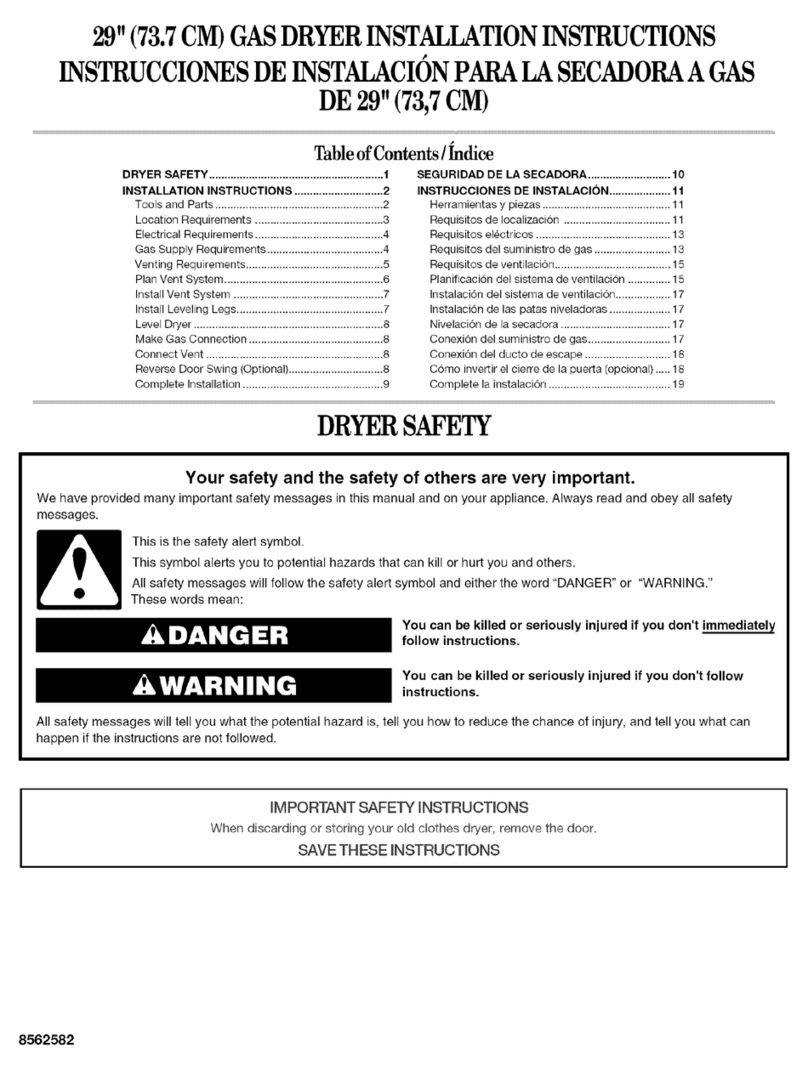

J

n

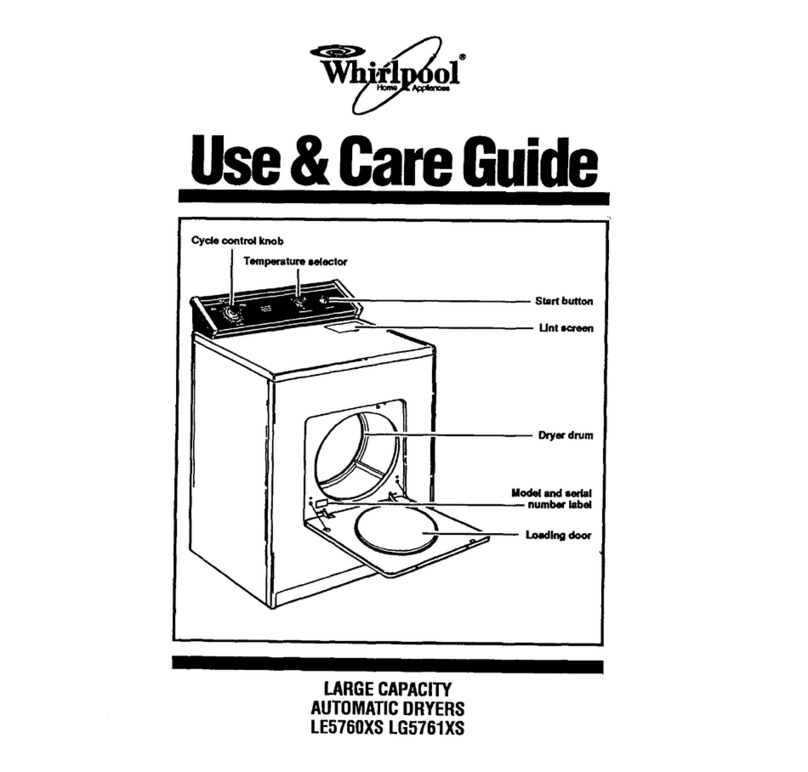

Make sure that lower edges of the

cabinet, plus the back and bottom sides of the

dryer are free of obstructions to permit

adequate clearance of air openings for

combustion air. See “Recessed and closet

installation instructions”, on the back cover, for

minimum spacing requirements.

K

w For ease of installation, operating and

servicing (if ever needed) adequate space

should be provided around the dryer.

L

w An 1/&inch NPT plugged tapping,

accessible for test gauge connection, must be

installed immediately upstream of the gas

supply connector to the dryer.

The dryer and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that

system at test pressures in exces of l/2 psig

(3.45 kPa).

The dryer must be isolated from the gas supply

piplng system by closing its individual manual

shutoff valve durlng any pressure testing of the

gas supply piping system at test pressures equal

to or less than l/2 psig (3.45 kPa).

Electrical

requirements

It uslng exlstlng exhaust system, clean llnt from

entlre length ot exhaust system. Make sure

exhaust hood Is not plugged wlth Ilnt.

Replace plasttc exhaust duct wlth rlgld metal or

tlexlble metal duct.

se duct tape

to seal

IIjoints, exhaust air

flow

better

Four-Inch rlgld metal

pipe

is preferred. Plan

/cJ

god

installation to use the

fewest number of

elbows and turns.

Metal rlexlble duct

should be fully extended

and supported when the dryer is in final

position. DO NOT KINK OR CRUSH THE DUCT.

The metal flexible duct must be completely

open to allow adequate exhaust air to flow.

Allow as much room as possible when using

elbows or making runs. Bend duct gradually to

avold kinking. Remove excess flexible duct to

avoid sagging and kinklng that may result in

reduced air flow.

