6

Model 8500 Instruction Manual

Articulator Adjustments

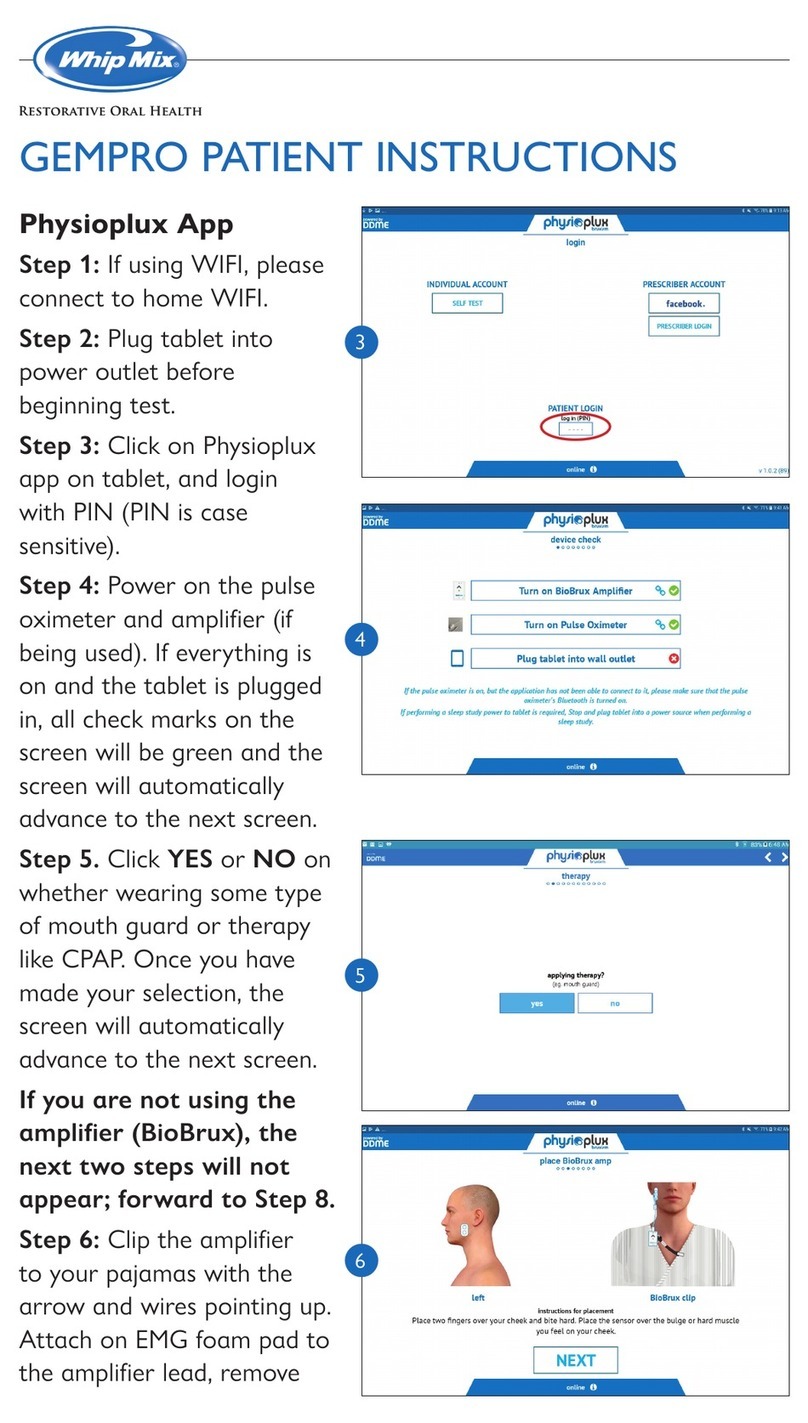

Protrusive Condylar Inclination: the angle of

the fossa in relation to the occlusal plane.

The inclination of the protrusive condylar path

can be adjusted by loosening the large black

clamp knob. The protrusive condylar path

inclination scale is on the side of the upper

member and is calibrated in increments of 5

degrees. The protrusive adjustment range is

0 – 70 degrees.

