Before you start... Electrical

Mark an X acrocthe letter or number

as you complete each step,

A

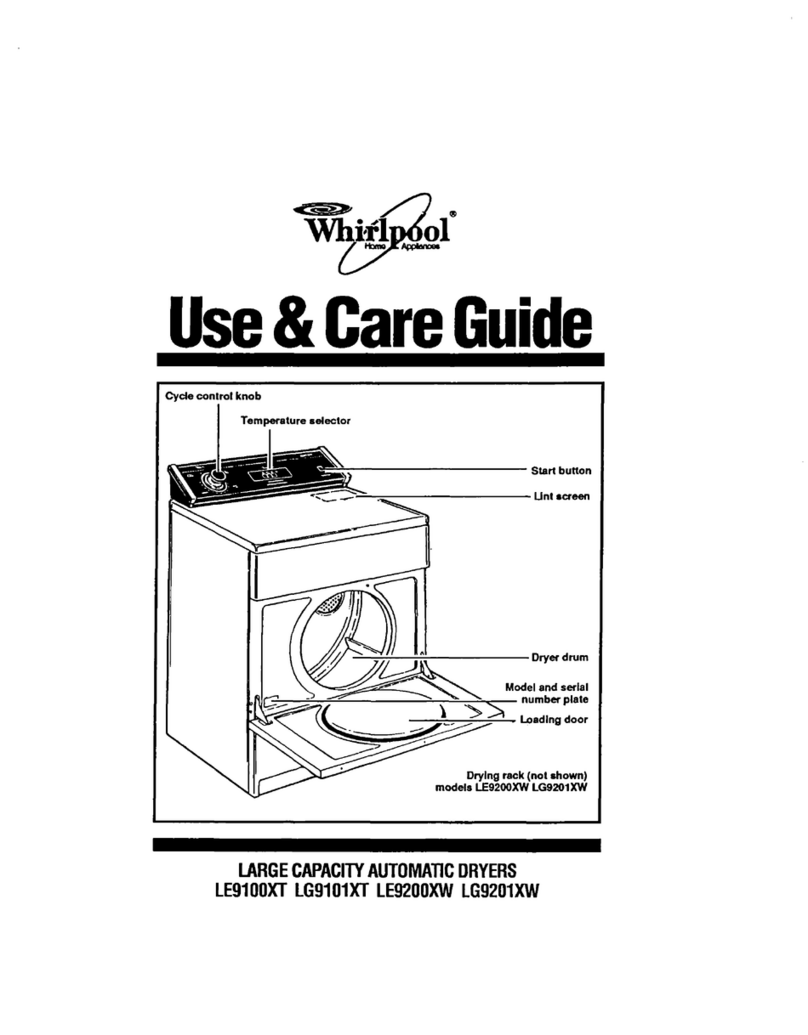

You need these

n

twls to install your Whirlpool

electric dryer. Get them together

in one place to keep track of them.

B

Check the spot

n

where you’re going to

install the dryer...proper installation is

your responsibilih/.

C

Make sure you

n

have evewihina

necessary for props~lnsto?lation. You’ll

need:

l

Tomeet code requirements: same

codes keep from 01limit installatiwr of

clothes dryers in garages, closets.

mobile homes and sleeping quarters.

[Check with your local bullding

inspects.)

Important: observe all govemlng

codes and ordinances.

l

TOcheck utllltles: proper connection

to electric supply should be

available.

l

Tocheck exhaust requirements:

a four inch metal exhaust duct is

recommended.