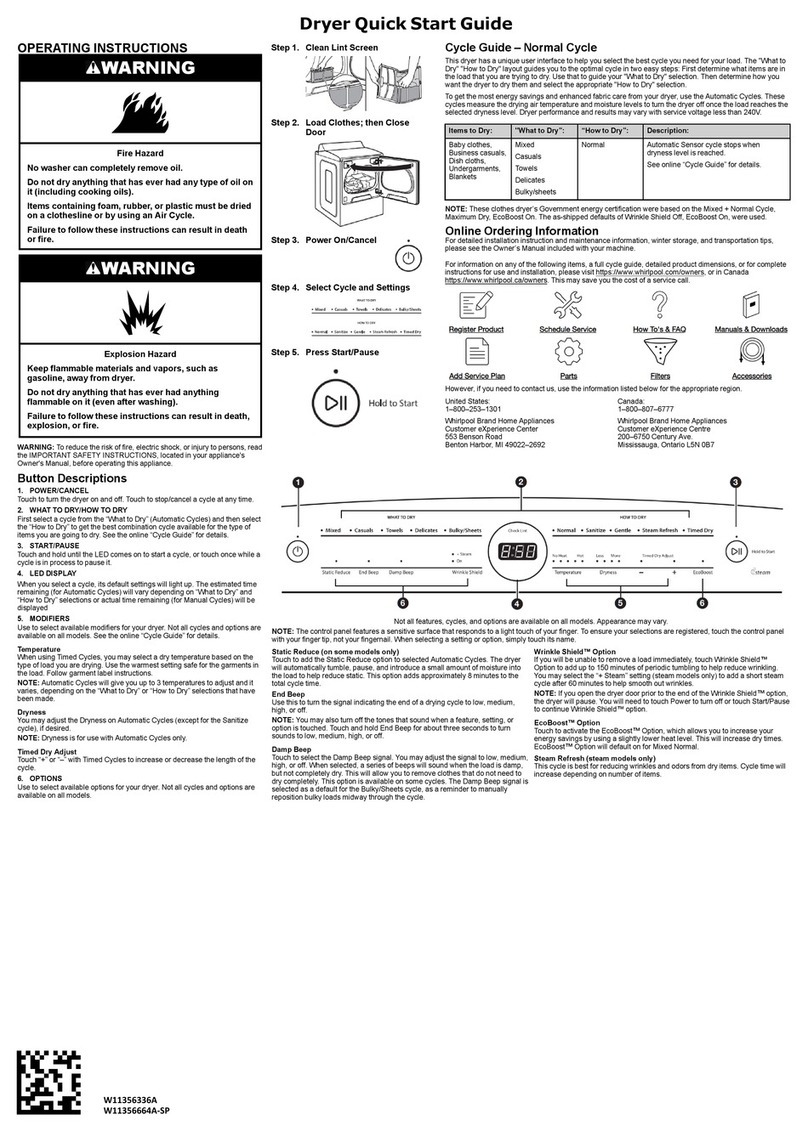

Electrlcal Shock Hazard

l

Electrlcal ground Is required on thls

appliance.

l

Do Not modify the power supply cord plug.

It It does not flt the outlet, have a proper

outlet Installed by a quaIltIed electrlclan.

l

Do Not have a tuse In the neutral or

groundlng clrcult. A tuse In the neutral or

groundlng clrcult could result In an

electrlcal shock.

l

Do Not use an extenslon cord wlth thls

appliance.

l

Check wlth a qualltled electrlclan It you are

In doubt as to whether the appliance Is

properly grounded.

Failure to tallow these lnstructlons could result

In serious Injury or death.

It codes permlt and a separate groundlng wire

Is used, It Is recommended that a qualltled

electrlclan determlne that the groundlng path Is

adequate.

A 120-volt, 6CWlz, AC-only, 15or 2Gampere

fused electrical supply is required. Time-delay

fuse or circuit breaker is recommended. It is

recommended that a separate circuit serving

only this appliance be provided.

The exhaust outlet

is

located at the

bottom rear of the

dryer.

The exhaust duct

can be routed up, down, left,

right or straight out of the back of the dryer.

