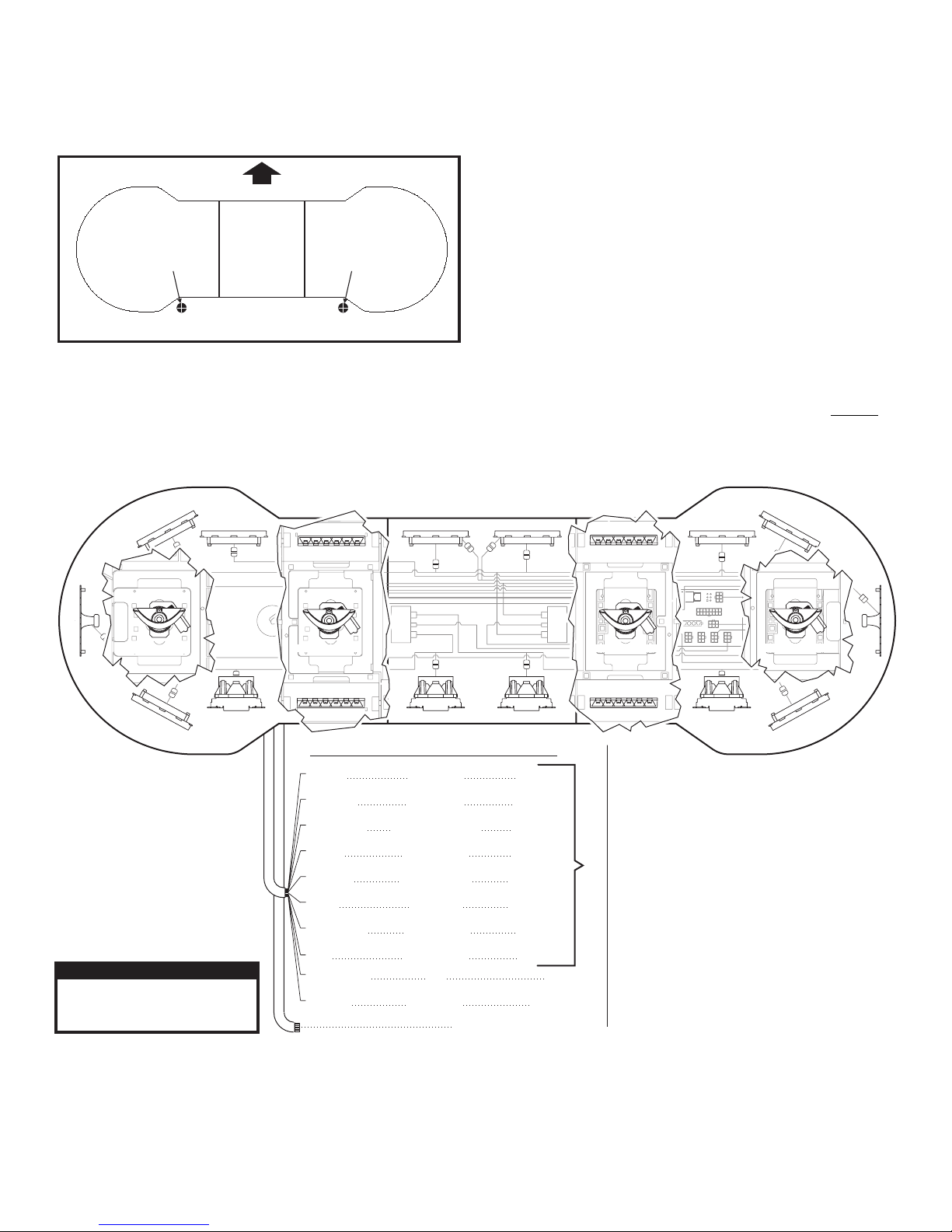

Whelen Engineering Company Freedom II WeCan User manual

Whelen Engineering Company

Whelen Engineering Company LFL Liberty LC 2010 User manual

Whelen Engineering Company

Whelen Engineering Company Inner Edge FST WeCan User manual

Whelen Engineering Company

Whelen Engineering Company 600-series User manual

Whelen Engineering Company

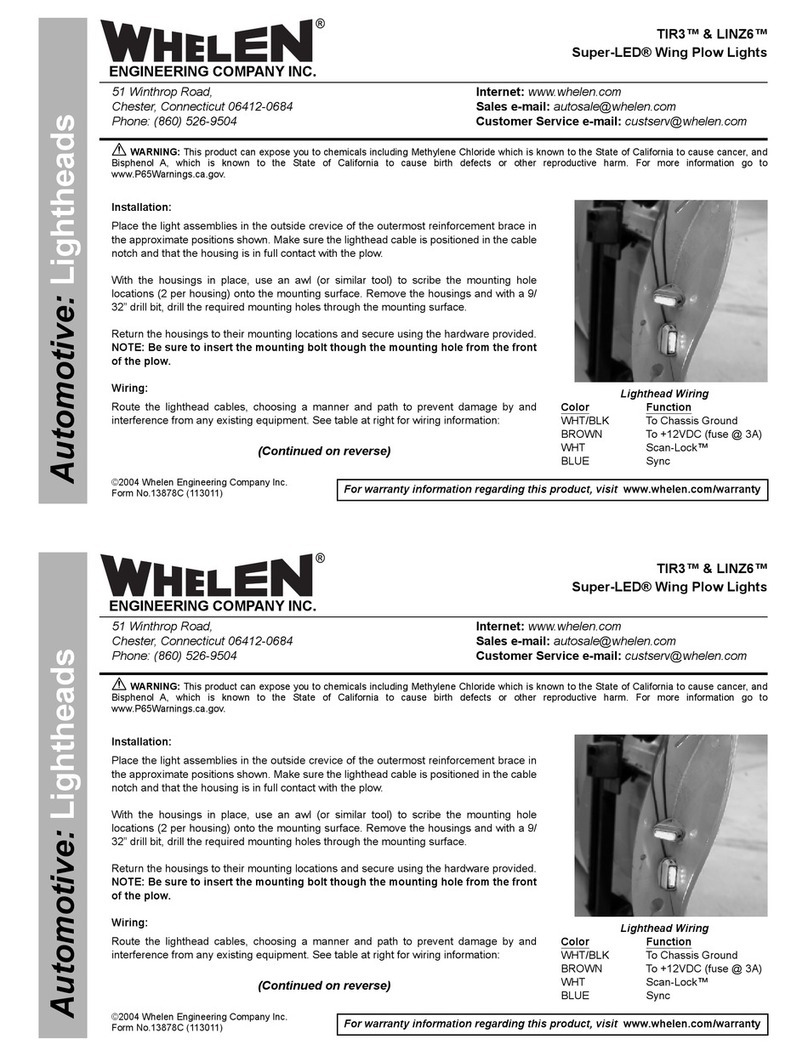

Whelen Engineering Company TIR3 User manual

Whelen Engineering Company

Whelen Engineering Company Responder R2HD Series User manual

Whelen Engineering Company

Whelen Engineering Company Inner Edge Interior Series User manual

Whelen Engineering Company

Whelen Engineering Company PAR36 Super-LED User manual

Whelen Engineering Company

Whelen Engineering Company 45FL Series User manual

Whelen Engineering Company

Whelen Engineering Company LFL Liberty Mini Edge User manual

Whelen Engineering Company

Whelen Engineering Company Safety Site User manual

Whelen Engineering Company

Whelen Engineering Company Freedom Mini Edge User manual

Whelen Engineering Company

Whelen Engineering Company Responder R9HD Series User manual

Whelen Engineering Company

Whelen Engineering Company Liberty WeCan Duo-Color User manual

Popular Light Fixture manuals by other brands

Emos

Emos CLASSIC ZY1431T manual

Westinghouse

Westinghouse Outdoor Lighting Fixture owner's manual

Hedler

Hedler C 12 silent Operation manual

Blizzard Lighting

Blizzard Lighting Puck: CSI manual

Energetic Lighting

Energetic Lighting ELYSL-5004 Series installation instructions

Lightmaxx

Lightmaxx Shaft 5R user manual

Cooper Lighting

Cooper Lighting Halo L3232E Specification sheet

Stageline

Stageline ODW-2410RGBW instruction manual

Light Sky

Light Sky Tornado Series user manual

Lightolier

Lightolier Paralyte 2424 PLA2G9LS26U specification

Lightolier

Lightolier Lytespan 83ED17S specification

Lightolier

Lightolier Calculite CS8226 specification