Progressive Side Shift: the path the orbiting

condyle follows on the medial wall of the fossa

as it orbits around the rotating condyle.

To set the progressive side shift, loosen the

side shift guide locking knob and move the

side shift guide until it touches the side of the

condyle element. The scale for the progressive

side shift adjustment is located on top of the

condylar guide and is calibrated in 5 degree

increments. The progressive side shift range is

0 – 40 degrees.

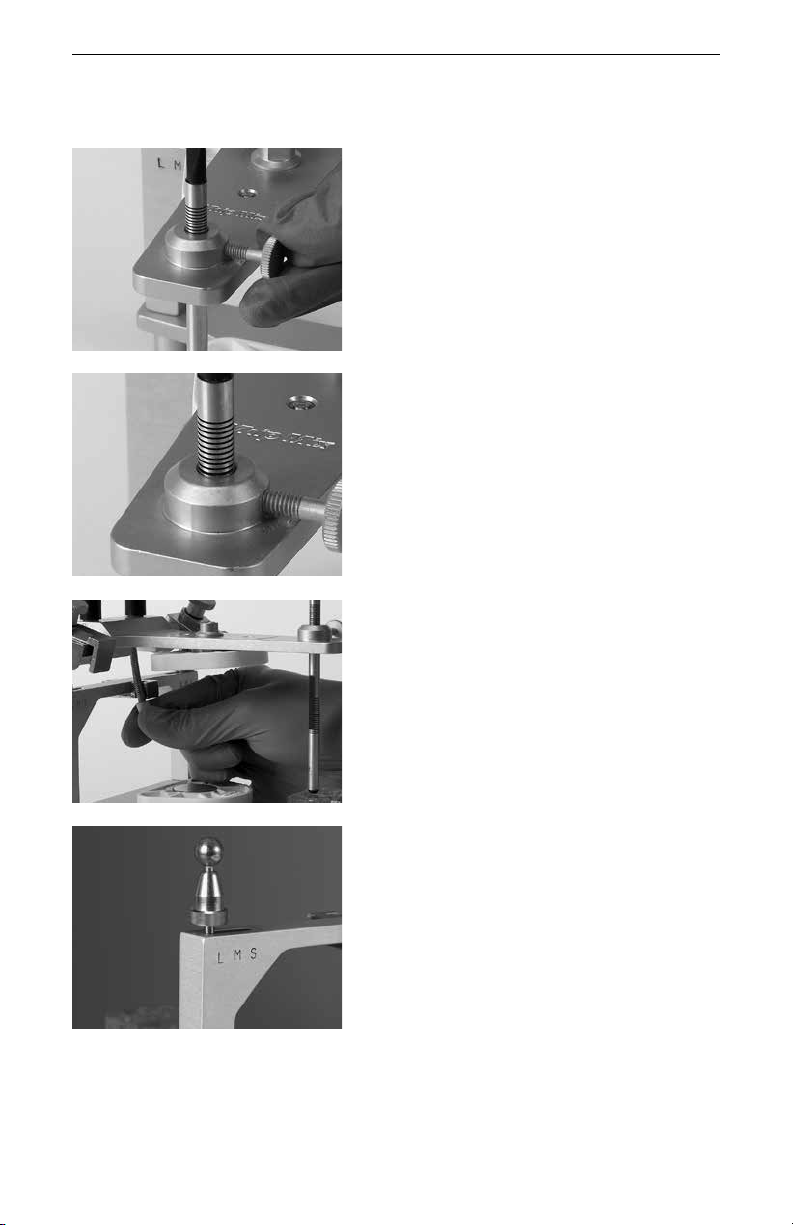

Direct Mounting the

Maxillary Cast

Remove or sufficiently raise the incisal guide

pin so the upper member of the articulator will

be able to rest on the horizontal crossbar of

the facebow.

Note: Set each condylar guide to 30 degrees

on the condylar inclination scale in preparation

for attaching the facebow assembly to the

upper frame of the articulator.

Mounting Casts on the 8500 Series

Articulators

In addition to a facebow record, the only records needed for complete programming

of the 8500 series are:

• Lateral bite records

• Protrusive bite record