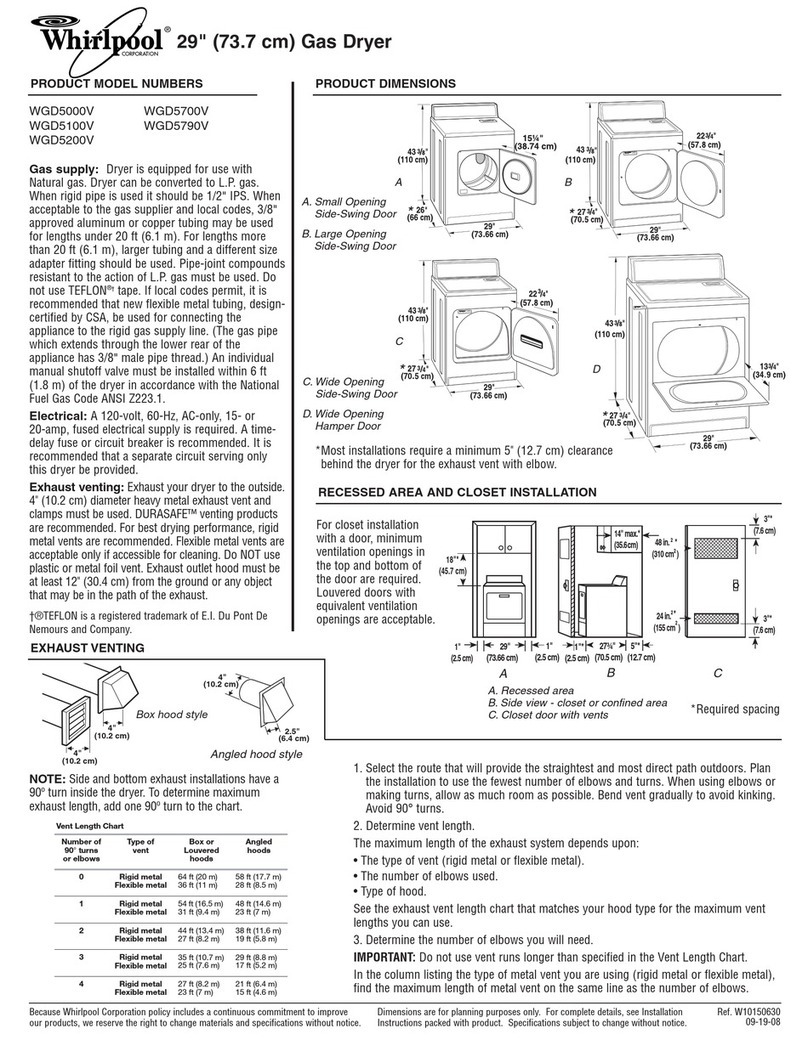

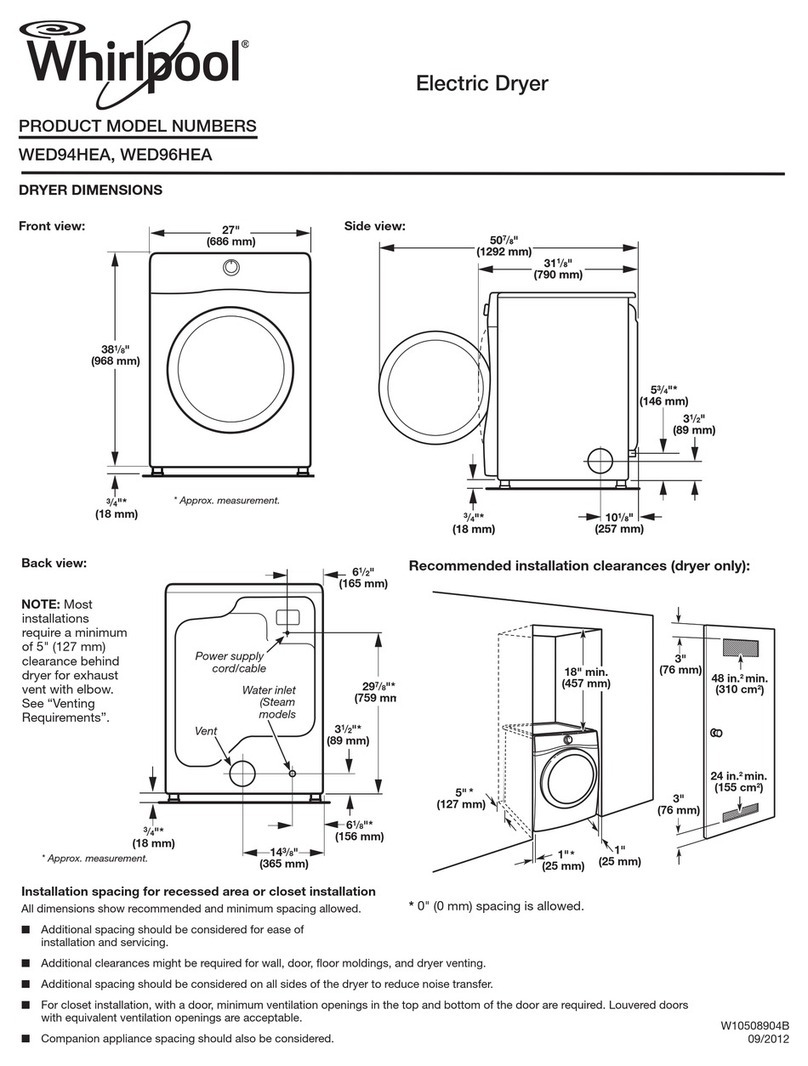

General space requlrements can be found in

“Recessed and closet installation instructions”

on the back cover. Use the straightest path you

can, where possible, to avoid 90” turns.