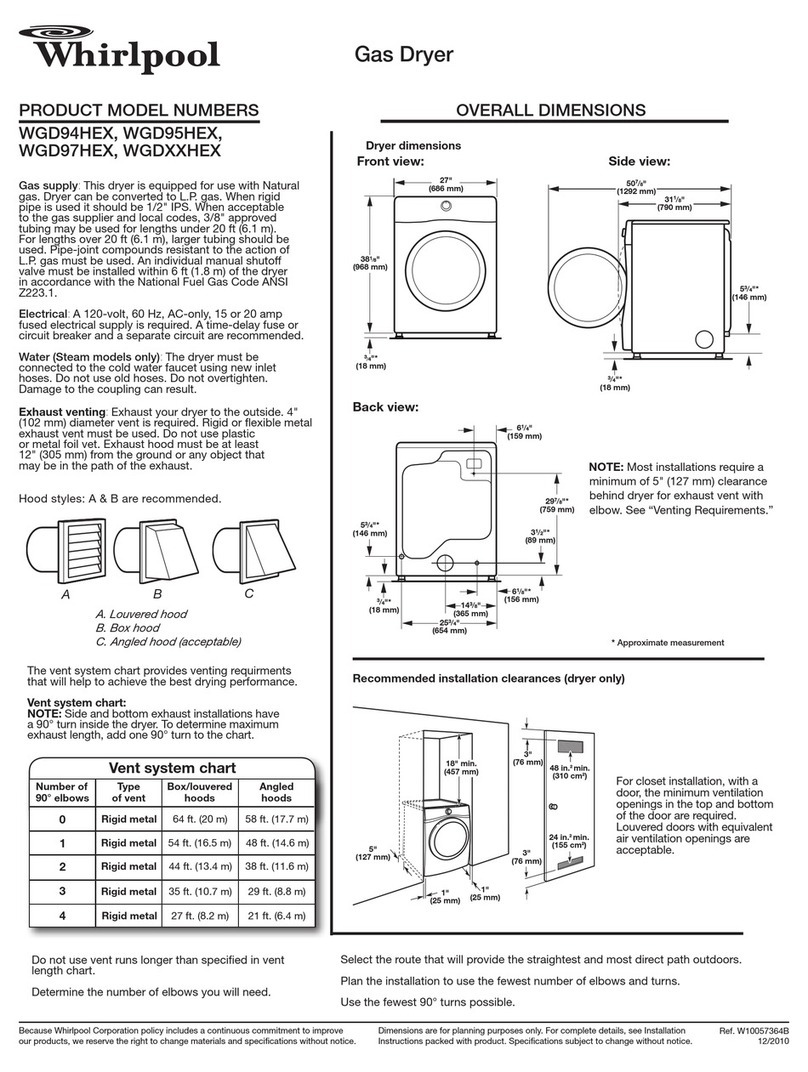

LOCATION

Size: Must be large enough to fully

open dryer door. For recessed or closet

installation spacing see back cover.

Support: The flo& must be able to

SUppOrtthe appliance Weight of 175

pounds.

level Floor: Maximum floor slope

under dryer - 1inch.

Protecllon from the weather: Proper

operation of dryer cycles requires

temperatures above 45°F..M the dryer

may not shut oft when automatic cycles

are used.

CAUTION:

l

It ISthe personal responsibility of the

customer to ensure that aasoline.

paint. thinners and other-flammable

materials are not used or stored near

the dryer. Fumes from these materials

could result in fire or explosion.