The maxlmum length

of the exhaust system

depends upon the type of duct used, number

of elbows and type of exhaust hood. The

maximum length for both rigid and flexible duct

is shown in chart.

n

If service is required, determine the

type of front panel your dryer has and follow

those instructions.

Recommended

grounding method

Electrlcal Shock Hazard

Disconnect tram electrlcal supply betore

removlng access panel.

Do not operate dryer wlthout access panel

securely In place.

Failure to kllow these lnstructlons could

result In electrlcal shock or death.

For your personal safety, this appliance must be

grounded. This appliance is equipped with a

power supply cord having a 3-prong grounding

plug. To minimize possible shock hazard, the

cord must be plugged into a mating 3-prong

grounding-type wall receptacle, grounded in

accordance with the National Electrical Code,

ANSI/NFPA 70 - latest edltlon’, and all local

codes and ordinances. If a mating wall

receptacle is not avallable, It is the personal

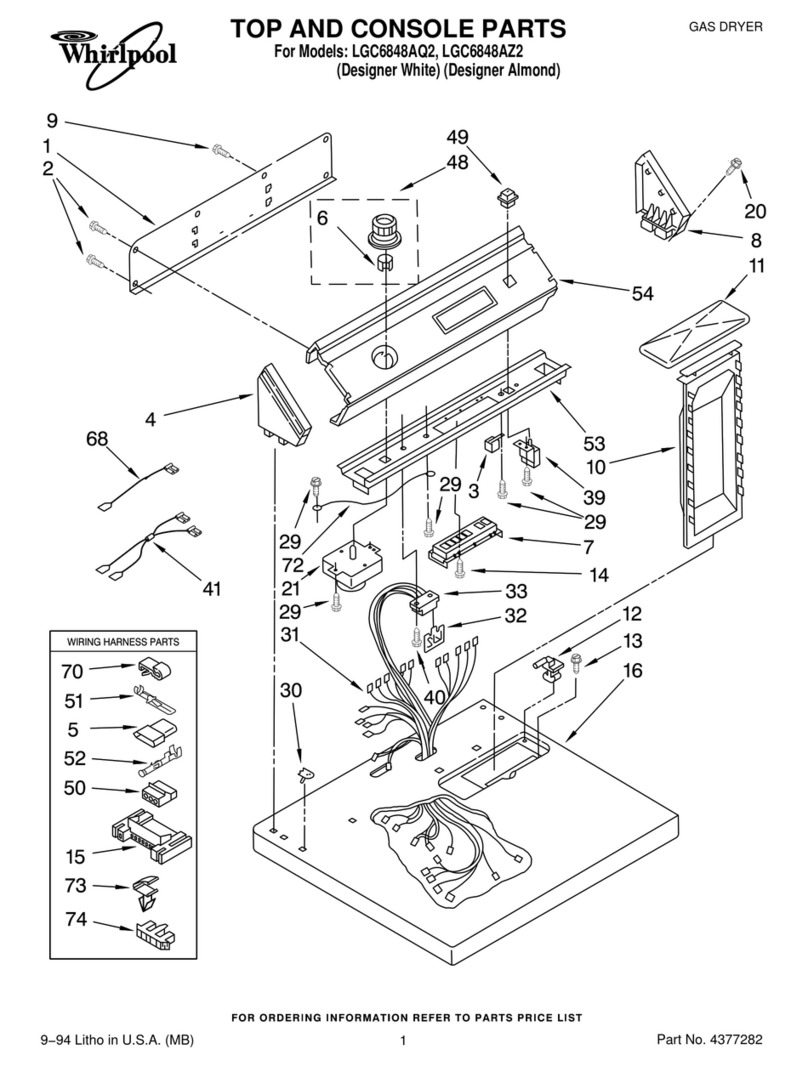

One-piece front panel

wiring diagram location

The dryer gas shutoff

valve is located

behind the one-piece

front panel.

responsibility and

obligation of the

customer to have a

properly grounded

3-prong wall

receptacle installed

by a qualified

electrician.

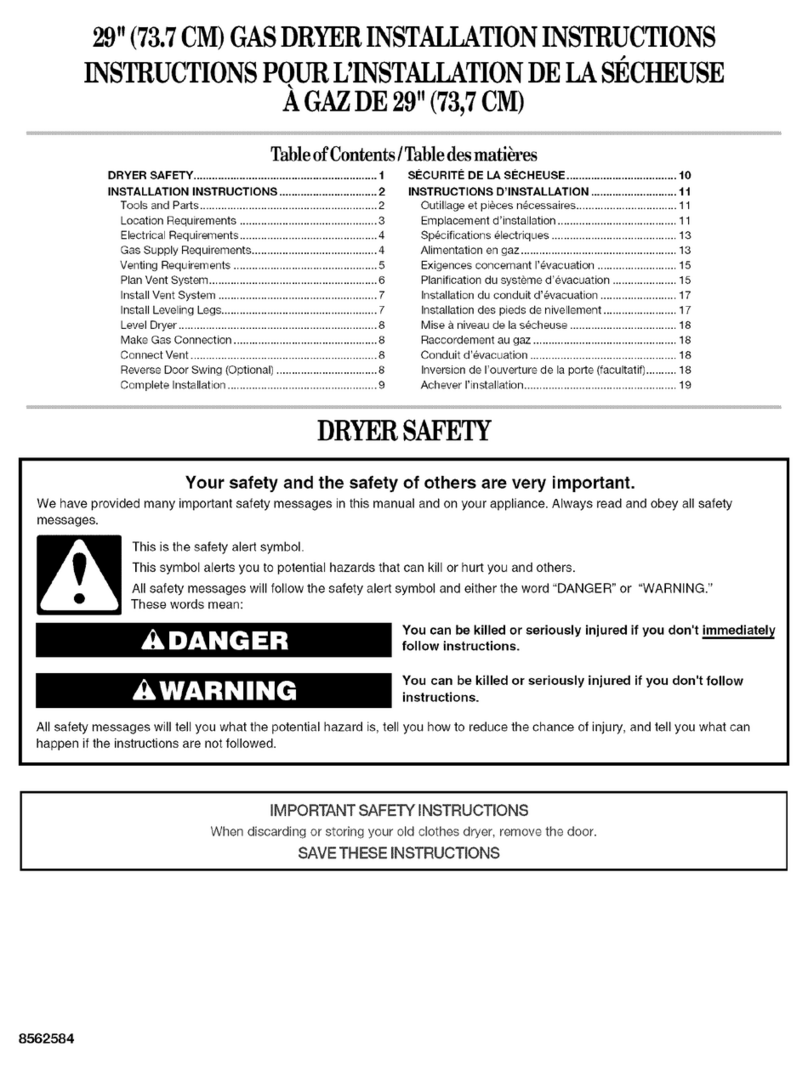

NUMBER

OF EXHAUST HOOD TYPE

90” TURNS A B C

0 64 FT. 64 FT. 58 Fr. MAXIMUM

1 54 FT. 54Fr. 48 FT. LENGTH OF

2 44 Fr. 44Fr 38 Fr. 4’ DIA. RIGIC

METAL

3 35 Fr. 35 Fr. 29Fr. DUCT.

4 27 Fr. 27 FT. 21 Fr.

0 36 FT. 36 FT. 28 FT. MAXIMUM

1 31 Fr. 31 FT. 23 FT. LENGTH OF

4’ DIA.

2 27 FT. 27 Fr. 19 FT. FLEXIBLE

61

The wiring diagram isThe wiring diagram is

1 located inside thelocated inside the

console.console.

These Items should beThese Items should be

accessed only by aaccessed only by a

. quallfled servicequallfled service

3 25 FT. 25 FT. 17 Fr. METAL

4 23 FT. 23Fr. 15 FT. DUCT.