l

Never install the dryer up against

draperies or curtains and be sure to

keep any and all items from falling

or collectlna behlnd the drver

. Replace all access or sewice panels

before operating dryer

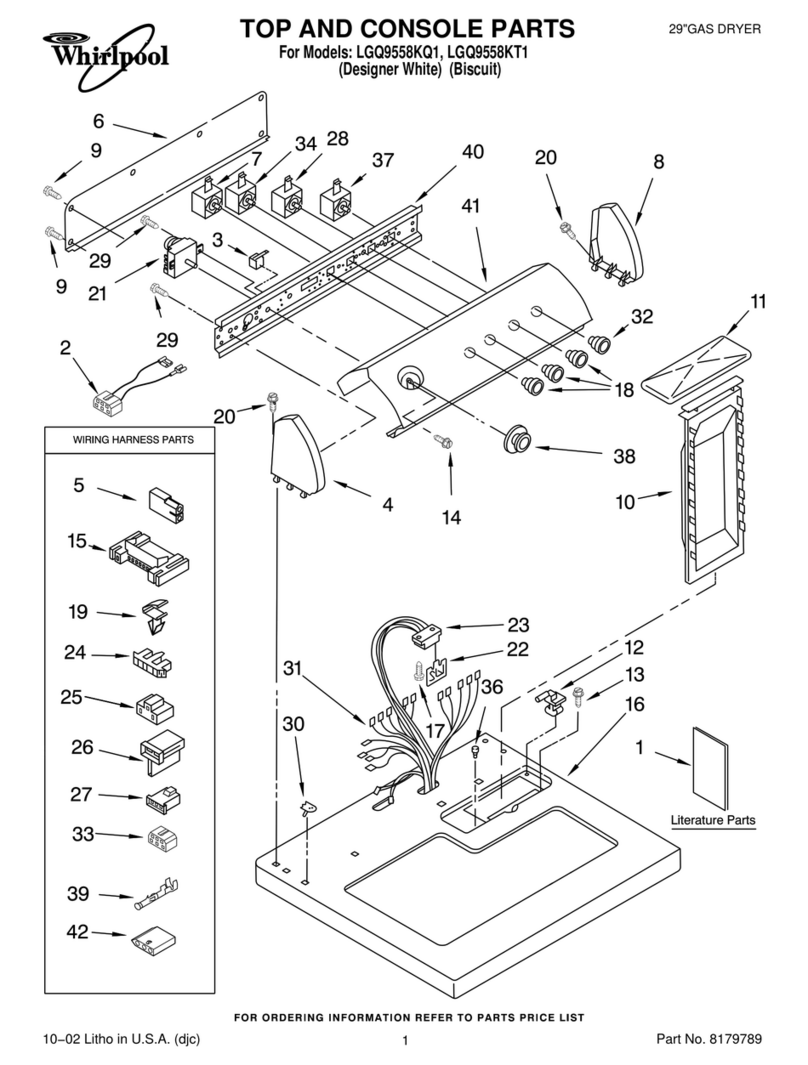

~qutrements

1. A threetire WfWf-wire single phase

120/240 volt 60 Hz AC only electrical

supply (of three-wire or four-wire

12Of2OBvoltif&riedcnnameplote)

is required on a separate 30 ampere

circuit. fused on both sides of the line

(time-delay fuse or circuit breaker is

recommended). Do NOT fuse

neutral. 3wlm

Typical 30 ampere

receptacles

for use where

local codes

permll “se of

flexible power

supply cord

(pigtall).

Flgurel V

2. THEDRYERMUST BECONNECTED

WITH 10 GAUGE COPPER WIRE ONLY

Aluminum wire must not be used

to avoid potentially unsatisfactory

connections.

3. Local cedes may permit the use of

a flexible type 30 ampere ULlisted

power supply cotd [pigtail] with

no smaller than No. 10 copper wire

to match three-wire receptacle

of NEMA Type ?O-30Rshown in

Figure4 A ULlisted strain relief must

be provided at the point the power

supply cord enters the appliance.

WARNING: Do not plug the power

supply cc& (pigtail) into a live ~11

rec0ptacle befcfe mting the

pigtail lo the dryer terminal block.

4. The appliance may be connected

directly to the fused disconnect (or

clrcult breaker] box

thrCUQh

flexible

armored o( non-metallic sheathed

copper cable. Allow two or three

feet of slack In the line between the

wall and the appliance so that it

can be moved if servicing isever

necessarv A UL listed stmln relief

must be provided at each end of

the power supply cord [at the

appliance and at the junction box)

Wire sizes (COPPER WIRE ONLY)

and connectlons must conform with

the rating of the appliance (30

amperes). Do not “se an extension

cord.

IMPORTANT:

OBSERVEALL GOVERNING CODES

AND ORDINANCES.

5. CAUTION: For mobile home

installations. the appliance wring

must be revised. The appliance

frame must not be co+ected to

the neutral terminal, but must be

connected to the ground wire

[green) of the power supply cord.

If four-wire recept&le of NEMA Type

14.30R isused [See FlQure21.a

matching ULlisted power supply cord

(plgtall] for mobile homes must be

used. Thlscord contains four No. 10

copper conductors with spade or ring

terminals on dryer end terminating in a

NEMA type 14.30P plug on supply end.

The fourth [grounding] conductor must

be Identified bY a green cover and the

neutral conductor bv a while cover.

Cord should TV Tvb SRD4 wire rscep,ac,e

orSRDT. with ULlisted

strain relief and be at

least 4 feel long. The

power supply cord

and strain relict are

not provided with the

dryer

ELECTRICAL CONNECTION

WARNING: Improper connection of the

equlpmenl grounding

conductor can

result In a risk of electrical shock

It isthe personal responsibility of the

customer to contact a qualified

installer to assure that the electrical

installation isadequate and isin

conformance with the National

Electrical Code and local codes and

ordinances.

Eleclrlcal ground Is required on this

oppllance. Thisappliance is

manufactured wlth the neutral terminal

connected to the frame.