The maximum length using a 2” x 6” rectan 9 ular duct

with 2 elbows and a 2-l/2 (TyPE C) exhaus hood is 8 ft.

power ‘/_

supply cord

Copies of the standards listed above may be-

obtained from:

l

National Fire Protection Association

Bafterymarch Park

Quincy, Massachusetts 02269

- technklan.

gas shuhl valve o\ne-piece

front panel

1.

Disconnect electrlcal supply.

2. Remove lint screen and set aside.

3. Remove two screws from lint screen area.

4. Grasp front cabinet top corners and pull

forward and up (top is hlnged at rear).

5. Remove two screws from front panel

flanges. Lift front panel off lower clips,

6. Remove door switch wires, if necessary,

and set front panel aside.

7. Reassemble in reverse order.

Note: The door switch wires must

not

touch

the drum.

Lower access panel

wlrlng diagram location

1,

Disconnect

electrlcal supply.

2. Insert flat-blade

screwdriver between

cabinet front and

lower access panel

3-inches in from

each side. Push

down on retalner

clips and pull lower

access panel

forward. The lower

access panel is

hinged at the

bottom.

access

3.

Close lower access

-..-.-..

valve

panel

panel.

Gas shutoff valve “open” and

“closed” position

Optional shutoff

valve /FL

Exhaust

requirements

For exhaust systems

not covered by the

exhaust length chart, see Service Manual, Part

No. 603197 available from your local parts

distributor.

Servlce check:

The back pressure in any

exhaust system used must not exceed 0.6

inches of water column measured with an

inclined manometer at the point that the

exhaust duct connects the dryer.

An exhaust hood

should cap the

exhaust duct to prevent exhausted

air from returning into dryer. The

outlet of the hood must be at least

12 inches from the ground or

anything else that may be in the

path of the exhaust. %

12” min.

Four-Inch outlet hood Is preterred.

However, a

2-l /2 inch outlet may be used with short

systems only. A 2-l /2 inch outlet can result in

longer drying times than other hood types.

For

permanent Installation, a statlonary exhaust

system Is required.

Mobile home installation

Thls appliance Is sultable for moblle home

Installations. The lnstallatlon ot the dryer must

conform to the Manutactured Home

Constructton and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard tar

Moblle Home Constructlon and Satety, Title 24,

HUD, Part 280, latest edltlon).

For all installations, this appliance MUST be

fastened to the wall with cable bracket and

MUST be exhausted to the outside.

The dryer must have an outside

exhaust. If the dryer is exhausted

through the floor and the area

under the mobile home is

enclosed, the exhaust system

must

terminate outside the

enclosed area. Extension

beyond the enclosure will

prevent lint and moisture

buildup under the mobile home.

Fire/Health Hazard

l

Do Not use non-metal, tlexlble duct.

l

Do Not use metal duct smaller than tour

Inches In diameter.

l

Do Not Use exhaust hoods wlth magnetic

latches.

l

Check that exhaust system Is not longer

than specltled. Exhaust systems longer

than speclfled wIII:

- Accumulate Ilnt.

- Shorten the llte ot the dryer.

- Reduce perlormance, resulting In

longer drying times and Increased

energy usage.

Failure to follow speclrlcatlons may result In a

flre.

l

Do Not exhaust dryer Into a chimney,

furnace cold alr duct, attlc or crawl space,

or any other duct used tar venting.

l

Clean the exhaust system every other year.

. Do Not Install tlexlble duct In enclosed

walls, celllngs or tloors.

Accumulated llnt could be tuel for a flre or

cause molsture damage.

Exhaust the dryer outslde to prevent

exposure to substances In the gas fuels and

combustion which may be harmtul to your

lealth.

he molsture and lint Indoors may cause:

- Lint to gather lnslde and around the

dryer and be a tuel for tlre.

- Molsture damage to woodwork,

turnlture, palnt, wallpaper, carpet, etc.

- Housecleanlng problems and possible

health problems.

:allure to tallow these lnstructlons could result

n

Hre damage, property damage, personal

nJury or health problems.

posItIon

gas shutoff va’lve i;

open or “on” position

Panel B