A

If local codes permit

n

connectlon of

the frame grounding conductor to the

neutral wire of the power supply cord:

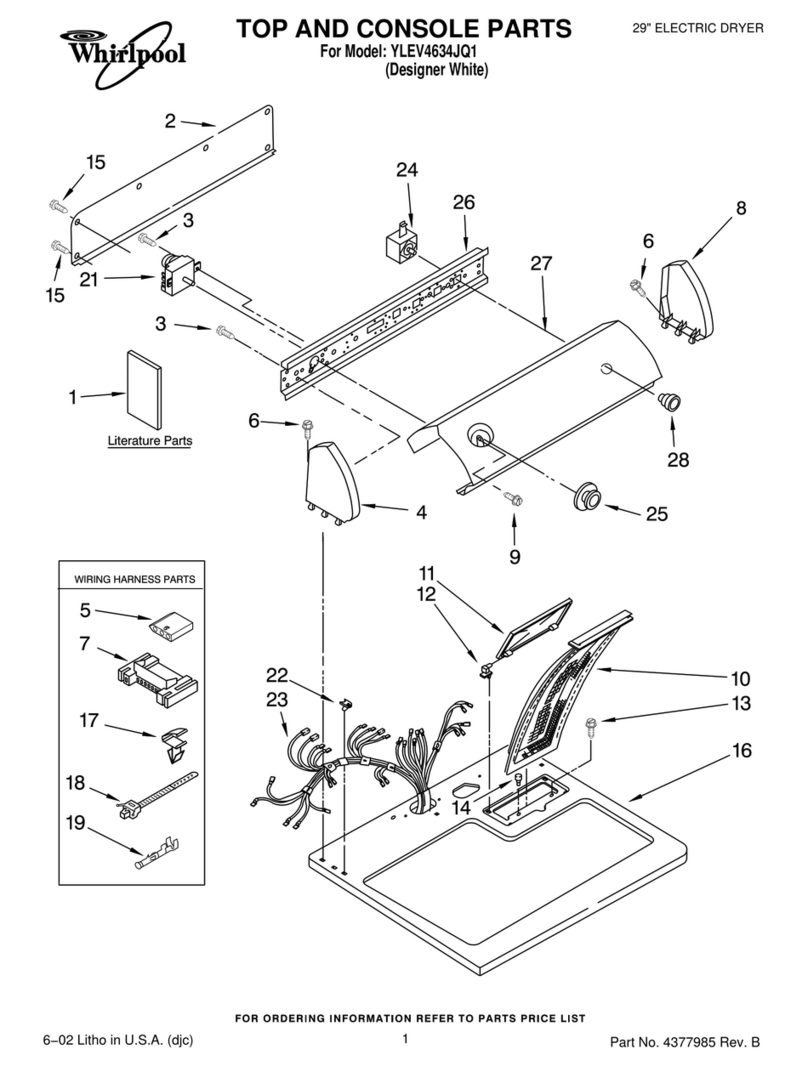

1. Remove the

cover by removing the-

screw shown in Figure 3.

dry&

through

the Dower

’ supply cord

See FlQure

ten strain

I reliefrirmly to

cabtnet. Place

the power supply

cord or direct

..“.I_ FlQure4 ,. ,

wire through the

straw7rarer

Flgure 5

Grounded neulral

3. Connect the neutral wire of the

power supply cord to the center

silver colored lem-mal of the terminal

block and connect the other wires

to the outer terminals. See Figure 5

4. Replace the terminal block cover

bv first installlna the tob of the cover

inio the slot of Thedryer rear panel

(See Figure 3 1.Secure the cover

with the mounting screw

5. IFYOUR POWER SUPPLYCORD OR

DIRECT WIRING HAS PLAIN WIREENDS

SEEFIGURE6 AND FOLLOW THESE

STEPS.

a. Strio outer coverina back 3 Inches

fro& the end exposing the 3 wires

b. Strip the insulation back 1inch

from the end of each wire. Form

the bare wire into a “U” shaped

hook.

c. Loosen, do not remove. the center.

sliver colored screw of the

terminal block.

d. Slide the end of the neutral (white

or center) wire under the screw

head with the open side of

the hook on the right Squeeze

the wire toaether lo form a 100~

e. TIghten the-screw firmly.

f. Connect the remaln!nQ 2 wires

lo the outer screws the same way

TIghten screws firmly

6. TIghten strain relief ClOmp on power

supply cord See FIGURE4